fe-co alloy sputtering target material and soft magnetic thin film layer, and perpendicular magnetic recording medium using it

A technology of sputtering target materials and alloys, which is applied in the directions of magnetic recording, magnetic layer coating, sputtering coating coating, etc., and can solve the problems of particles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

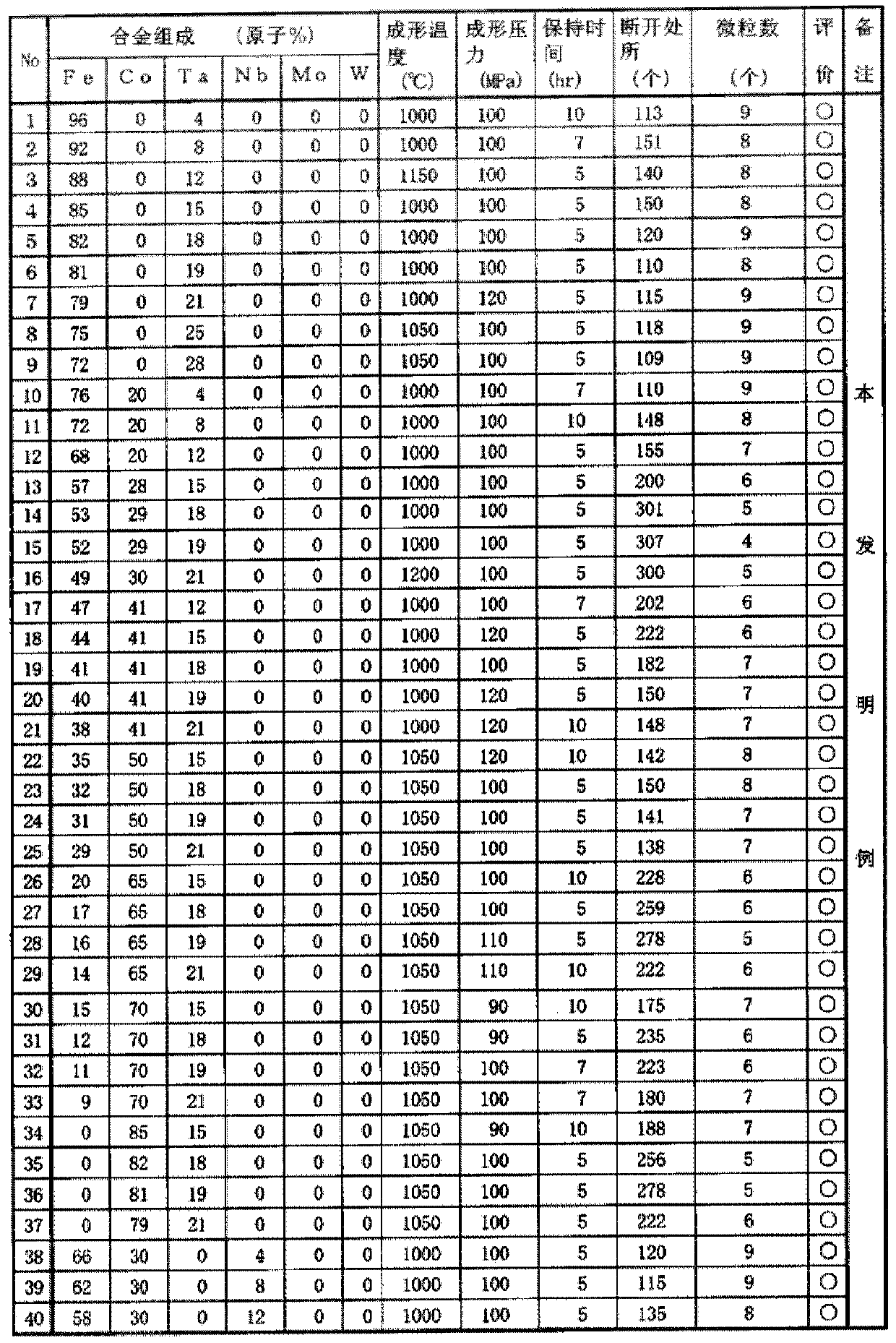

[0045] Hereinafter, the present invention will be specifically described by way of examples.

[0046] With the compositions shown in Tables 1 to 4, soft magnetic alloy powders were prepared by a gas atomization method. The obtained powder was classified to 500 μm or less, and used as a raw material powder for HIP molding (hot isostatic pressing). The billet for HIP molding is produced by filling a carbon steel tank with a diameter of 250mm and a length of 50mm, filling the raw material powder, and then vacuum degassing and sealing. With respect to this powder-filled billet, HIP molding was performed under the conditions of molding pressure, molding temperature, and holding time shown in Tables 1-4. Thereafter, a sputtering target with a diameter of 180 mm and a thickness of 7 mm was produced from the compact.

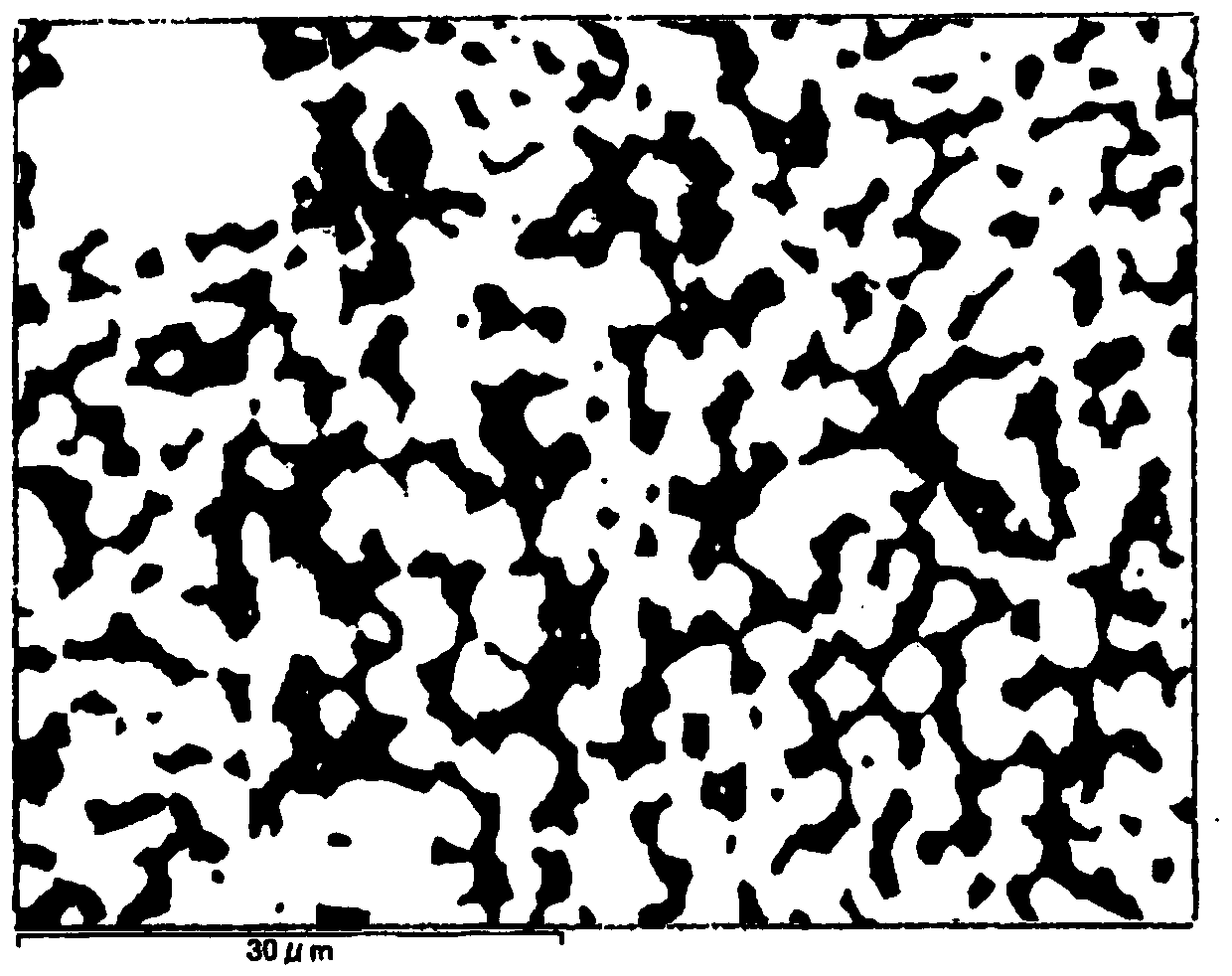

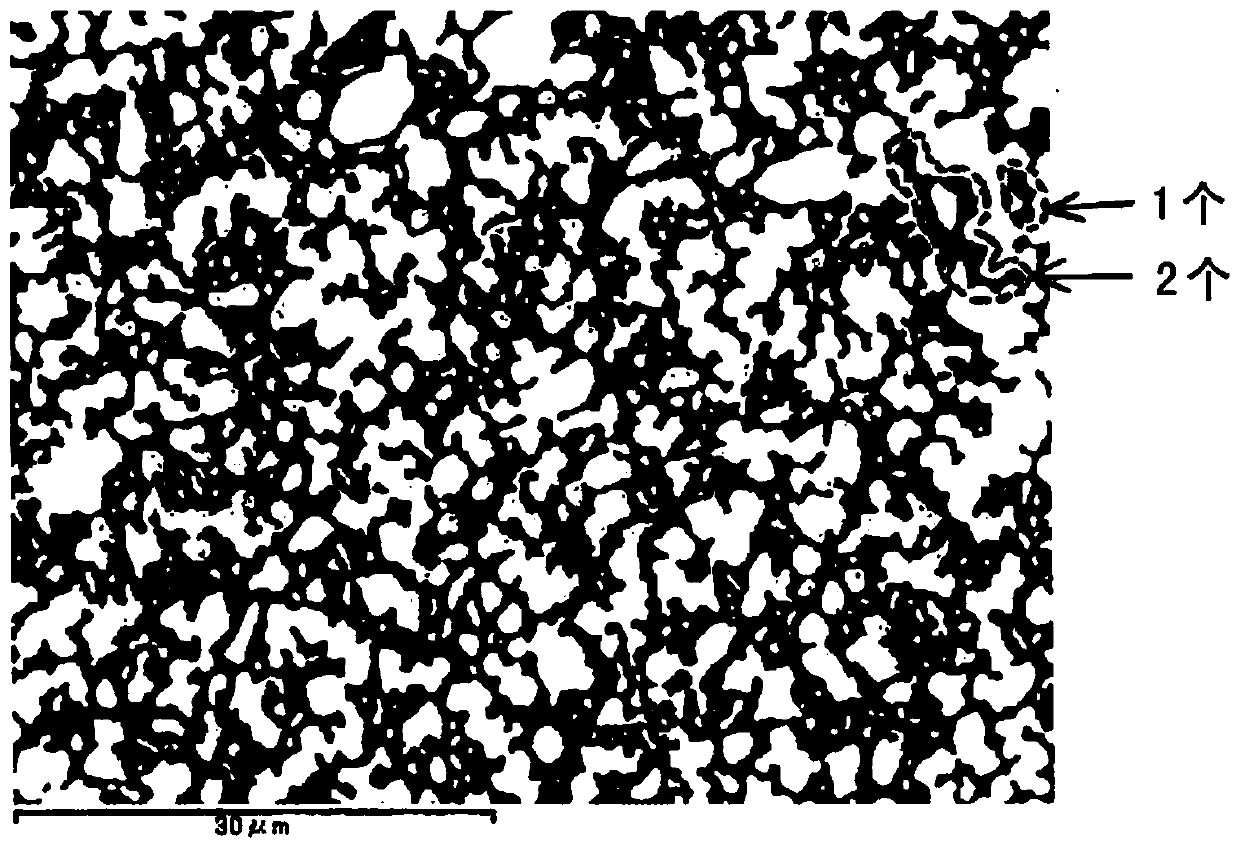

[0047] It has a phase mainly composed of Fe and Co, and an intermetallic compound phase containing one or two of Fe and Co and M elements, and the phase of one or two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com