Method for preparing high-conductivity zinc oxide ceramic at ultralow temperature

A high-conductivity, zinc oxide technology is applied in the field of ultra-low temperature preparation of high-conductivity zinc oxide ceramics, which can solve the problems of poor conductivity of ceramics, affecting the conductivity of ceramics, and low conductivity of ceramics, achieving good practicability and improving conductivity. rate, and the effect of improving crystalline properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

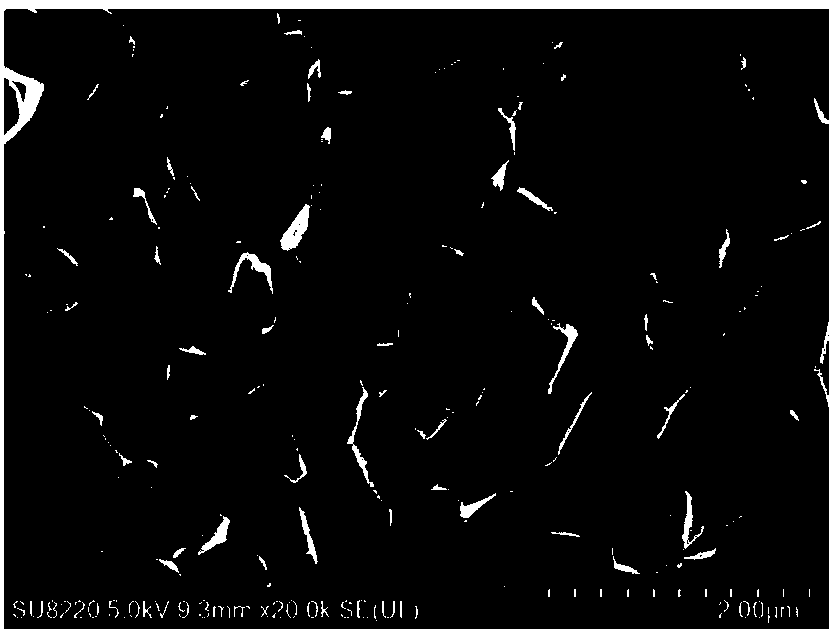

[0026] ① Grinding and granulation: use zinc oxide powder as raw material, add 1mol / L acetic acid solution at a mass ratio of 4:1, mix thoroughly, and grind to moderately wet particles;

[0027] ②Ultra-low temperature sintering: Put the granules prepared in ① into a Φ20mm mold, the mold pressure is 300MPa, during the pressing process, the mold is heated from room temperature to 250℃ at a rate of 5℃ / min, and kept for 1h, and the obtained size is Φ20 ×3mm 3 Zinc oxide ceramic samples;

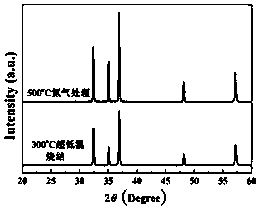

[0028] ③Heat treatment in an inert atmosphere: put the zinc oxide ceramic sample prepared in ② into an atmosphere furnace, and pass in nitrogen gas, raise the temperature from room temperature to 300°C at a rate of 2°C / min, and keep it for 10 hours to prepare high-conductivity zinc oxide ceramics.

[0029] The prepared high-conductivity zinc oxide ceramics were processed according to the test size requirements, and tested by the four-probe method. It was measured that the density of the zinc oxi...

Embodiment 2

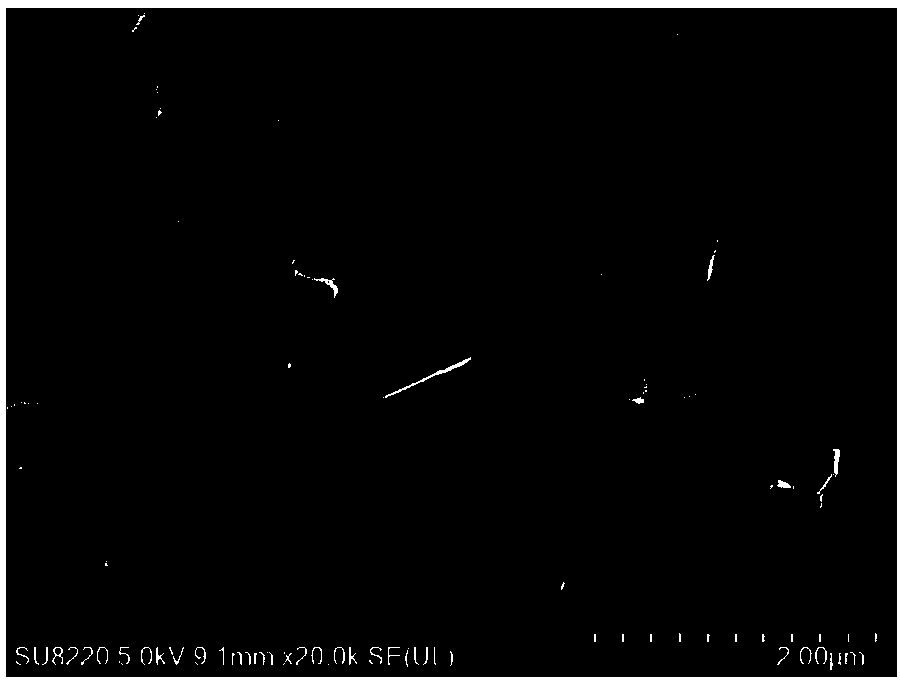

[0031] ① Grinding and granulation: use zinc oxide powder as raw material, add 3mol / L acetic acid solution at a mass ratio of 4:1, mix thoroughly, and grind to moderately wet particles;

[0032] ②Ultra-low temperature sintering: Put the granules prepared in ① into a Φ20mm mold, and the mold pressure is 150MPa. During the pressing process, the mold is heated from room temperature to 300℃ at a heating rate of 5℃ / min, and kept for 2h, and the obtained size is Φ20 ×3mm 3 Zinc oxide ceramic samples;

[0033] ③Heat treatment in an inert atmosphere: put the zinc oxide ceramic sample prepared in ② into an atmosphere furnace, and pass in nitrogen gas, raise the temperature from room temperature to 500°C at a rate of 5°C / min, and keep it for 1h to prepare zinc oxide with high conductivity ceramics.

[0034] The prepared high-conductivity zinc oxide ceramics were processed according to the test size requirements, and tested by the four-probe method. It was measured that the density of t...

Embodiment 3

[0036] ① Grinding and granulation: use zinc oxide powder as raw material, add 3mol / L acetic acid solution at a mass ratio of 7:1, mix thoroughly, and grind to moderately wet particles;

[0037] ②Ultra-low temperature sintering: Put the granules prepared in ① into a Φ20mm mold, the mold pressure is 500MPa, during the pressing process, the mold is heated from room temperature to 120℃ at a rate of 1℃ / min, and kept for 4h, and the obtained size is Φ20 ×3mm 3 Zinc oxide ceramic samples;

[0038] ③Heat treatment in an inert atmosphere: put the zinc oxide ceramic sample prepared in ② into an atmosphere furnace, and pass in nitrogen gas, raise the temperature from room temperature to 500°C at a rate of 5°C / min, and keep it for 3 hours to prepare high-conductivity zinc oxide ceramics.

[0039] The prepared high-conductivity zinc oxide ceramics were processed according to the test size requirements, and tested by the four-probe method. It was measured that the density of the zinc oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com