Cu-Ga alloy sputtering target and method for manufacturing same

A sputtering target and alloy technology, applied in sputtering coating, metal processing equipment, metal material coating technology and other directions, can solve the problems of unstable high-power sputtering, etc., to eliminate the generation of target cracks and stabilize sputtering. radiation, reducing the effect of abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Next, the Cu—Ga alloy sputtering target of the present invention will be described more specifically by way of examples below.

[0041] [Example]

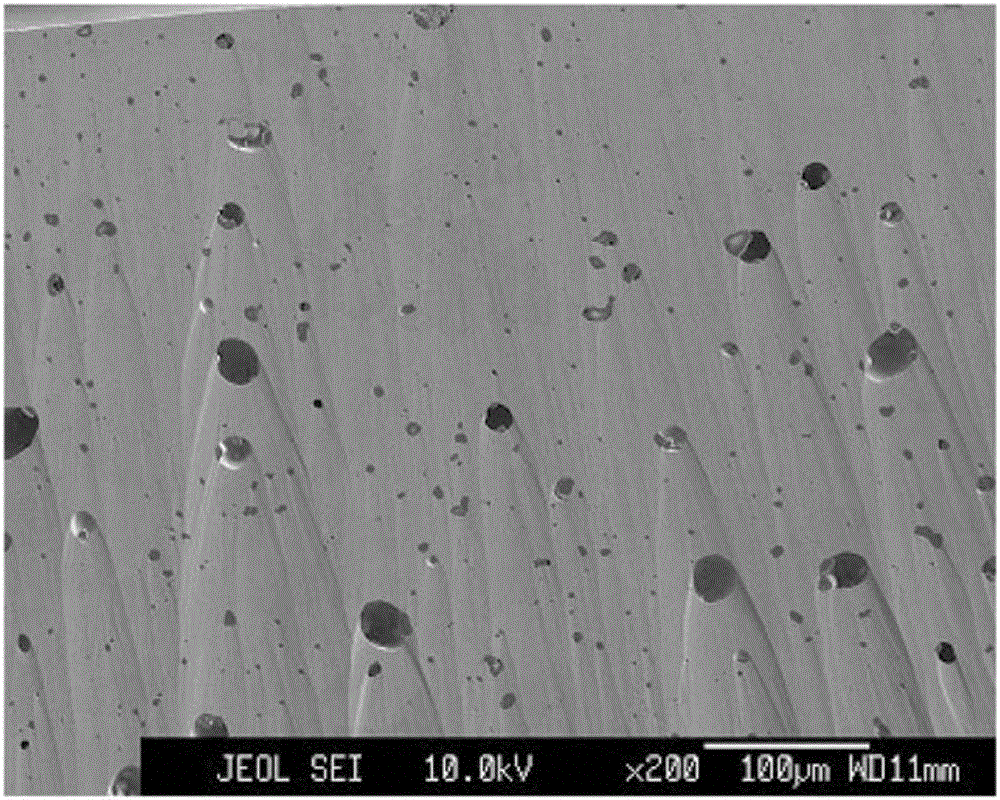

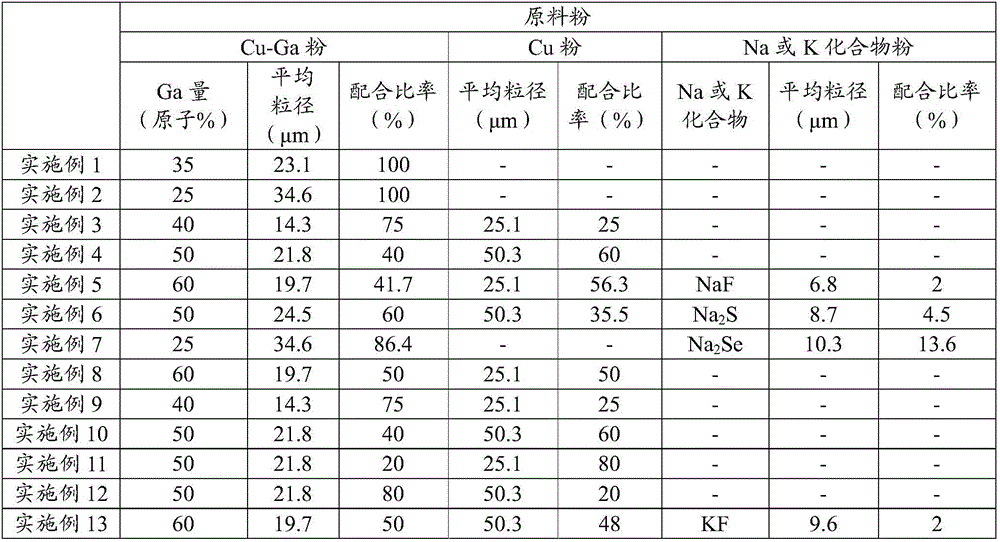

[0042] First, when producing the Cu-Ga alloy sputtering target of this invention, Cu-Ga alloy powder and pure copper powder were prepared. Cu—Ga alloy powders were produced by a gas atomization method after weighing Cu metal lumps and Ga metal lumps so that the Ga contents shown in Table 1 were obtained and melted in crucibles respectively. Examples 1 and 2 are for the case where the Cu-Ga alloy powder is used as the raw material powder, and Examples 3, 4, 8 to 12 are for mixing the above-mentioned Cu-Ga alloy powder and pure copper powder in the mixing ratio shown in Table 1. The case where powder is used as raw material powder. In this mixing, the rotation speed was set to 72 rpm, and the mixing time was set to 30 minutes, and it was performed with a rocking mixer. In addition, in Examples 5 to 7, Na compound was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com