Al-based alloy sputtering target and manufacturing method thereof

A manufacturing method and alloy-based technology, which is applied in the field of Al-based alloy sputtering target and its manufacturing, can solve the problems of poor sputtering, FPD yield and action performance reduction, etc., to improve action performance, reduce abnormal discharge, The effect of preventing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

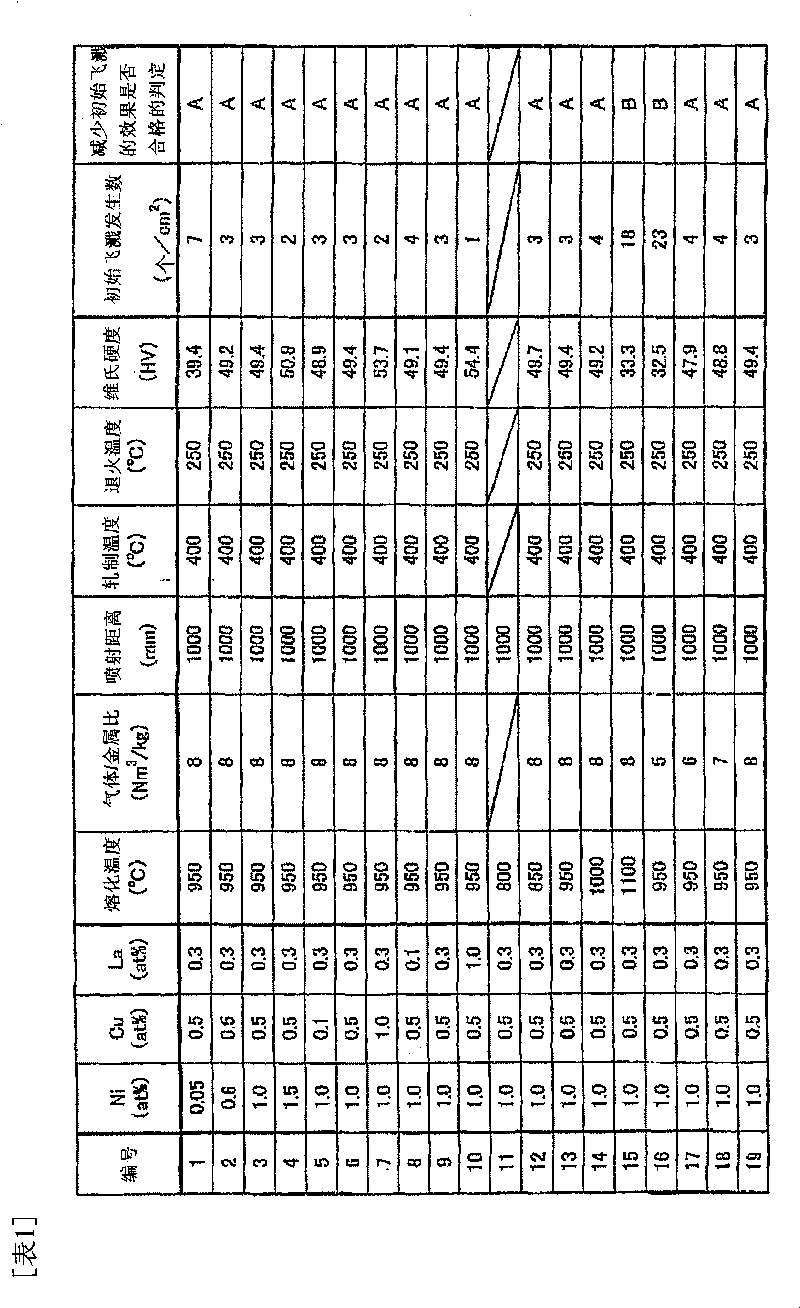

[0108] Using an Al-Ni-Cu-La alloy, under various conditions shown in Table 1 and Table 2, an Al-based alloy preform (density: about 50 to 60%) was obtained by spray molding.

[0109] (Injection molding conditions)

[0110] Melting mixing degree: 800~1100℃ (see Table 1, Table 2)

[0111] Gas / metal ratio: 5~8Nm 3 / kg (see Table 1, Table 2)

[0112] Spray distance: 800 ~ 1300mm (see Table 1, Table 2)

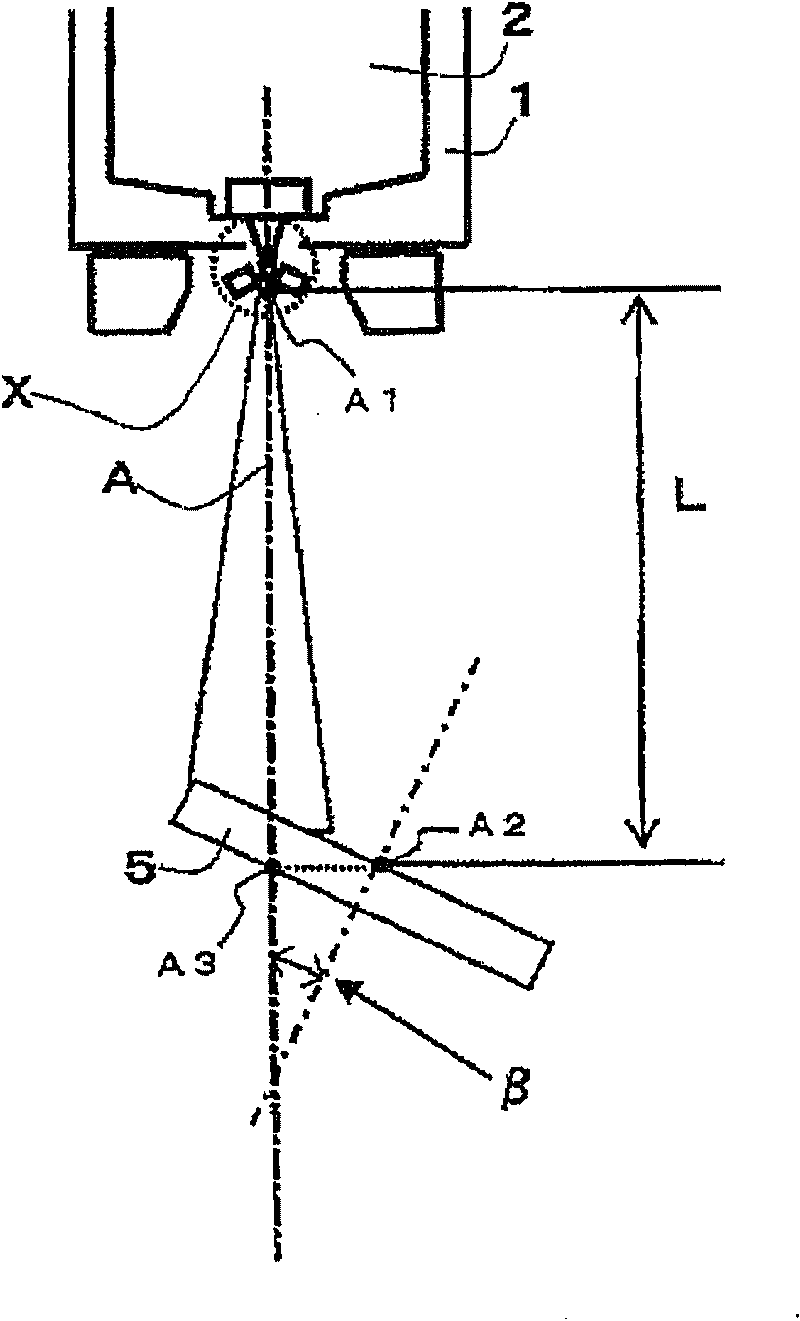

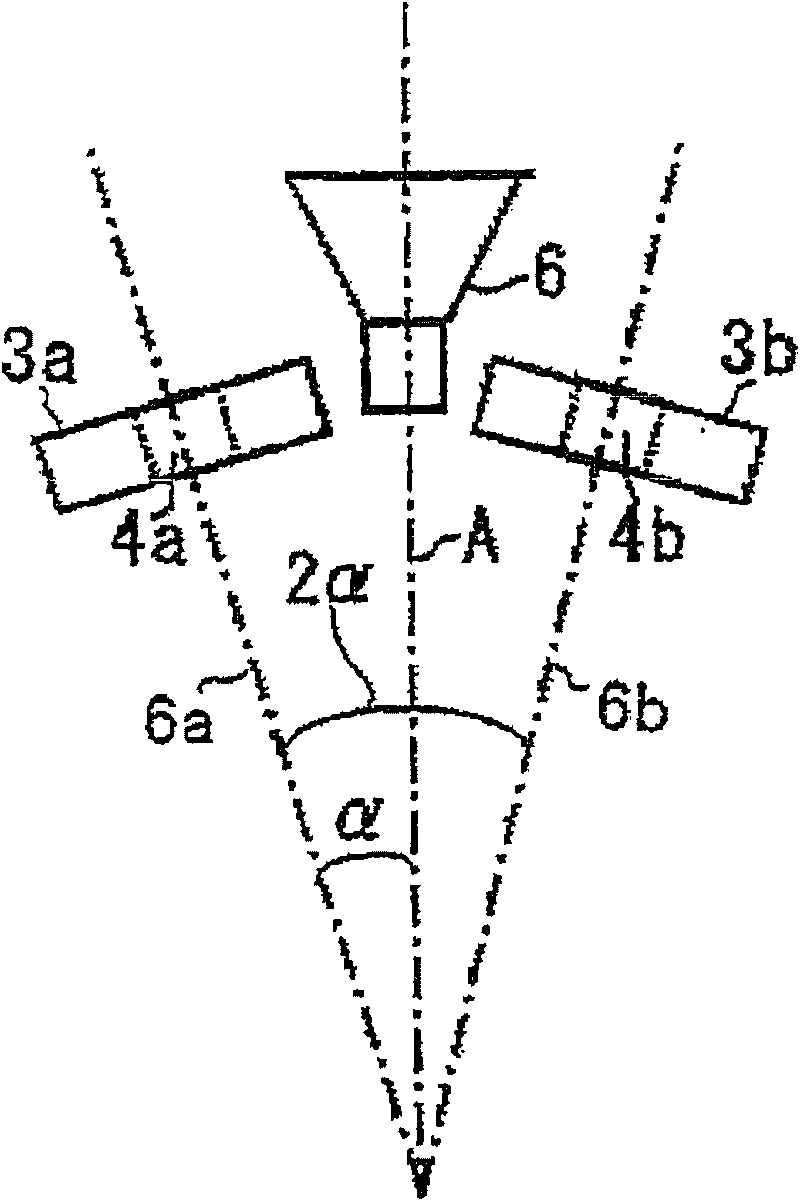

[0113] Aerosolizer outlet angle α (see figure 2 ): 7°

[0114] Collector Angle β: 35°

[0115] The preform obtained as described above was enclosed in a container for degassing, and the entire container was subjected to hot isostatic pressing (HIP) to obtain a dense body of Al—Ni—Cu—La alloy. HIP treatment was carried out under the conditions of HIP temperature of 550° C., HIP pressure of 85 MPa, and HIP time of 2 hours.

[0116] Then, the obtained dense body is forged to form a plate-shaped metal material, and then rolled so that the thickness of the plate becomes approxim...

Embodiment 2

[0147] Next, use the Al-Co-Ge-La alloy (Table 3, Table 4), use the same method and conditions as in Example 1 (excluding the conditions shown in Table 3, Table 4) to produce Al-based alloy sputtering Target (sample) (No. 34-66). The Vickers hardness (HV) of the obtained Al-based alloy sputtering target was measured, and a sputtering test was performed, thereby evaluating the occurrence of initial spattering.

[0148]

[0149]

[0150] In table 3, table 4, Co (at %) represents the content (at %) of Co element, Ge (at %) represents the content (at %) of Ge element, La (at %) represents the content (at %) of La element ). From Table 3 and Table 4, the following contents can be known. Numbers 34~43, 45~47, 50~52, 54~56, 58~60, 63~65 are due to proper control of the Vickers hardness (HV) of the Al-Co-Ge-La alloy sputtering target, so the initial The number of splashes is less than 8 / cm 2 , which has the effect of reducing the initial splash.

[0151] On the other hand, t...

Embodiment 3

[0161] Next, using Al-Ni-Ge-Nd alloys (Table 5, Table 6), through the same method and conditions as in Example 1 (excluding the conditions shown in Table 5, Table 6), Al-based alloys were produced Sputtering target (sample) (No. 67-99). The Vickers hardness (HV) of the obtained Al-based alloy sputtering target was measured, and further a sputtering test was performed to evaluate the occurrence of initial spattering.

[0162]

[0163]

[0164] In Table 5 and Table 6, Ni (at %) represents the content (at %) of Ni element, Ge (at %) represents the content (at %) of Ge element, Nd (at %) represents the content (at %) of Nd element ). From Table 5 and Table 6, we can know the following contents. Numbers 67~76, 78~80, 83~85, 87~89, 91~93, 96~98 due to proper control of the Vickers hardness (HV) of the Al-Ni-Ge-Nd alloy sputtering target, the initial splash The occurrence number is less than 8 / cm 2 , which has the effect of reducing the initial splash.

[0165] On the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com