Microwave dielectric ceramic material as well as preparation method and application thereof

A technology of microwave dielectric ceramics and applications, which is applied in the field of microwave dielectric ceramic materials and its preparation, and can solve the problems of high dielectric constant and sintering temperature of microwave dielectric ceramic materials, limited use of microwave communication devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0036] The present embodiment 1-7 provides a kind of microwave dielectric ceramic material, adopts Zn 3 B 2 o 6 and Mg 3 B 2 o 6 Two materials, Zn 3 B 2 o 6 and Mg 3 B 2 o 6 The molar ratio of is (1-x):x, wherein, x=0.05~0.40. Prepared from the oxides of the components in the following mole percentages:

[0037] Main ingredient ZnO, 71.25-45.00%;

[0038] Main ingredient B 2 o 3 , 25.00%;

[0039] Substituting material MgO, 3.75-30.00%;

[0040] The sum of the molar percentages of the above components is 100%, and the molar ratio of the ZnO to the MgO is (0.95:0.05)˜(0.60:0.40).

[0041] The molar percentages of oxides in each embodiment are specifically shown in Table 1.

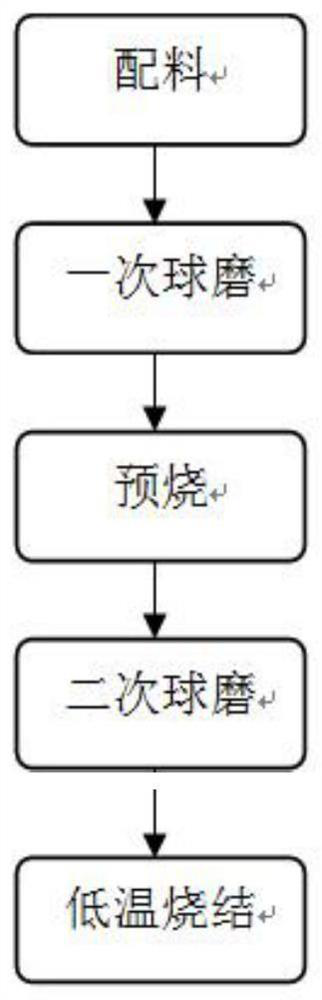

[0042] Such as figure 1 As shown, its preparation method comprises the steps of batching, primary ball milling, pre-calcination, secondary ball milling, and low-temperature sintering, specifically comprising the following steps:

[0043] S1, using the oxide method to prepare (1-x)Zn accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com