Vacuum electric arc deposition equipment

A technology of vacuum arc and deposition equipment, which is applied in the direction of vacuum evaporation plating, circuit, discharge tube, etc., and can solve the problem of low degree of freedom of layered film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

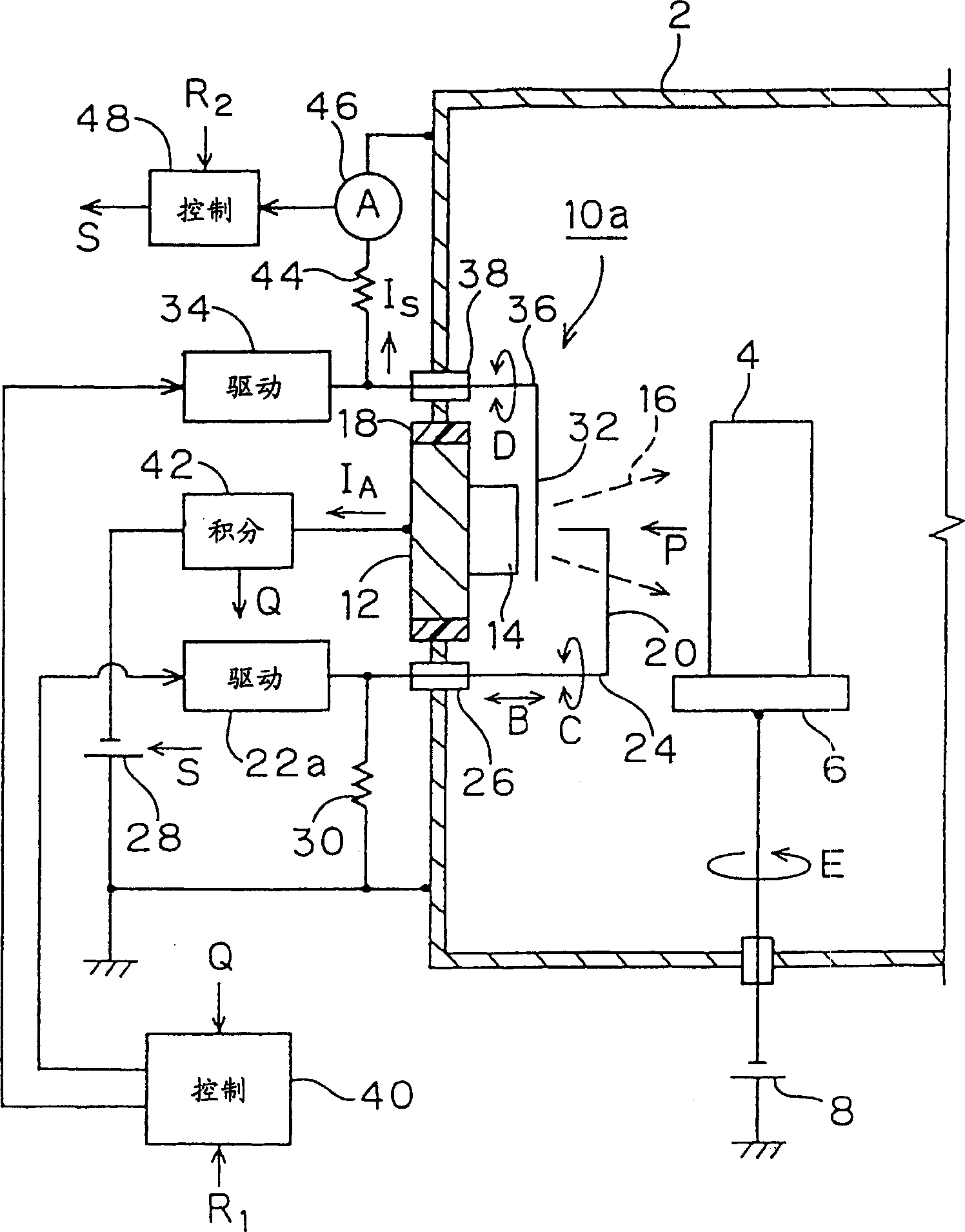

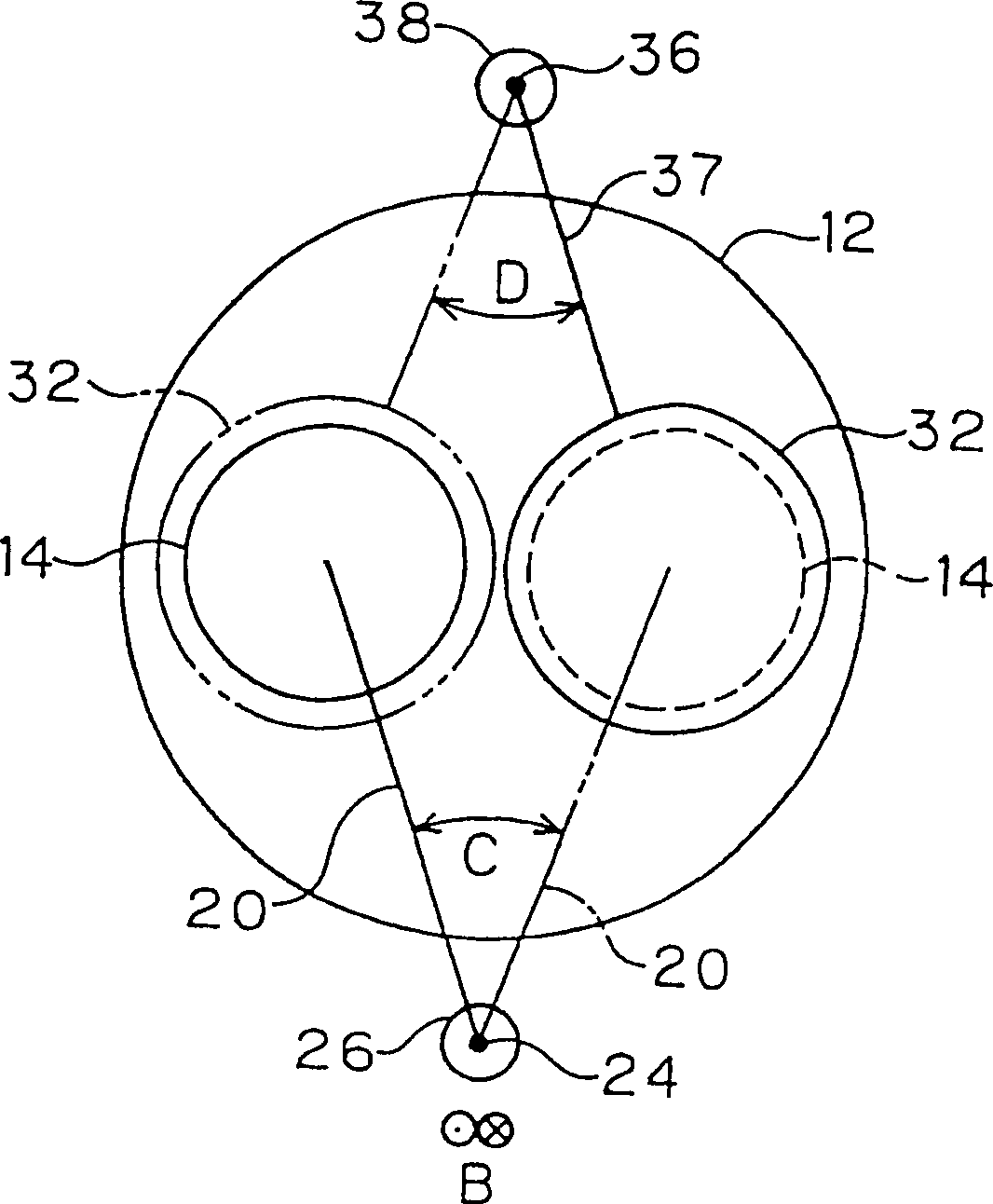

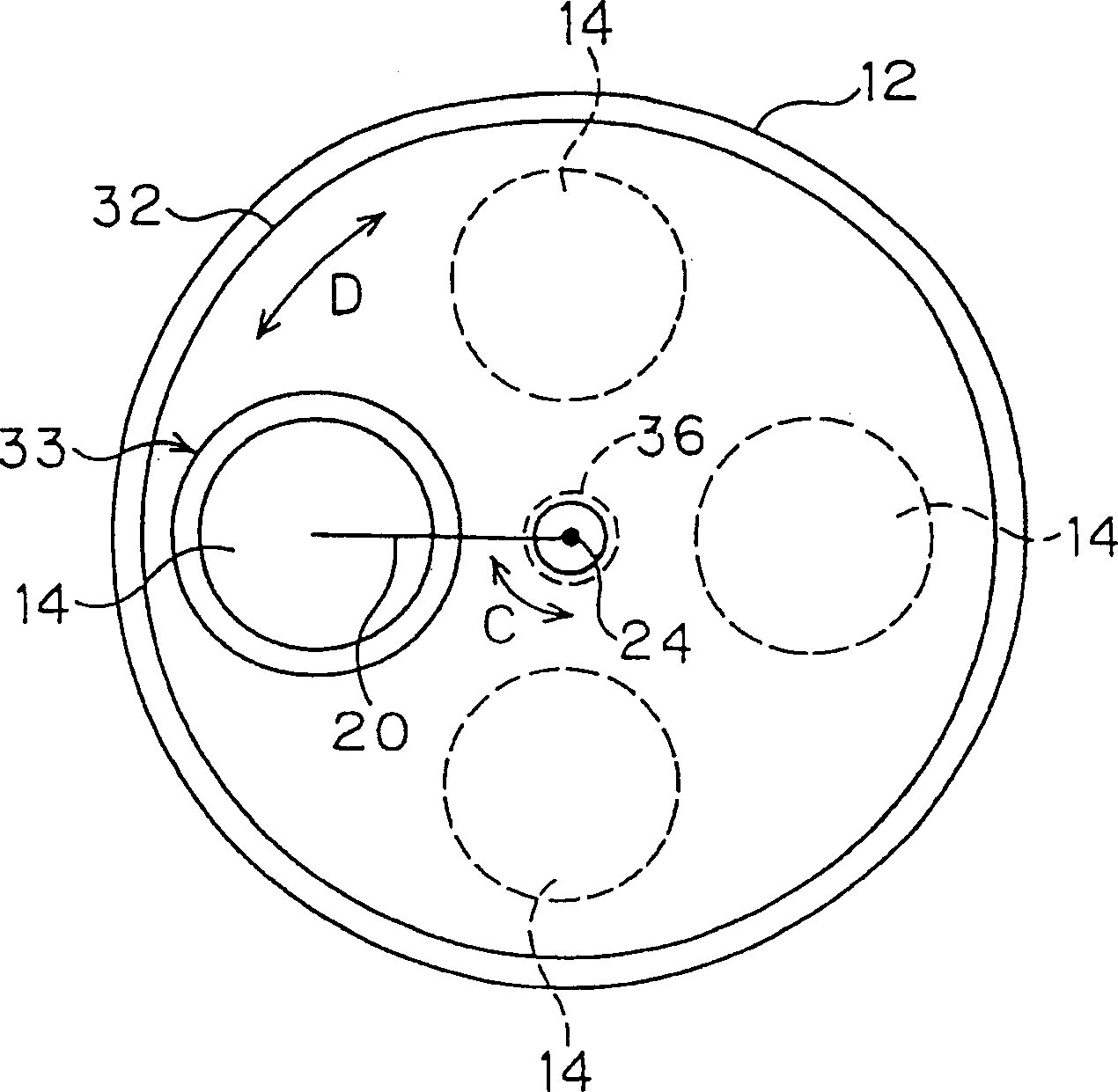

[0034] figure 1 is a sectional view showing an embodiment of a vacuum arc deposition apparatus according to the present invention. figure 2 From figure 1 The front view obtained by looking in the direction of the arrow P in , shows an example of the peripheral portion of the cathode in an arc evaporation source used in the vacuum arc deposition apparatus according to the present invention. Correspondingly, in this embodiment with Figure 4 , 5 The same or corresponding parts in the shown prior art examples will be designated with the same numerals, and the following will mainly focus on their differences from the prior art examples.

[0035] The vacuum arc deposition apparatus of the present invention has an arc evaporation source 10a instead of the arc evaporation source 10 in the prior art. As discussed above, the number of arc evaporation sources 10a may be one or more.

[0036] In this embodiment, the arc evaporation source 10a has: a cathode holder 12 as described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com