A kind of preparation method of indium gallium zinc oxide powder and its ceramic target material

A technology of indium gallium zinc oxide and ceramic targets, which is applied in chemical instruments and methods, gallium/indium/thallium compounds, zinc oxide/zinc hydroxide, etc., can solve the problem of reducing target service life, affecting target density, Resistivity uniformity, affecting the performance of TFT devices and other issues, to achieve the effect of reducing abnormal discharge, small grains, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

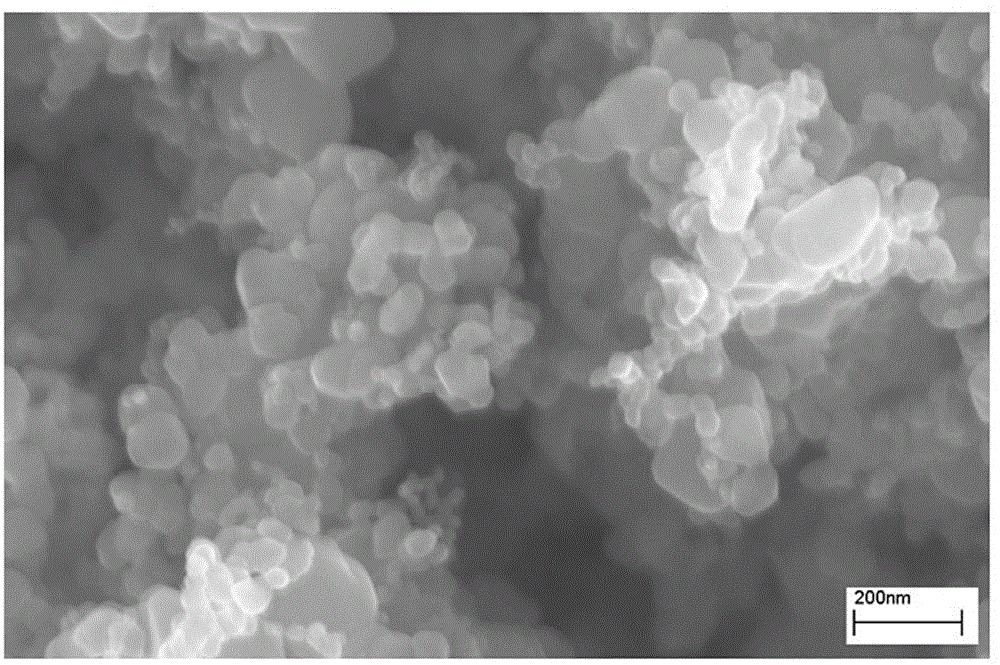

[0040] Using metal indium, gallium chloride, and zinc chloride with a purity of 99.99% as raw materials, according to the ratio of In:Ga:Zn=1:1:1, weigh 36.6g of metal indium, 102.0g of gallium chloride hydrate, and Zinc 43.5g. Dissolve indium with 36% concentrated hydrochloric acid. After indium is completely dissolved, mix gallium chloride, zinc chloride and indium solution evenly. The concentration of indium ions is 1.0mol / L. Stir the solution at a speed of 200 rpm in a water bath, control the reaction temperature at 40° C., and quickly add concentrated ammonia water with a concentration of 25%. When the pH of the reaction solution is 6.5, stop adding ammonia water, continue to stir for more than 2 hours, and then age for more than 6 hours. Wash the precipitate with deionized water until the conductivity is less than 20us / cm, then wash with alcohol, and dry the precipitate to constant weight. Calcining the obtained hydroxide powder at 700°C for more than 2 hours to obtain...

Embodiment 2

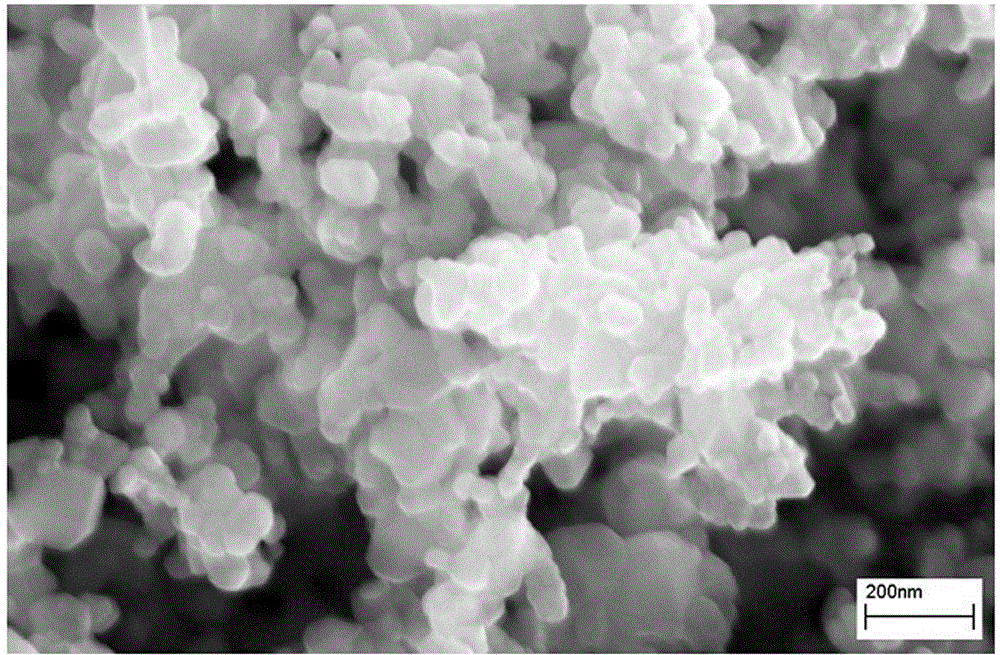

[0042] Using metal indium, gallium chloride, and zinc chloride with a purity of 99.99% as raw materials, according to the ratio of In:Ga:Zn=2:2:1, weigh 22.2509g of metal indium with an electronic balance, and use 36% concentrated Hydrochloric acid dissolves indium, after the indium is completely dissolved, add 79.2010g hydrated GaCl 3 , 13.1919g ZnCl 2 , stir it evenly, and the indium ion concentration is 1.0mol / L. Stir the solution at a speed of 200 rpm in a water bath, control the reaction temperature at 10° C., and quickly add concentrated ammonia water with a concentration of 25%. When the pH of the reaction solution is 7.5, stop adding ammonia water dropwise, continue to stir for more than 2 hours, and then age for more than 6 hours. Wash the precipitate with deionized water until the conductivity is less than 20us / cm, then wash with alcohol, and dry the precipitate to constant weight. The obtained hydroxide powder was calcined at 800°C for more than 2 hours to obtain...

Embodiment 3

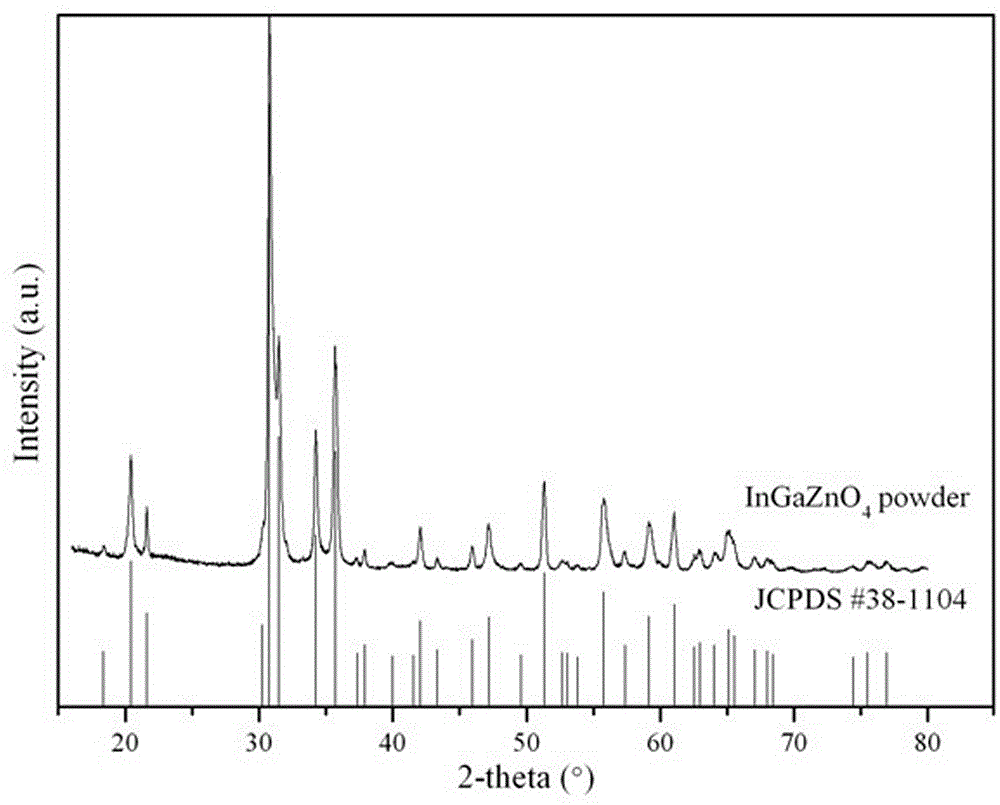

[0044] Prepared InGaZnO with the synthetic technique of embodiment 1 4 The powder is 1000g, and the PVA solution with a concentration of 3wt% is used as a binder. Add 10g of binder to the powder for granulation, and use a circular stainless steel mold with a diameter of 100mm to mold it to prepare a green body with a thickness of 5mm. The molded green body is degreased at 600°C for 6h, and then sintered at 1450°C for 6h after degreasing. The sintering atmosphere is air. The density of the sintered body is 97.5%, and the resistivity is 9.5×10 -2 ? cm. The X-ray diffraction spectrum of the target is as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com