Preparation method for continuous fiber-reinforced carbon/carbon-niobium composite material

A technology of carbon composite materials and continuous fibers, applied in the field of preparation of carbon/carbon-niobium composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

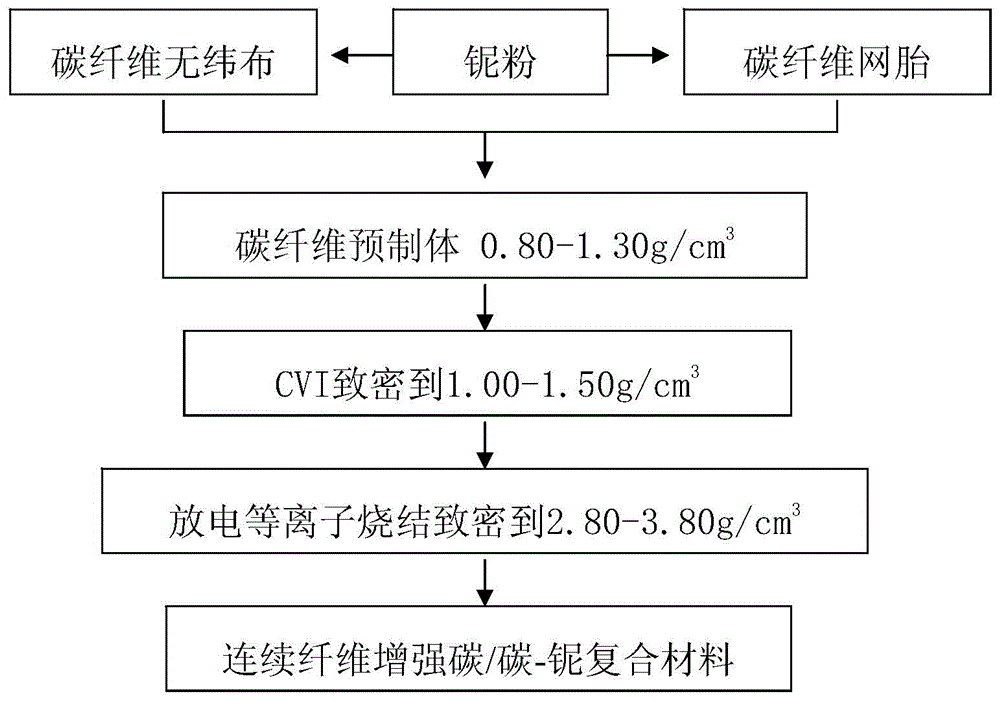

Method used

Image

Examples

Embodiment 1

[0046] (1) Lay niobium powder with a particle size of 100-140 microns on each layer of latitude cloth and mesh respectively, and layer 12 layers of latitude cloth and mesh one by one, needle punching and hooking to prepare carbon fiber preform, control The initial density of the preform is 0.83g / cm 3 , The mass fraction of niobium in the preform is 40%;

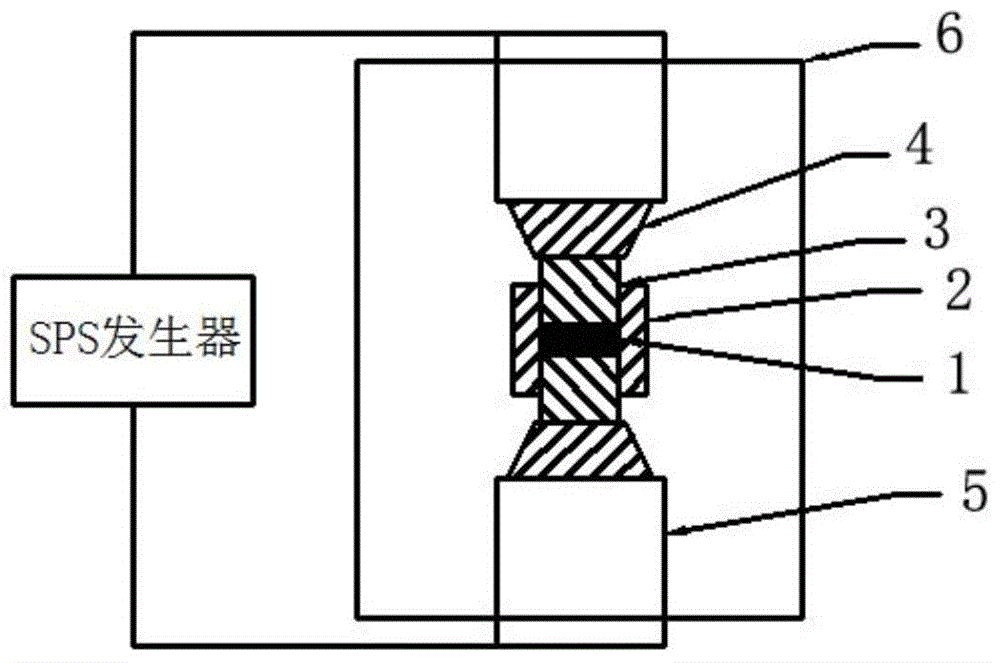

[0047] (2) Densify the preform to 1.00g / cm by CVI 3 , Control the microstructure of the matrix pyrolytic carbon to rough layer structure pyrolytic carbon; machined into a workpiece with a diameter of 40mm and a height of 10mm, put it into the graphite mold of the SPS furnace, and pre-compression molding with a force of 5KN to keep the sample surface smooth.

[0048] (3) Using SPS furnace, vacuum to 10 -2 After Pa, the carbon / carbon-niobium composite material is quickly heated to a temperature of 1700°C, then slowly pressurized to a pressure of 31MPa, and the heating rate is controlled to be 120°C / min and the pressurizing rate to b...

Embodiment 2

[0051] (1) Lay niobium powder with a particle size of 100-140 microns on each layer of latitude cloth and mesh, and layer 15 layers of latitude cloth and mesh, and needle-punching to prepare a carbon fiber preform. The initial density of the preform is 0.91g / cm 3 , The mass fraction of niobium in the preform is 45%;

[0052] (2) Densify the preform to 1.09g / cm by CVI 3 , Control the microstructure of the matrix pyrolytic carbon to rough layer structure pyrolytic carbon; machined into a workpiece with a diameter of 40mm and a height of 10mm, put it into the graphite mold of the SPS furnace, and pre-compression molding with a force of 5KN to keep the sample surface smooth.

[0053] (3) Using SPS furnace, vacuum to 10 -2 After Pa, the carbon / carbon-niobium composite material is quickly heated to a temperature of 1720°C, then slowly pressurized to a pressure of 33MPa, and the heating rate is controlled to 160°C / min and the pressurizing rate to 0.9MPa / min;

[0054] (4) Keep heat preserva...

Embodiment 3

[0056] (1) Lay niobium powder with a particle size of 100-140 microns on each layer of latitude cloth and mesh, and layer 14 layers of latitude cloth and mesh, and needle-punching to prepare a carbon fiber preform. The initial density of the preform is 1.00g / cm 3 , The mass fraction of niobium in the preform is 50%;

[0057] (2) Densify the preform to 1.20g / cm by CVI 3 , Control the microstructure of the matrix pyrolytic carbon to rough layer structure pyrolytic carbon; machined into a workpiece with a diameter of 40mm and a height of 10mm, put it into the graphite mold of the SPS furnace, and pre-compression molding with a force of 5KN to keep the sample surface smooth.

[0058] (3) Using SPS furnace, vacuum to 10 -2 After Pa, the carbon / carbon-niobium composite material is quickly heated to a temperature of 1670°C, then slowly pressurized to a pressure of 31MPa, and the heating rate is controlled to be 140°C / min and the pressurizing rate to be 1MPa / min;

[0059] (4) Keep heat pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com