Patents

Literature

50results about How to "Reduce abnormal discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

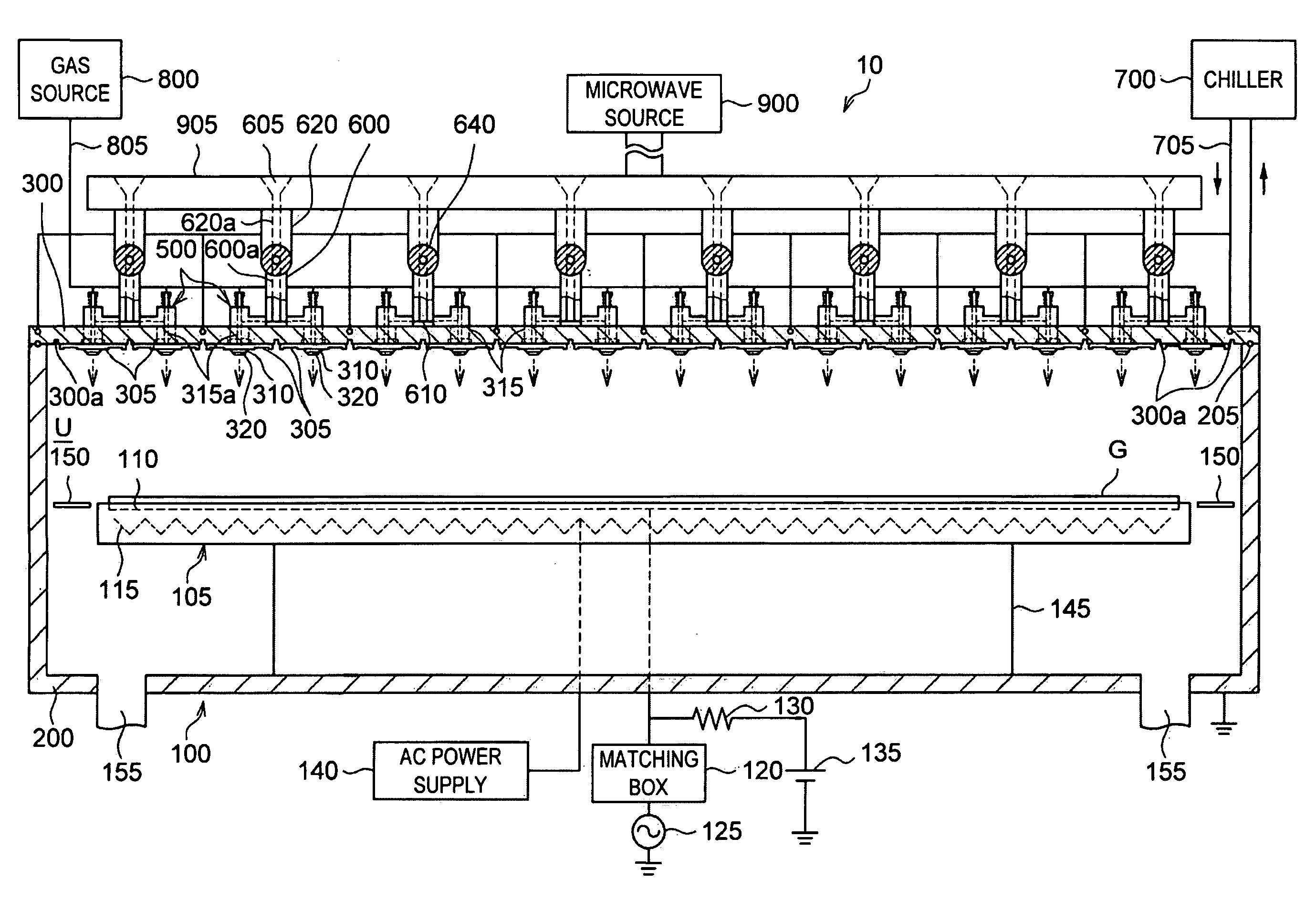

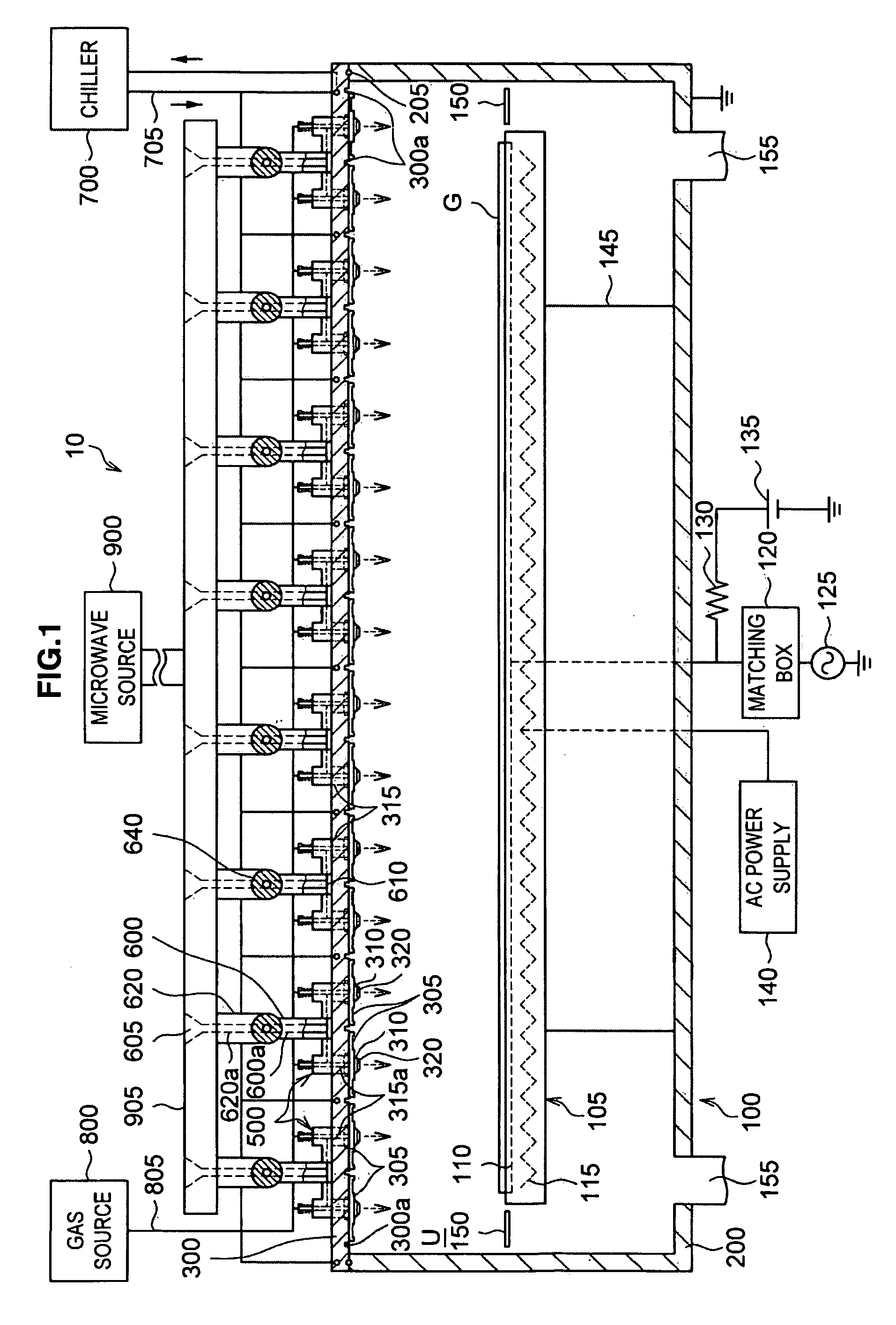

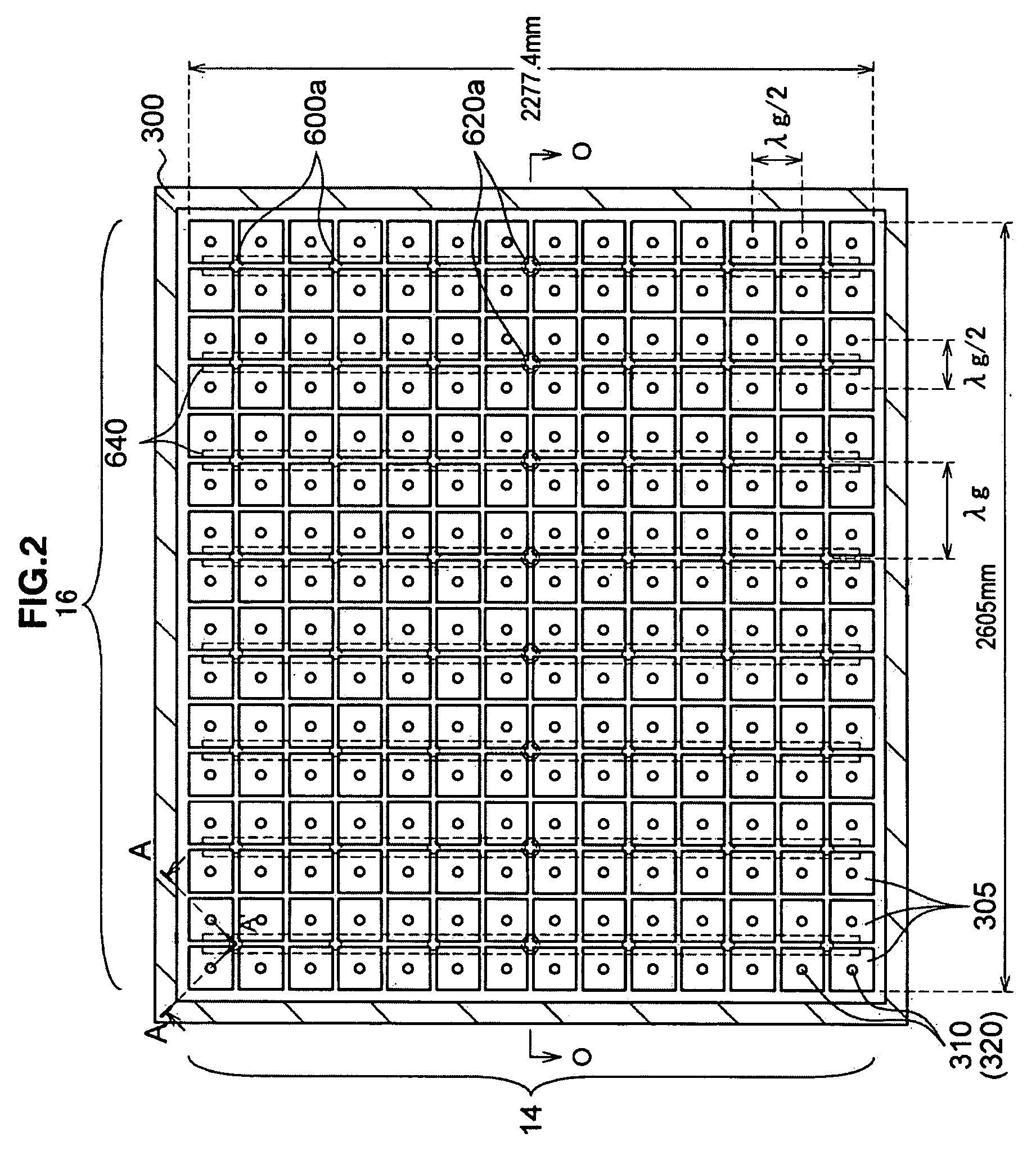

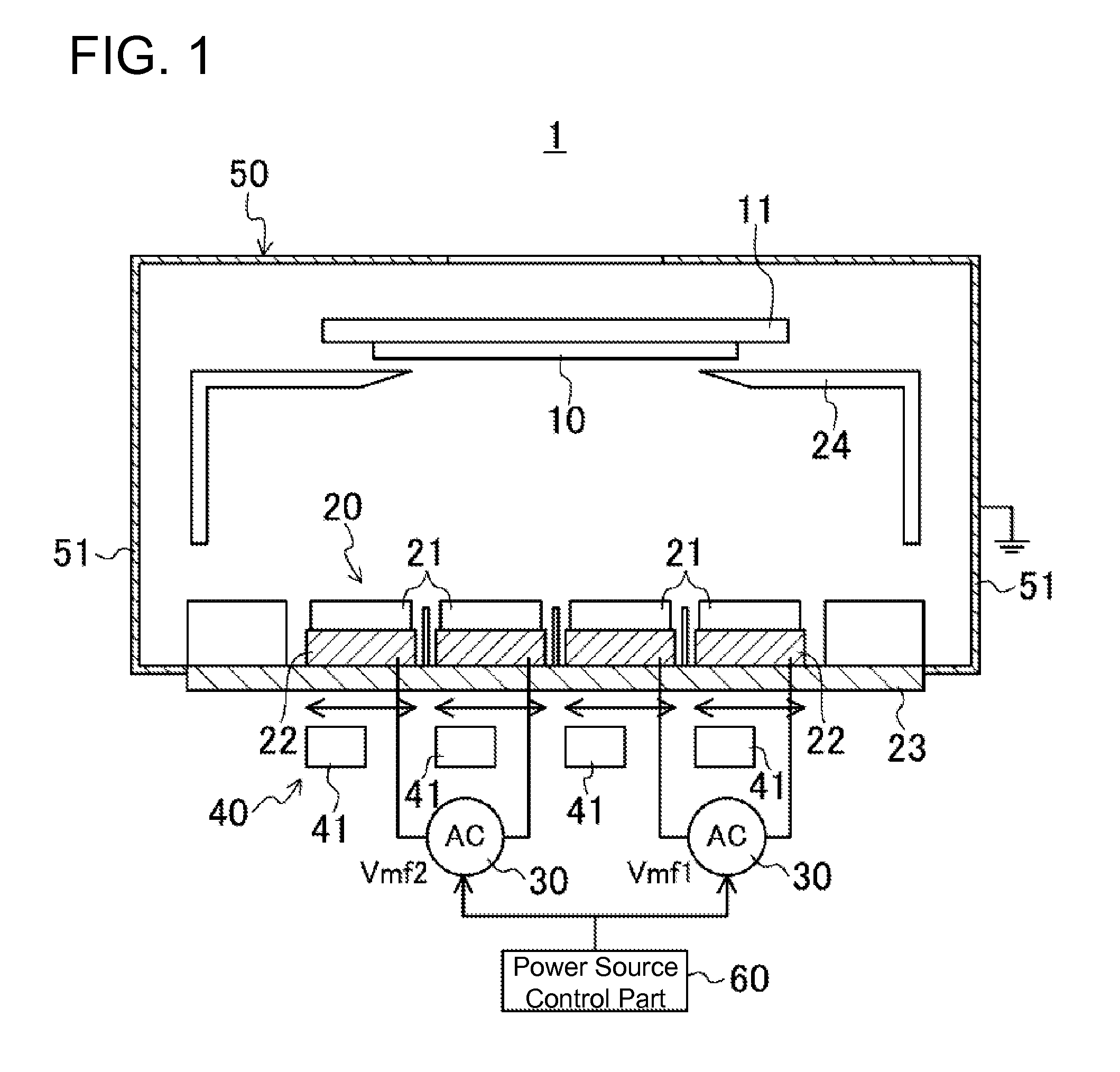

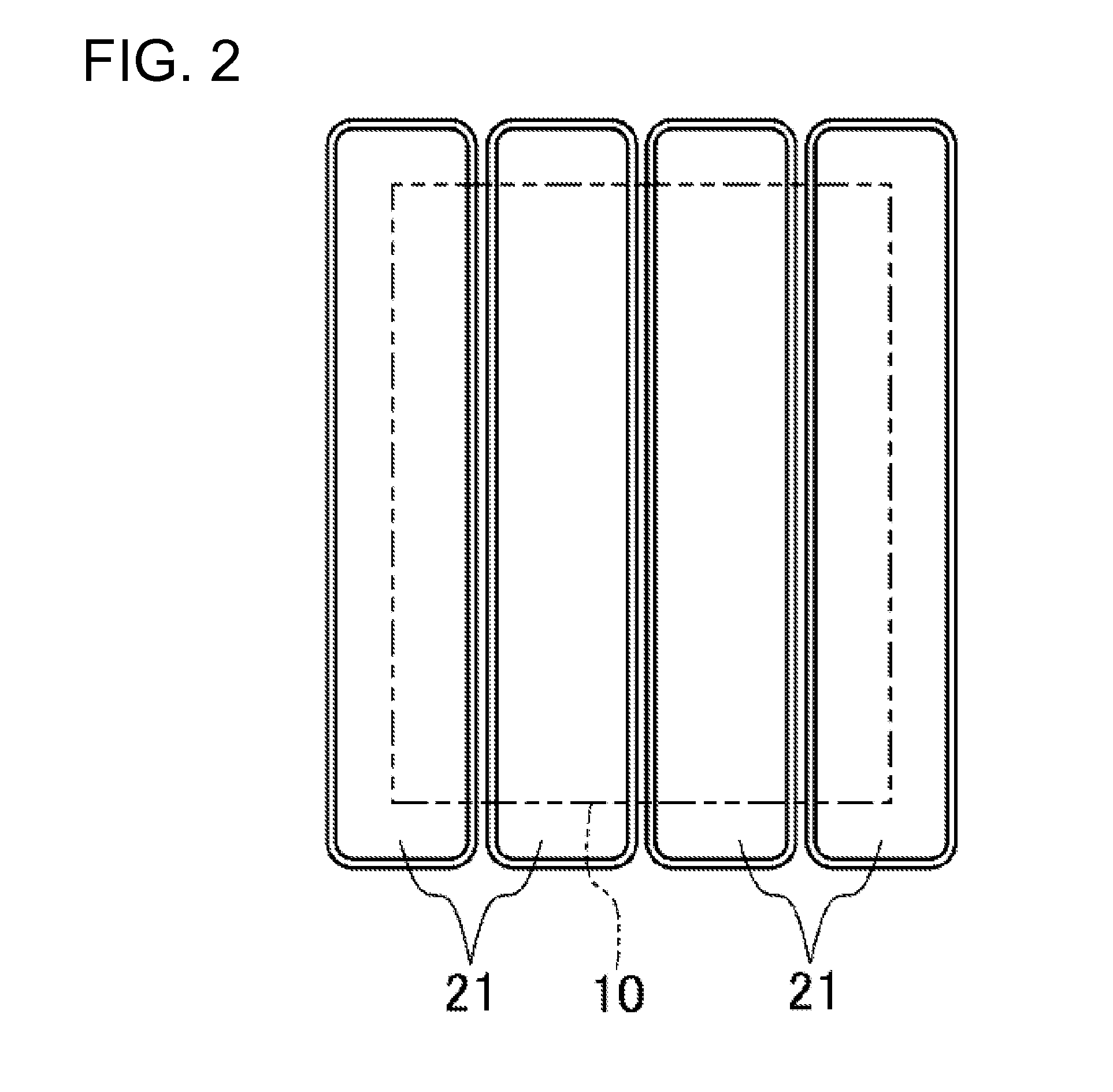

Plasma processing system, antenna, and use of plasma processing system

InactiveUS20080303744A1Reduce the electric fieldImprove uniformityElectric discharge tubesRadiating elements structural formsElectrical conductorDielectric plate

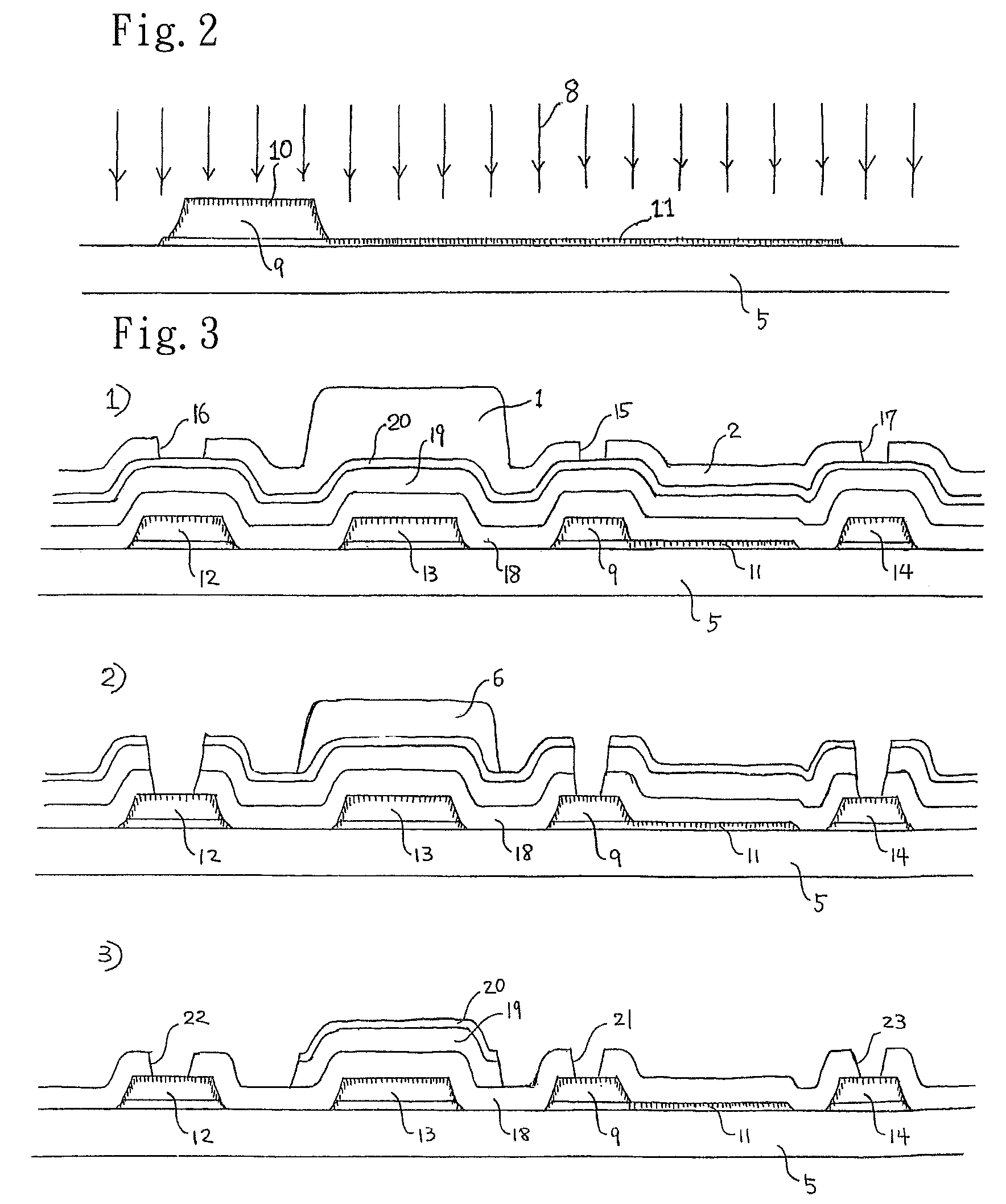

A plasma processing system 10 includes a processing chamber 100, a microwave source 900 that outputs a microwave, an inner conductor of a coaxial waveguide 315a that transfers the microwave, a through-hole 305a, a dielectric plate 305 that transmits the microwave transferred through the inner conductor 315a and discharges it into a processing chamber 100, and a metal electrode 310 that is coupled to the inner conductor 315a via the through-hole 305a, the metal electrode 310 being exposed on the surface of the dielectric plate 305 that faces the substrate with at least a portion of the metal electrode 310 being adjacent to the surface of the dielectric plate 305 that faces the substrate. A surface of the exposed surface of the metal electrode 310 is covered by the dielectric cover 320.

Owner:TOKYO ELECTRON LTD +1

Conductive, plasma-resistant member

InactiveUS20070248832A1Improve corrosion resistanceSuppress particle contaminationMolten spray coatingNatural mineral layered productsDisplay deviceFlat panel display

An electrically conductive, plasma-resistant member adapted for exposure to a halogen-based gas plasma atmosphere includes a substrate having formed on at least part of a region thereof to be exposed to the plasma a thermal spray coating composed of yttrium metal or yttrium metal in admixture with yttrium oxide and / or yttrium fluoride so as to confer electrical conductivity. Because the member is conductive and has an improved erosion resistance to halogen-based corrosive gases or plasmas thereof, particle contamination due to plasma etching when used in semiconductor manufacturing equipment or flat panel display manufacturing equipment can be suppressed.

Owner:SHIN ETSU CHEM IND CO LTD

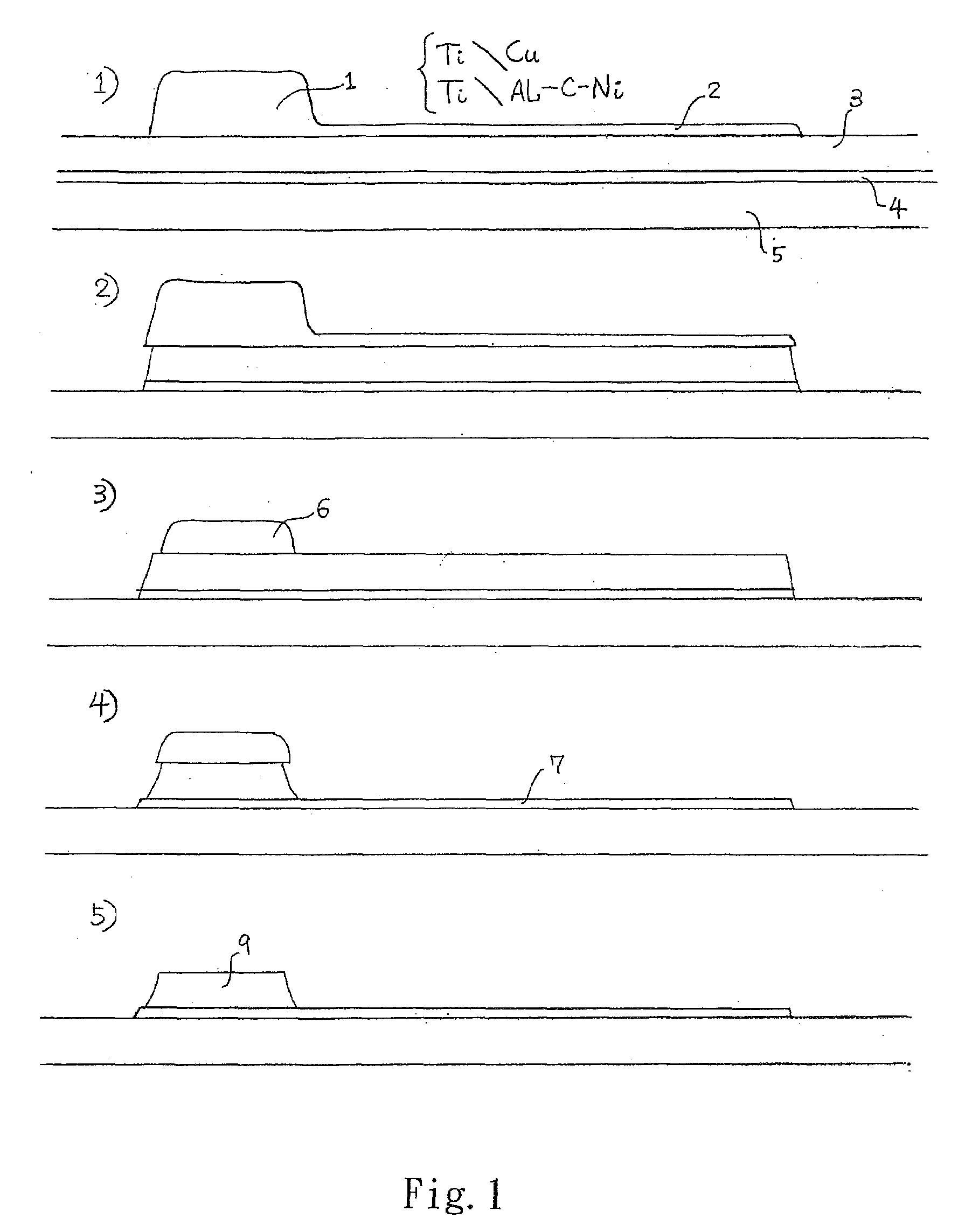

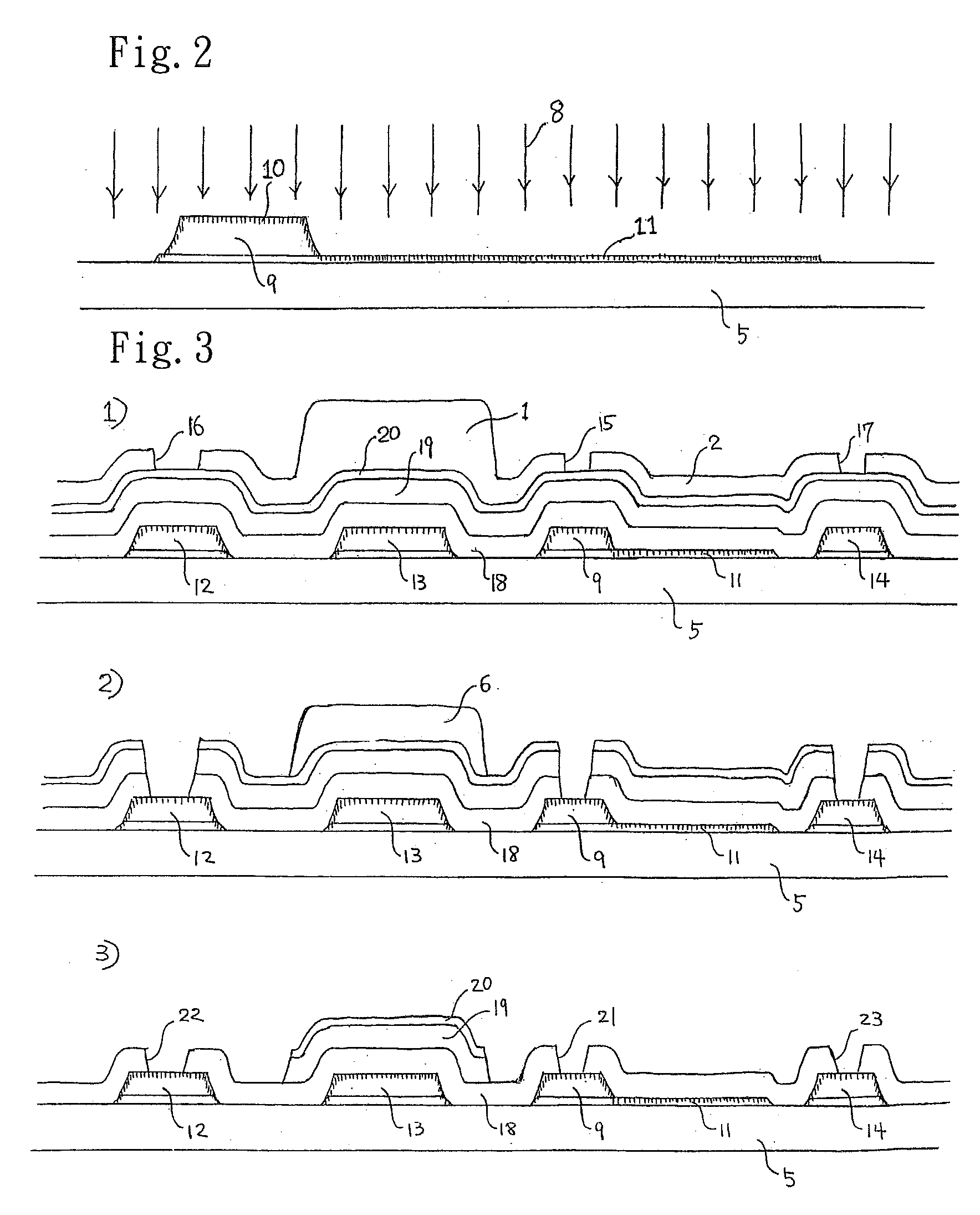

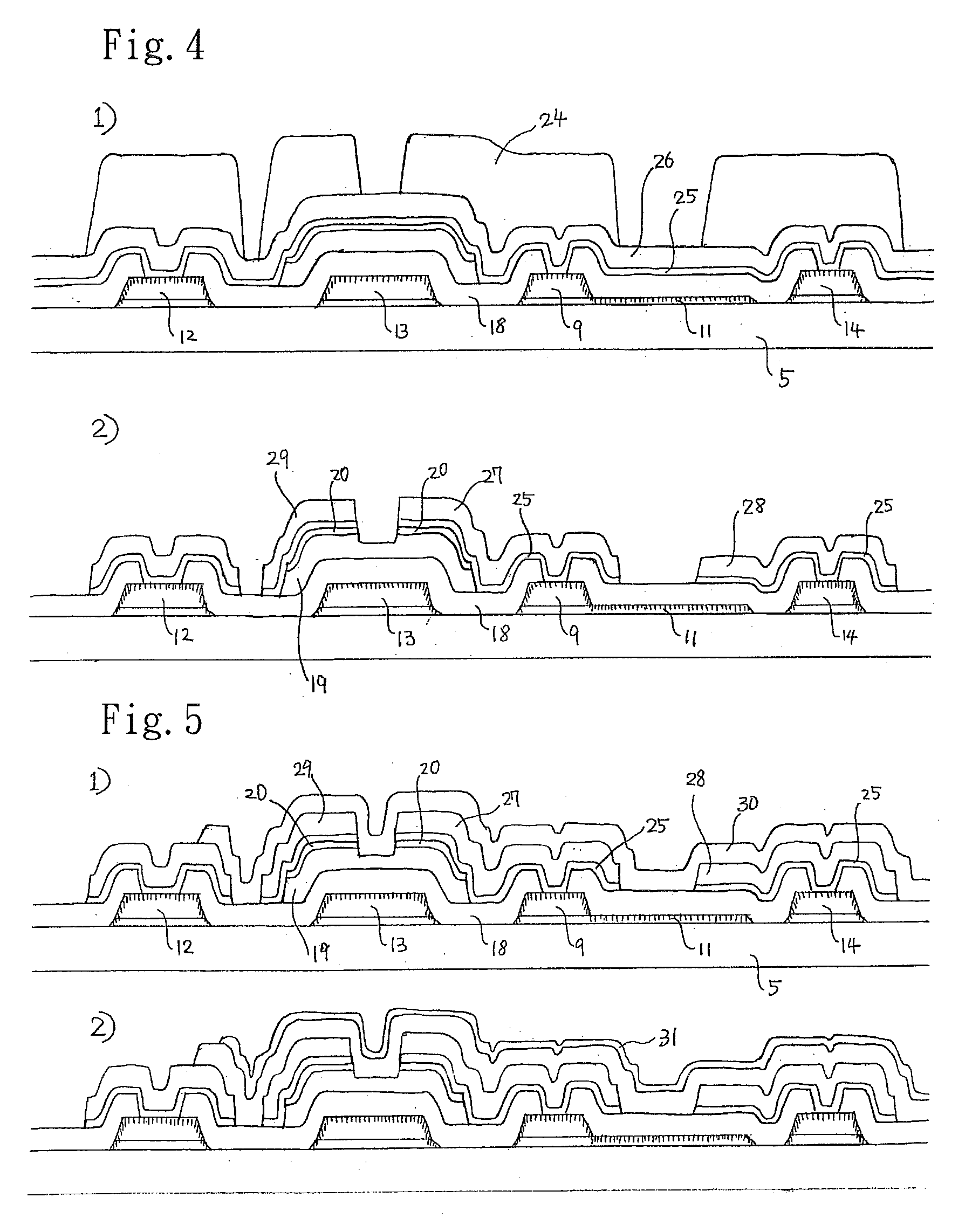

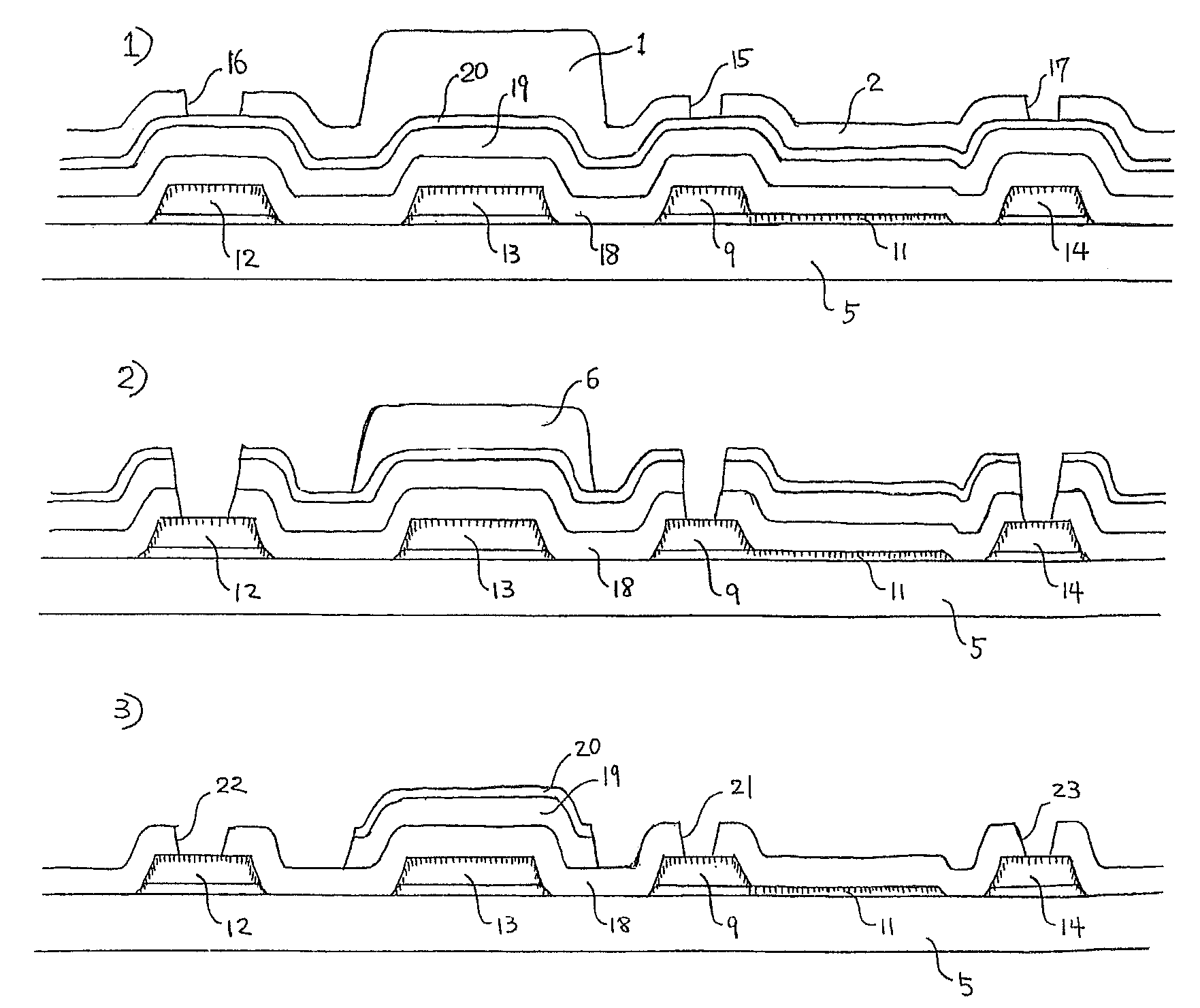

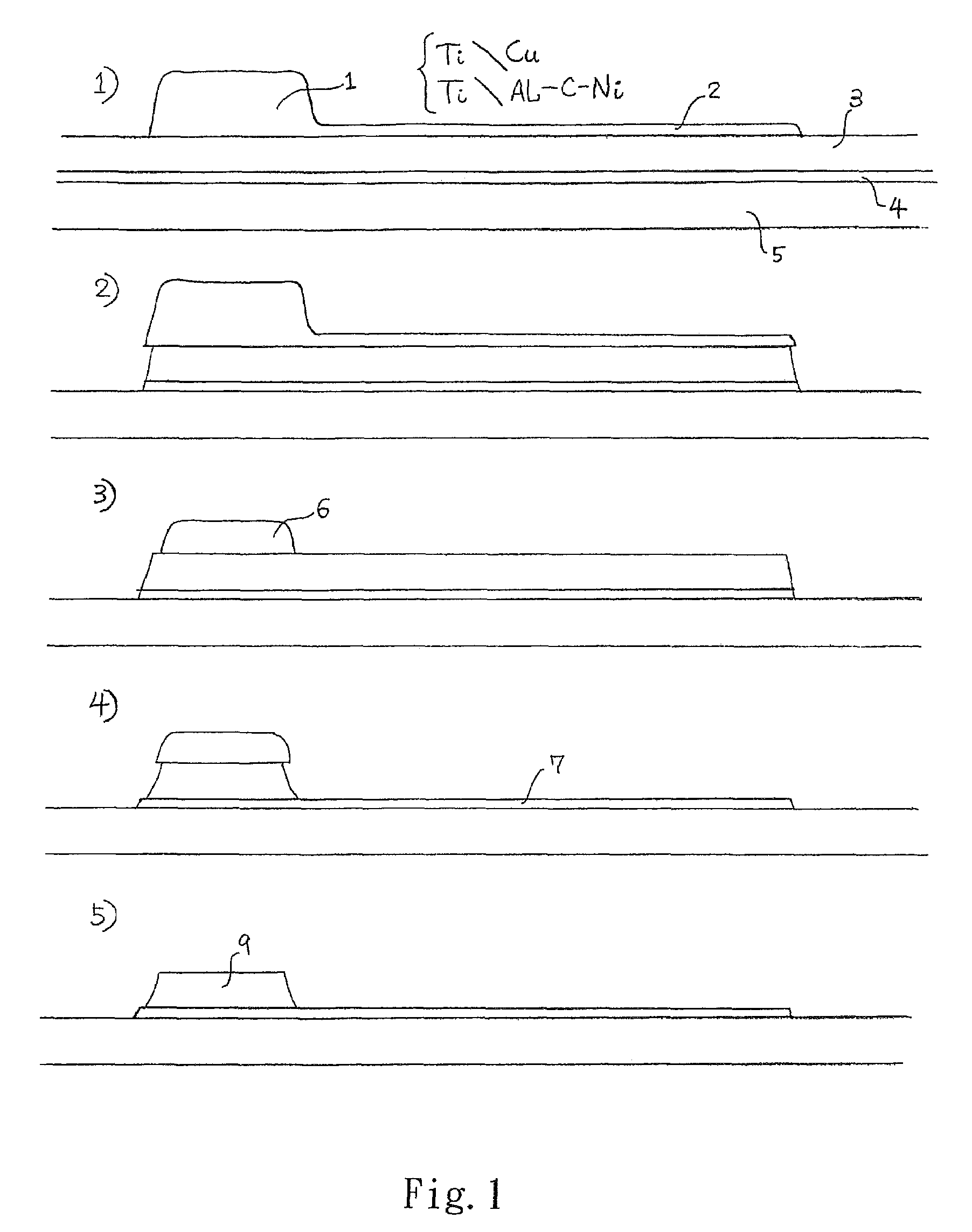

Method of manufacturing LCD apparatus by using halftone exposure method

InactiveUS20070269936A1Reduce production processIncrease contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingContact padNitrogen

The present invention discloses a method of manufacturing a super large wide-angle super high-speed response LCD apparatus by using a photolithographic process for three times. The invention adopts a halftone exposure technology and a nitrogen ion doped technology to form a gate electrode, a common electrode, a pixel electrode and a contact pad, and then uses the halftone exposure technology to form a silicon (Si) island and a contact hole, and a general exposure technology to form a source electrode, a drain electrode and an alignment control electrode. A P-CVD apparatus is provided for forming a passivation layer into a film by using a masking deposition method, or an ink-jet coating method is used to coat a protective layer at a partial area, and a photolithographic process is performed for three times to manufacture a TFT matrix substrate of the super large wide-angle super high-speed response LCD.

Owner:MIKUNI ELECTORON

Method of manufacturing LCD apparatus by using halftone exposure method

InactiveUS7602456B2Reduce production processIncrease contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingContact padNitrogen

The present invention discloses a method of manufacturing a super large wide-angle super high-speed response LCD apparatus by using a photolithographic process for three times. The invention adopts a halftone exposure technology and a nitrogen ion doped technology to form a gate electrode, a common electrode, a pixel electrode and a contact pad, and then uses the halftone exposure technology to form a silicon (Si) island and a contact hole, and a general exposure technology to form a source electrode, a drain electrode and an alignment control electrode. A P-CVD apparatus is provided for forming a passivation layer into a film by using a masking deposition method, or an ink-jet coating method is used to coat a protective layer at a partial area, and a photolithographic process is performed for three times to manufacture a TFT matrix substrate of the super large wide-angle super high-speed response LCD.

Owner:MIKUNI ELECTORON CO LTD

Conductive, plasma-resistant member

InactiveUS7655328B2Solve the lack of resistanceReduce abnormal dischargeMolten spray coatingNatural mineral layered productsDisplay deviceFlat panel display

An electrically conductive, plasma-resistant member adapted for exposure to a halogen-based gas plasma atmosphere includes a substrate having formed on at least part of a region thereof to be exposed to the plasma a thermal spray coating composed of yttrium metal or yttrium metal in admixture with yttrium oxide and / or yttrium fluoride so as to confer electrical conductivity. Because the member is conductive and has an improved erosion resistance to halogen-based corrosive gases or plasmas thereof, particle contamination due to plasma etching when used in semiconductor manufacturing equipment or flat panel display manufacturing equipment can be suppressed.

Owner:SHIN ETSU CHEM IND CO LTD

Gallium oxide-zinc oxide sputtering target, method of forming transparent conductive film and transparent conductive film

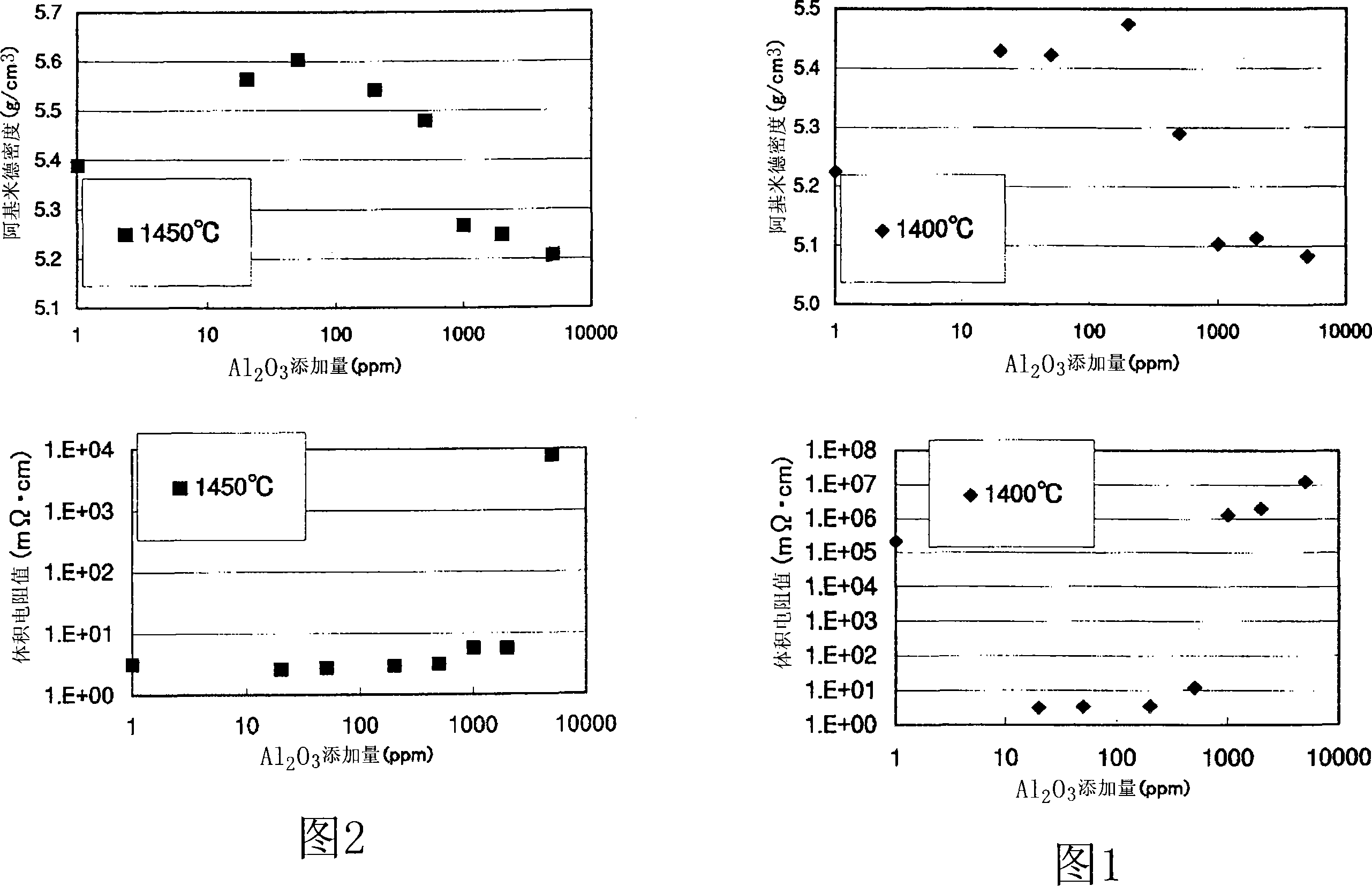

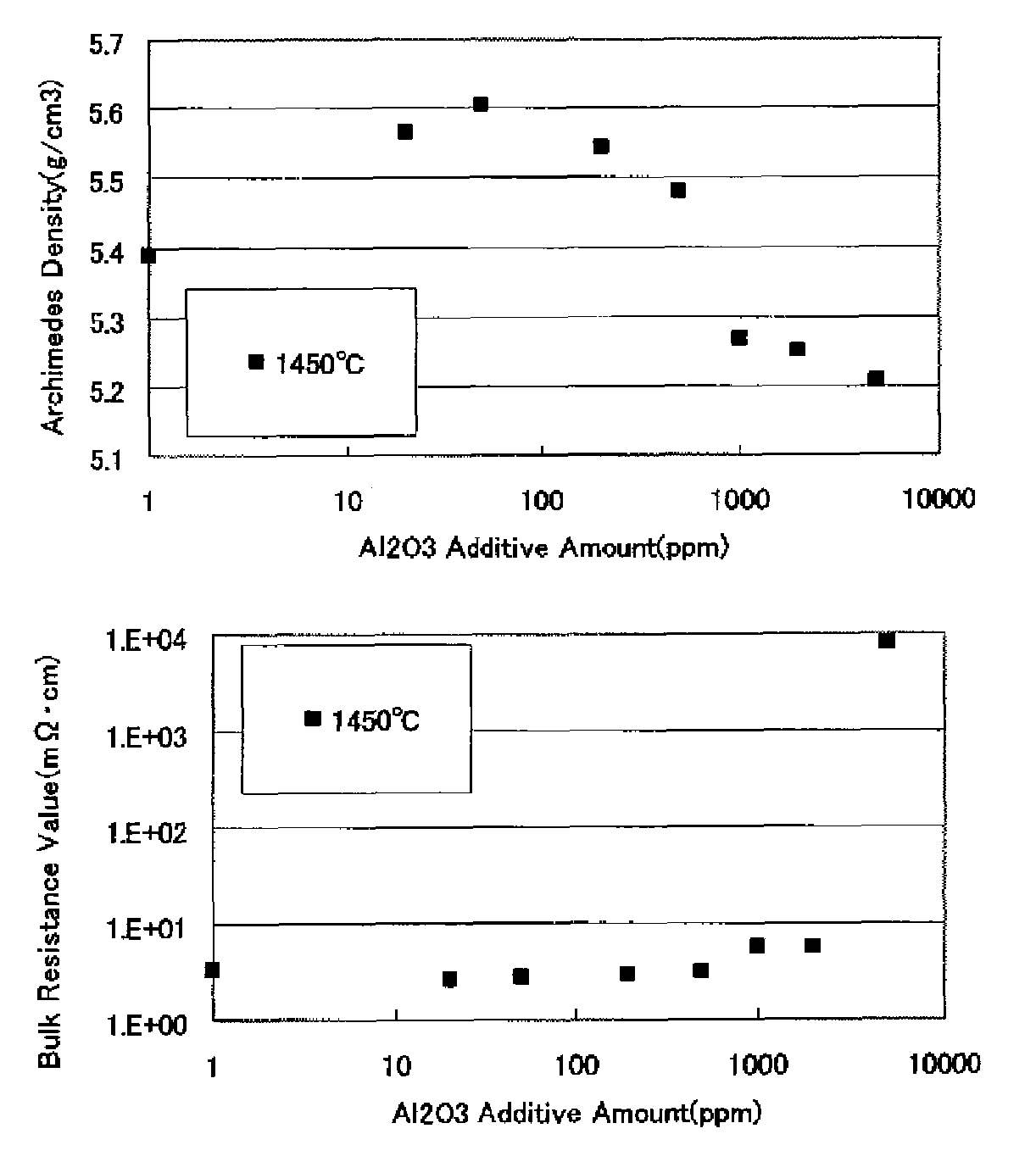

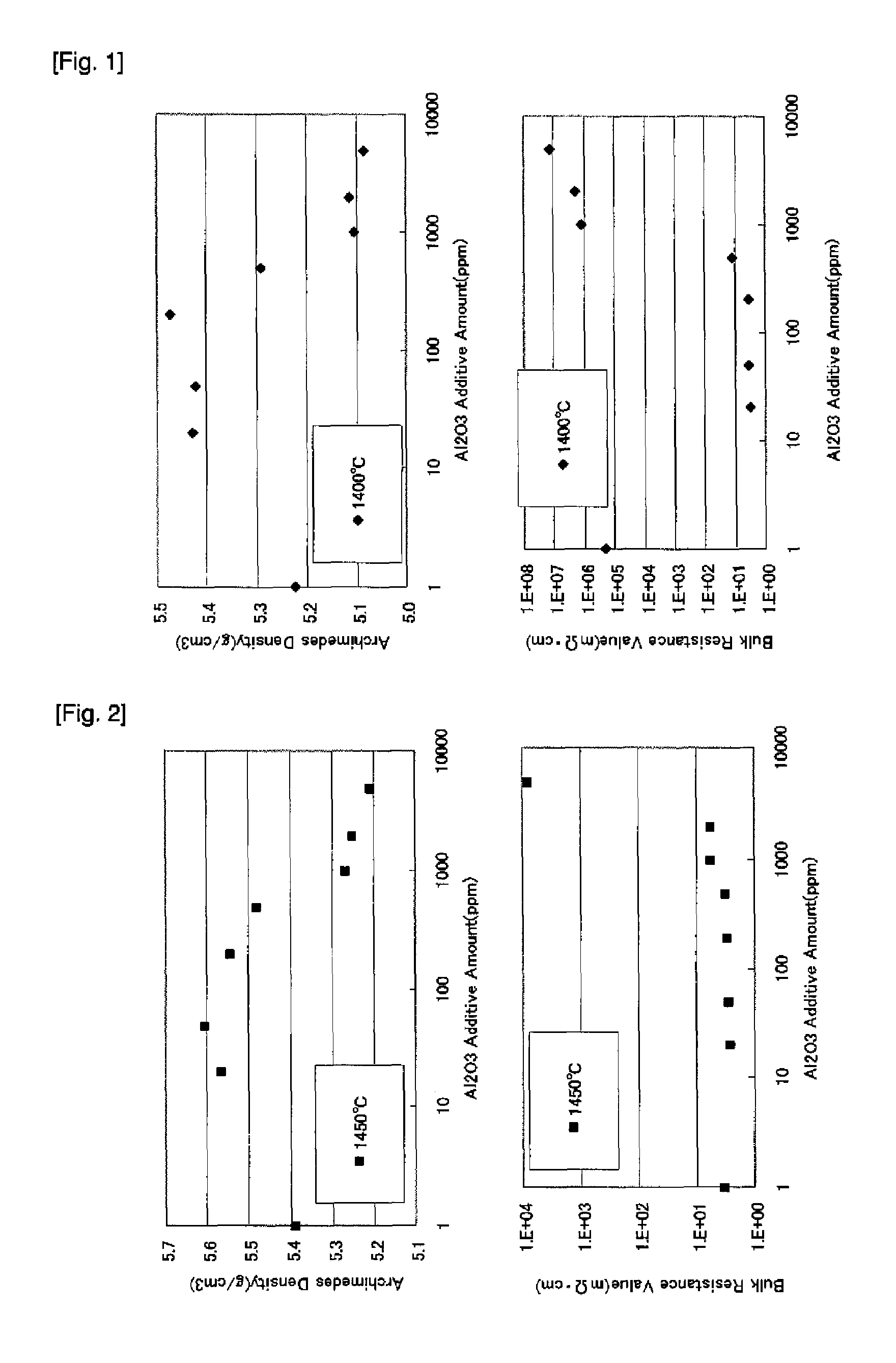

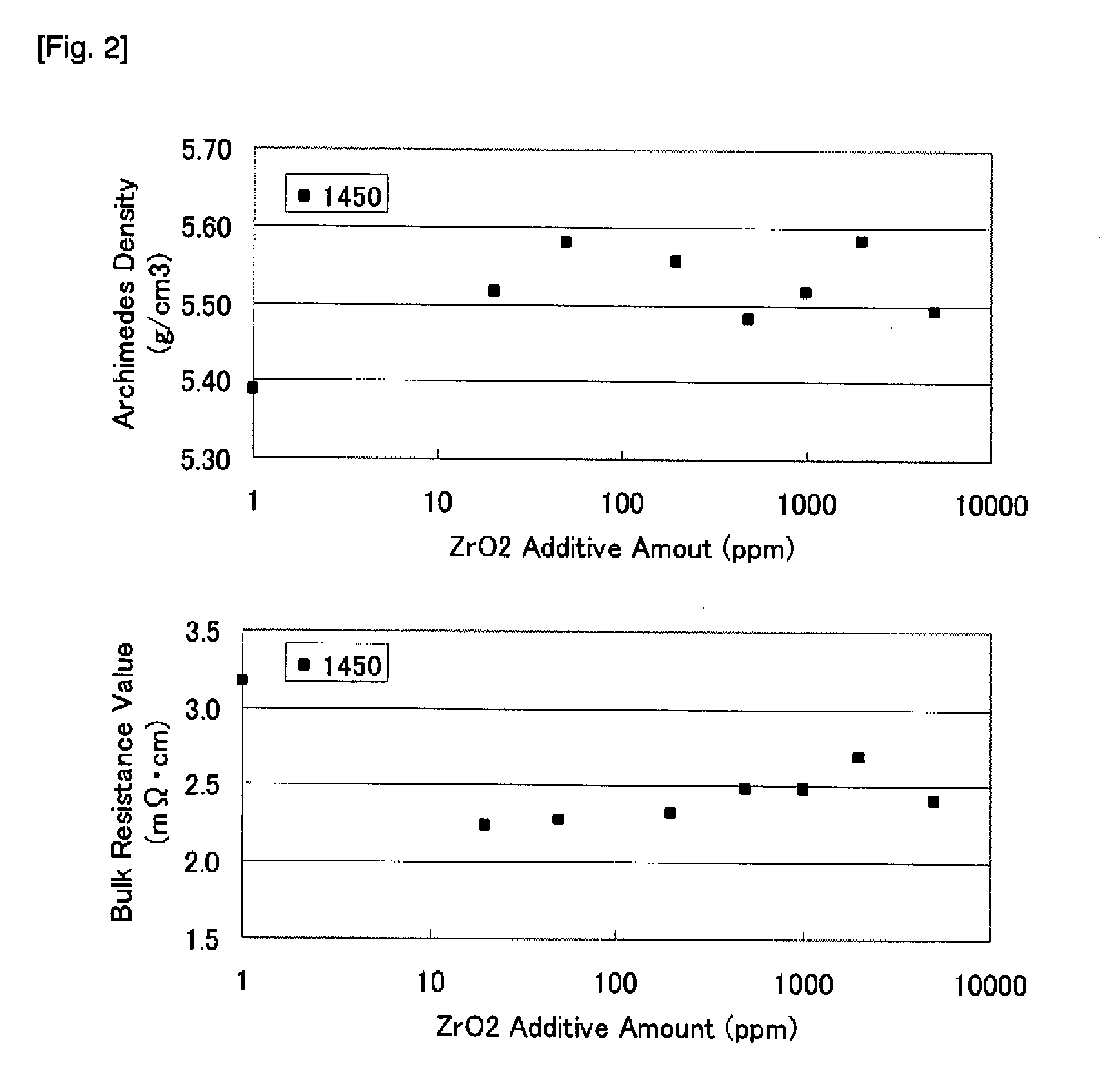

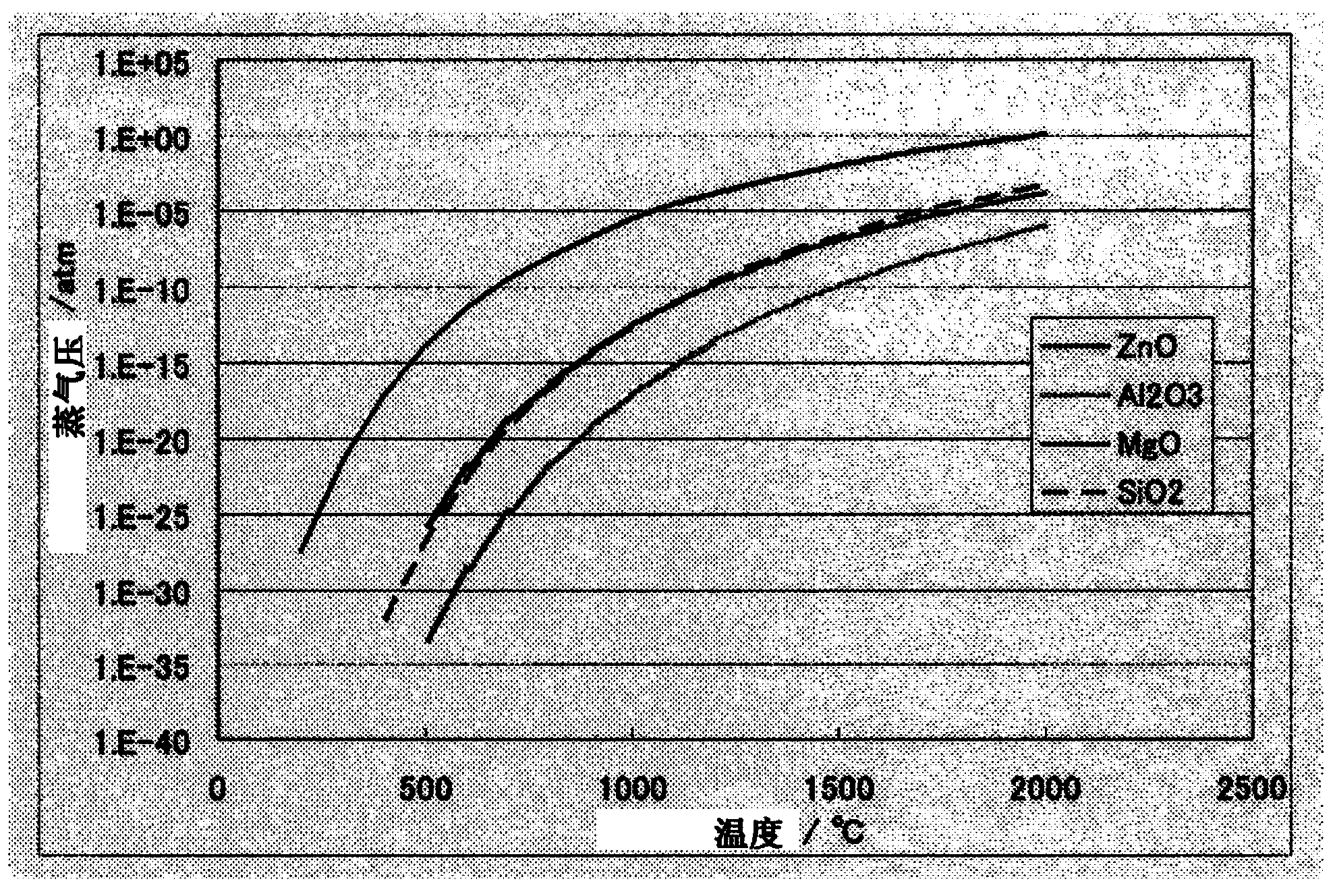

ActiveCN101208453AIncrease target densityInhibits the formation of nodulesConductive layers on insulating-supportsVacuum evaporation coatingSputteringHigh density

Provided is a high density gallium oxide-zinc oxide series sintered body sputtering target for forming a transparent conductive film containing 20 to 500 mass ppm of aluminum oxide. In a gallium oxide(Ga 2 O 3 )-zinc oxide (ZnO) series sputtering target (GZO series target) for forming a transparent conductive film, trace amounts of specific elements are added to obtain a target capable of improving the conductivity and the bulk density of the target; in other words, capable of improving the component composition to increase the sintered density, inhibit the formation of nodules, and prevent the generation of an abnormal electrical discharge and particles. Also provided are a method for forming a transparent conductive film using such a target, and a transparent conductive film formed thereby.

Owner:JX NIPPON MINING & METALS CO LTD

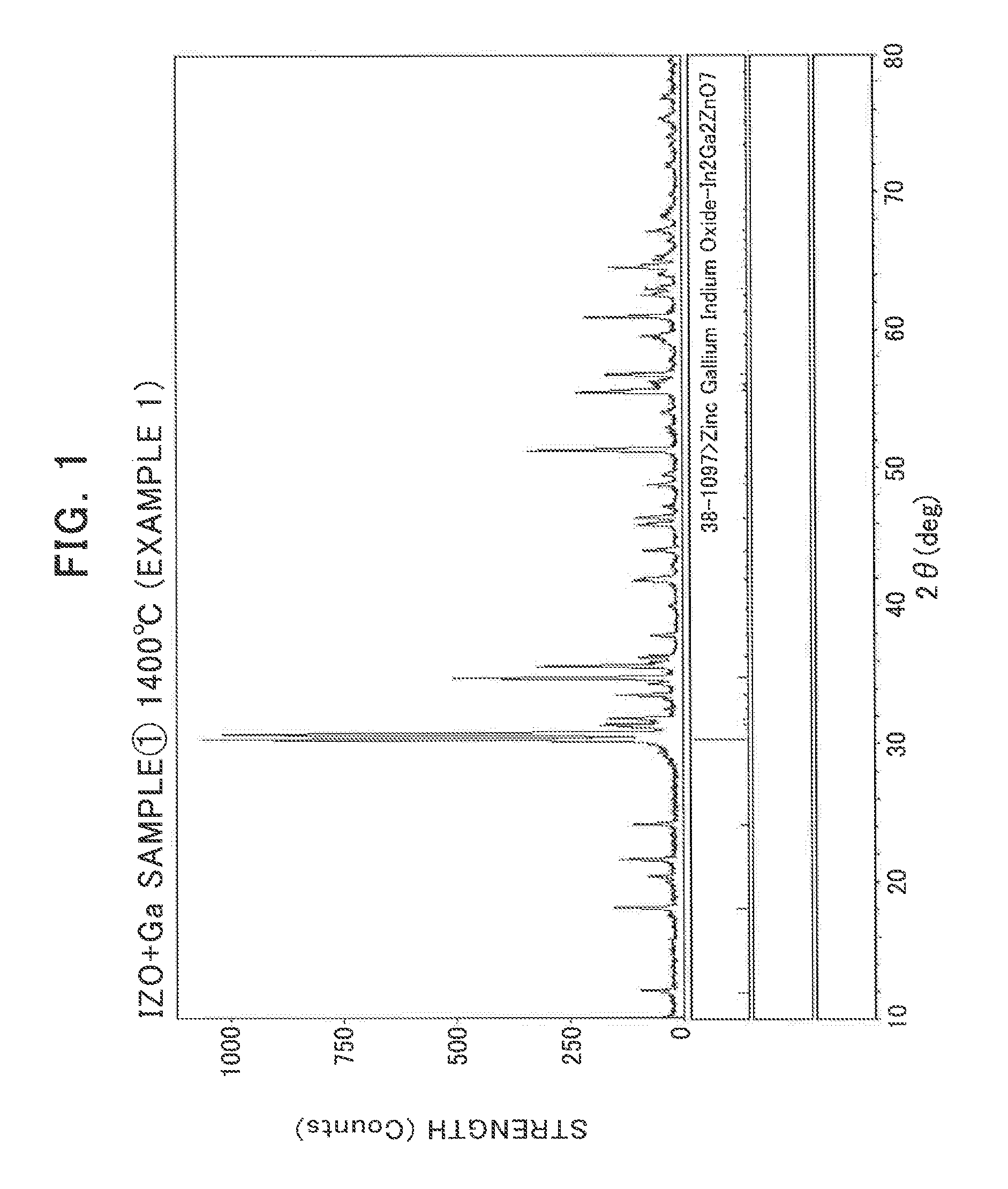

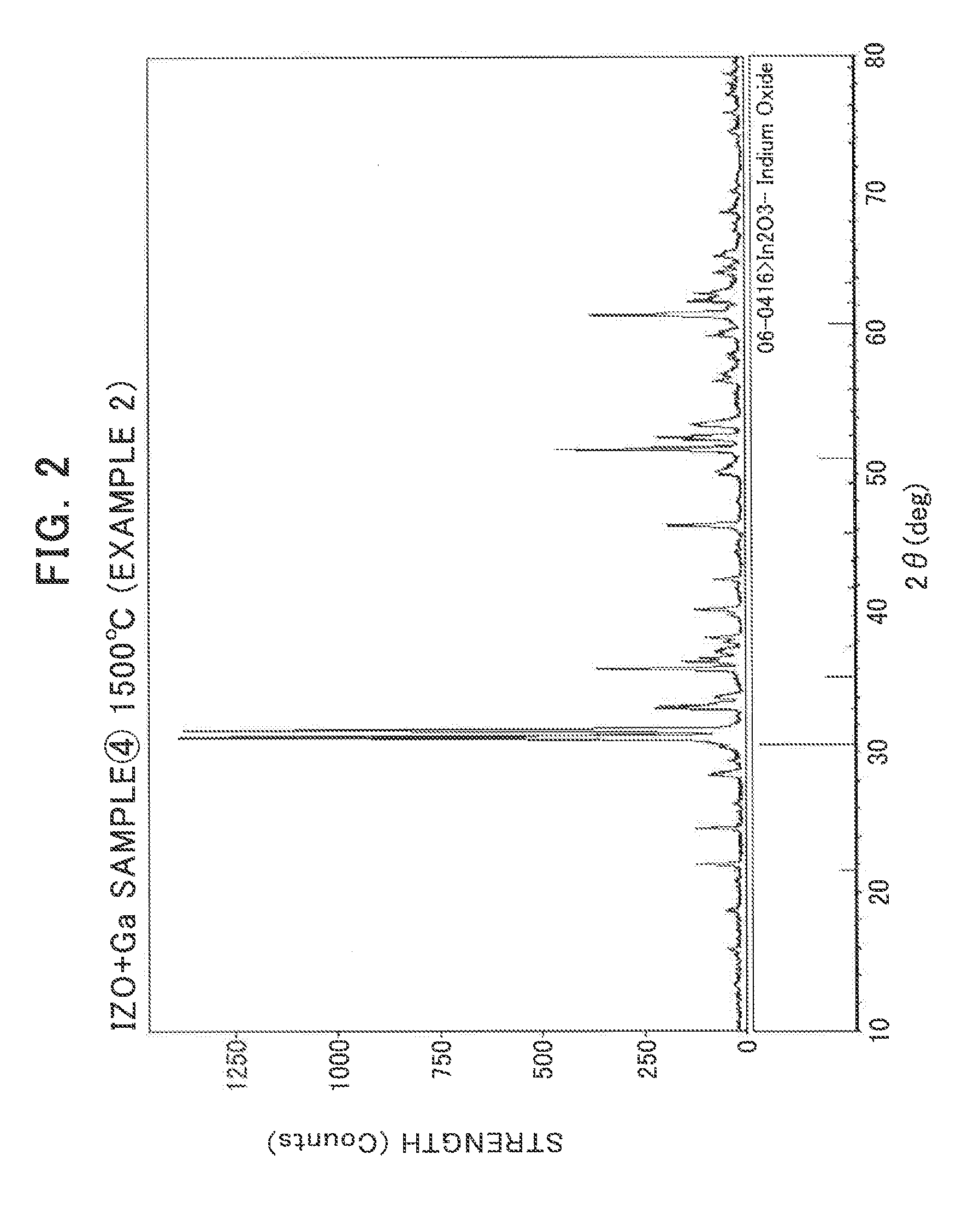

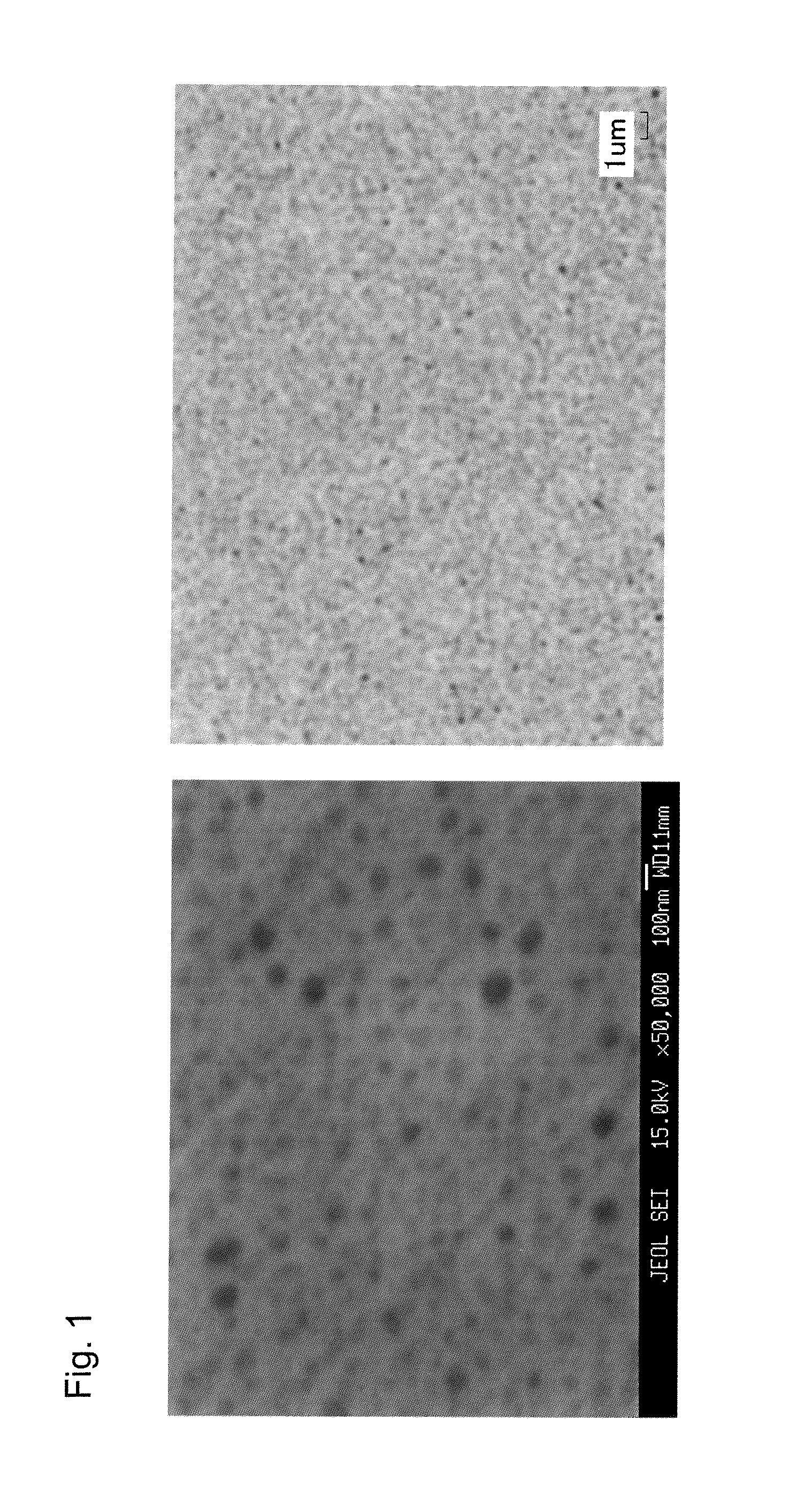

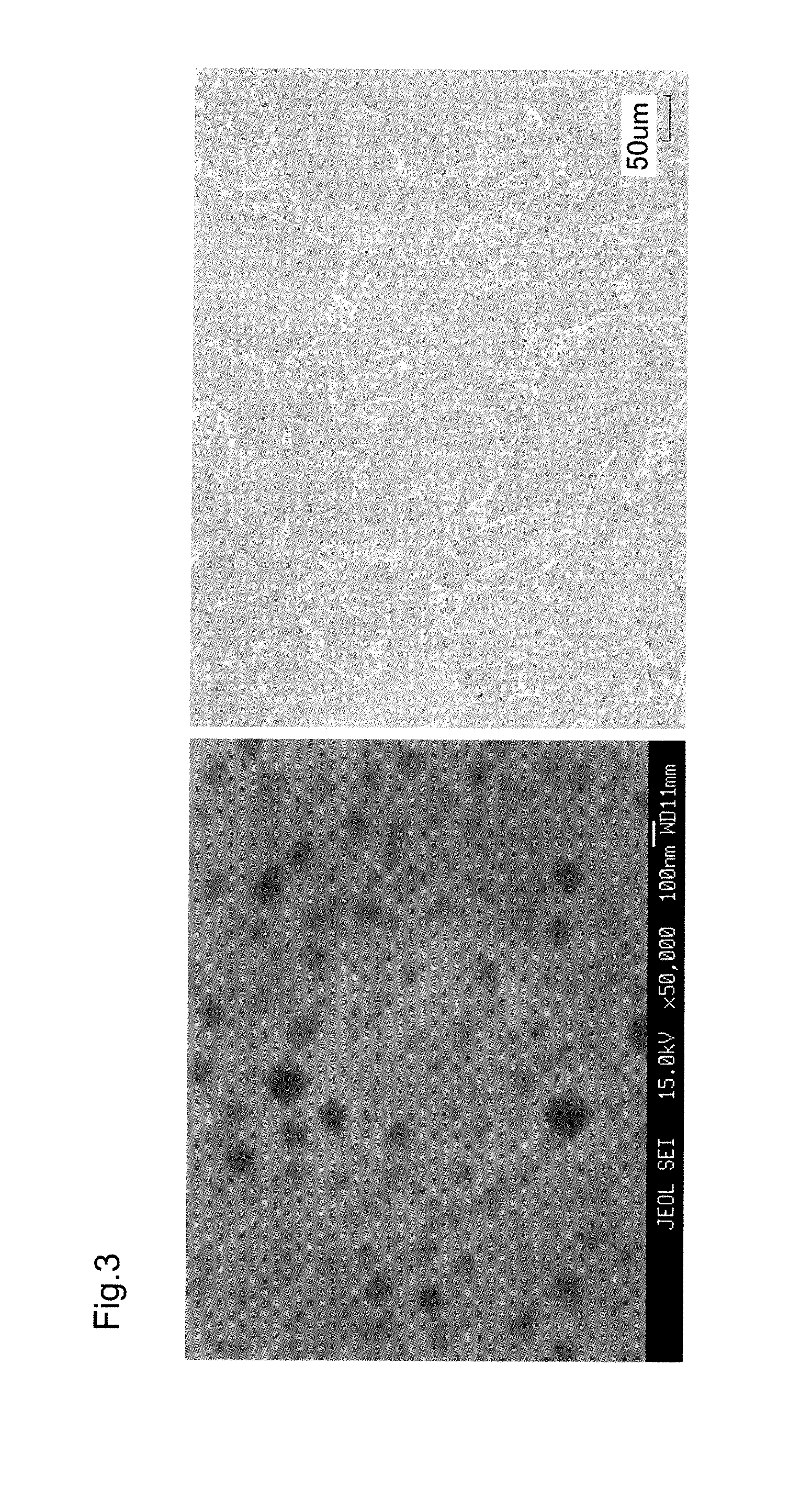

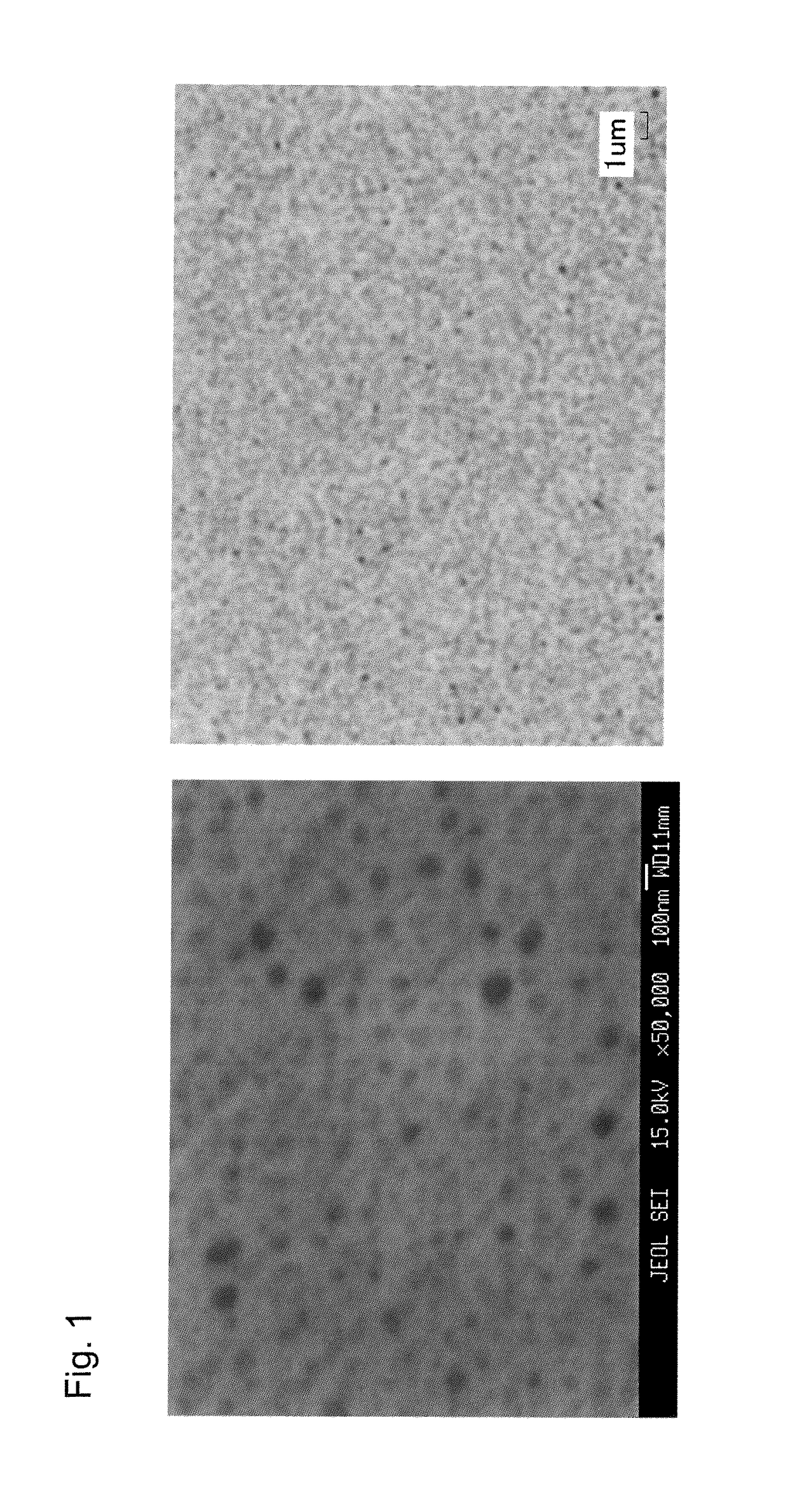

Sputtering Target for Oxide Thin Film and Process for Producing the Sputtering Target

Disclosed is a sputtering target that can suppress the occurrence of anomalous discharge in the formation of an oxide semiconductor film by sputtering method and can continuously and stably form a film. Also disclosed is an oxide for a sputtering target that has a rare earth oxide C-type crystal structure and has a surface free from white spots (a poor appearance such as concaves and convexes formed on the surface of the sputtering target). Further disclosed is an oxide sintered compact that has a bixbyite structure and contains indium oxide, gallium oxide, and zinc oxide. The composition amounts (atomic %) of indium (In), gallium (Ga), and zinc (Zn) fall within a composition range satisfying the following formula: In / (In+Ga+Zn)<0.75

Owner:IDEMITSU KOSAN CO LTD

Gallium oxide-zinc oxide sputtering target, method of forming transparent conductive film, and transparent conductive film

ActiveUS7686985B2Improve conductivityHigh densityConductive layers on insulating-supportsConductive materialSputteringHigh density

Provided is a high density gallium oxide-zinc oxide series sintered body sputtering target for forming a transparent conductive film containing 20 to 500 mass ppm of aluminum oxide. In a gallium oxide (Ga2O3)-zinc oxide (ZnO) series sputtering target (GZO series target) for forming a transparent conductive film, trace amounts of specific elements are added to obtain a target capable of improving the conductivity and the bulk density of the target; in other words, capable of improving the component composition to increase the sintered density, inhibit the formation of nodules, and prevent the generation of an abnormal electrical discharge and particles. Also provided are a method for forming a transparent conductive film using such a target, and a transparent conductive film formed thereby.

Owner:JX NIPPON MINING & METALS CORP

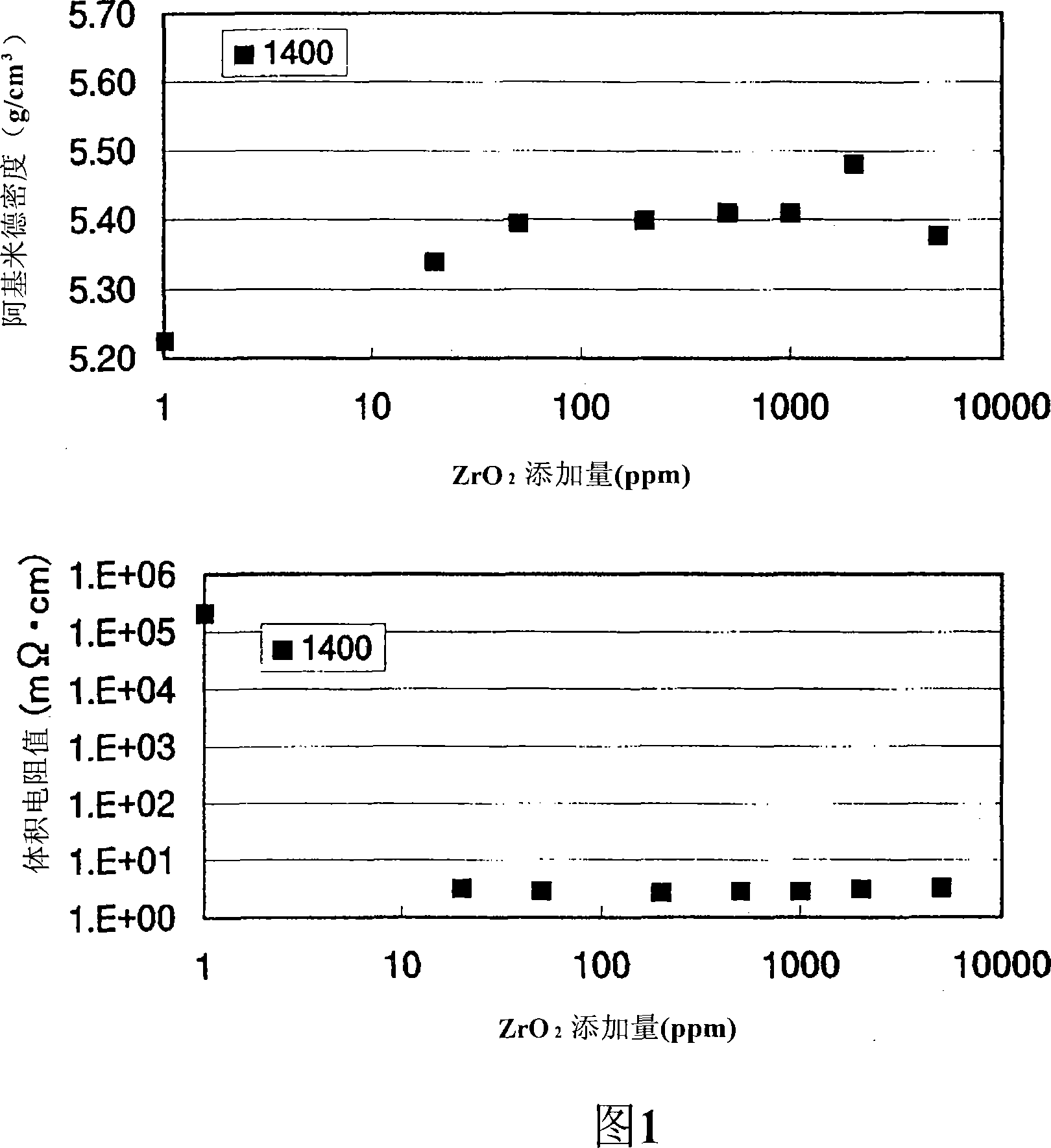

Gallium Oxide-Zinc Oxide Sputtering Target, Method for Forming Transparent Conductive Film, and Transparent Conductive Film

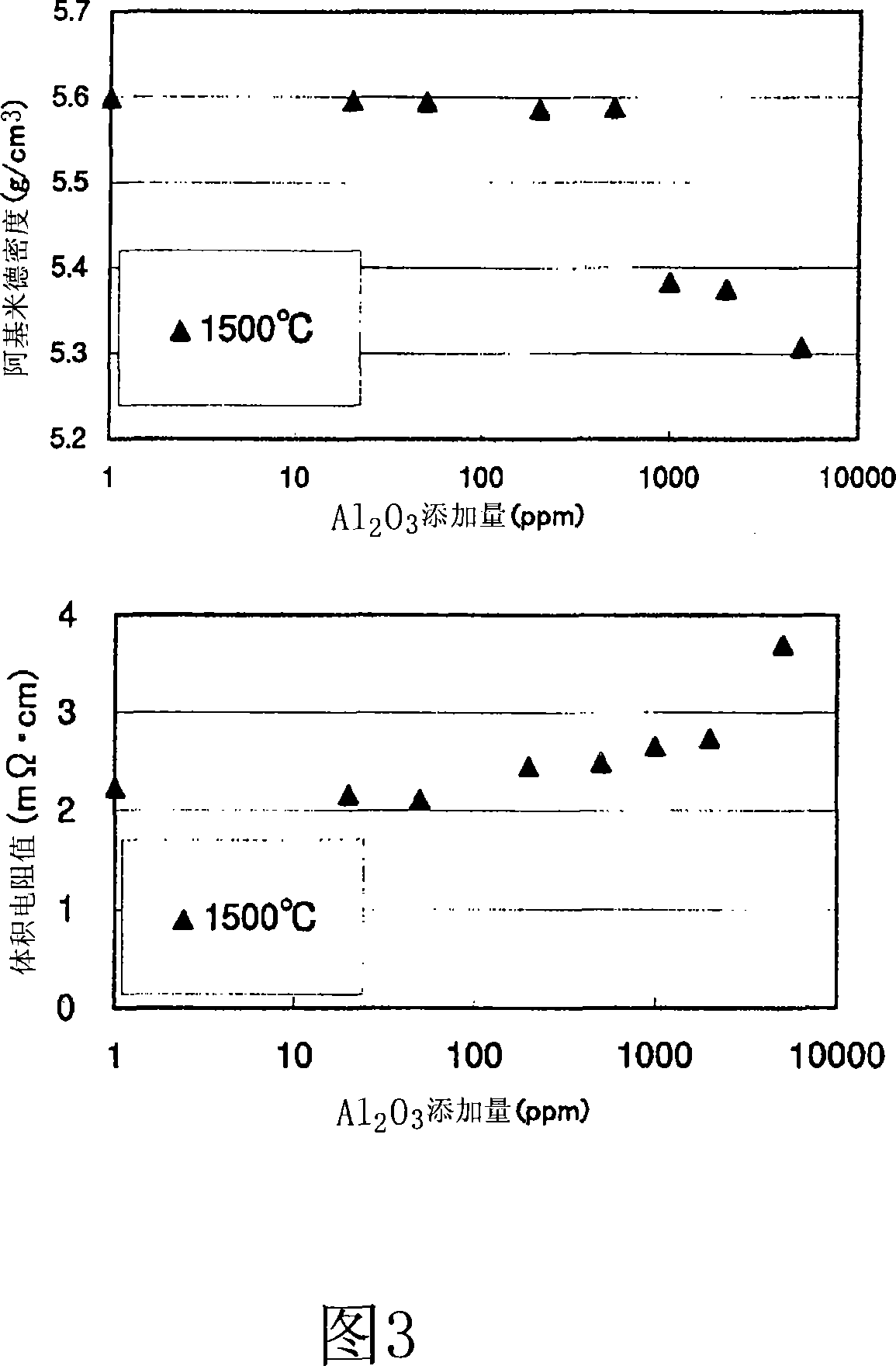

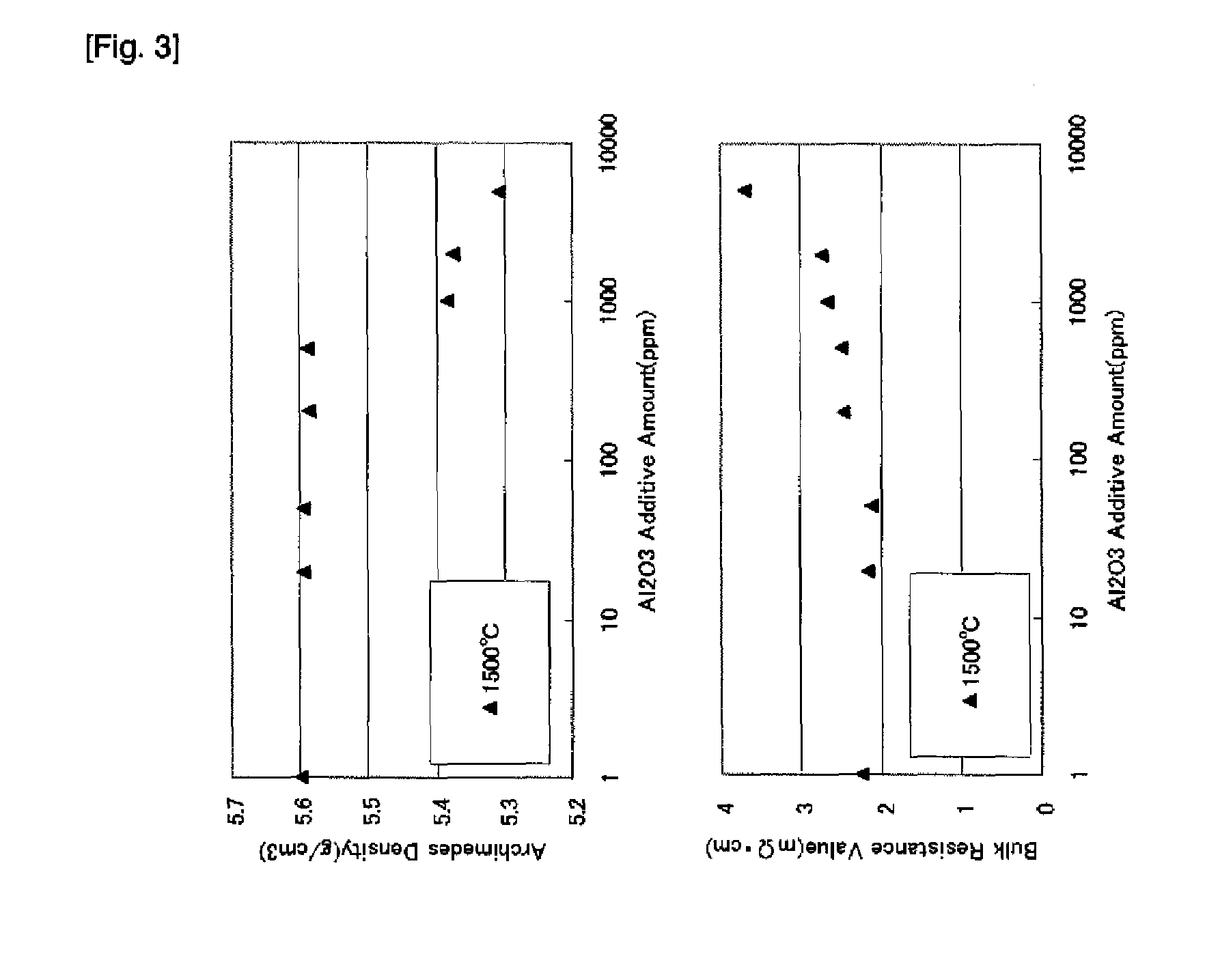

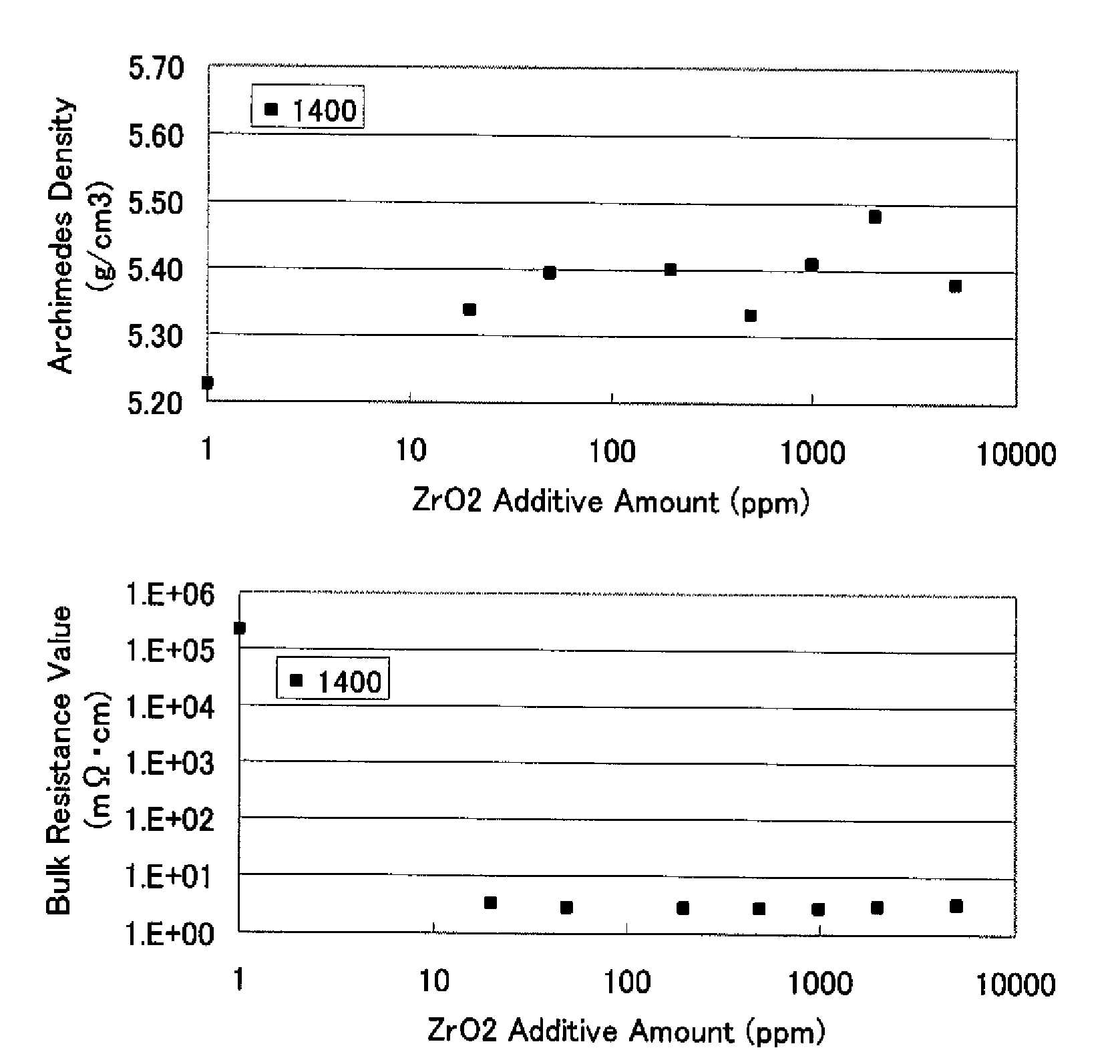

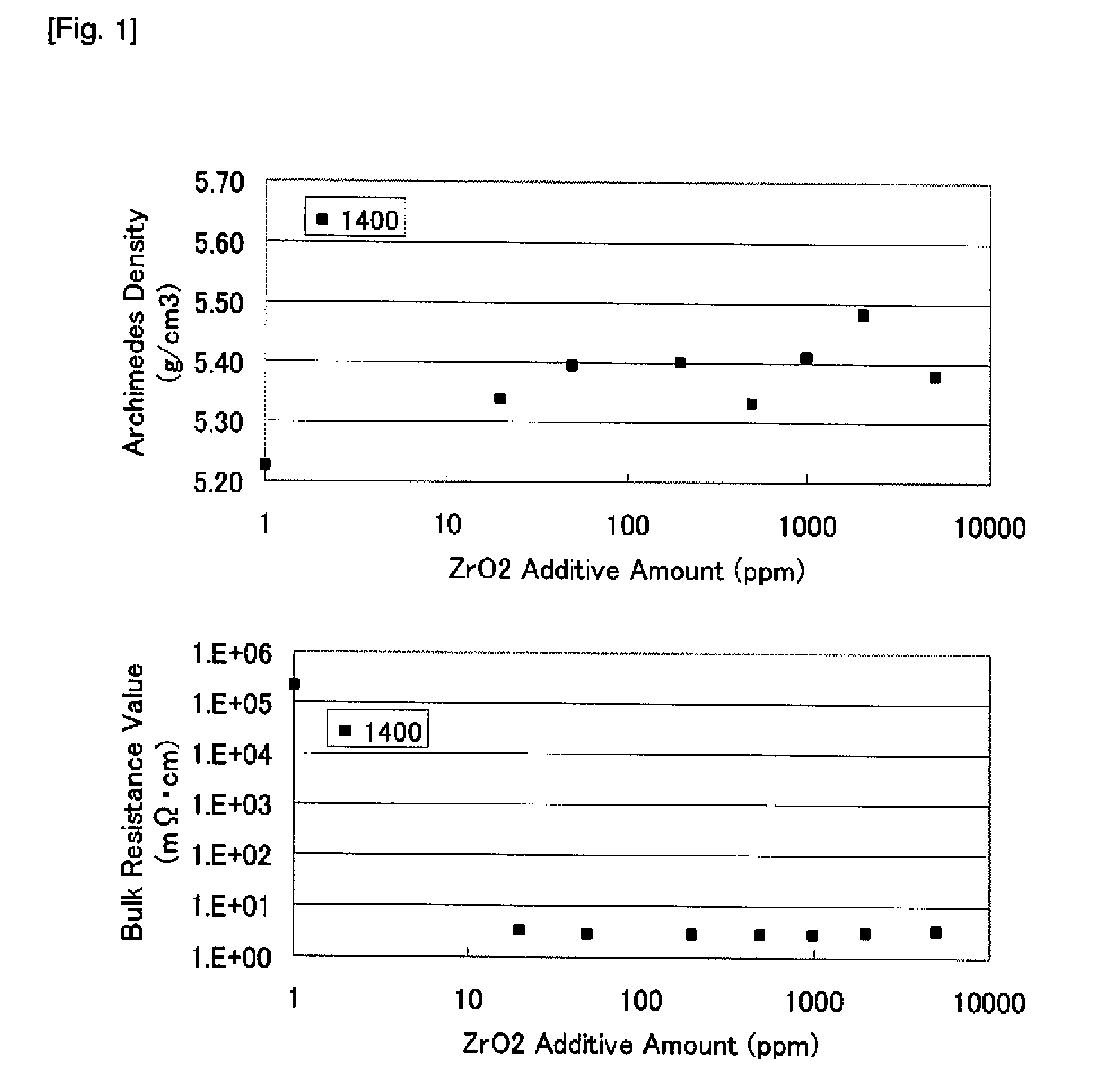

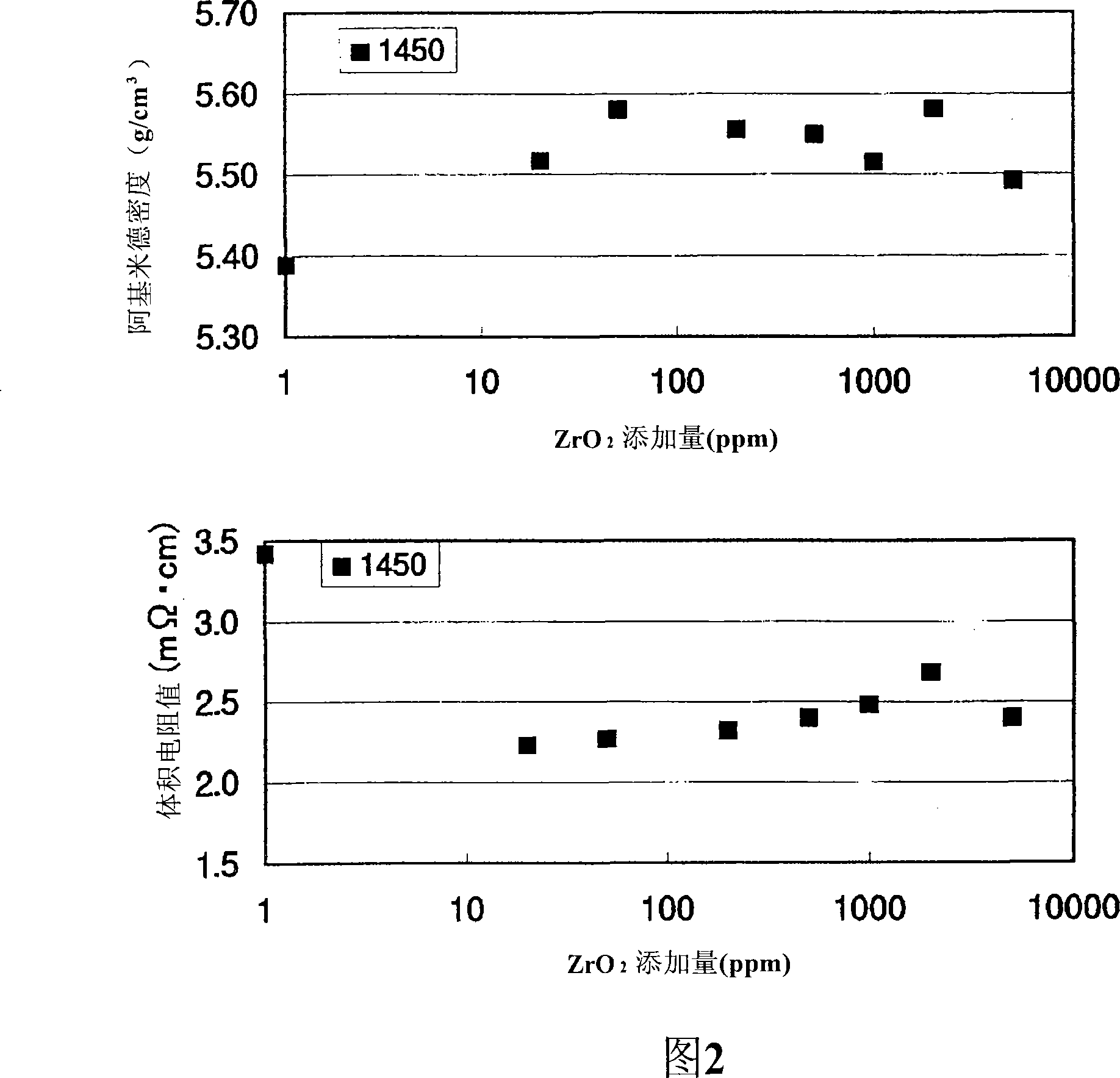

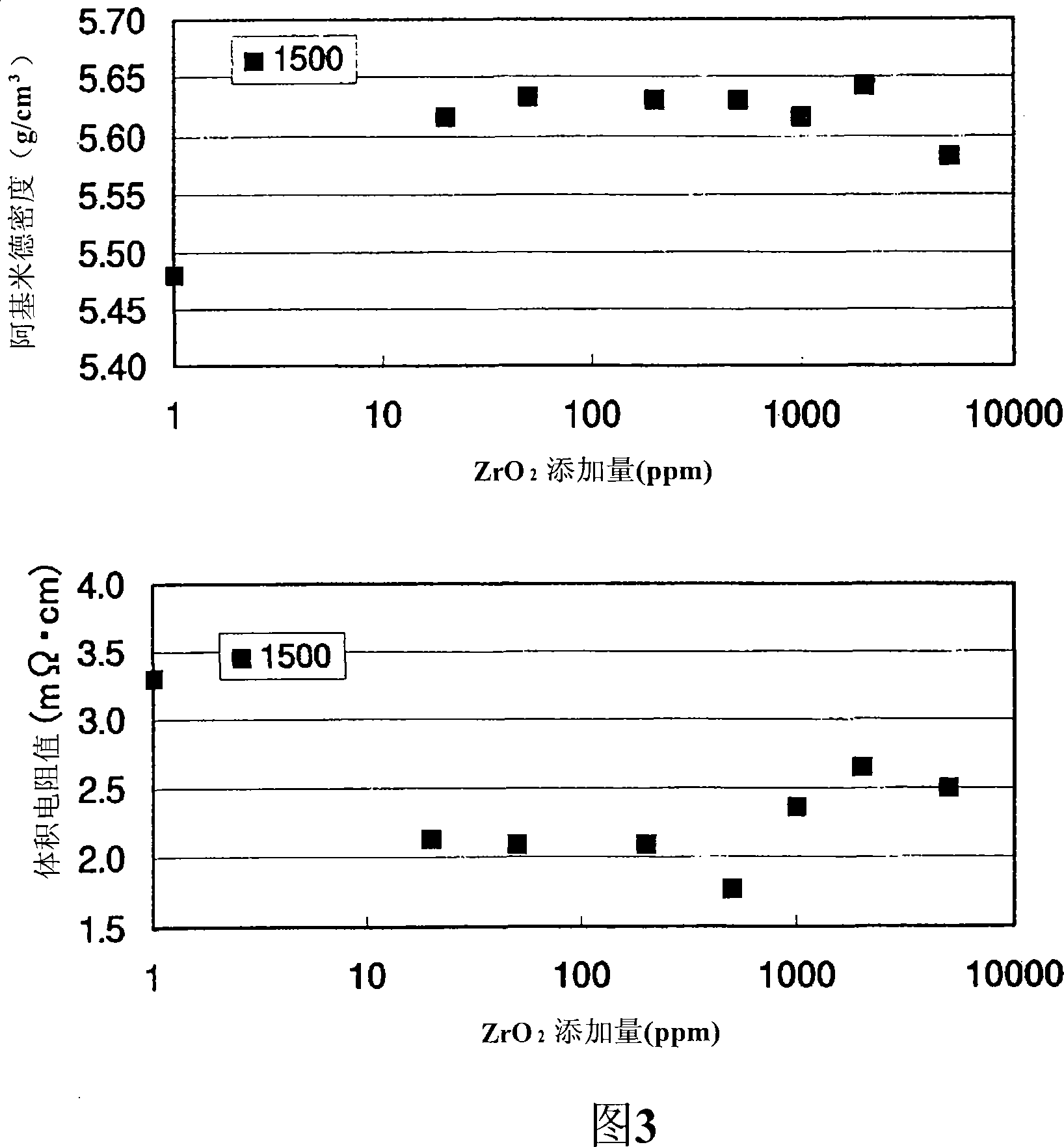

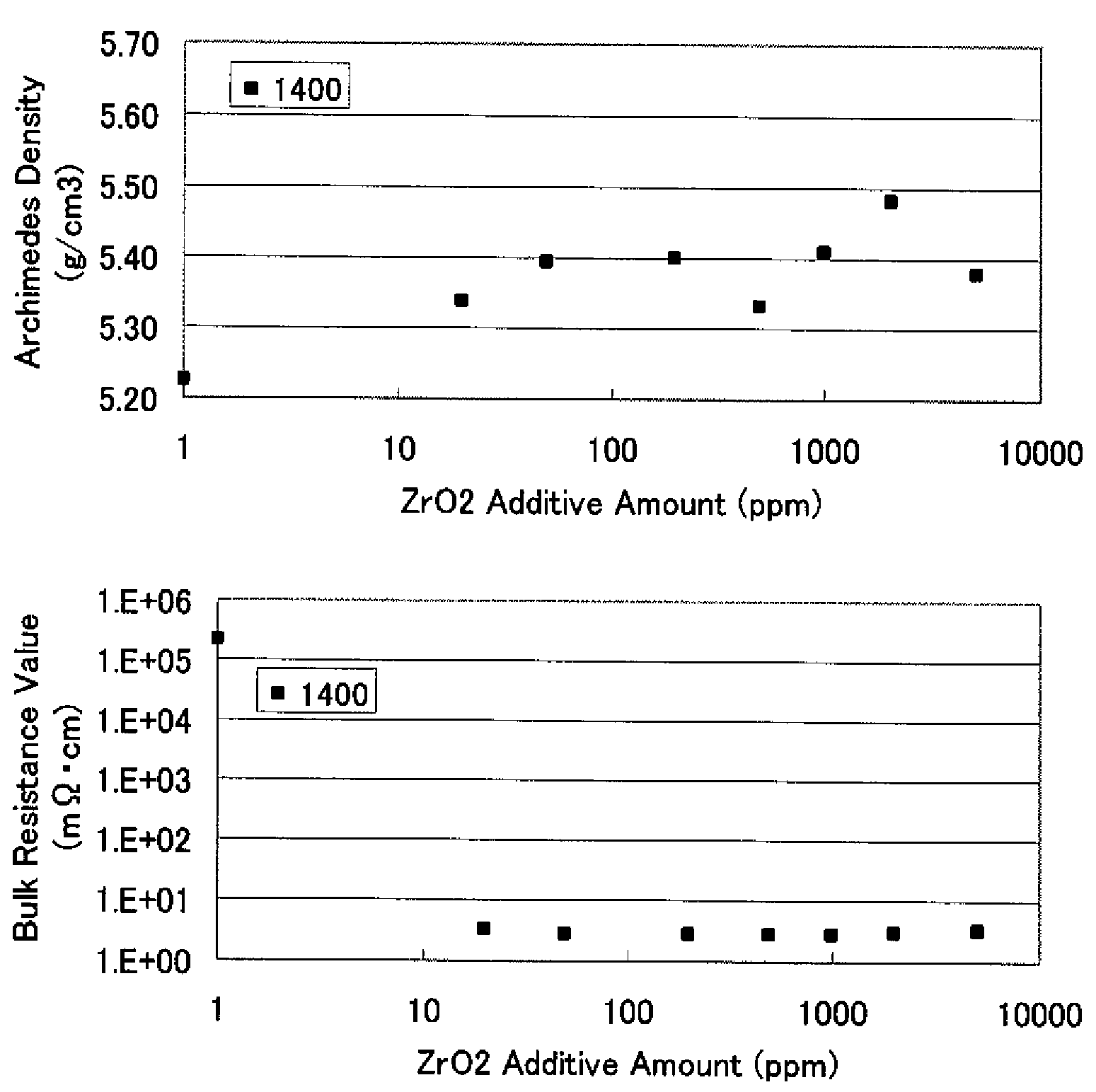

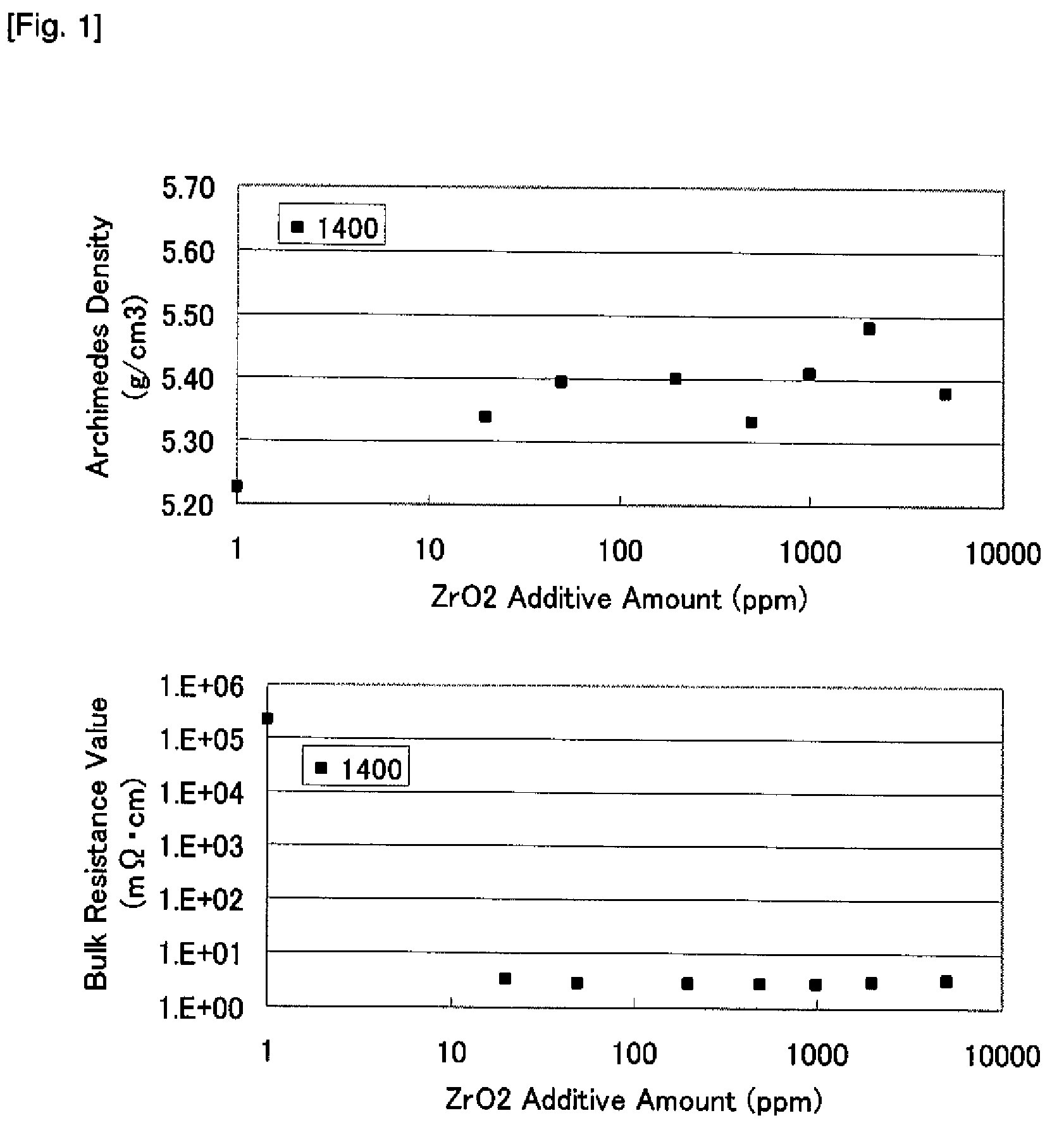

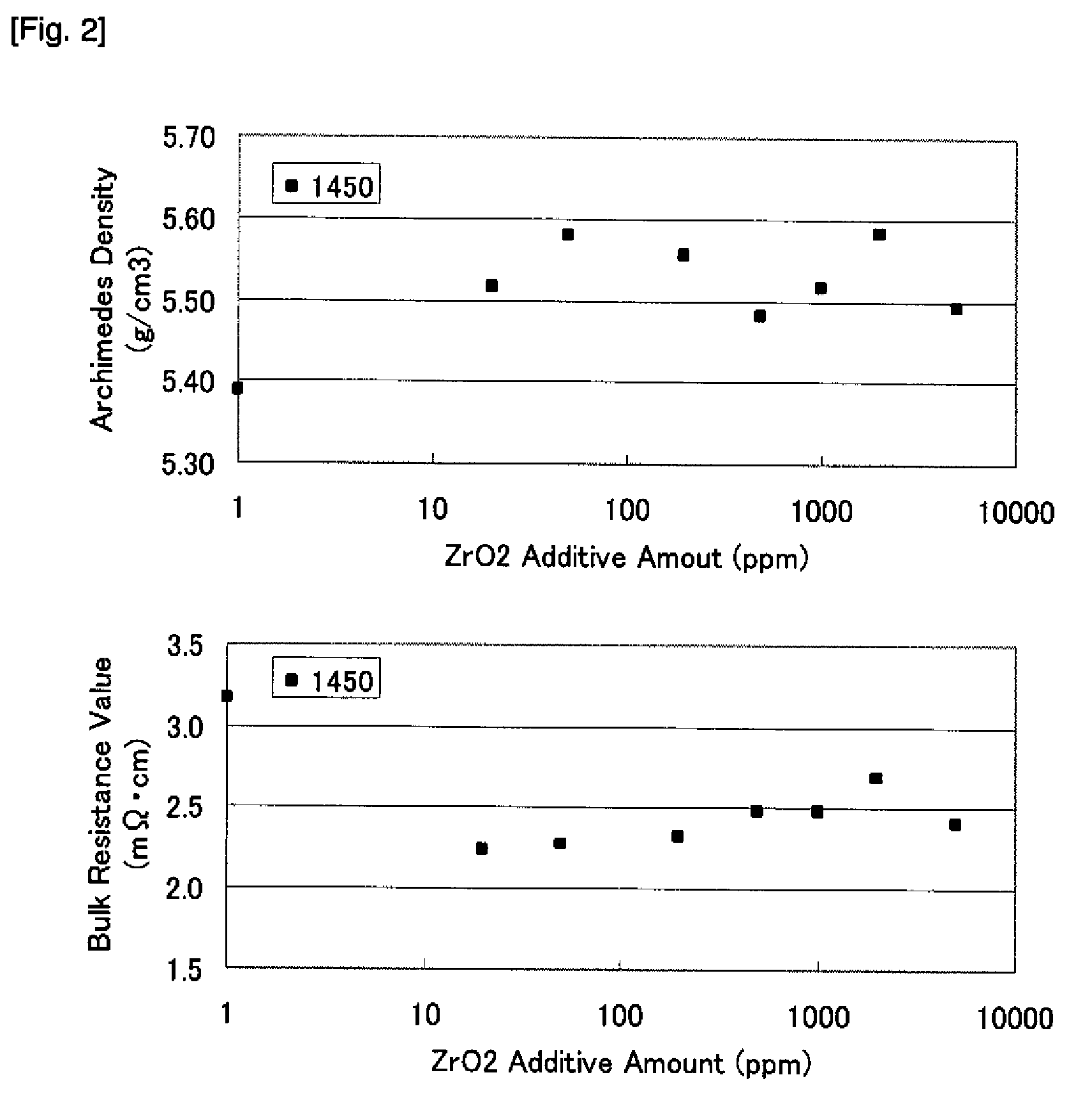

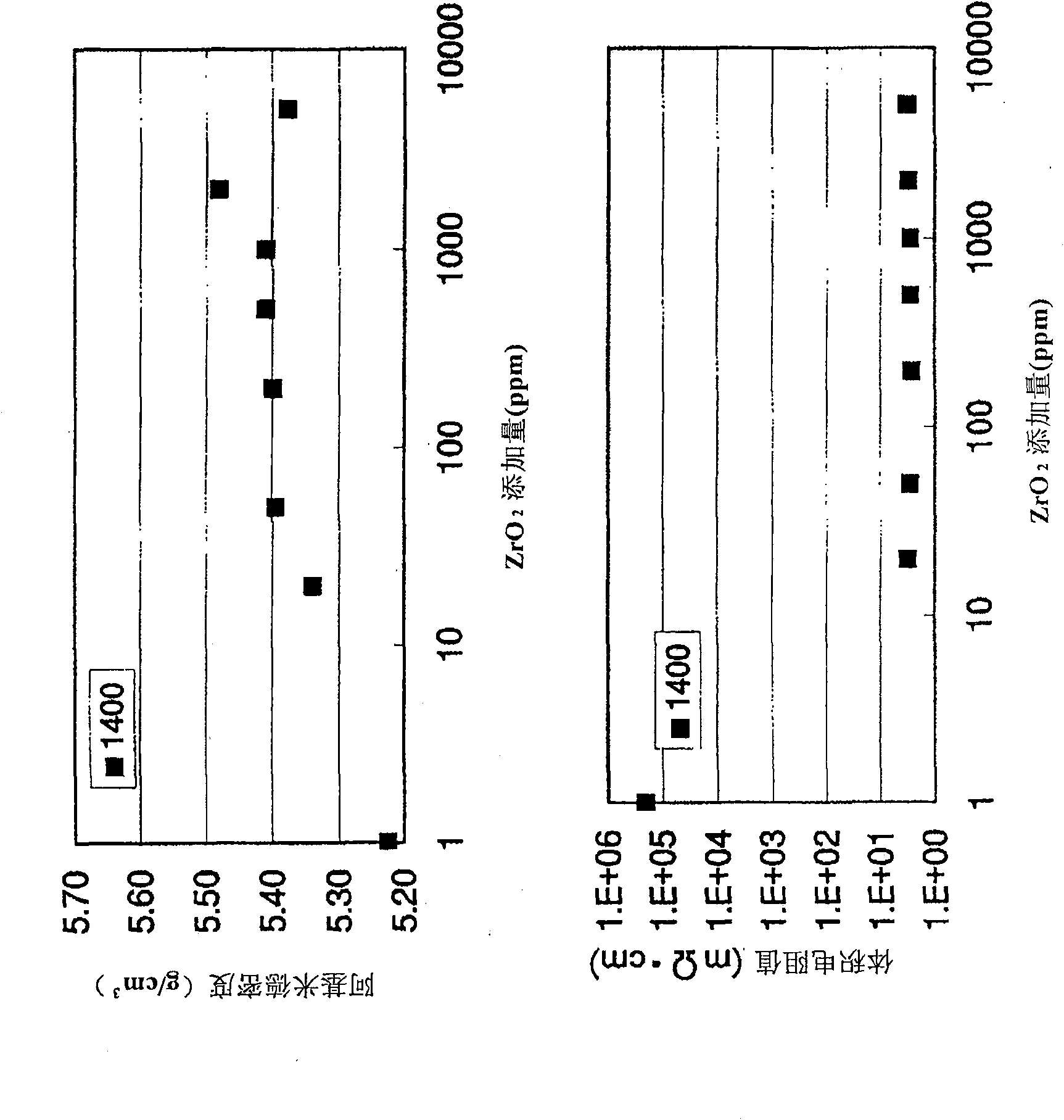

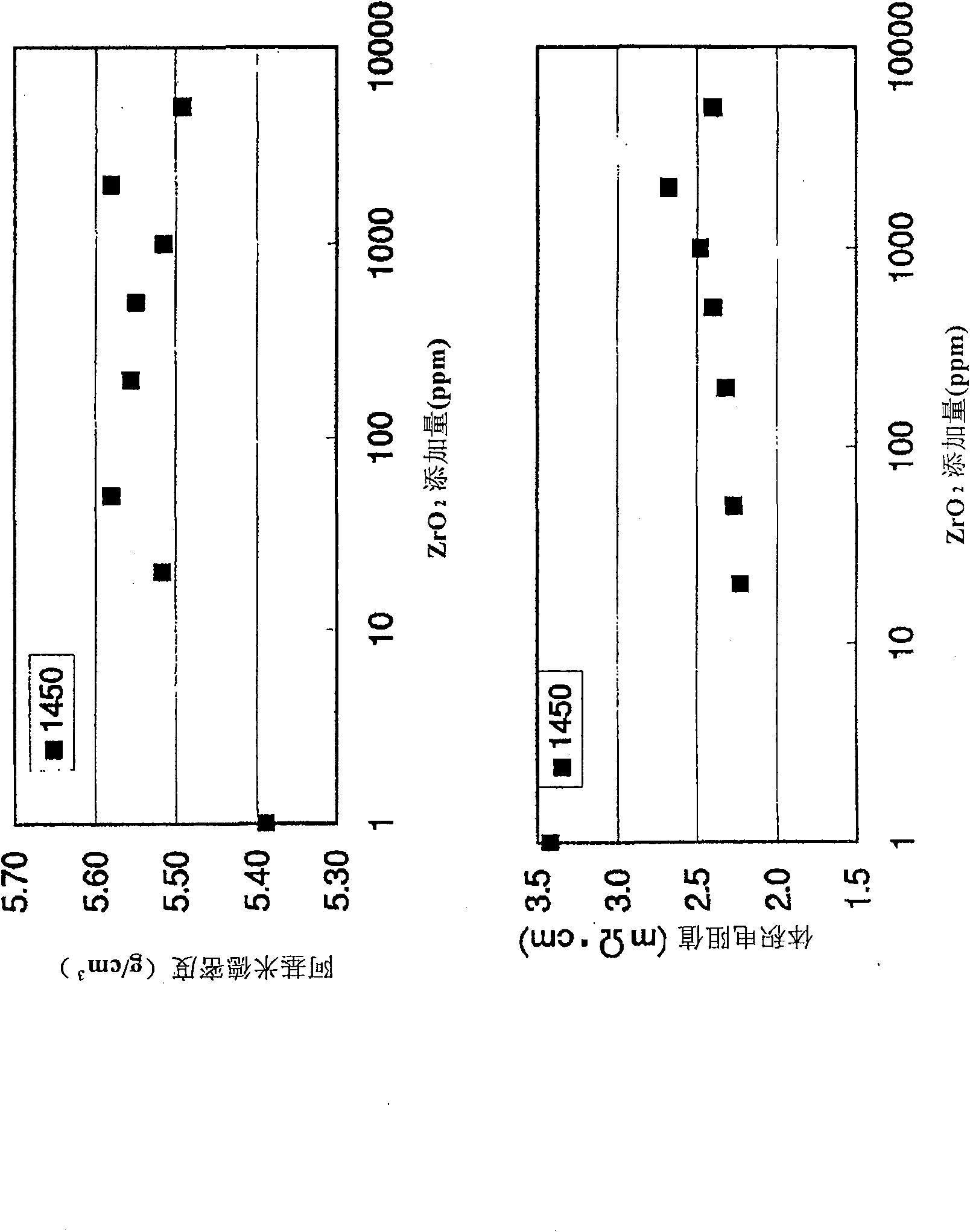

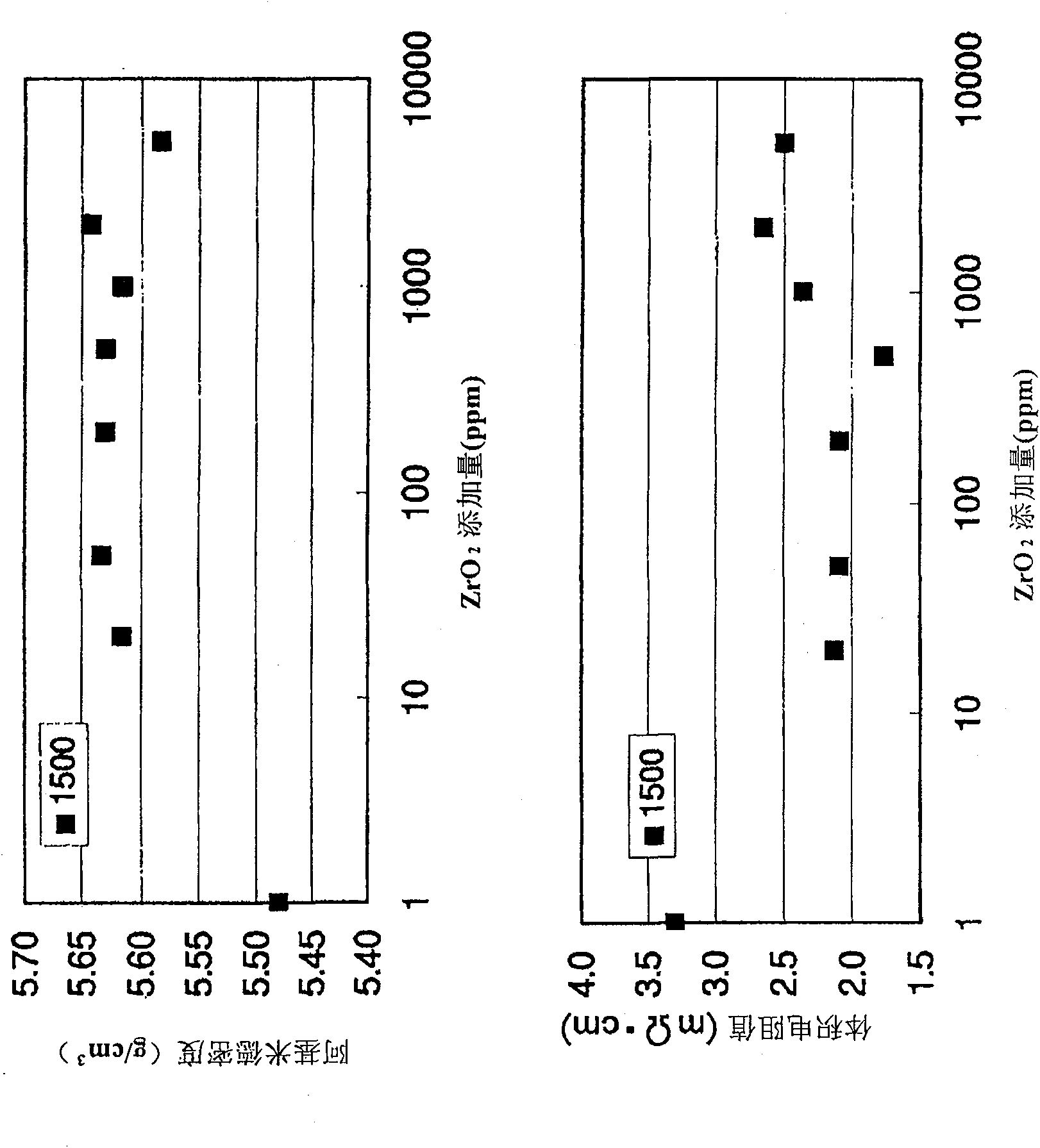

ActiveUS20090206303A1Increase target densityInhibit bulk resistance valueCellsLayered productsSputteringHigh density

Provided is a high density gallium oxide-zinc oxide series sintered body sputtering target for forming a transparent conductive film containing 20 to 2000 mass ppm of zirconium oxide. In a gallium oxide (Ga2O3)-zinc oxide (ZnO) series sputtering target (GZO series target) for forming a transparent conductive film, trace amounts of specific elements are added to obtain a target capable of improving the conductivity and the bulk density of the target; in other words, capable of improving the component composition to increase the sintered density, inhibit the formation of nodules, and prevent the generation of an abnormal electrical discharge and particles. Also provided are a method for forming a transparent conductive film using such a target, and a transparent conductive film formed thereby.

Owner:JX NIPPON MINING& METALS CORP

Gallium Oxide/Zinc Oxide Sputtering Target, Method of Forming Transparent Conductive Film and Transparent Conductive Film

ActiveUS20090250669A1High densityLow bulk resistanceCellsConductive materialHigh densityVolumetric Mass Density

Provided is a high-density gallium oxide / zinc oxide sintered sputtering target containing 20 massppm or greater of each zirconium oxide and aluminum oxide, wherein the total content thereof is less than 250 ppm. This gallium oxide (Ga2O3) / zinc oxide (ZnO) sputtering target (GZO target) improves the conductivity and bulk density of the target by adding trace amounts of specific elements. In other words, it is possible to obtain a target capable of increasing the sintered density, inhibiting the formation of nodules, and preventing the generation of abnormal electrical discharge and particles by improving the component composition. Further, provided are a method of forming a transparent conductive film with the use of the target, and a transparent conductive film formed thereby.

Owner:JX NIPPON MINING& METALS CORP

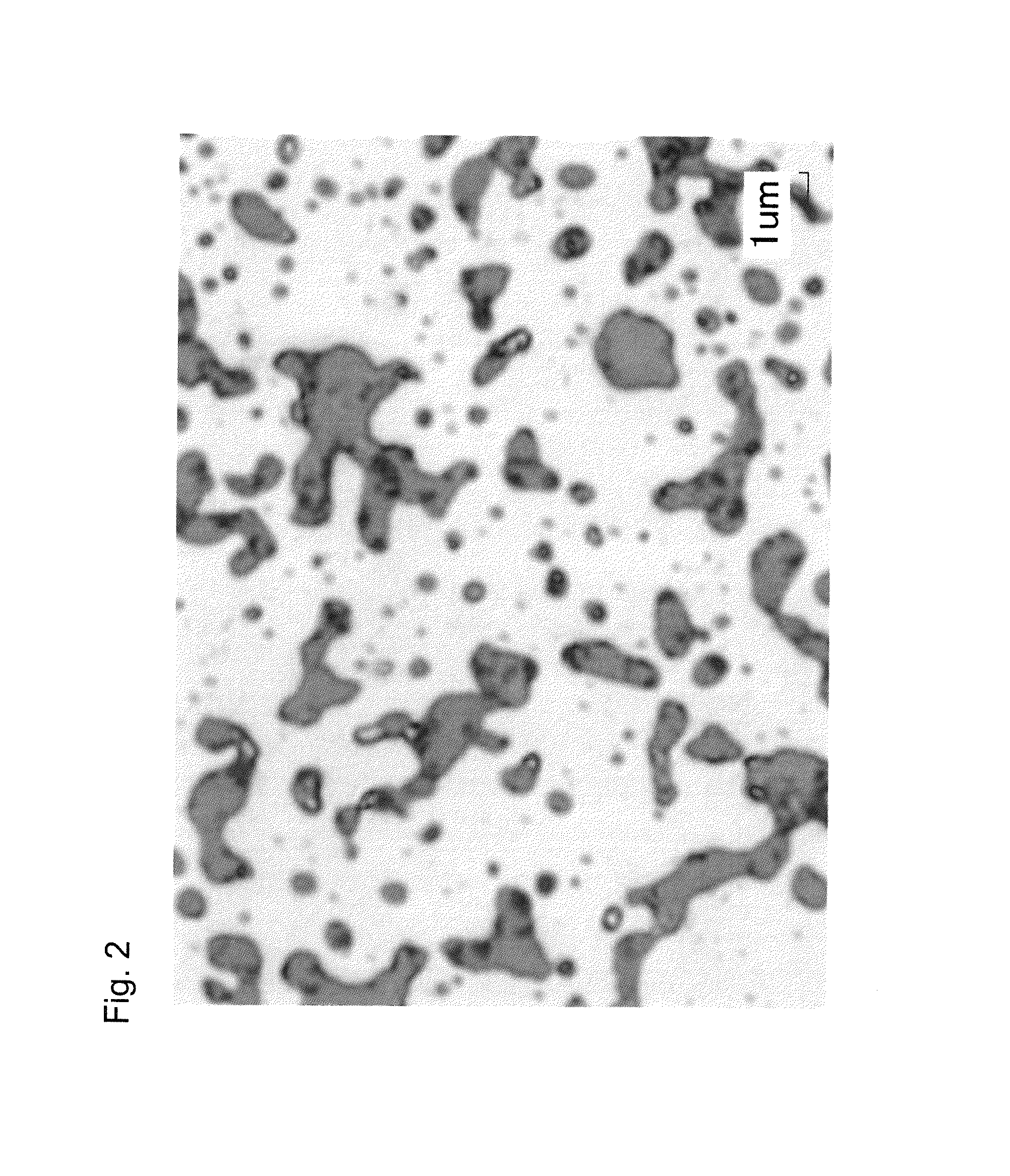

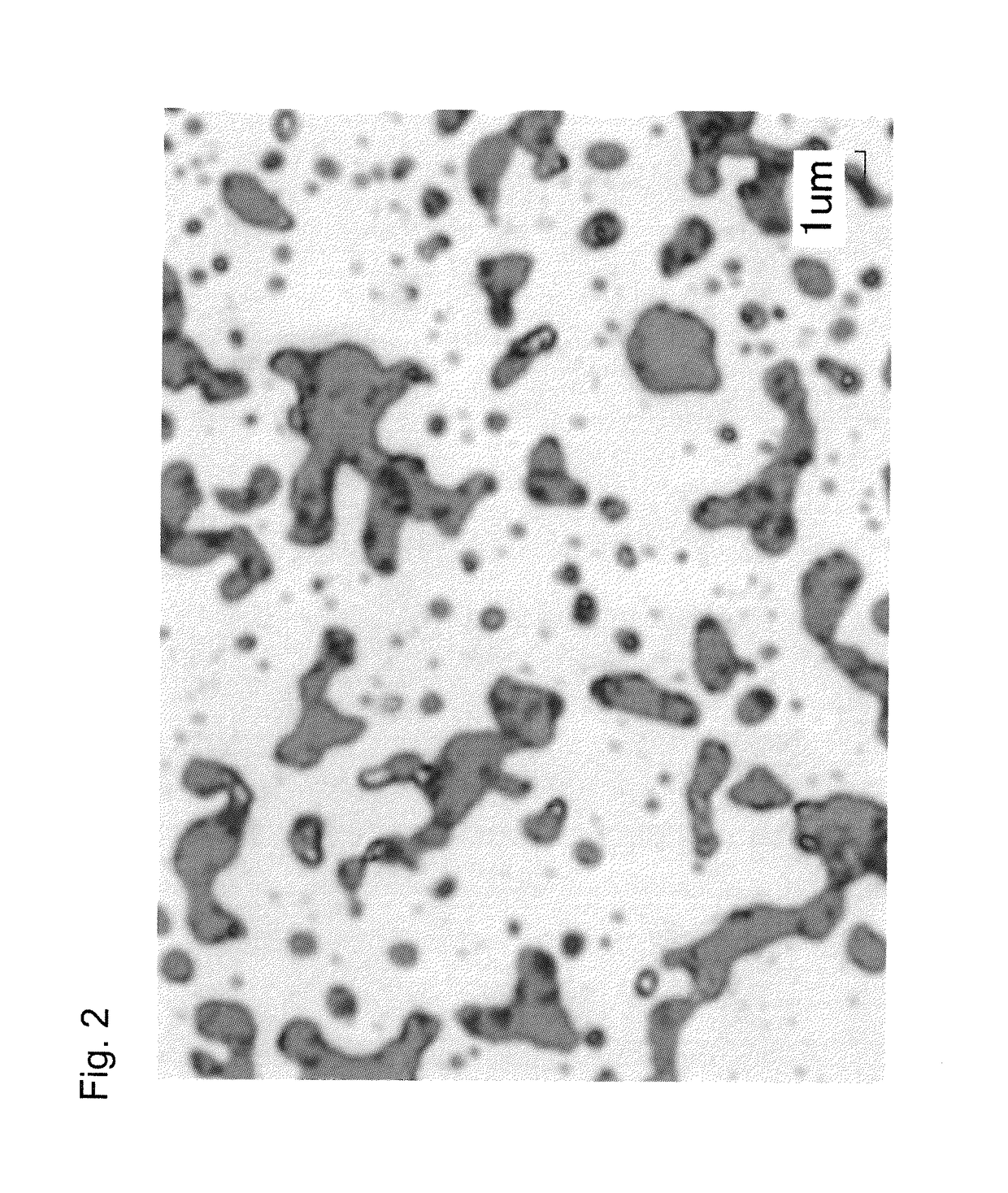

Magnetic Material Sputtering Target and Manufacturing Method Thereof

ActiveUS20140311902A1Reduce impurity pollutionSmooth dischargeCellsElectric discharge tubesSputteringParticle generation

Provided is an oxide-containing magnetic material sputtering target wherein the oxides have an average grain diameter of 400 nm or less. Also provided is a method of producing an oxide-containing magnetic material sputtering target. The method involves depositing a magnetic material on a substrate by the PVD or CVD method, then removing the substrate from the deposited magnetic material, pulverizing the material to obtain a raw material for the target, and further sintering the raw material. An object of the present invention is to provide a magnetic material target, in particular a nonmagnetic grain-dispersed ferromagnetic sputtering target capable of suppressing discharge abnormalities of oxides that are the cause of particle generation during sputtering.

Owner:JX NIPPON MINING& METALS CORP

Gallium oxide-zinc oxide sputtering target, method for forming transparent conductive film, and transparent conductive film

ActiveCN101208452AIncrease target densityInhibits the formation of nodulesConductive layers on insulating-supportsVacuum evaporation coatingHigh densityVolumetric Mass Density

Disclosed is a high-density gallium oxide-zinc oxide sintered body sputtering target for forming a transparent conductive film. This sputtering target is characterized by containing 20-2000 mass ppm of zirconium oxide. By adding a small amount of a specific element to a gallium oxide (Ga2O3)-zinc oxide (ZnO) sputtering target (GZO type target) for forming a transparent conductive film, the conductivity and bulk density of the target can be improved. In other words, it is disclosed a sputtering target wherein the sintering density is improved and formation of nodules is suppressed by improving the components composition, thereby preventing abnormal discharge and formation of particles. Also disclosed are a method for forming a transparent conductive film by using such a target, and a transparent conductive film formed by such a method.

Owner:JX NIPPON MINING & METALS CO LTD

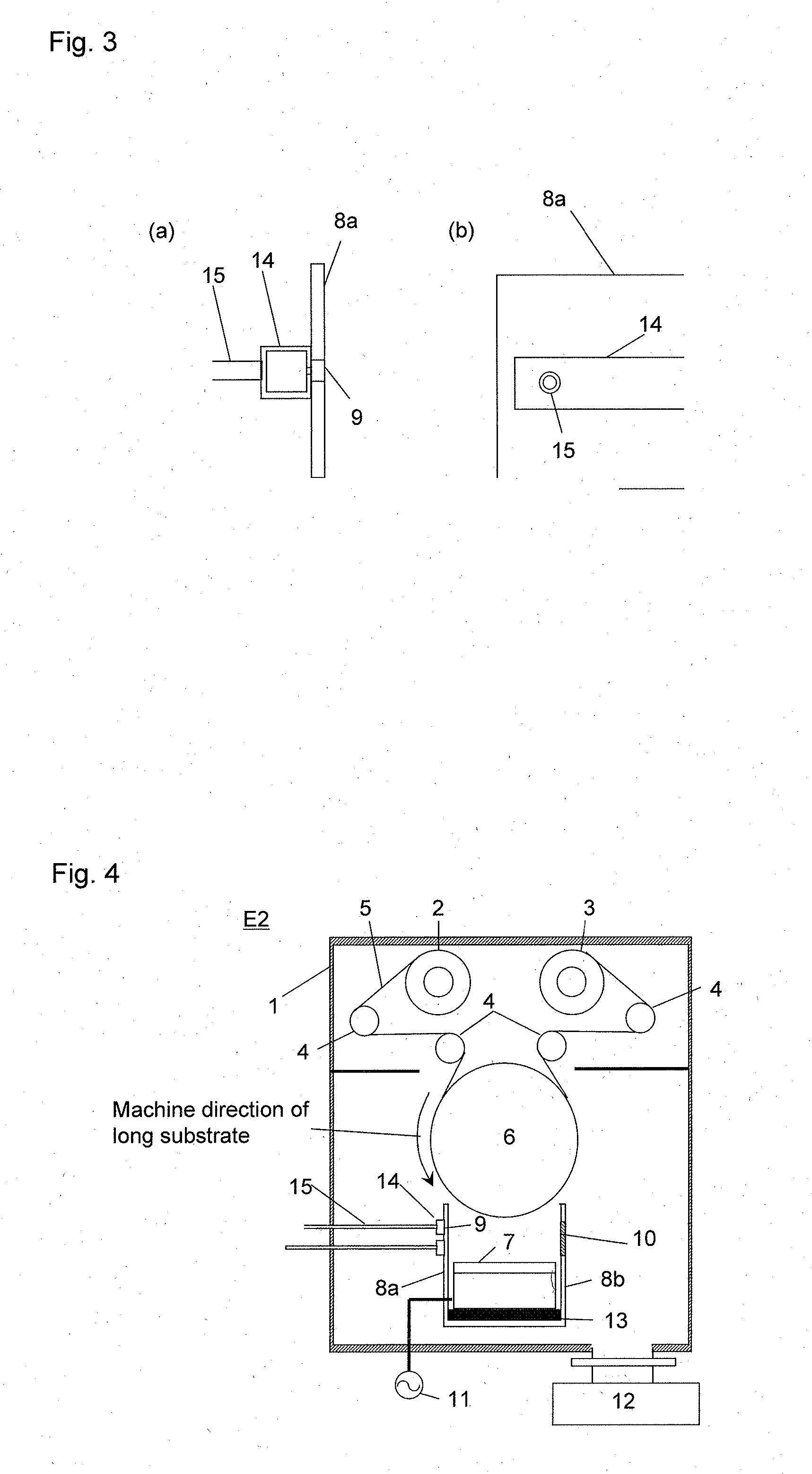

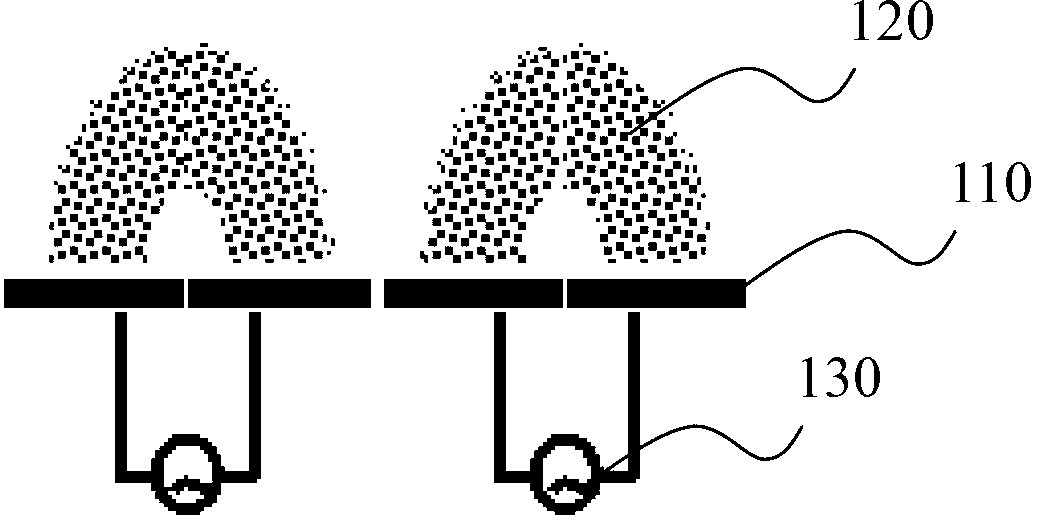

Plasma CVD apparatus, plasma CVD method, reactive sputtering apparatus, and reactive sputtering method

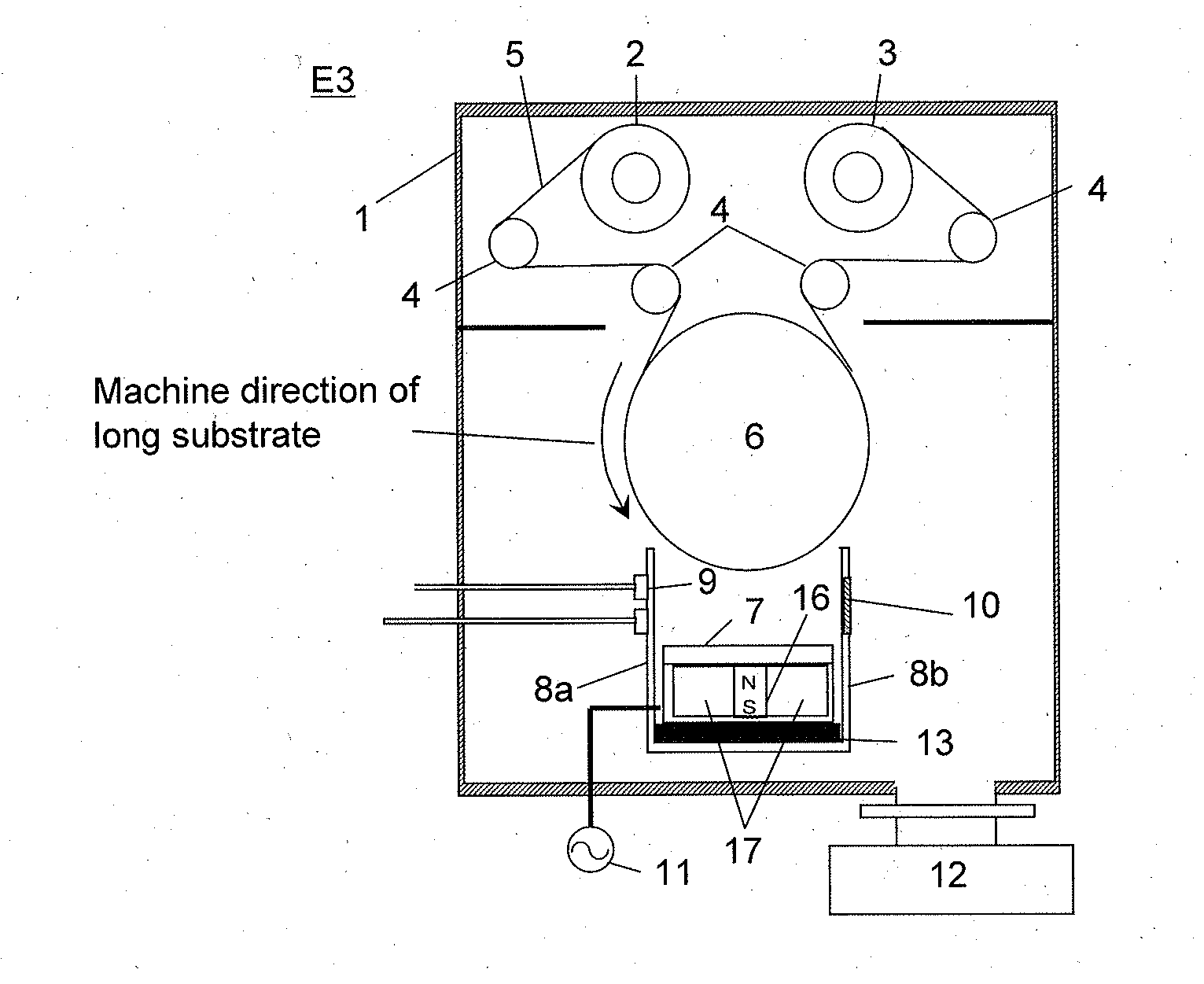

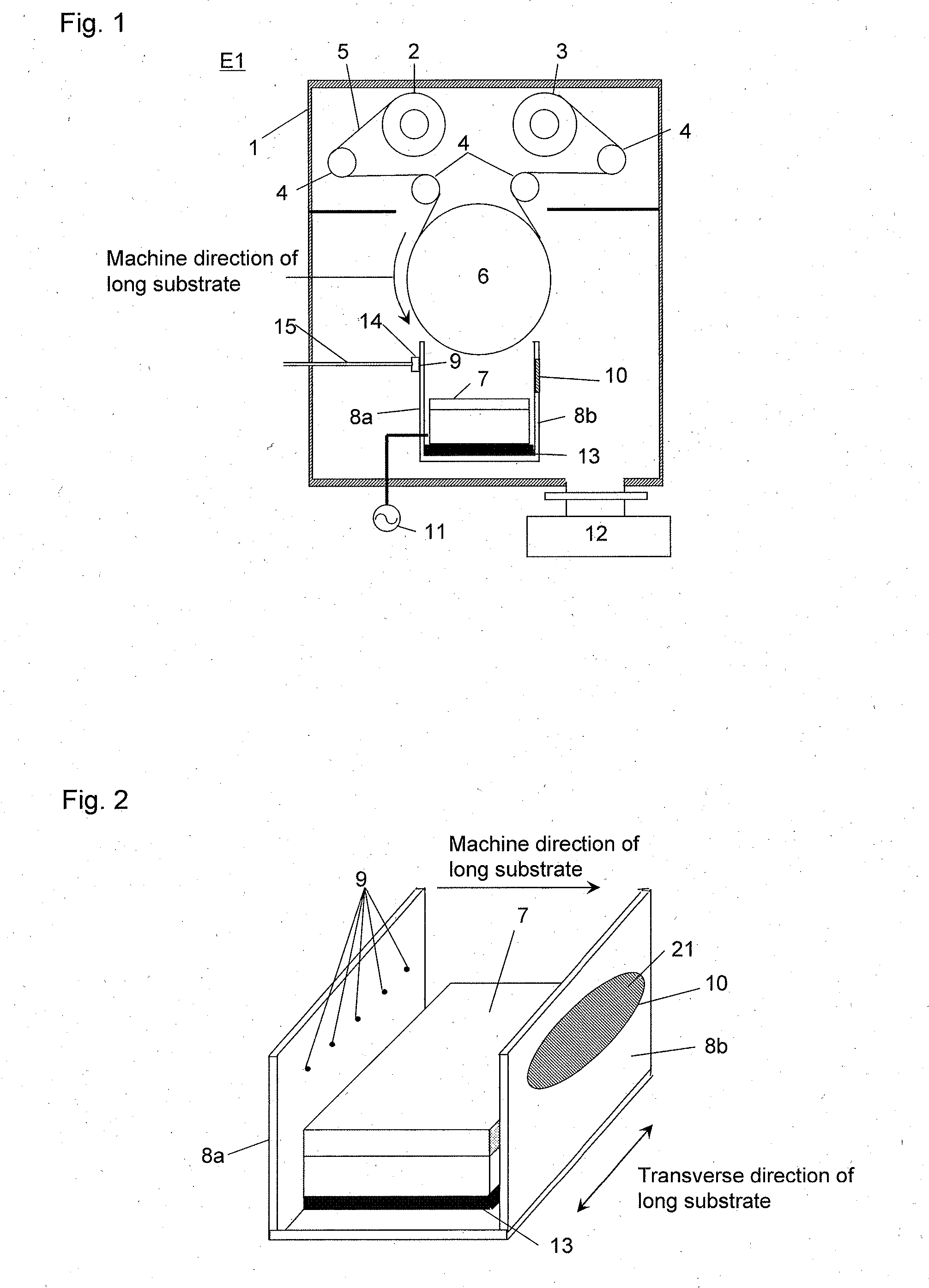

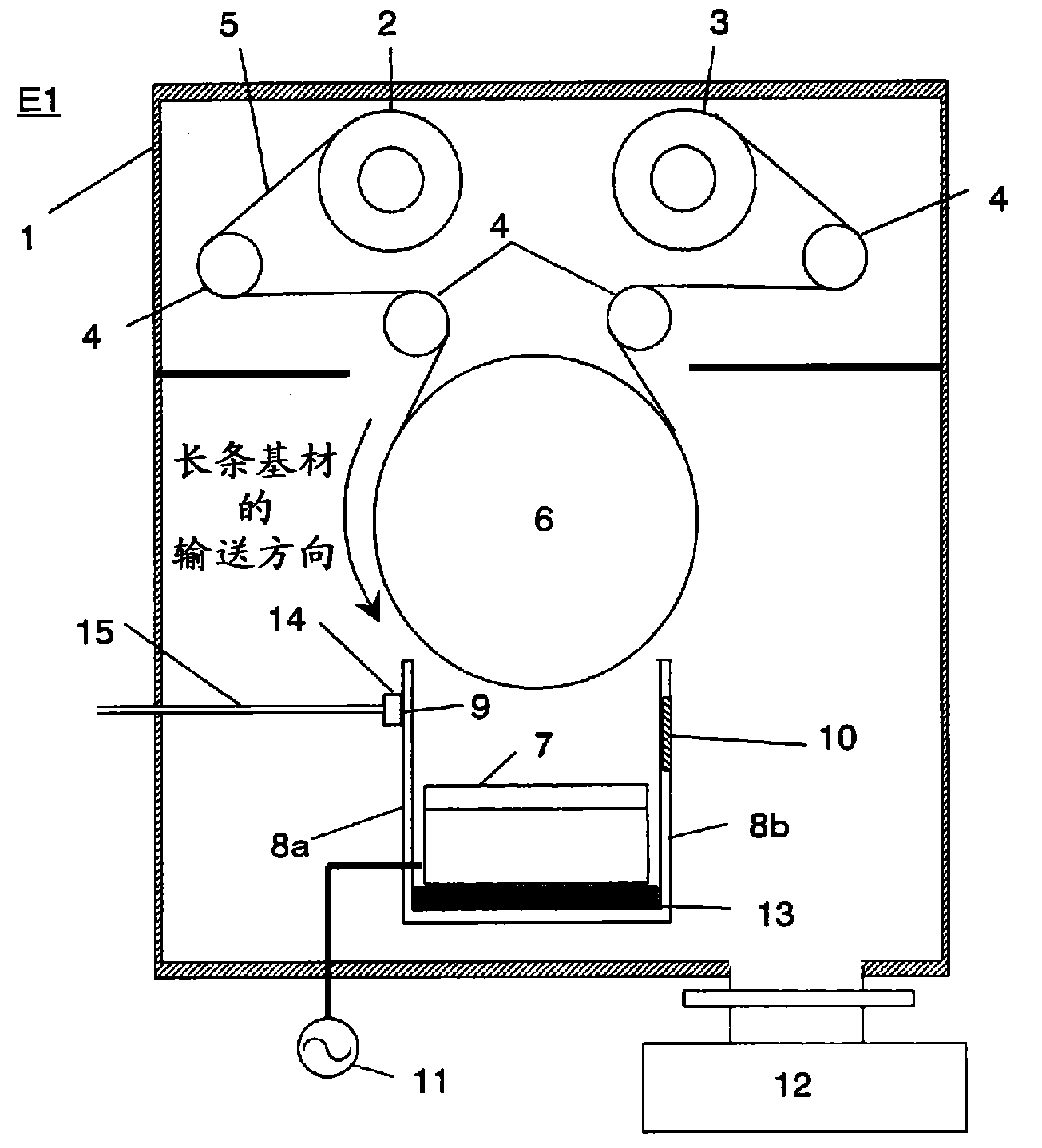

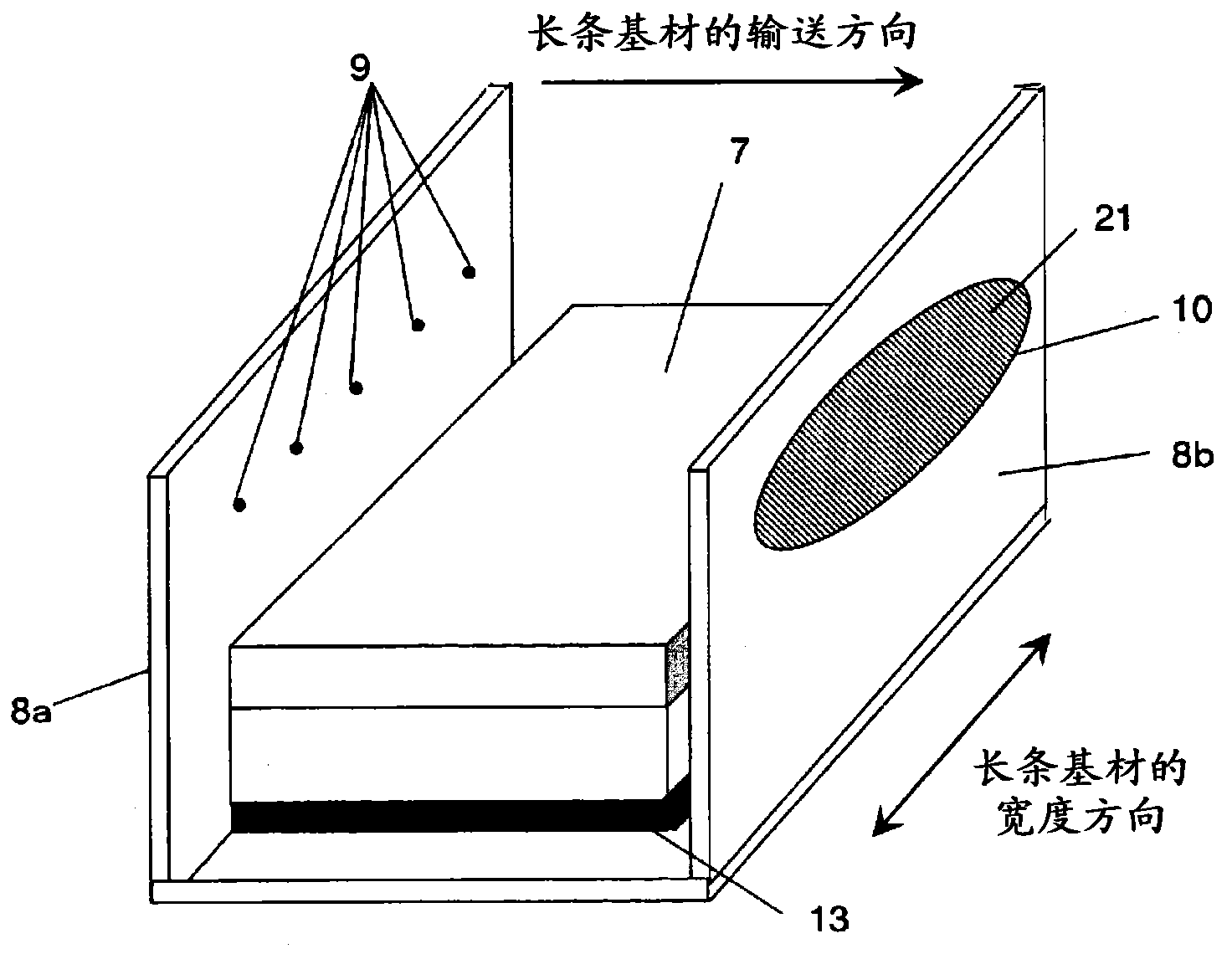

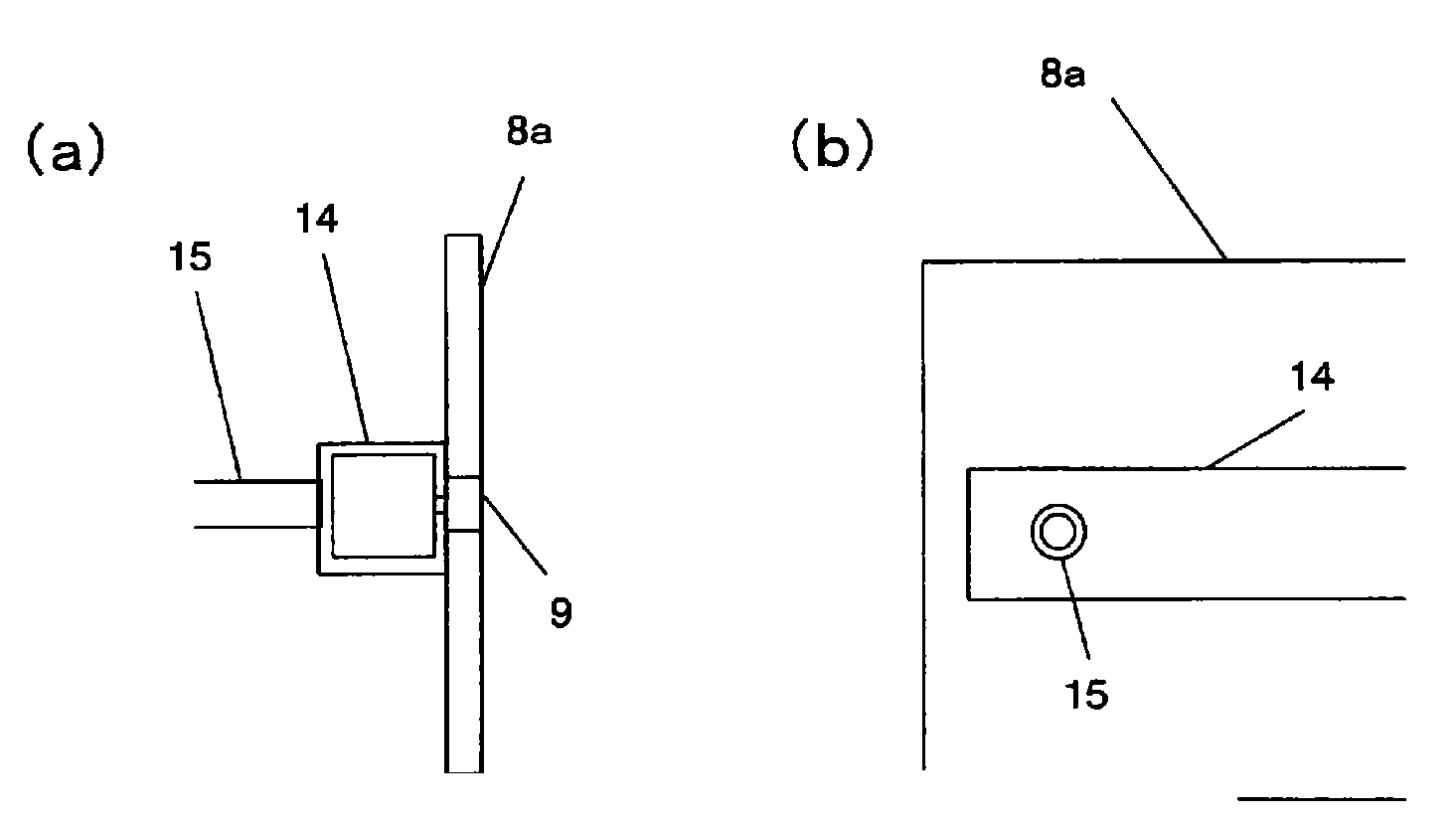

InactiveUS20140023796A1Electrode surface is suppressedQuality improvementCellsElectric discharge tubesEngineeringGas supply

A plasma CVD apparatus comprising a vacuum chamber, and a main roll and a plasma generation electrode in the vacuum chamber, wherein a thin film is formed on a surface of a long substrate which is conveyed along the surface of the main roll is provided. At least one side wall extending in transverse direction of the long substrate is provided on each of the upstream and downstream sides in the machine direction of the long substrate, and the side walls surrounds the film deposition space between the main roll and the plasma generation electrode. The side walls are electrically insulated from the plasma generation electrode. The side wall on either the upstream or the downstream side in the machine direction of the long substrate is provided with at least one raw of gas supply holes formed by gas supply holes aligned in the transverse direction of the long substrate.

Owner:TORAY IND INC

Gallium oxide-zinc oxide sputtering target, method for forming transparent conductive film, and transparent conductive film

ActiveUS7682529B2Inhibition formationImprove conductivityCellsConductive materialSputteringHigh density

Provided is a high density gallium oxide-zinc oxide series sintered body sputtering target for forming a transparent conductive film containing 20 to 2000 mass ppm of zirconium oxide. In a gallium oxide (Ga2O3)-zinc oxide (ZnO) series sputtering target (GZO series target) for forming a transparent conductive film, trace amounts of specific elements are added to obtain a target capable of improving the conductivity and the bulk density of the target; in other words, capable of improving the component composition to increase the sintered density, inhibit the formation of nodules, and prevent the generation of an abnormal electrical discharge and particles. Also provided are a method for forming a transparent conductive film using such a target, and a transparent conductive film formed thereby.

Owner:JX NIPPON MINING & METALS CORP

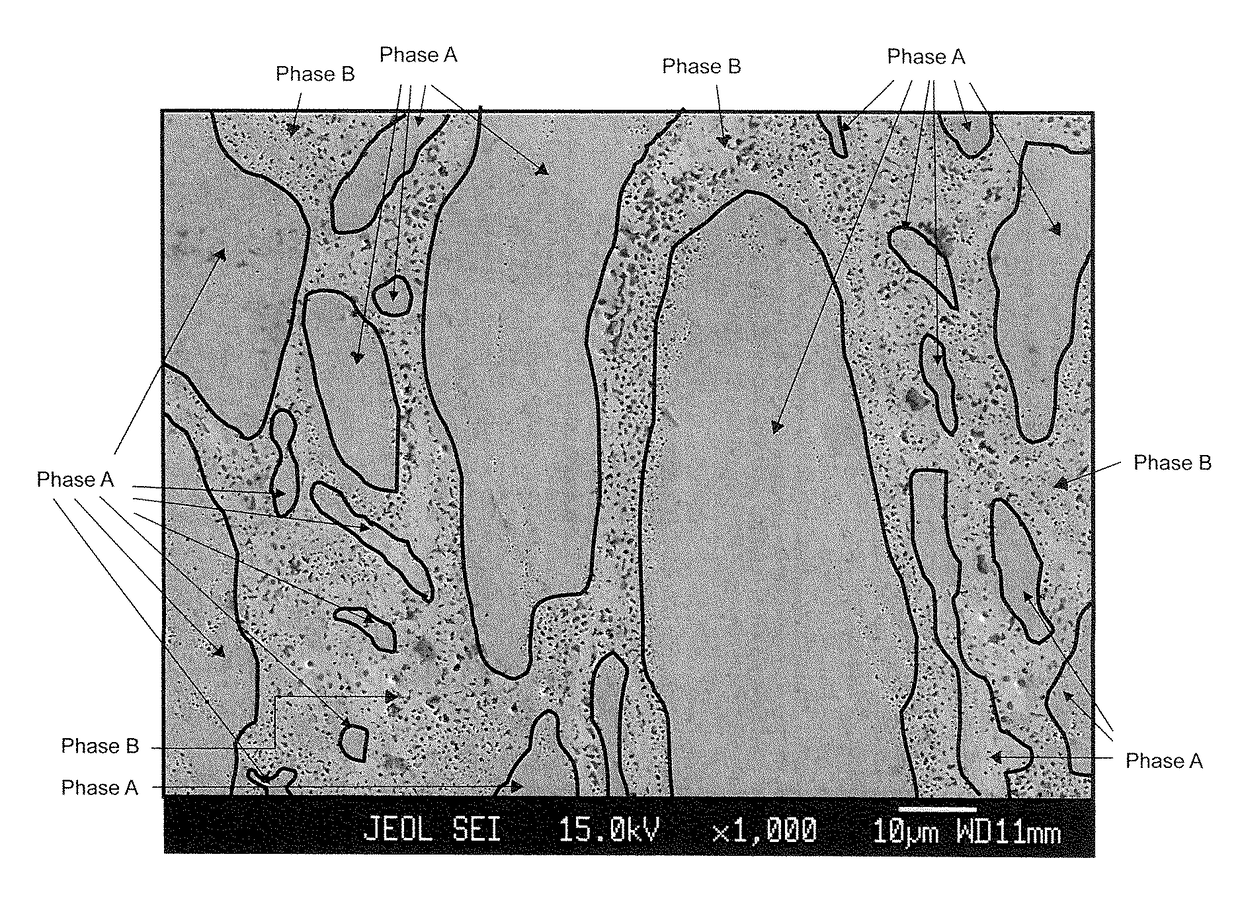

FE-PT-Based Ferromagnetic Sputtering Target and Method for Producing Same

InactiveUS20130292245A1Less particle generationReduce abnormal dischargeCellsVacuum evaporation coatingSputteringElectric discharge

A ferromagnetic sputtering target having a composition comprising 5 to 50 mol % of Pt, 5 to 15 mol % of SiO2, 0.05 to 0.60 mol % of Sn, and Fe as the balance, wherein the Sn is contained in SiO2 grains (B) dispersed in a metal base (A). Provided is a nonmagnetic grain-dispersed ferromagnetic sputtering target which can suppress abnormal electric discharge of the oxide that may cause particle generation during sputtering.

Owner:JX NIPPON MINING& METALS CORP

Plasma CVD apparatus, plasma CVD method, reactive sputtering apparatus, and reactive sputtering method

ActiveCN103459661AReduce defectsReduce qualityElectric discharge tubesVacuum evaporation coatingEngineeringGas supply

Provided is a plasma CVD apparatus that is a vacuum film formation apparatus provided with a main roll and a plasma generating electrode in a vacuum container, and forming a thin film on a surface of an elongated base material while transporting the elongated base material along a surface of the main roll, wherein at least one side wall extending in the width direction of the elongated base material is provided on each of an upstream side and a downstream side in the transportation direction of the elongated base material and sandwiches a film forming space so as to surround the film forming space sandwiched between the main roll and the plasma generating electrode, the side walls are electrically insulated from the plasma generating electrode, and at least one row of a gas supply hole row that forms a plurality of gas supply holes aligning in the width direction of the elongated base material is provided on either one of the side walls on the upstream side and the downstream side of the transportation direction of the elongated base material.

Owner:TORAY IND INC

Sputtering target material and sputtering device

ActiveCN103014639AEven consumptionExtended service lifeVacuum evaporation coatingSputtering coatingElectrical polarityAlternating current

The invention discloses a sputtering target material, comprising a plurality of first sub-blocks and a plurality of second sub-blocks, wherein the plurality of first sub-blocks and the plurality of second sub-blocks are distributed in a plurality of rows and columns; the first sub-blocks and the second sub-blocks in each row are distributed in a staggered manner; and the first sub-blocks and the second sub-blocks in each column are also distributed in the staggered manner. A sputtering device comprising the sputtering target material is also disclosed by the invention; the sputtering device comprises an alternating current power supply; the alternating current power supply comprises a first electrode and a second electrode, of which the polarities are opposite; each first sub-block of the sputtering target material is correspondingly connected with the first electrode of the alternating current power supply; and each second sub-block of the sputtering target material is correspondingly connected to the second electrode of the alternating current power supply. The sputtering target material is designed into blocks, so that the target material is fully utilized, and a product membrane has good uniformity.

Owner:BOE TECH GRP CO LTD +1

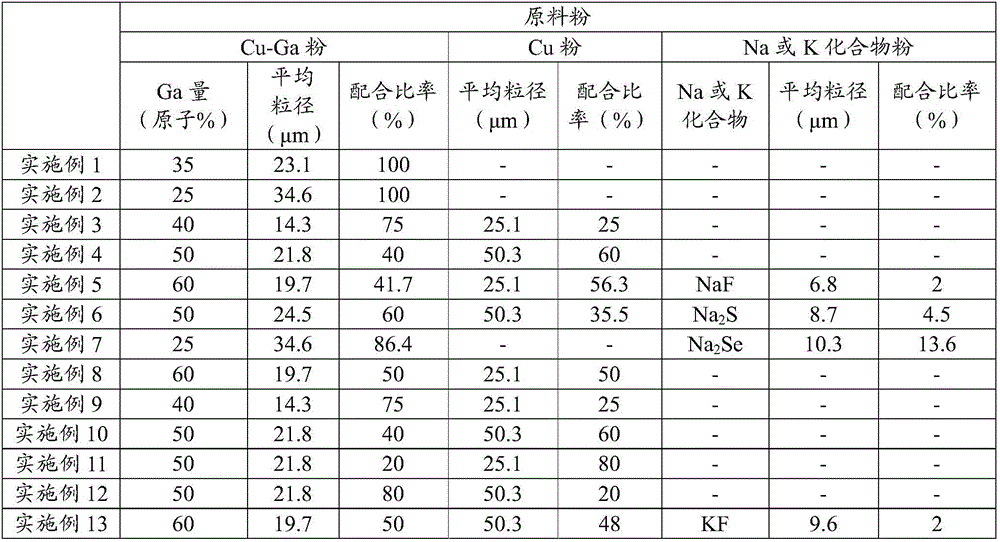

Cu-Ga alloy sputtering target and method for manufacturing same

ActiveCN106170581AReduce oxygen contentSuppress generationElectric discharge tubesTransportation and packagingPorosityAlloy

This Cu-Ga alloy sputtering target has a component composition containing 0.1-40.0% (atom basis) of Ga with the remainder made up by Cu and unavoidable impurities, wherein the porosity of the target is 3.0% or less, the average diameter of inscribed circles of the pores is 150 [mu]m or less, and the average crystal grain diameter of Cu-Ga alloy grains is 50 [mu]m or less.

Owner:MITSUBISHI MATERIALS CORP

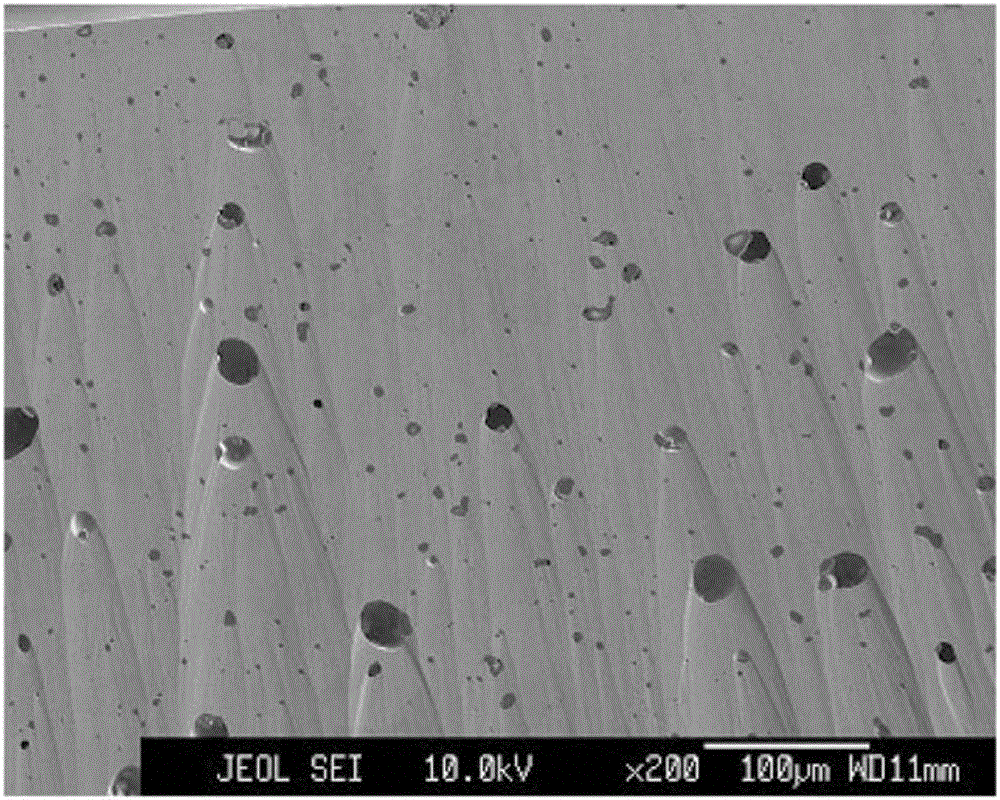

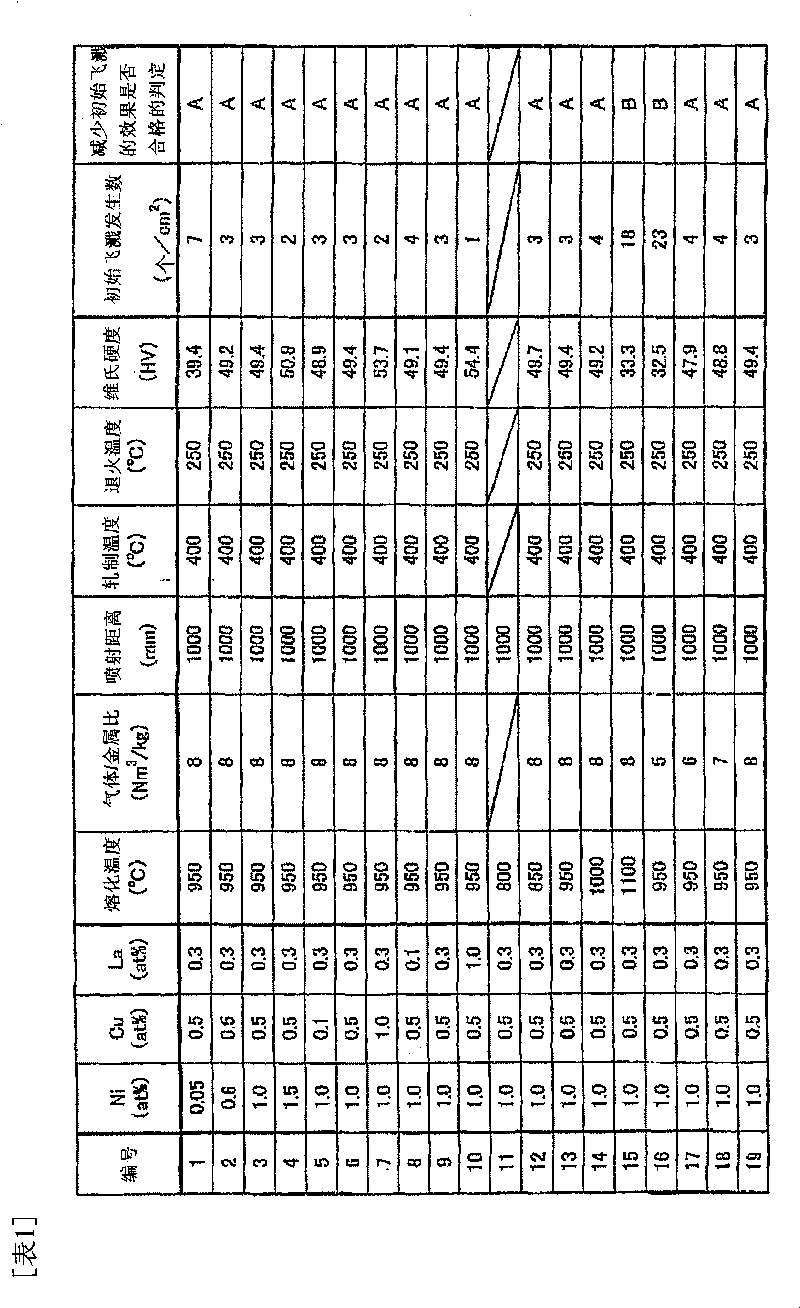

Al-based alloy sputtering target and manufacturing method thereof

ActiveCN101691657AReduce abnormal dischargeAvoid defectsVacuum evaporation coatingSputtering coatingAlloyHardness

The present invention provides an Al-(Ni, Co)-(Cu, Ge)-(La, Gd, Nd) alloy sputtering target capable of decreasing a generation of splashing in an initial stage of using the sputtering target, preventing defects caused thereby in interconnection films or the like and improving a yield and operation performance of an FPD, as well as a manufacturing method thereof. The invention relates to an Al-based alloy sputtering target which is an Al-(Ni, Co)-(Cu, Ge)-(La, Gd, Nd) alloy sputtering target comprising at least one member selected from the group A (Ni, Co), at least one member selected from the group B (Cu, Ge), and at least one member selected from the group C (La, Gd, Nd) wherein a Vickers hardness (HV) thereof is 35 or more.

Owner:KOBELCO RES INST +1

Gallium oxide-zinc oxide sputtering target, method for forming transparent conductive film, and transparent conductive film

ActiveCN100549219CIncrease target densityInhibits the formation of nodulesConductive layers on insulating-supportsVacuum evaporation coatingChemical compositionHigh density

The present invention provides a high-density gallium oxide-zinc oxide sintered body sputtering target for forming a transparent conductive film, characterized in that it contains 20 to 2000 mass ppm of zirconium oxide. Adding trace amounts of specified elements to the gallium oxide (Ga2O3)-zinc oxide (ZnO) sputtering target (GZO target) can improve its conductivity and the volume density of the target, that is, improve the composition, increase the sintering density, and inhibit The formation of nodules prevents the occurrence of abnormal discharge and particles. While obtaining such a target, the present invention also provides a method of using the target to form a transparent conductive film and the transparent conductive film formed thereby.

Owner:JX NIPPON MINING & METALS CORP

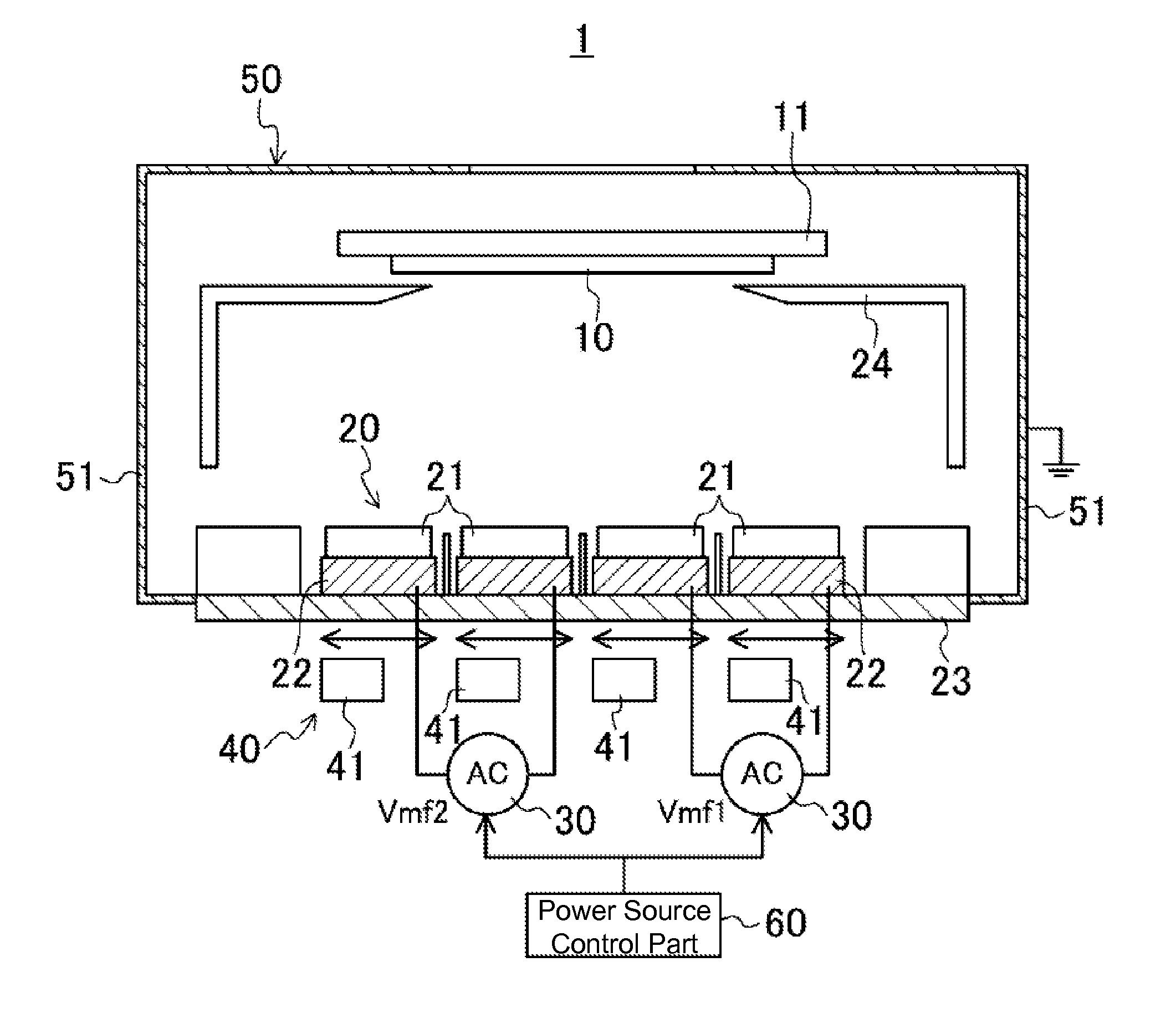

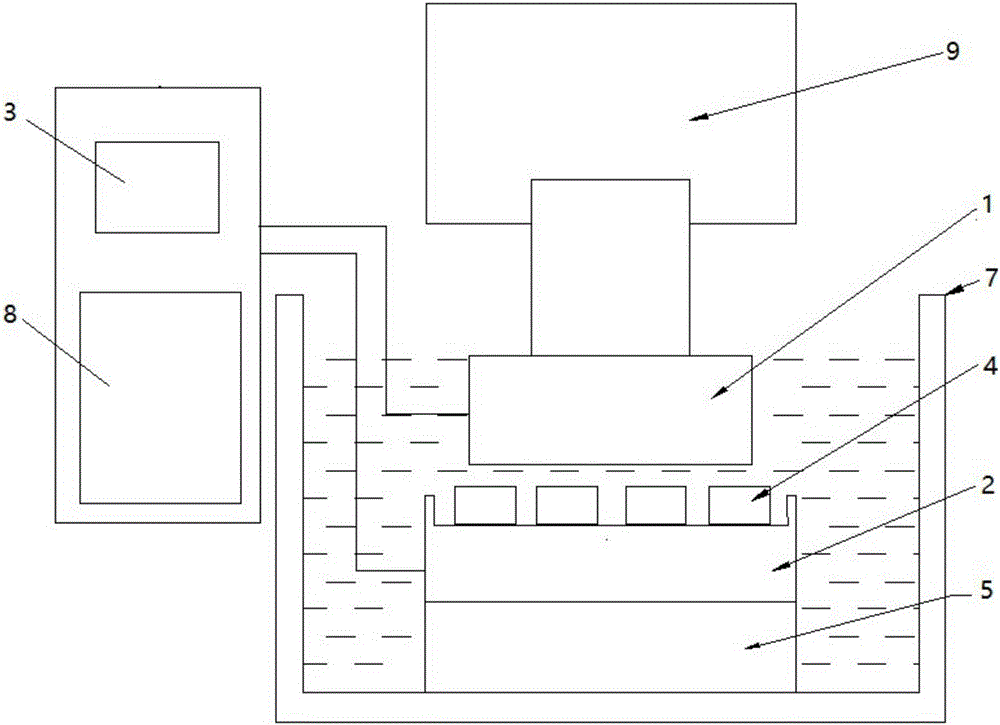

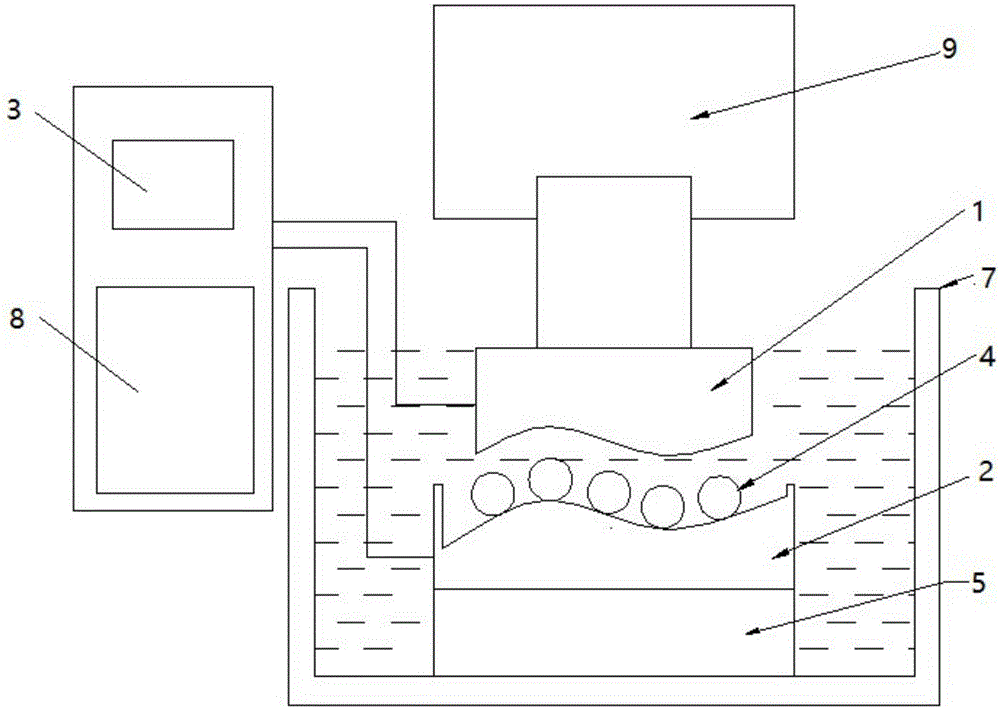

Magnetron sputtering device, method for controlling magnetron sputtering device, and film forming method

InactiveUS20130213798A1Quality improvementPrescribed voltageCellsElectric discharge tubesElectricityMagnet

A magnetron sputtering device is provided with: a target part positioned in such a manner as to face a substrate held by a substrate holding part; a power source that supplies power to the target part; a magnet part that moves back and forth along the rear of the target part; a chamber having side walls that are electrically grounded; and a power source control part that controls the power source in such a manner that, while the magnet part is away from approach points, which are points respectively closest to the side walls, a prescribed voltage is applied to the target part by the power source, but the prescribed voltage is reduced when the magnet part reaches one of the approach points.

Owner:SHARP KK

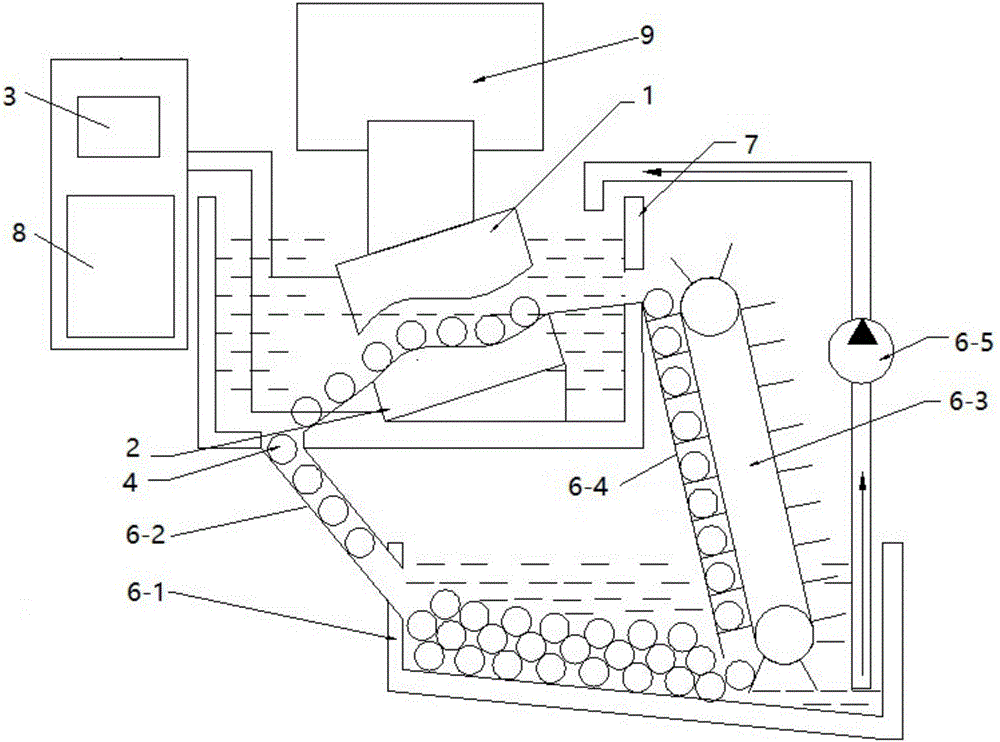

Electric spark discharge machining method of free electrodes and equipment thereof

ActiveCN106238837ARealize processingProcessing applicableElectrical-based machining electrodesElectric dischargeAbnormal discharge

The invention relates to an electric spark discharge machining method of free electrodes and equipment thereof. A work-piece and a tool electrode are connected to a positive pole and a negative pole of a pulse power source respectively, the free electrodes move on the surface of the tool electrode, the work-piece, the tool electrode and the free electrodes are all immersed into insulating media in the electric spark machining process, the tool electrode is used for charging the free electrodes, the moving free electrodes and the work-piece to be machined generate electric spark discharge, then materials on the surface of the work-piece are removed, finally the shape of the tool electrode is copied on the work-piece, and part machining is realized. The method and the equipment have the beneficial effects that loss of the tool electrode is effectively avoided, and therefore the manufacturing cost and the manufacturing time of the tool electrode are greatly reduced. The method and the equipment are especially suitable for machining the parts with complex shapes. Meanwhile, because the free electrodes are always in the motion process, the inter-electrode discharge condition can be effectively improved, abnormal discharge can be reduced, and the machining efficiency and the machining quality can be improved.

Owner:江苏美通导体科技有限公司

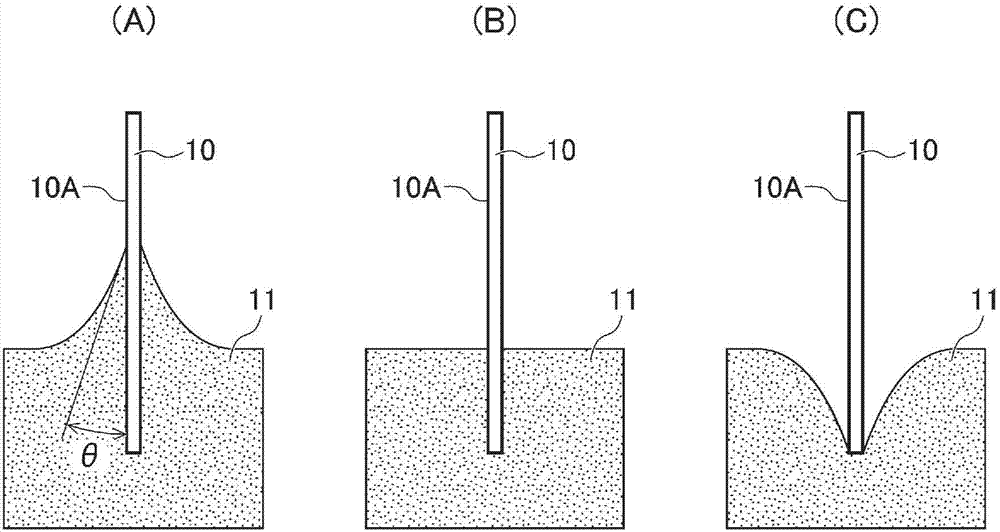

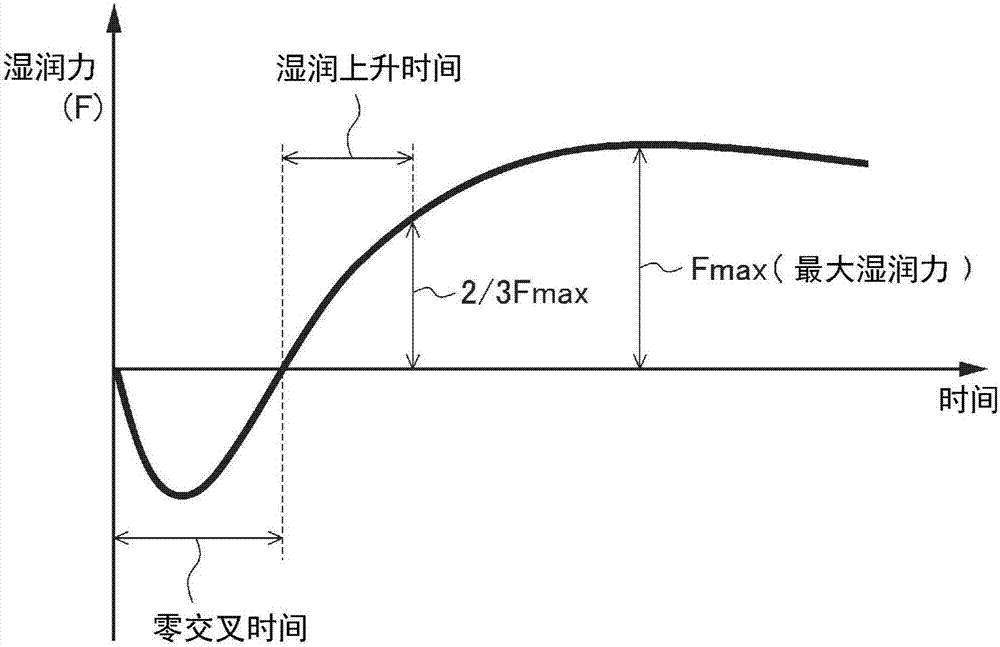

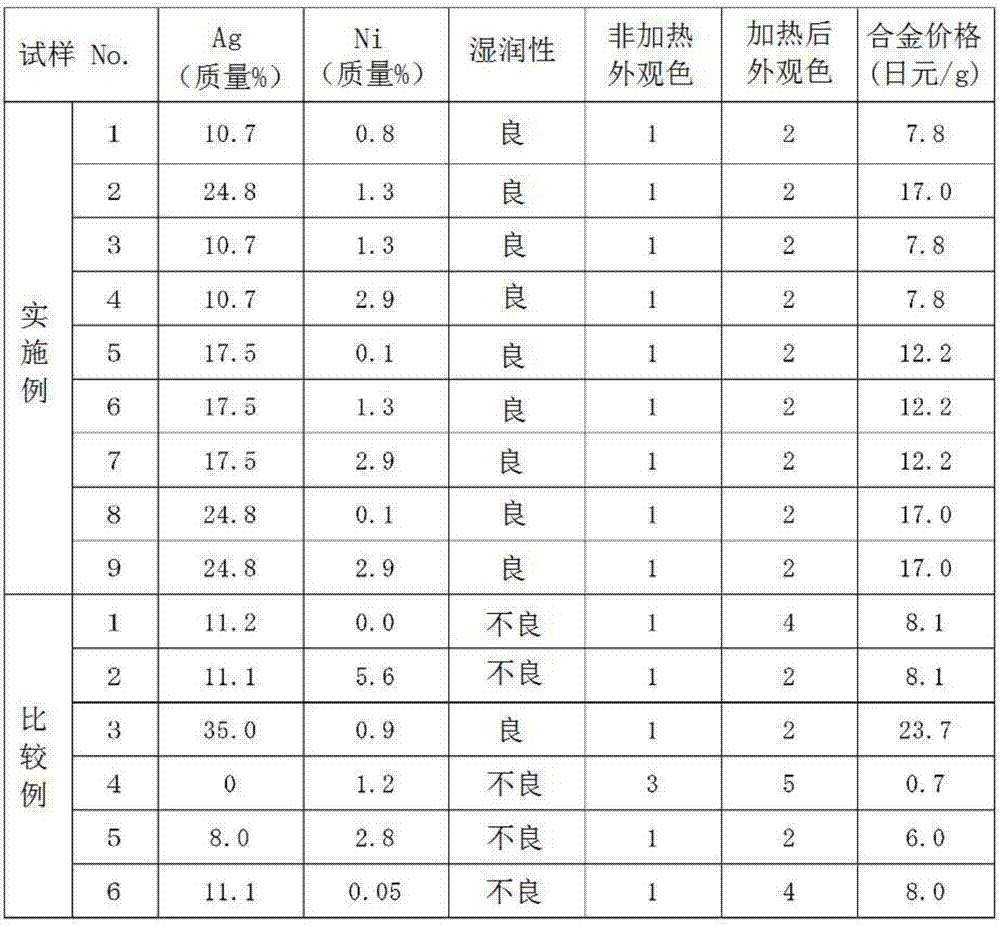

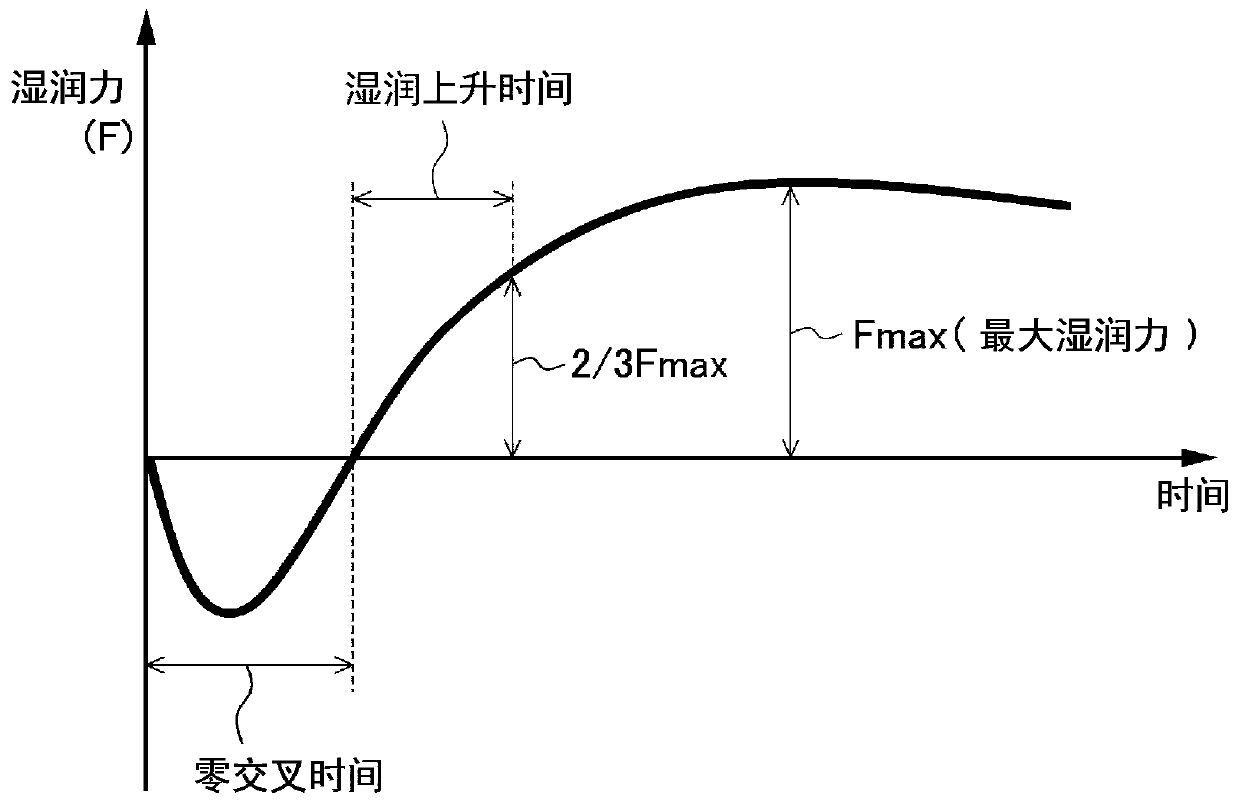

Copper alloy target

ActiveCN107075667AGood lookingIncrease moistureVacuum evaporation coatingSemiconductor/solid-state device manufacturingSputteringMetal

Provided is a copper alloy target for forming a film of an electrode to be soldered, said copper alloy target enabling low-cost formation of a copper alloy film that is not discolored after sputtering different from pure copper films, shows good solder joint properties even after treating with an inert flux, and has an excellent solder wettability. The copper alloy target according to the present invention for forming a film of an electrode to be soldered comprises copper as a main component together with 10-25 mass% exclusive of silver and 0.1-3 mass% inclusive of nickel. The copper alloy target is produced preferably by evacuating a sealable chamber to 0.01 Pa or below, then introducing an inert gas to adjust the pressure in the chamber to 50-90000 Pa inclusive, and then melting and casting metal materials therein.

Owner:SUMITOMO METAL MINING CO LTD

Copper alloy target

ActiveCN107075667BGood lookingIncrease moistureVacuum evaporation coatingSemiconductor/solid-state device manufacturingSputteringMetal

The present invention provides a copper alloy target for welding electrode film formation capable of forming a copper alloy film at a low price. The sputtering film formation of the copper alloy film does not change color like pure copper film formation, and even after a After treatment with inactive flux, it also shows good solderability and has excellent solder wettability. The copper alloy target for welding electrode film formation according to the present invention contains copper as a main component, contains silver in a ratio of more than 10 mass % to less than 25 mass %, and contains nickel in a ratio of 0.1 mass % to 3 mass %. The copper alloy target is preferably produced in the following manner: after vacuumizing the sealable cavity to below 0.01Pa, introducing an inert gas, adjusting the pressure in the cavity to not less than 50Pa and not more than 90000Pa, and carrying out vacuuming of the metal material. Melting and casting.

Owner:SUMITOMO METAL MINING CO LTD

Sputtering target and its production method

InactiveCN1865490AReduce abnormal dischargeTube/lamp screens manufactureSingle unit pavingsSurface roughnessTitanium

A sputtering target and a manufacturing method thereof are provided to acquire a black matrix thin film without Cr and to reduce an environmental pollution. A sputtering target is made of tungsten of 5 to 30 weight%, a predetermined material, oxygen, and nickel. The predetermined material is made of at least one selected from a group consisting of aluminium and titanium. The weight% of the predetermined material is in a predetermined range of 0.1 to 10. The weight% of the oxygen is in a predetermined range of 0.05 or less. The mean grain size of the sputtering target is in a predetermined range of 100 mum or less. The surface roughness of the sputtering target is in a predetermined range of 10 mum or less.

Owner:SUMITOMO METAL MINING CO LTD

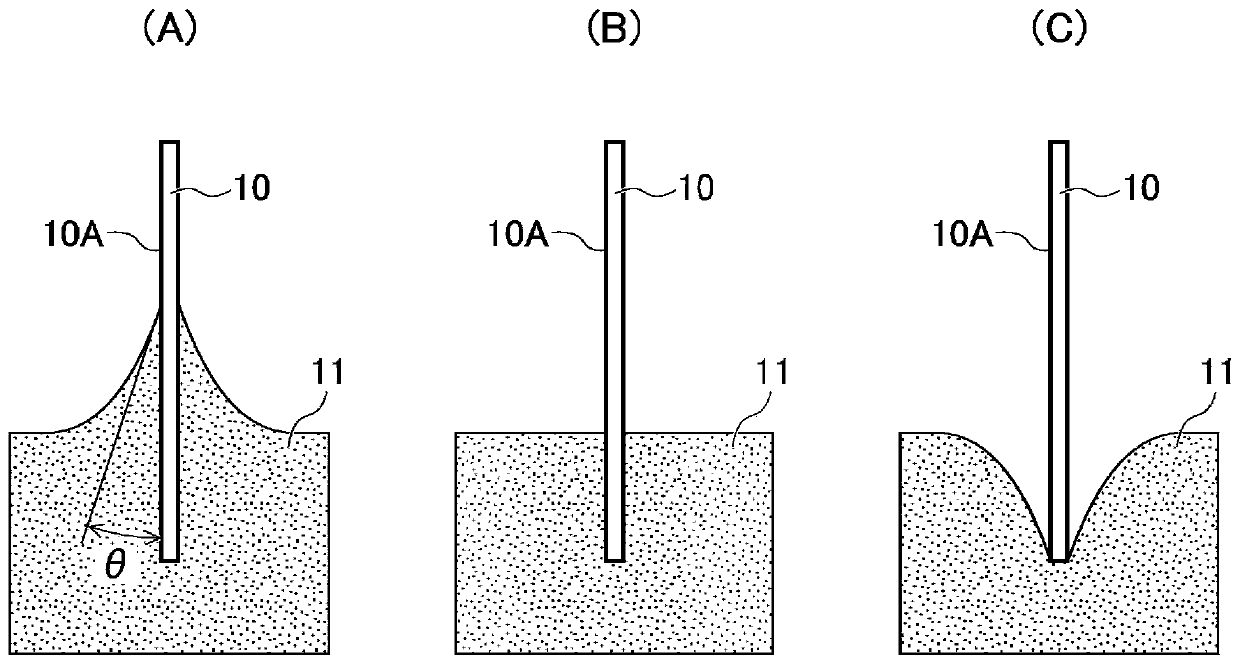

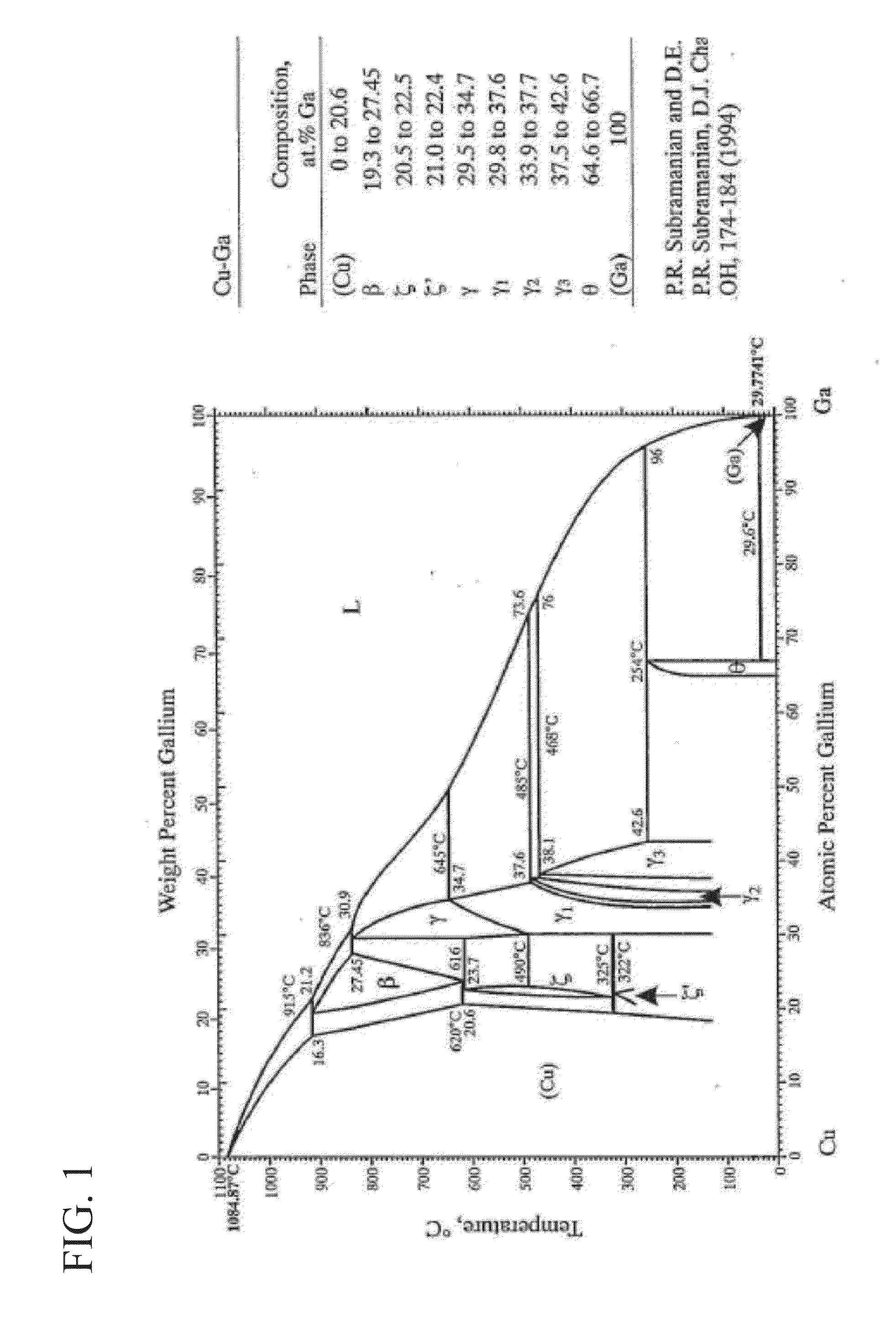

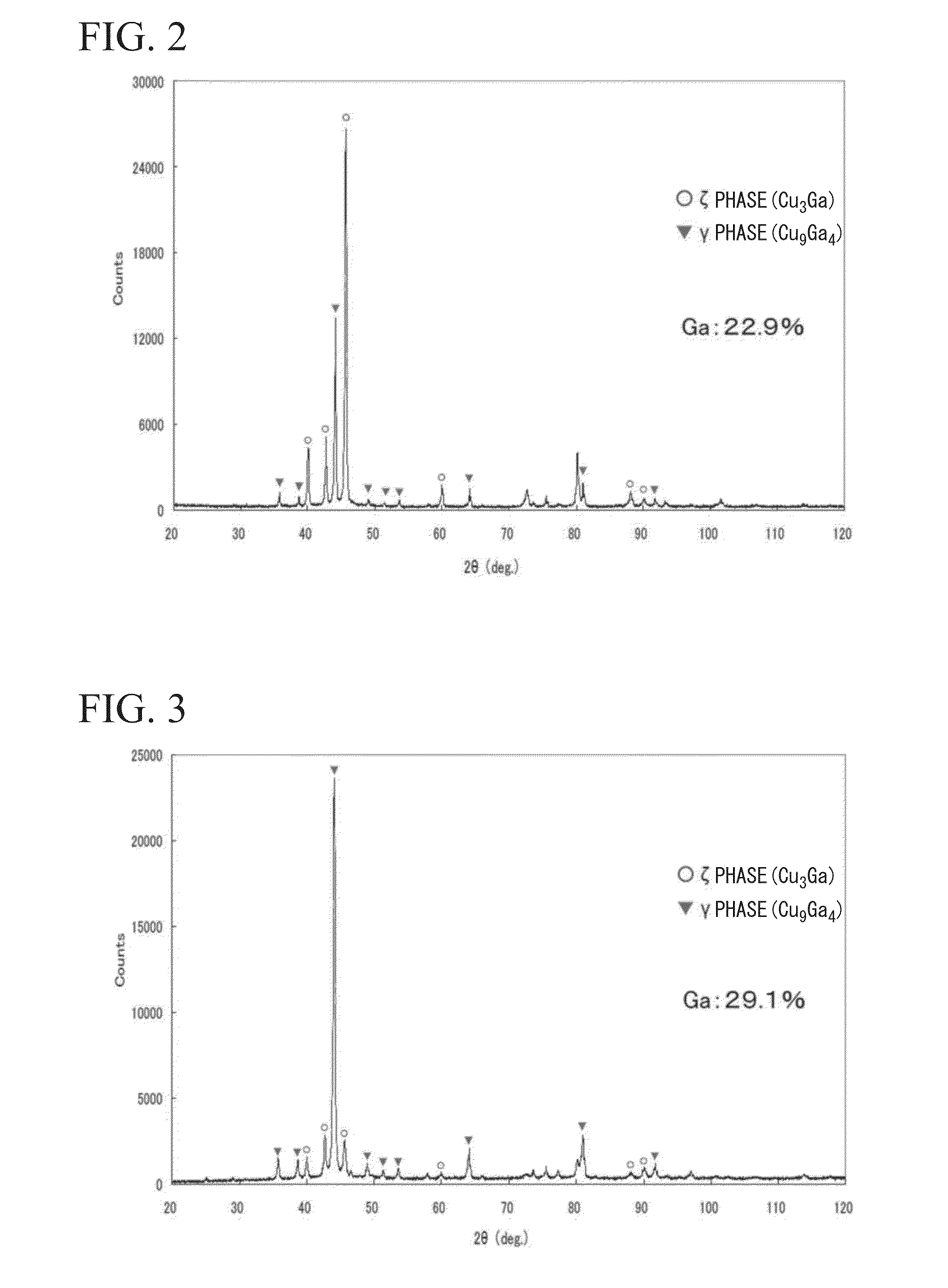

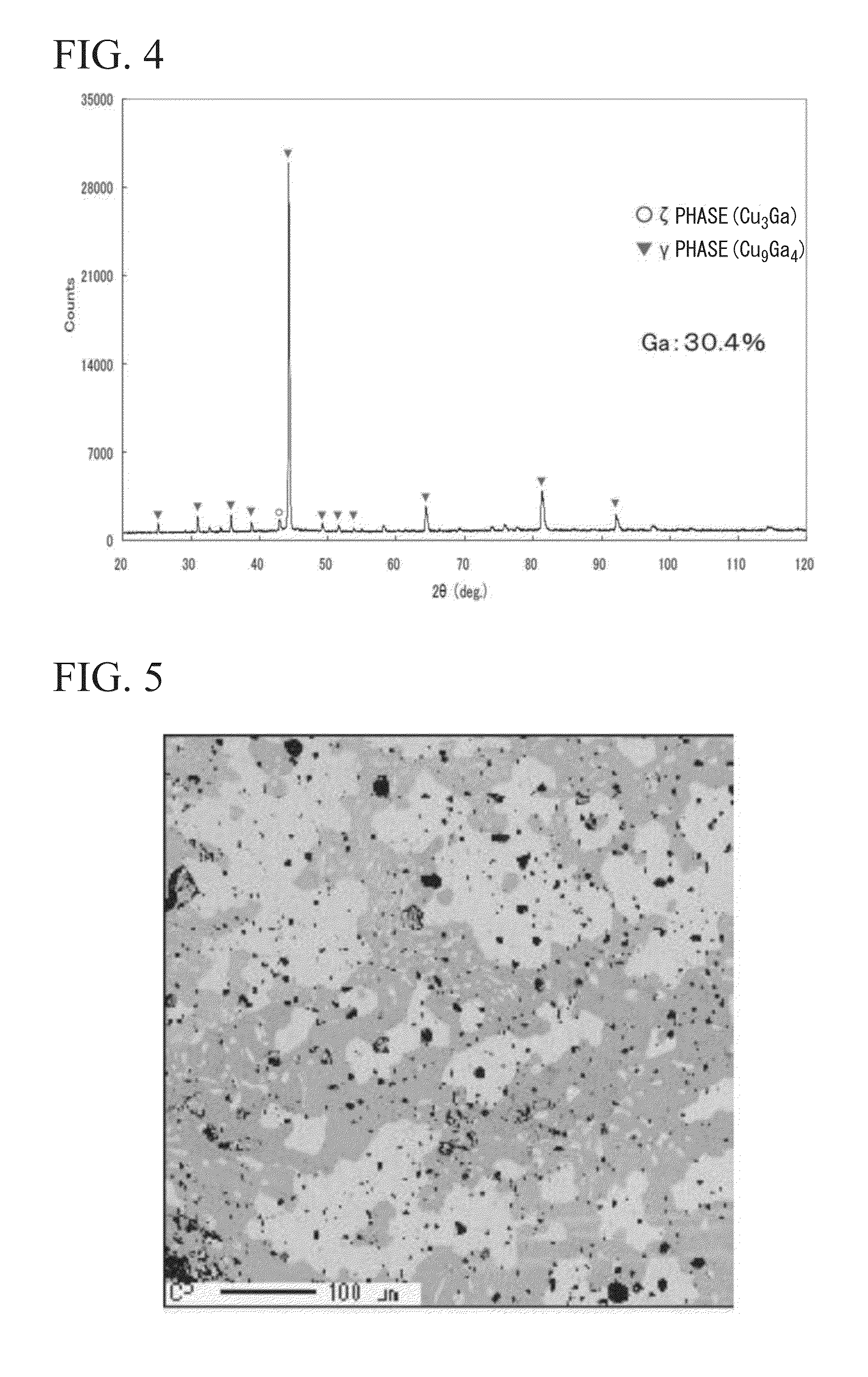

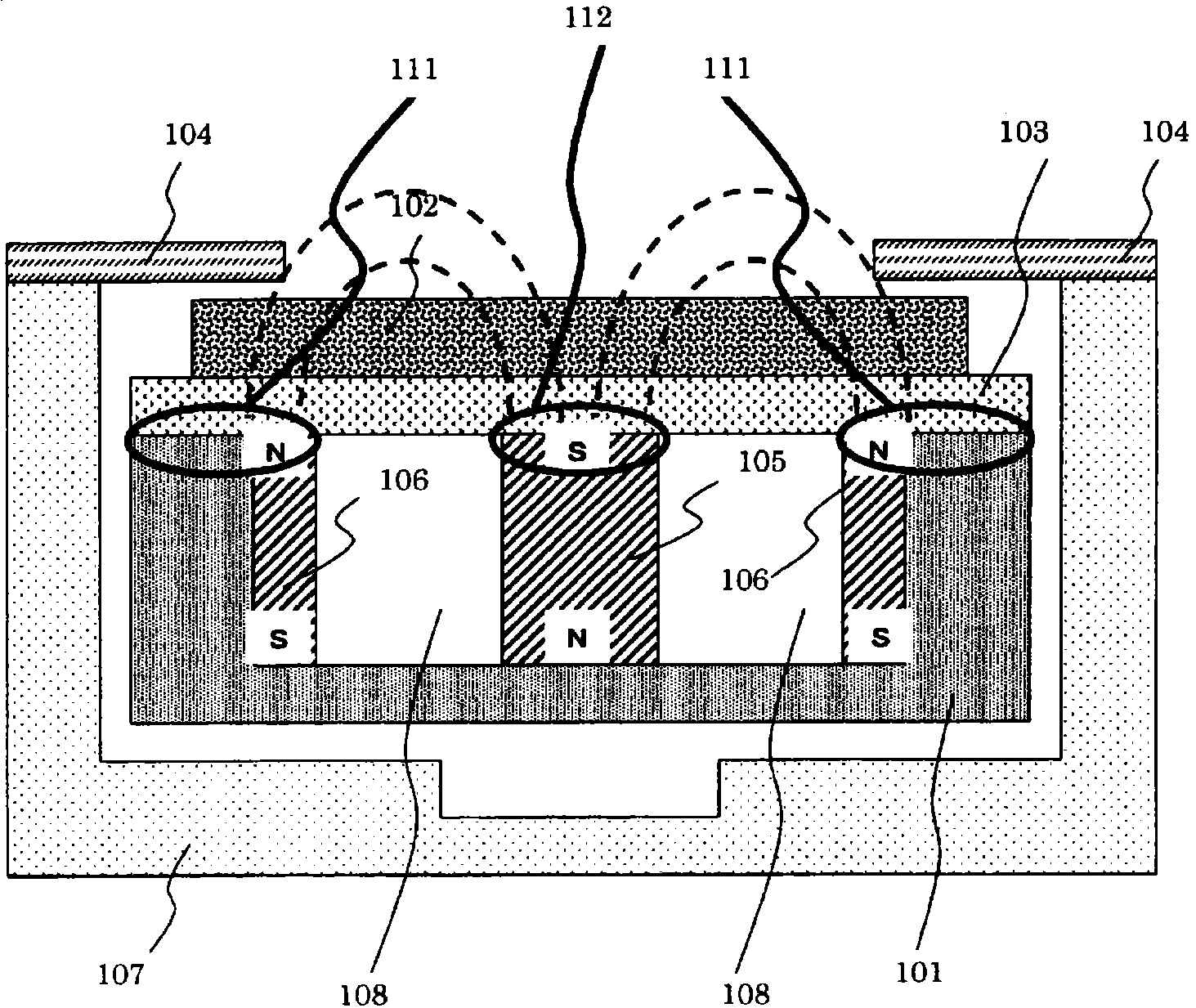

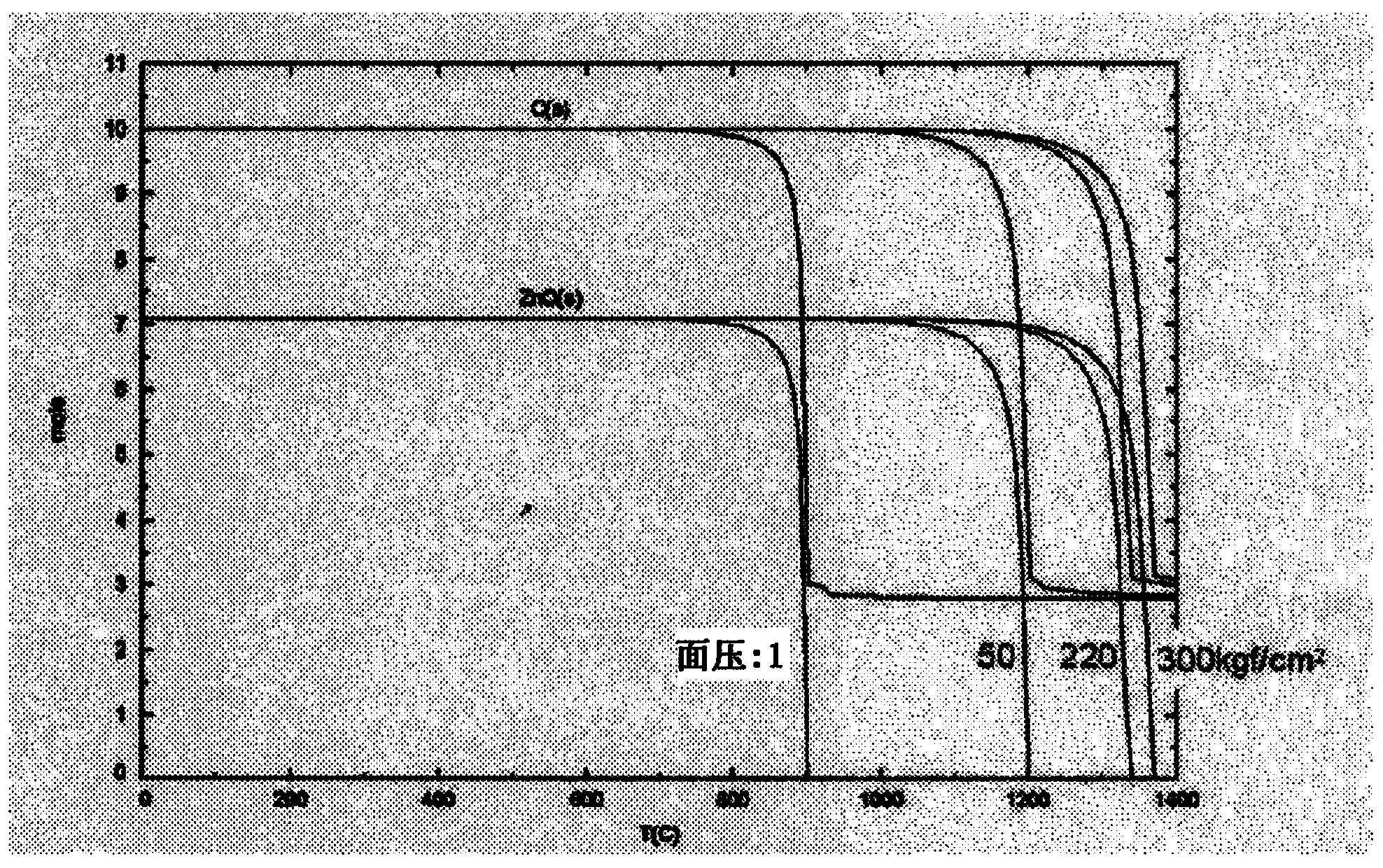

Cu-ga alloy sputtering target, and method for producing same

ActiveUS20160208376A1Easy dischargeReduce abnormal dischargeElectric discharge tubesVacuum evaporation coatingMetallurgyOxygen content

The present invention provides a sputtering target of a Cu—Ga sintered body in which the oxygen content is further reduced and the abnormal discharging can be suppressed, and a method for producing the same. The sputtering target according to the present invention is a sintered body having: a texture in which Na compound phases are dispersed in a matrix with a γ phase and a ζ phase of a Cu—Ga alloy; and a component composition made of: 20 atomic % to 30 atomic % of Ga; 0.05 atomic % to 10 atomic % of Na; and the Cu balance and inevitable impurities including elements other than Na in the Na compound, wherein an average grain size of the γ phase is 30 μm to 100 μm, and an average grain size of the Na compound phases is equal to or less than 8.5 μm.

Owner:MITSUBISHI MATERIALS CORP

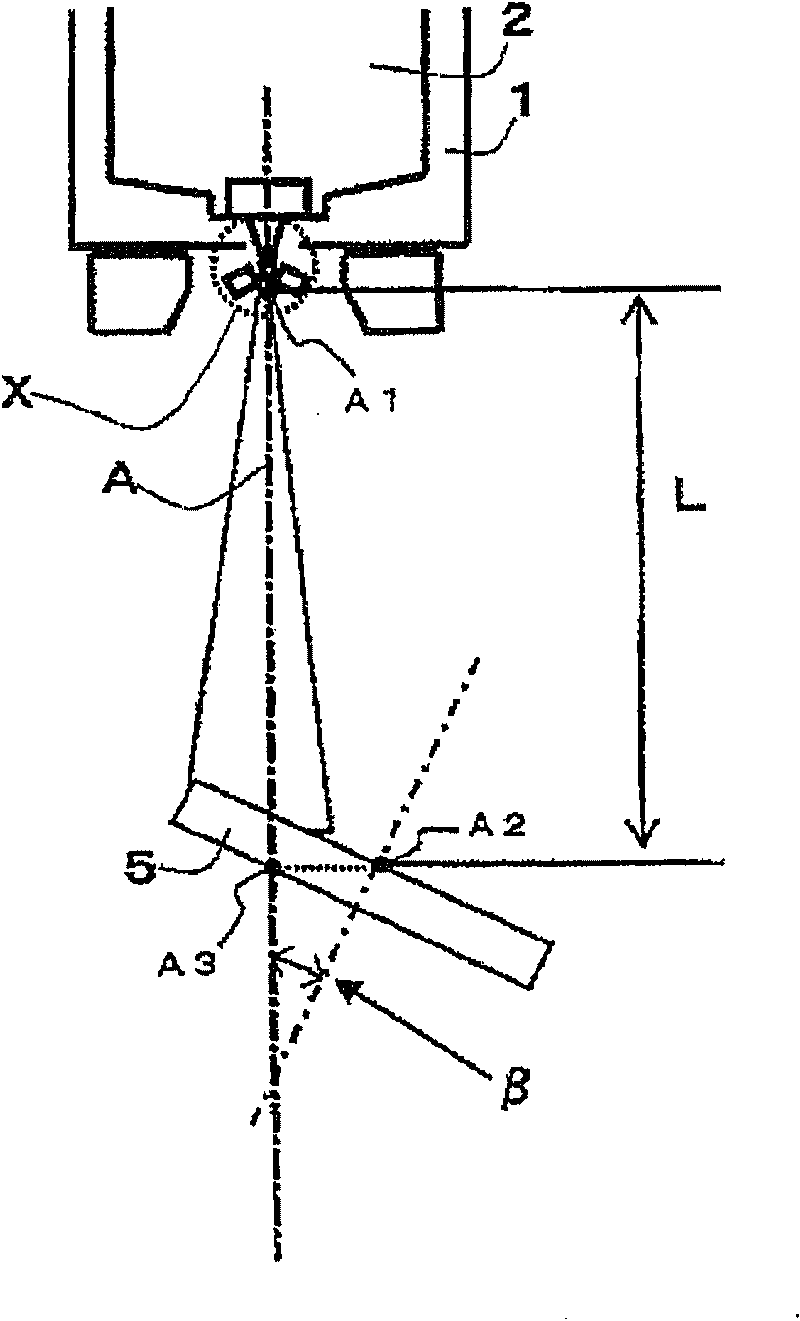

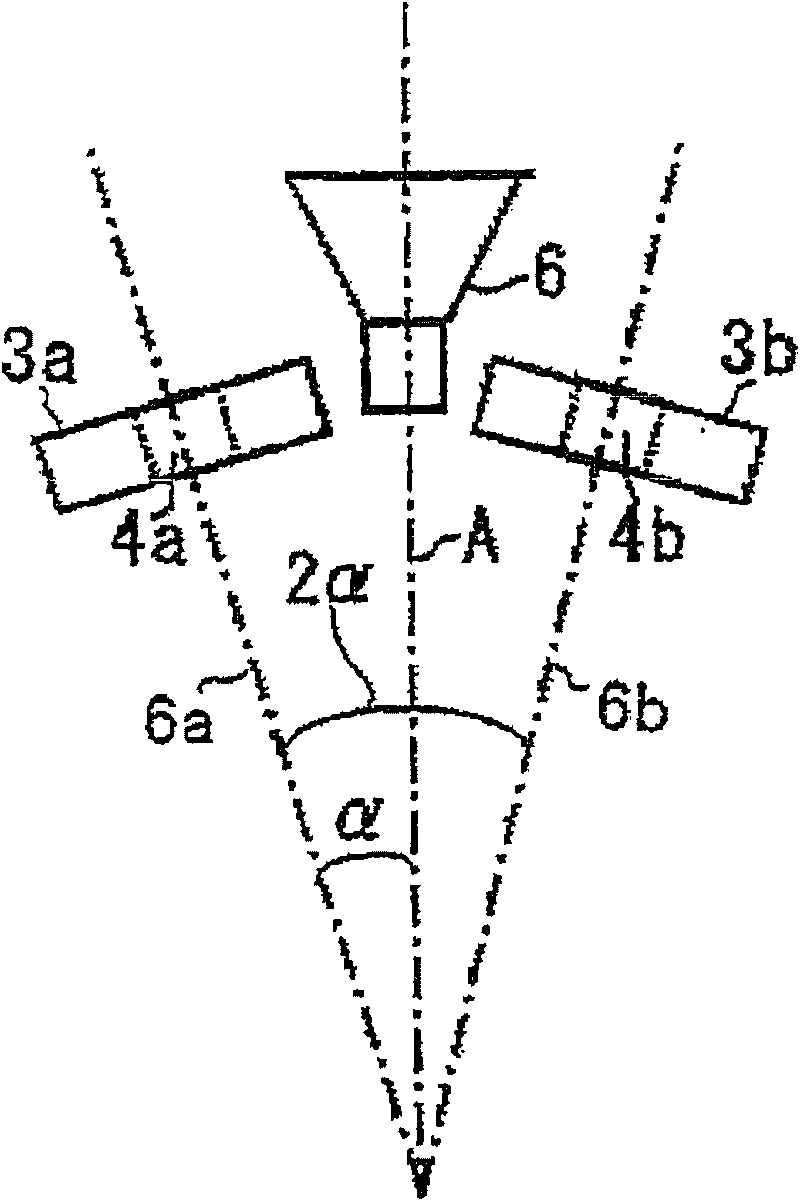

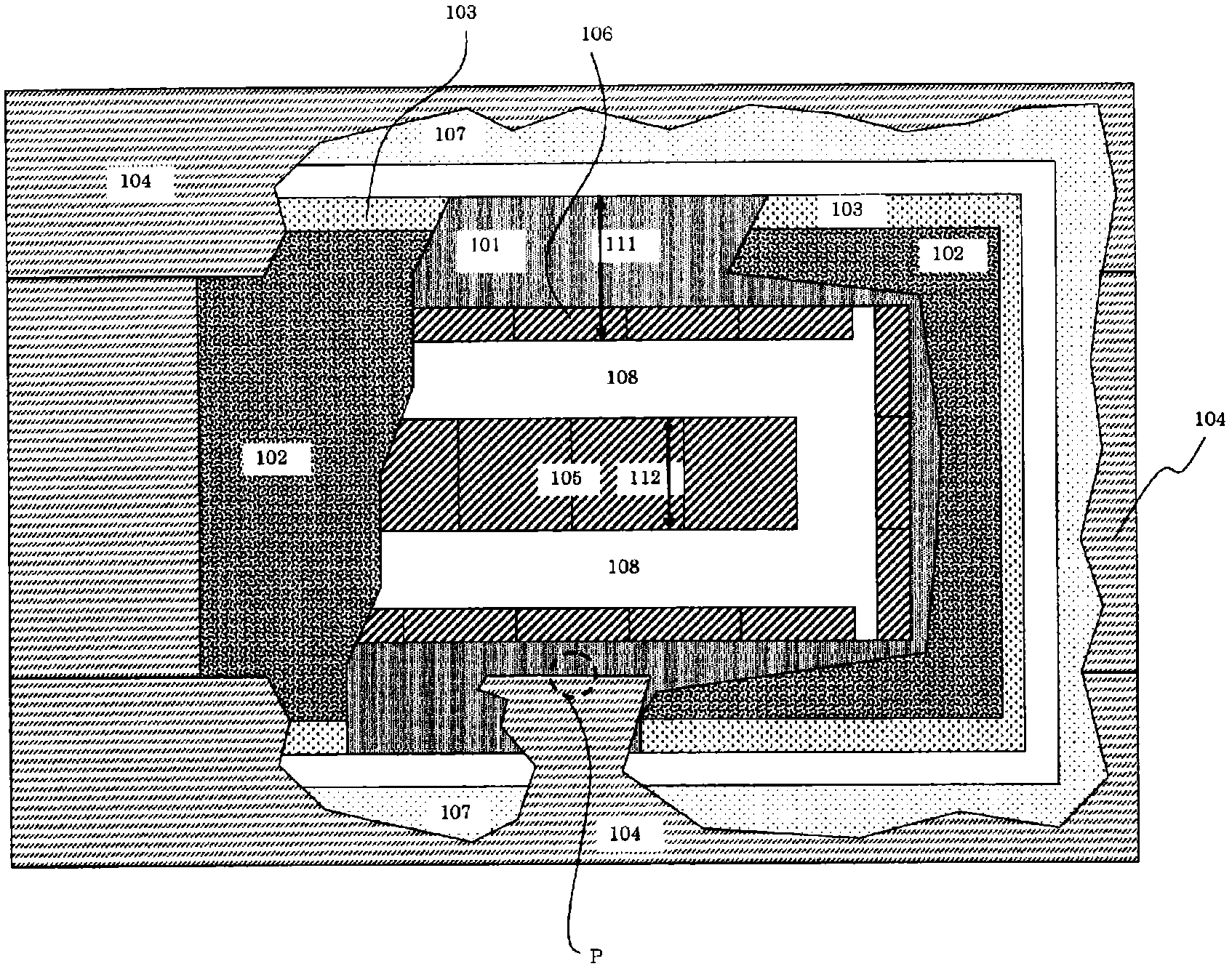

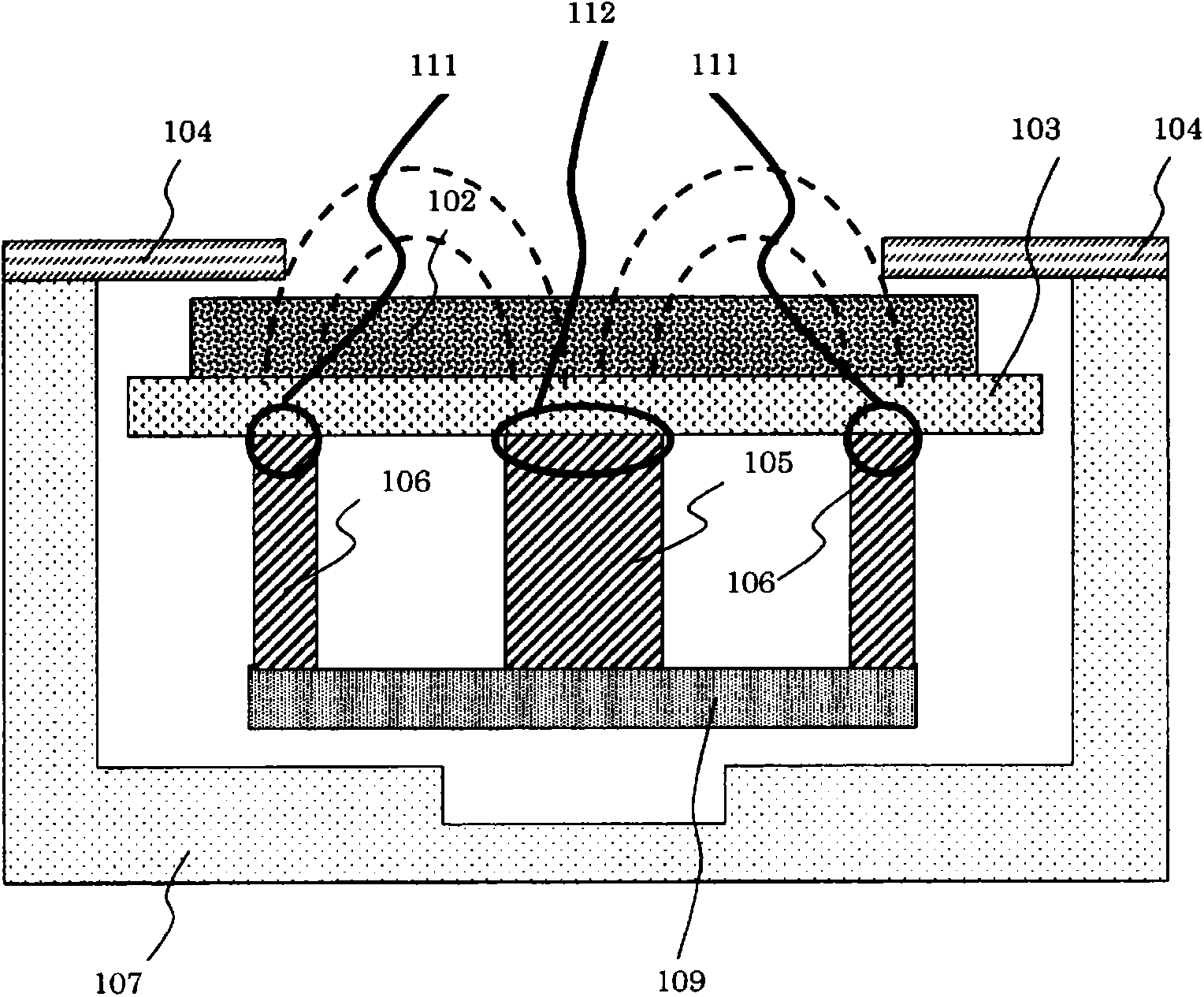

Magnetron electrode for plasma processing

InactiveCN103403219AReduce abnormal dischargeSmooth dischargeVacuum evaporation coatingSputtering coatingMagnetic polesMagnetic flux

Owner:TORAY IND INC

Sputtering target and process for manufacturing same

ActiveCN104136654AInhibit deteriorationExcellent optical propertiesVacuum evaporation coatingSputtering coatingElemental compositionRefractive index

A sputtering target characterized by further containing 0.1 to 20wt% (in terms of the weight of oxide) of a metal which can form a low-melting oxide having a melting point of up to 1000°C relative to an elemental composition which has an Al content of 0.2 to 3.0mol% in terms of Al2O3 and a content of Mg and / or Si of 1 to 27mol% in terms of MgO and / or SiO2 with the balance being Zn in an amount in terms of ZnO. The present invention provides: a target which is free from sulfur and has such a low bulk resistance as to permit DC sputtering and which is useful in forming an optical thin film having a low refractive index; and a process for manufacturing the same. The target itself has a high density and therefore enables stable sputtering with little abnormal discharge. A thin film formed by a sputtering method using the target exhibits a high transmittance and is composed of a sulfur-free system, so that a reflecting or recording layer adjacent to the thin film is less susceptible to degradation. Thus, the target is useful in forming a thin film for an optical information recording medium. The sputtering target can improve the characteristics of an optical information recording medium, reduce the facility cost, and enhance the speed of film formation, thus achieving a remarkably improved throughput.

Owner:JX NIPPON MINING & METALS CO LTD

Magnetic material sputtering target and manufacturing method thereof

ActiveUS9793099B2Reduce impurity pollutionReduce Particle GenerationElectric discharge tubesVacuum evaporation coatingSputteringParticle generation

Owner:JX NIPPON MINING & METALS CORP

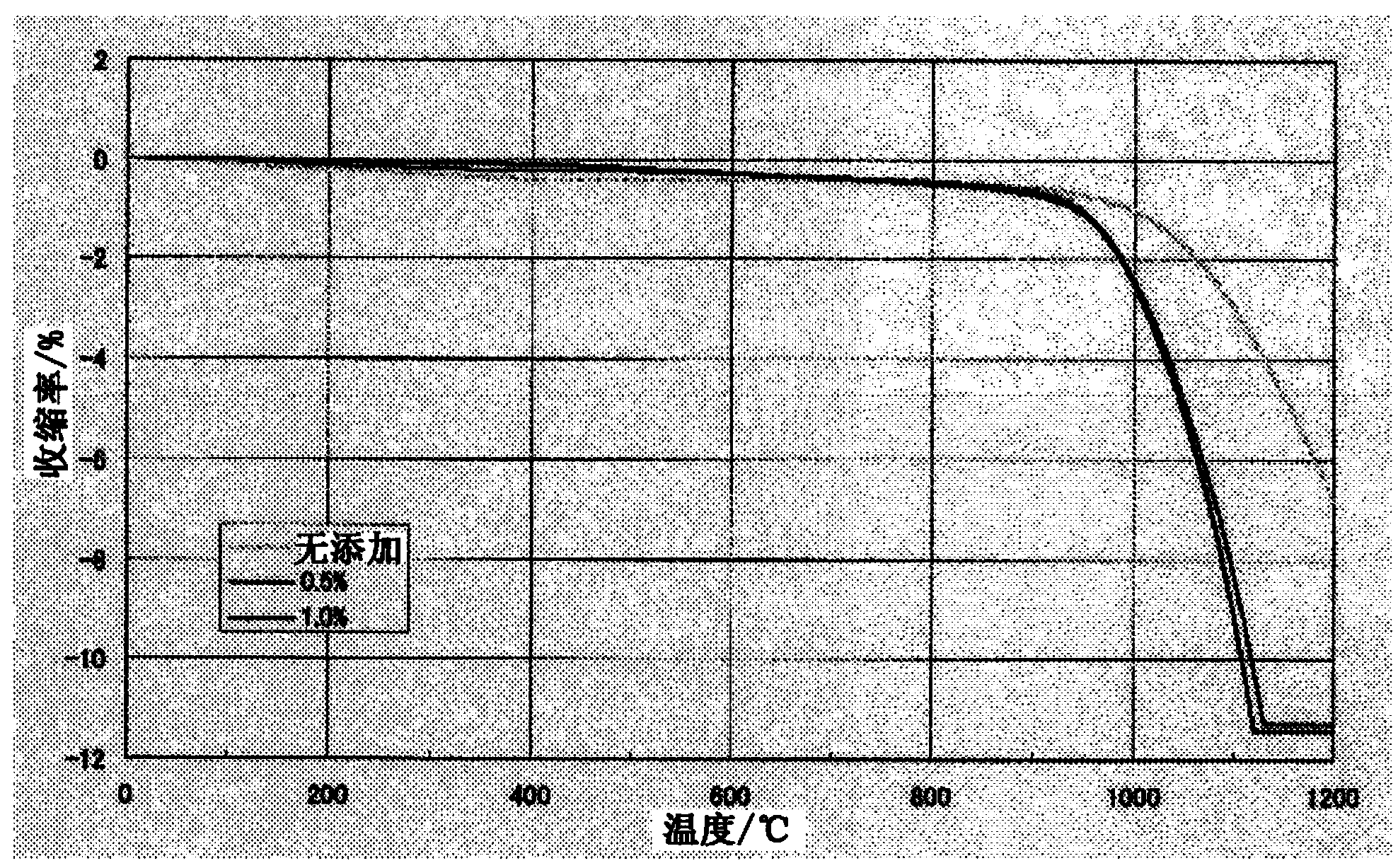

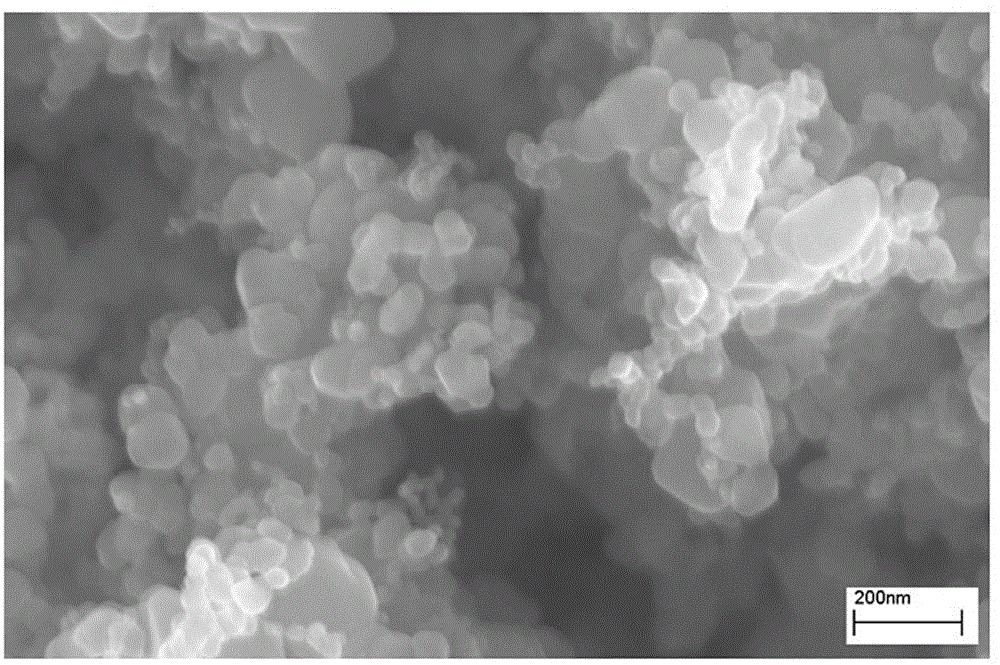

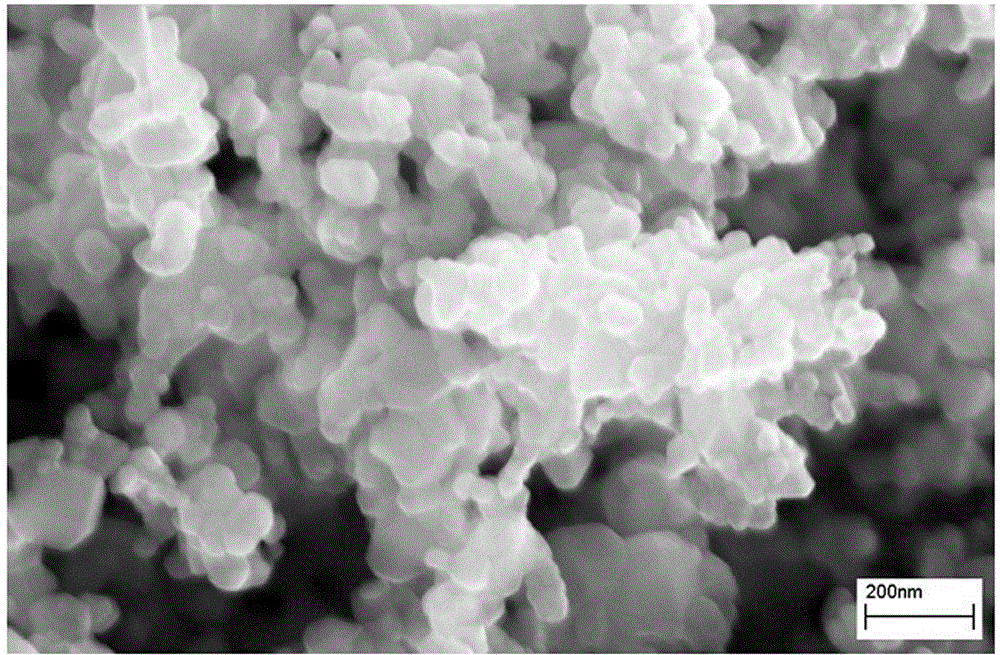

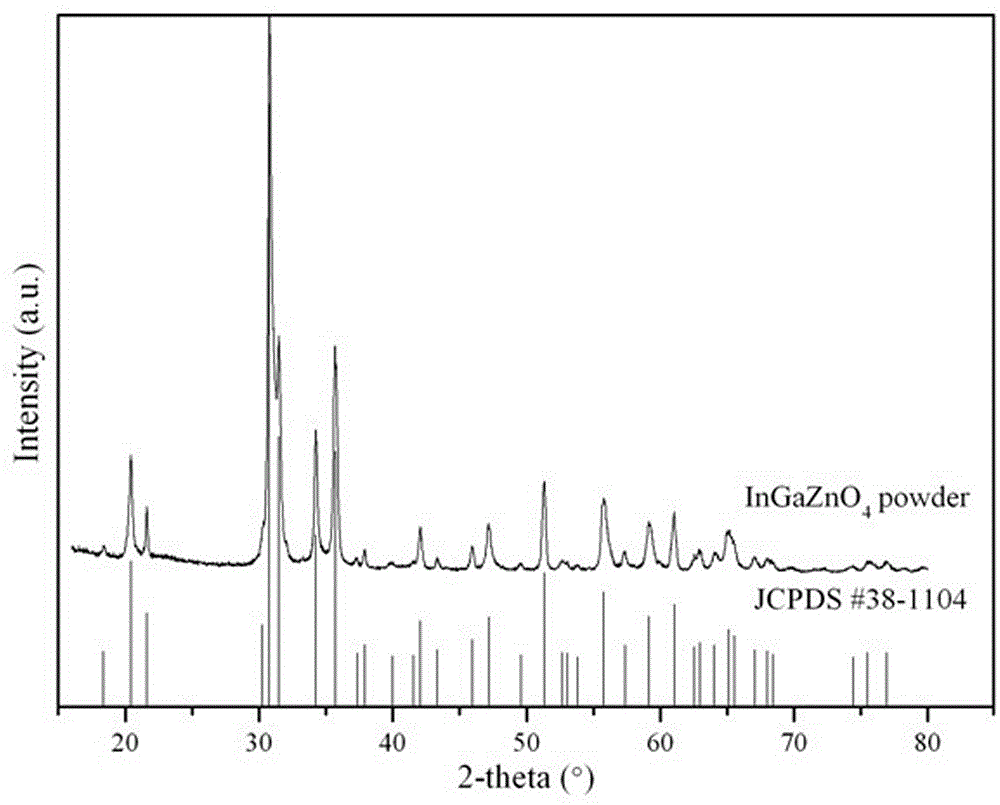

A kind of preparation method of indium gallium zinc oxide powder and its ceramic target material

ActiveCN103193262BMonodisperseHigh sintering activityZinc oxides/hydroxidesGallium/indium/thallium compoundsCompression moldingIndium

The invention provides an indium-gallium-zinc oxide powder and a preparation method of a ceramic target thereof. The indium-gallium-zinc oxide powder comprises indium, gallium, zinc and oxygen, and the indium-gallium-zinc oxide powder is expressed as a composition formula x(In2O3)-y(Ga2O3)-z(ZnO). In the formula, x is smaller than 3.5 and greater than 0.5, and y / z is smaller than 2.0 and greater than 0.5. The preparation method is characterized by comprising the following steps: preparing raw materials including indium, the gallium and the zinc into clear liquor, adding the precipitator to produce precipitate, and calcining after washing, filtering and drying to obtain the mono-dispersed nano-scale IGZO powder; and preparing the ceramic target by adopting the synthetic IGZO powder as the raw material, adding the adhesive for granulating, carrying out compression molding or cold isostatic pressure strengthening to obtain the green body, degreasing the green body in a high-temperature furnace, and sintering the degreased green body at a high temperature. Because of adoption of the steps, the IGZO ceramic target which has high density and low resistivity is obtained, and the formations of the paradoxical discharge and knots on the surface of the ceramic target can be prevented.

Owner:广州市尤特新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com