Sputtering target material and sputtering device

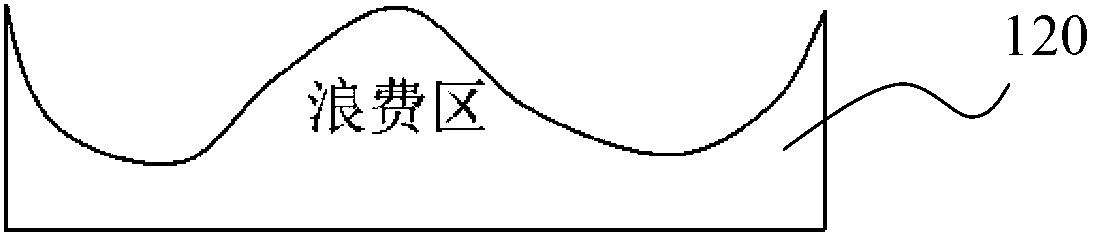

A sputtering target and sputtering device technology, which is applied in sputtering coating, metal material coating process, ion implantation coating, etc., can solve the problems of uniform distribution of plasma 120, low target utilization rate, and target Eliminate material consumption and other issues, achieve the effect of improving film quality uniformity, increasing service life, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

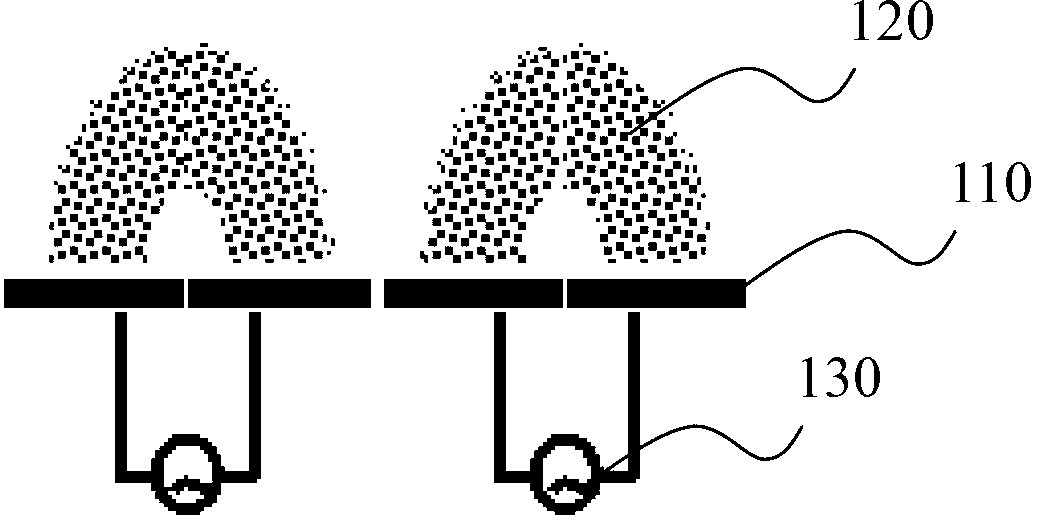

[0020] Figure 4 Shown is a schematic structural view of a sputtering target described in this embodiment, the sputtering target includes a plurality of first blocks A and a plurality of second blocks B, and the plurality of first blocks A and the second block B are distributed in multiple rows and columns, wherein the first block A and the second block B in each row are staggered, and in each column the first block A and the second block Block B is also staggered.

[0021] The first sub-block A and the second sub-block B of the above-mentioned row and column staggered distribution are respectively connected to two electrodes with opposite polarities of the AC power supply when in use. When the two electrodes of the AC power supply are switched between forward and reverse polarity, The first block A and the second block B also switch the anode and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com