Sb-te base alloy sinter sputtering target

A technology of base alloy and sintered body is applied in the field of Sb-Te base alloy sintered body sputtering target, which can solve the problems of target cracking, inability to add additives, and easy occurrence of abnormal discharge, and achieve the effect of suppressing particle generation and preventing abnormal discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Ag, In, Sb, and Te powder raw materials with a purity of 4N or higher, except for gas components, are used to form Ag 5 In 5 Sb 70 Te 20 Alloys are formulated and synthesized, and mechanically pulverized in an inert atmosphere. Thus, a powder (X) having an average particle size of 8.0 μm as shown in Table 1 was obtained.

[0064] Next, the powder is divided into four types (1), (2), (3), and (4). In each powder, 5 atomic % of the average particle diameters shown in Table 1 are mixed to be 30 nm, 50 nm, 7 nm, 750nm carbon powder (Y), and hot press. The sintered body thus obtained is machined and then ground to produce an Ag containing a predetermined amount of carbon. 5 In 5 Sb 70 Te 20 alloy target.

[0065] The target has a structure in which fine carbon particles surround Sb-Te-based alloy particles. The ratio and density of Y / X are shown in Table 1. The generation of cracks was not observed on the target at all.

[0066] Sputtering was performed on a sili...

Embodiment 2

[0073] Use a gas atomization device, and use argon (100kgf / cm 2 ) as sparge gas at 780°C for Ge 22.2 Sb 22.2 Te 55.6 Alloy raw materials are sprayed to produce atomized powder. Thus, a completely spherical powder is obtained.

[0074] As this gas atomized powder, powder (X) having a particle size with an average diameter of 32.0 μm as shown in Table 2 was obtained. Next, divide the powder into four types (1), (2), (3), and (4), and in each powder, mix 5 atomic % of the average particle diameters shown in Table 2 as 30nm, 50nm, 7nm, and 750nm Carbon powder (Y), and hot pressing.

[0075] The sintered body thus obtained is machined and then ground to produce Ge 22.2 Sb 22.2 Te 55.6 alloy target. The ratio and density of Y / X are shown in Table 2.

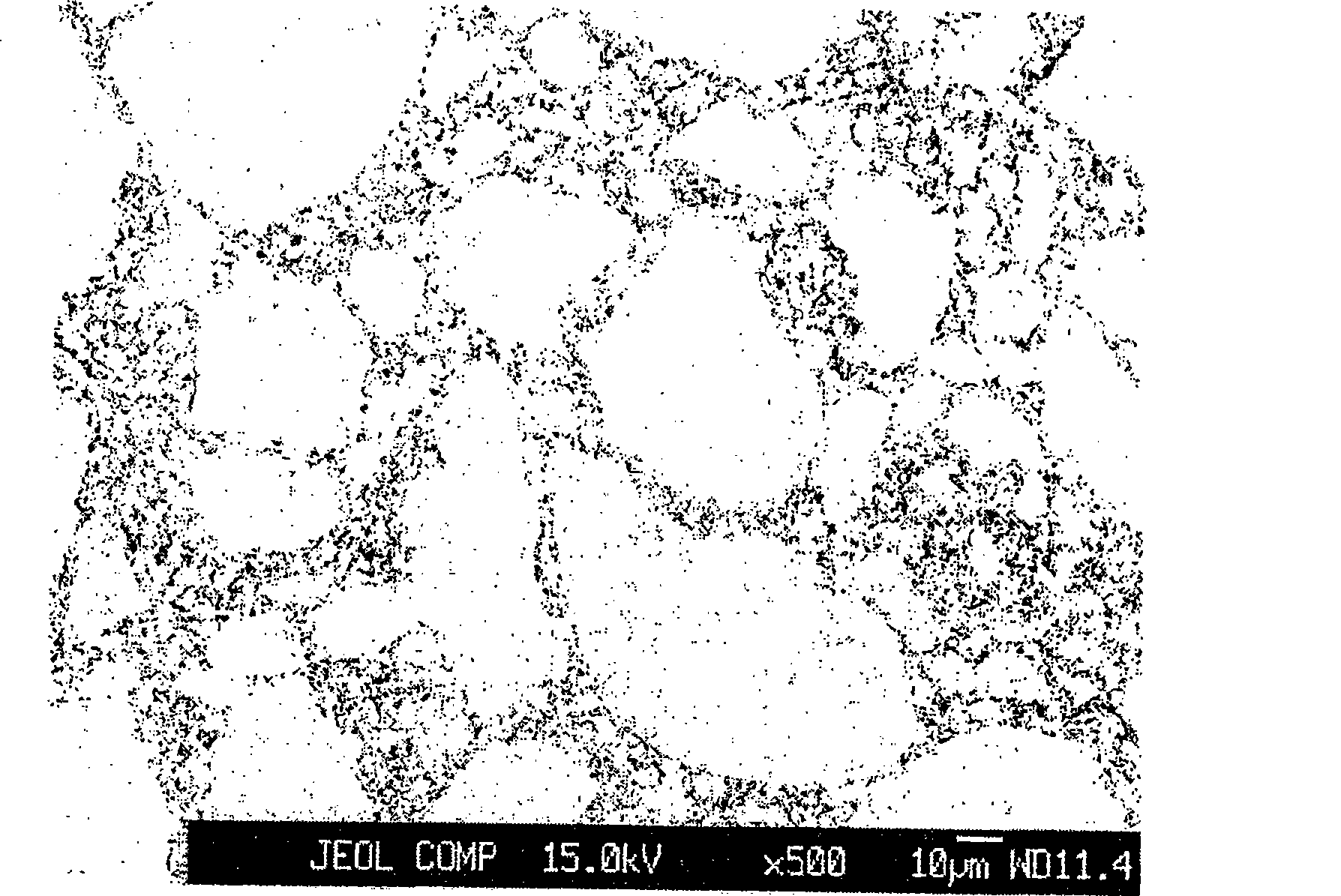

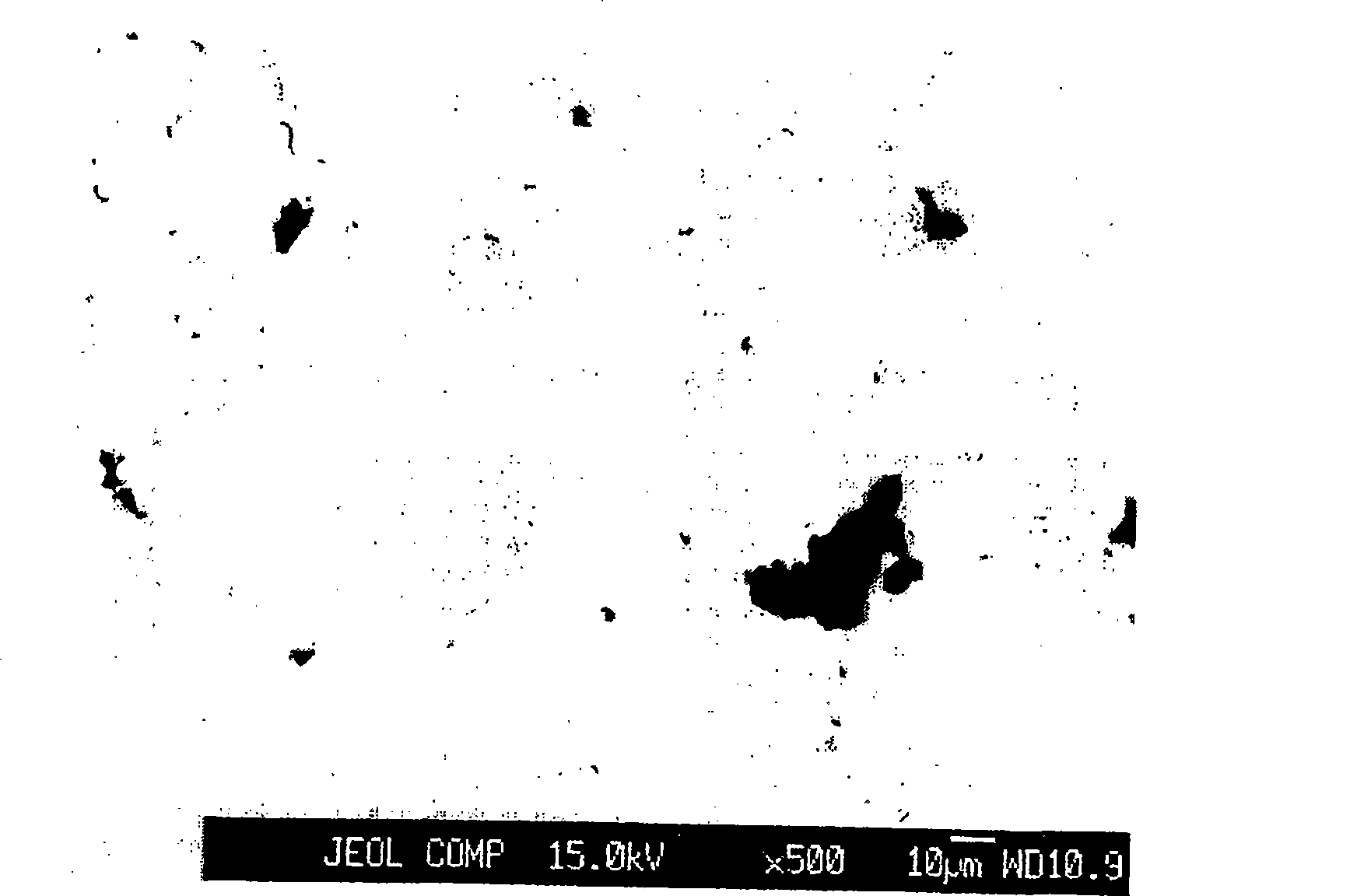

[0076] The SEM photographs of the thus obtained target surface are shown in figure 1 . as it should figure 1 As shown, no defects such as cracks were observed at all, and there was a structure in which Sb—Te-based alloy pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative density | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com