Electric spark discharge machining method of free electrodes and equipment thereof

A technology of electrical discharge machining and electric spark, which is applied in the direction of electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of tool electrode loss, workpiece material removal, tool electrode can not be reused, etc., to improve discharge conditions and uniform size , Reduce the effect of abnormal discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

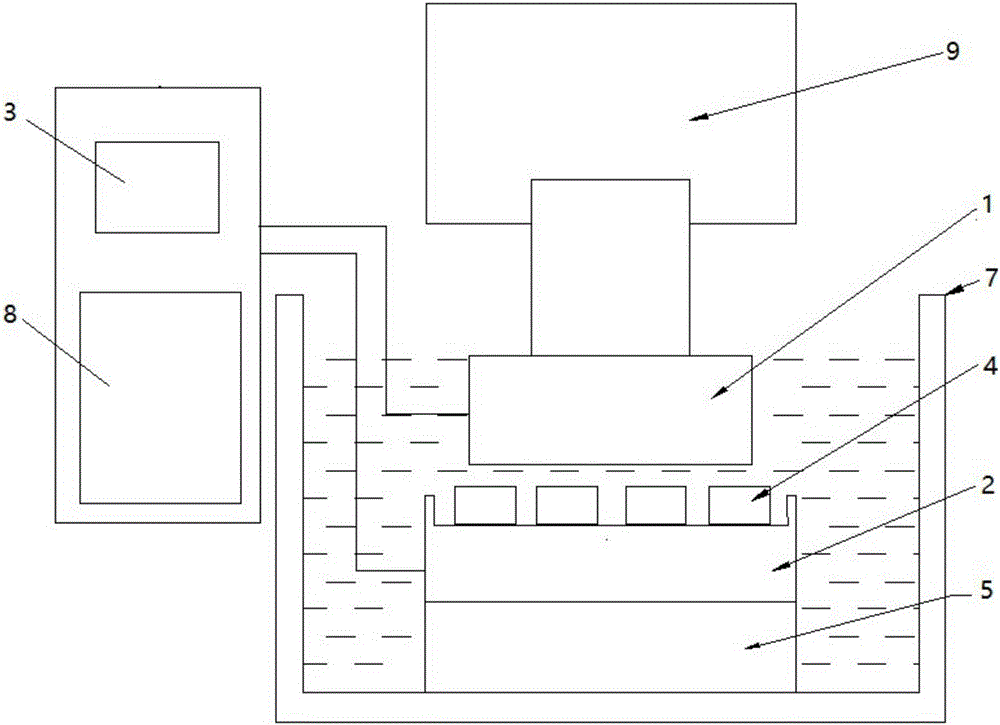

[0026] An electric spark discharge machining method of free electrodes, the workpiece 1 and the tool electrode 2 are respectively connected to the positive and negative poles of the pulse power supply 3, the free electrodes 4 with the same shape and uniform size move on the surface of the tool electrode 2, during the electric discharge machining process , the workpiece 1, the tool electrode 2 and the free electrode 4 are all immersed in the insulating medium, and the free electrode 4 is powered by the tool electrode 2, and the moving free electrode 4 generates electric spark discharge with the workpiece 1 to be processed, and then removes the surface of the workpiece 1 material, and finally copy the shape of the tool electrode 2 on the workpiece 1 to realize the processing of the part.

[0027] Such as figure 1 As shown, the EDM equipment of the free electrode for realizing the method includes a working medium tank, a workpiece 1, a pulse power supply 3 and a tool electrode 2,...

Embodiment 2

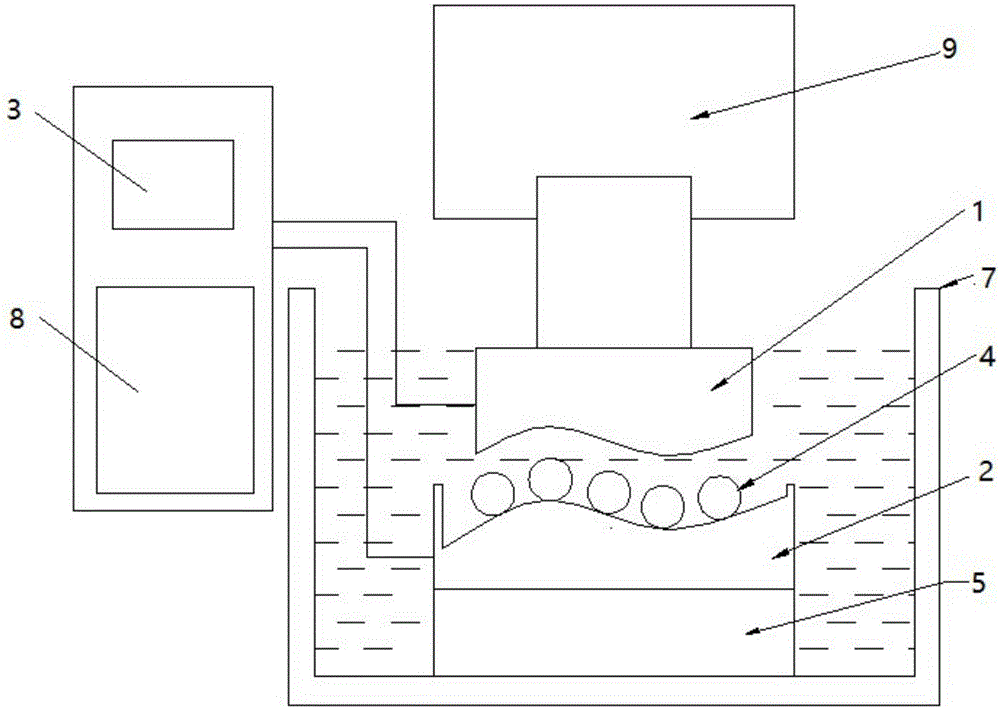

[0030] Such as figure 2 As shown, the workpiece 1 is placed above the tool electrode 2, the workpiece 1 is connected to the negative pole of the pulse power supply 3, and the tool electrode 2 is connected to the positive pole. The material types of the workpiece 1, the tool electrode 2 and the spherical free electrode 4 are stainless steel, brass and No. 45 steel respectively, and the radius of the spherical free electrode 4 is 2 cm. The working medium is special oil for EDM, the open circuit voltage is 120V, the peak current is 25A, the pulse width is 80μs, and the pulse interval is 40μs. The moving magnetic field generated by the magnetic control device 5 drives the free electrode 4 to reciprocate back and forth, so that the free electrode 4 can It moves on the entire surface of the tool electrode 2 at a speed of 0.05m / s. The detection servo system 8 of the EDM equipment controls the feed device 9 to drive the workpiece 1 close to the tool electrode 2 and check the gap to ...

Embodiment 3

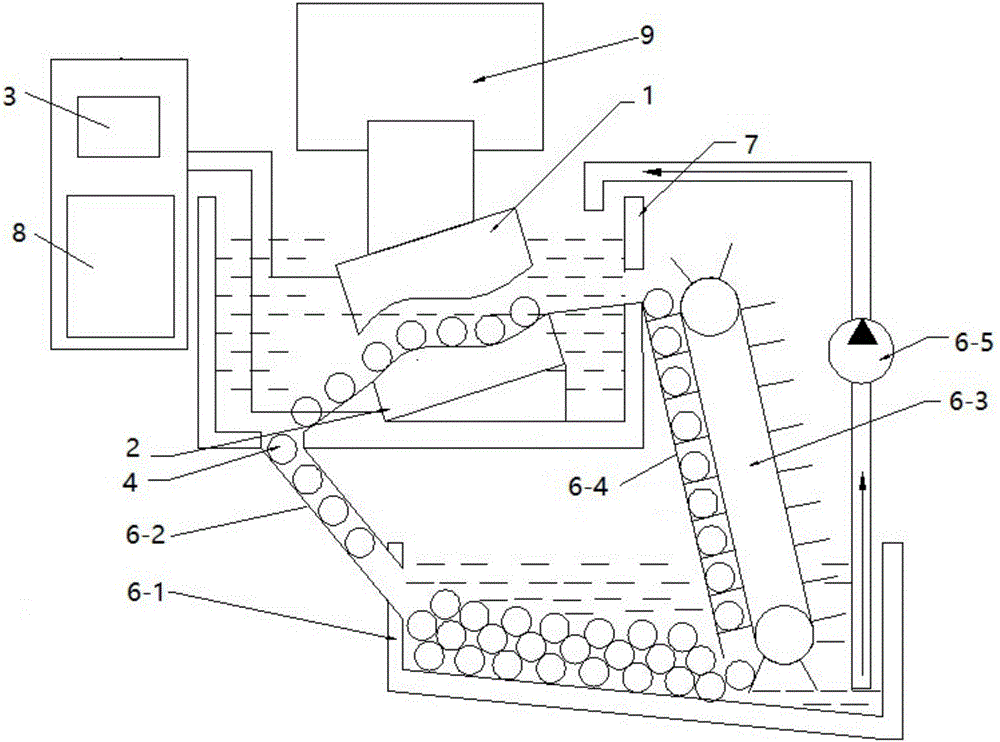

[0032] An electric spark discharge processing equipment with free electrodes, comprising a working medium tank, a workpiece 1, a pulse power supply 3 and a tool electrode 2, the workpiece 1 and the tool electrode 2 are respectively connected to the positive and negative poles of the pulse power supply 3, and the free electrodes 4 have the same shape, The size is uniform, the tool electrode 2 is located below the workpiece 1, the surface of the tool electrode 2 has an inclination, and the free electrode 4 uses the inclination of the surface of the tool electrode 2 to move from a high point to a low point on the surface of the tool electrode 2 under the action of its own gravity. After the point is recovered by the free electrode recovery device, the free electrode recovery device retransmits the recovered free electrode 4 to the high point on the surface of the tool electrode 2, so that the surface of the tool electrode 2 is continuously moved by the free electrode 4.

[0033]Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com