Copper alloy target

A copper alloy target and metal material technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of difficult target utilization, poor operability, productivity and safety, and achieve low price, Effects of reduced abnormal discharge and excellent solder wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Hereinafter, the present invention will be described in more detail using examples and comparative examples, but the present invention is not limited to the following examples at all.

[0047] "Examples and Comparative Examples"

manufacture example 1

[0049] In Examples and Comparative Examples, copper alloy melts were prepared so as to have the component compositions shown in Table 1 below, and copper alloy samples were produced. In addition, as shown in Table 1, as a component, silver and nickel were contained in predetermined ratios, respectively.

[0050] Specifically, using a high-frequency vacuum melting furnace, after evacuating the cavity to below 0.009Pa, introducing argon gas to 500Pa to produce a copper alloy melt with the composition shown in Table 1 below, at the pressure After being kept under the same conditions for 10 minutes, it was poured into a graphite mold to make an ingot. Then, a disc shape with a thickness of 5 mm and a diameter of 75 mm was cut out from the produced ingot as a copper alloy target, and was used for the following evaluation.

[0051]

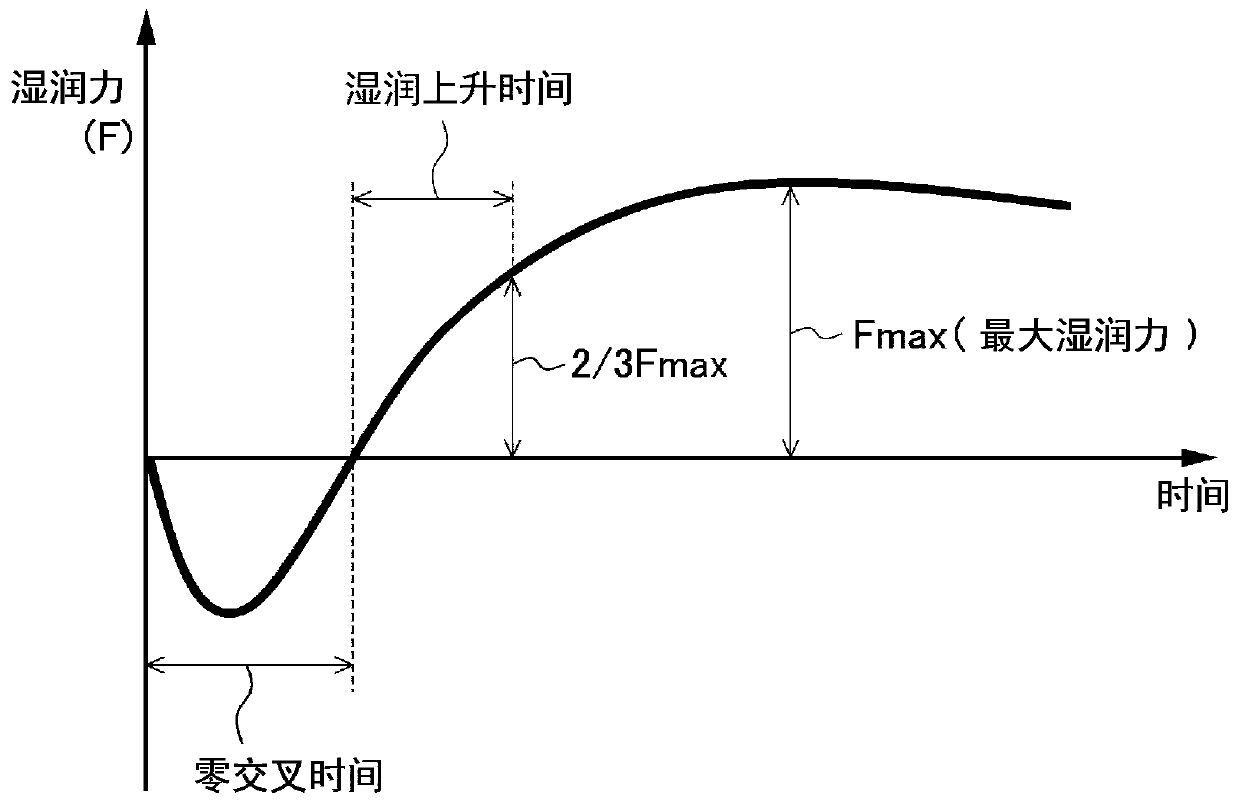

[0052] Using the prepared copper alloy target, a film was formed on a monel plate (Ni-34% by mass Cu) by the sputtering method, and the solder wetta...

manufacture example

[0064] "Manufacturing example (reference example) 2 to 4"

[0065]

[0066] For reference, Manufacturing Example 2 employs the same composition as that of the copper alloy target in Example 1, and the cavity is evacuated and melted in this state. It should be noted that other conditions are the same as in Example 1.

[0067]As a result, silver adhered to the inner side of the inspection window of the cavity, and the inspection window quickly became blurred, and the inside of the cavity could not be observed, and the operation could not be continued. After cooling down, the inside of the chamber was observed, and it was found that silver had adhered not only to the inner wall of the chamber, but also to all parts such as the oscillation coil and electrode terminals, and it was in an unsafe state. It should be noted that the vacuum degree during the melting is 0.4 Pa.

[0068]

[0069] In addition, as Production Example 3, casting was performed with the same composition as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com