Sputtering target, transparent conductive oxide, and method for preparing sputtering target

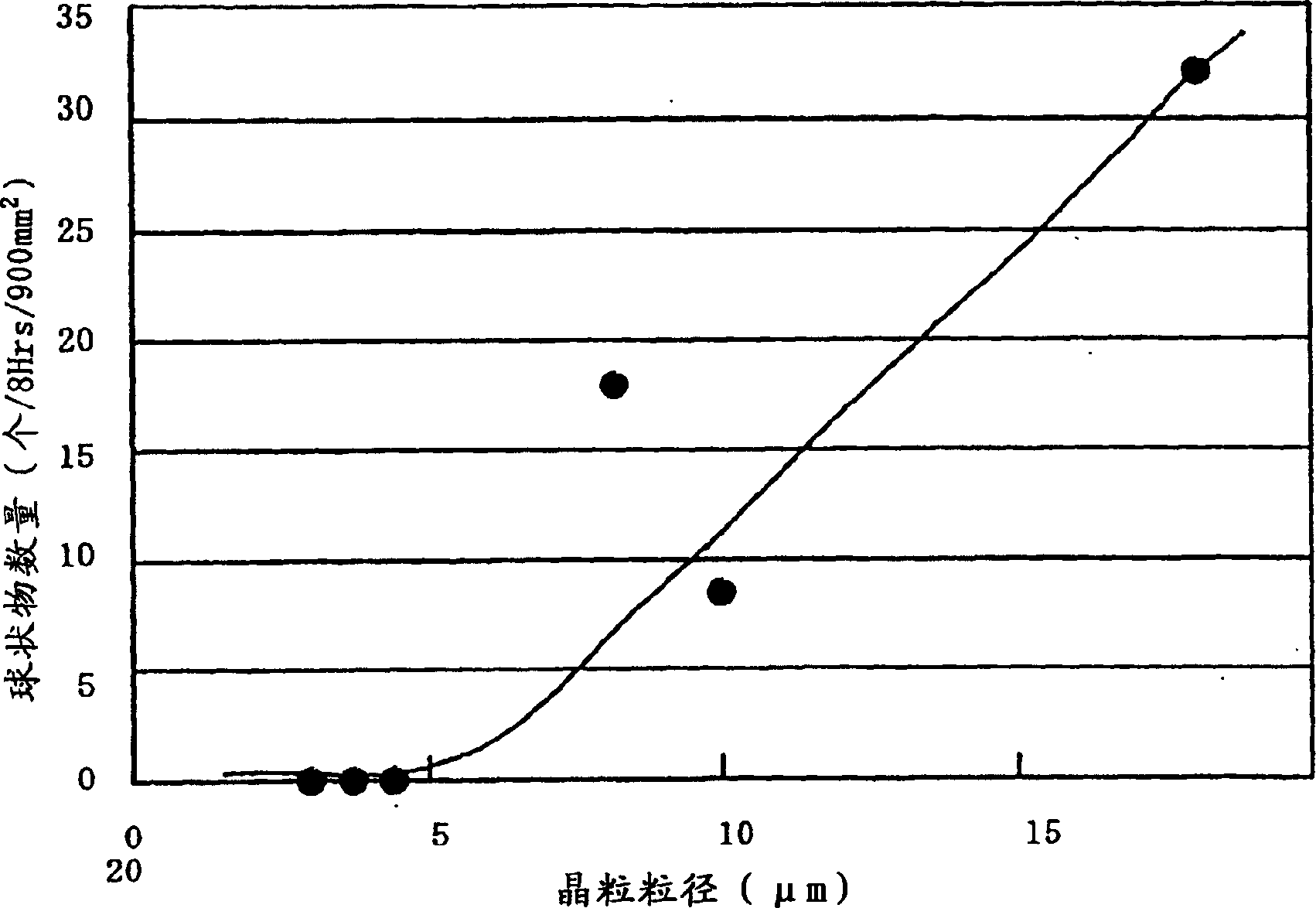

A transparent conductive, sputtering target technology, applied in the field of sputtering targets, can solve problems such as the inability to completely remove spherical objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0452] (1)

[0453] ① Target preparation

[0454] Indium oxide with an average particle size of 1 micron and zinc oxide with an average particle size of 1 micron are used as raw materials, mixed with each other so that the atomic ratio of In / (In+Zn) is 0.83, and added to a wet ball mill. After 72 Mixing and milling for hours yields a fine powdery raw material.

[0455] The fine powdery raw material was granulated, and the obtained granules were subsequently pressed into specifications of 10 cm in diameter and 5 mm in thickness. This was placed in a sintering furnace and sintered at 1,450° C. for 36 hours in compressed oxygen to obtain a sintered body (target) made of a transparent conductive oxide.

[0456] ② Target evaluation

[0457] Density, volume resistance, X-ray diffraction analysis, crystal grain size and various physical properties of the obtained target were measured.

[0458] The density of the sintered body is 6.8g / cm 3 , the volume resistance determined by th...

Embodiment 2 to 3

[0474] (1) Preparation of sputtering target

[0475] Targets [B1] and [C1] were obtained in the same manner as in Example 1, but in Examples 2 and 3, the same indium oxide and zinc oxide as in Example 1 were used in the form of In / (In+Zn), respectively. A mixture mixed so that the atomic ratio was 0.93 and a mixture in which the same indium oxide and zinc oxide as in Example 1 were mixed so that the atomic ratio of In / (In+Zn) was 0.95 were used as raw materials.

[0476] The measurement results of compositions and physical properties of the targets [B1] and [C1] are shown in Table 1.

[0477] (2) Evaluation of targets and transparent conductive oxides

[0478] In the same manner as in Example 1, transparent conductive oxides were prepared from [B1] and [C1], respectively. The target and transparent conductive oxide were evaluated. The results obtained are listed in Table 2.

Embodiment 4

[0496] (1) Preparation of sputtering target

[0497] Indium oxide with an average particle size of 1 micron, zinc oxide with an average particle size of 1 micron and tin oxide with an average particle size of 0.5 micron are used as raw materials, and the percentages of indium oxide, zinc oxide and tin oxide are respectively 75% by weight, 5.5% by weight and 19.5% by weight were mixed with each other and added to the wet ball mill. The raw material is then mixed and pulverized to obtain a finely powdered raw material.

[0498] The fine powdery raw material obtained here was granulated, and the obtained granules were subsequently compressed into specifications of 10 cm in diameter and 5 mm in thickness. Put it into a sintering furnace and sinter at 1,450°C for 36 hours in compressed oxygen to obtain a sintered body made of transparent conductive oxide.

[0499] As a result, the density is 6.8g / cm 3 , the volume resistance determined by the 4-probe method is 0.84 × 10 -3 Ω.cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com