Sputtering method

A sputtering and sputtering gas technology, applied in sputtering plating, ion implantation plating, lighting and heating equipment, etc., can solve the problems of time waste required for exchange, inability to perform film forming operations, etc., to shorten the processing time. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

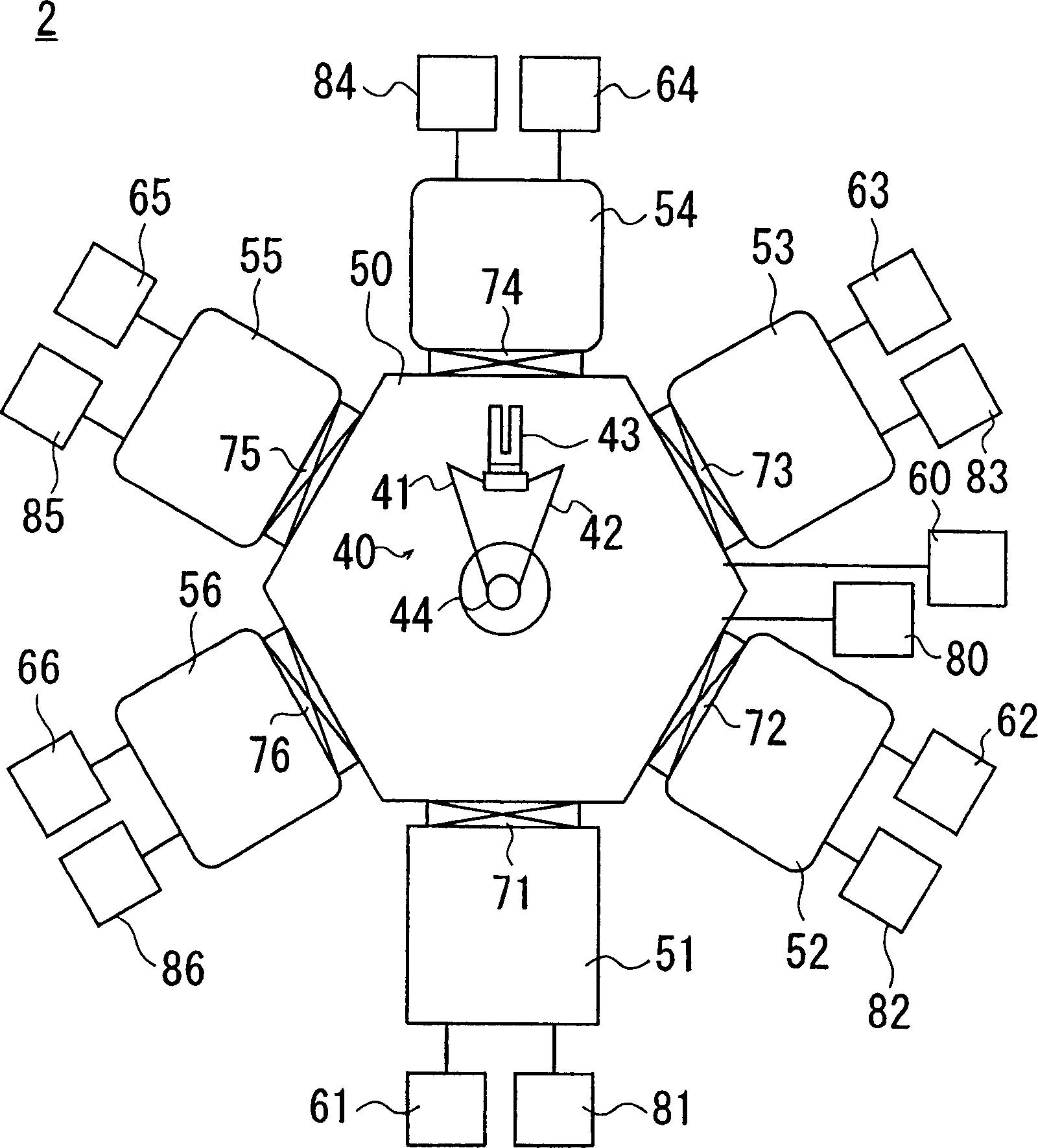

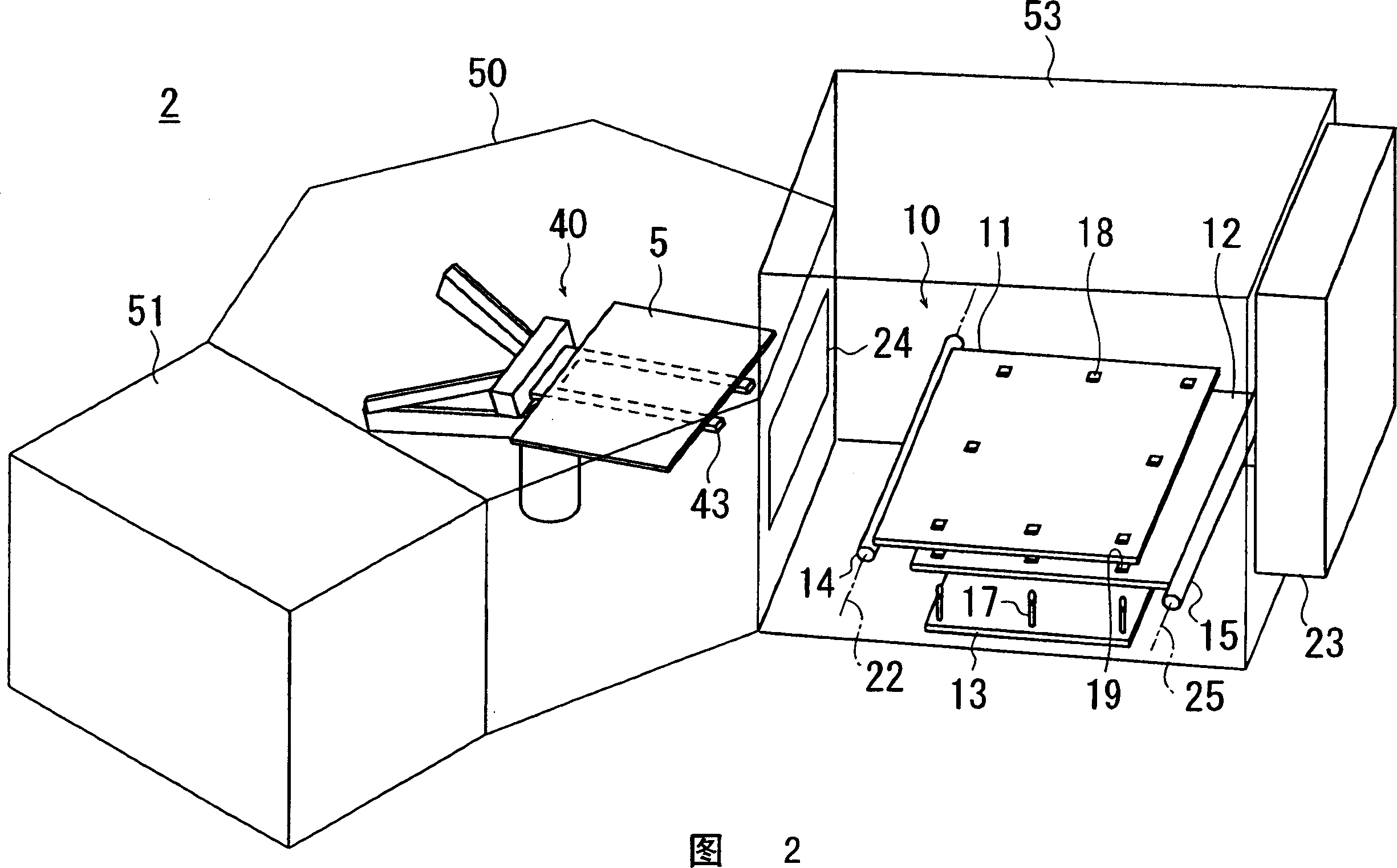

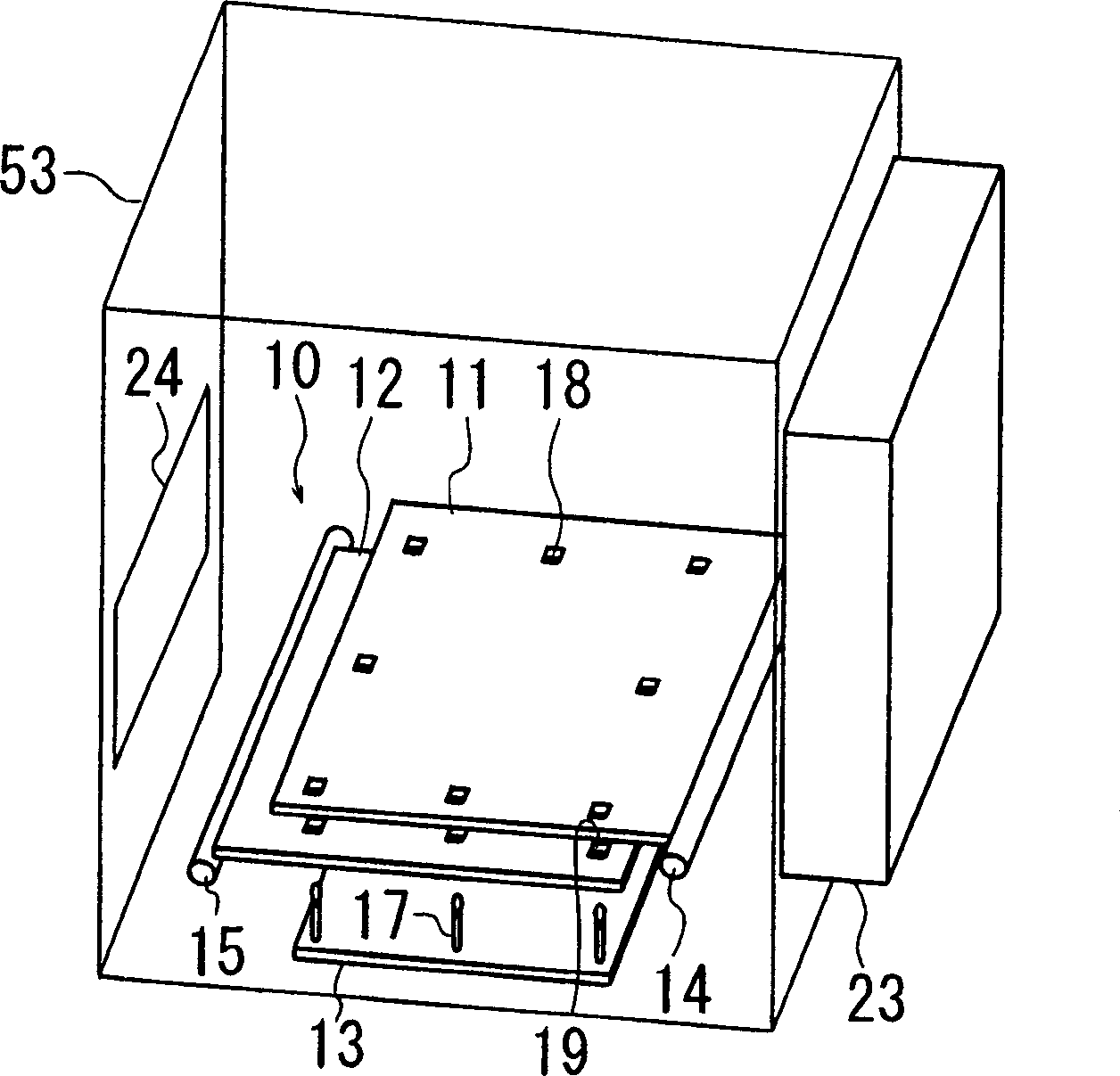

[0038] figure 1 The symbol of represents an example of the vacuum processing apparatus which can employ|adopt the sputtering method of this invention.

[0039] The vacuum processing device 2 has a transport chamber 50, an in-out chamber 51, and processing chambers 52-56. The inlet and outlet chamber 51 and each processing chamber 52-56 communicate with the side of the transfer chamber 50 through gate valves 71-76, respectively.

[0040] In the delivery chamber 50, the access chamber 51, and the processing chambers 52-56, there are respectively connected vacuum systems 60-66 and gas input systems 80-86. When closing the gate valves 71-76 and making the vacuum systems 60-66 work , the interiors of the in-out chamber 51, the transfer chamber 50, and the processing chambers 52-56 can be evacuated individually.

[0041] Gas input systems 82-86 associated with each of the processing chambers 52-56 are associated with gas cylinders corresponding to the processing performed within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com