Plasma process apparatus

a plasma process and plasma technology, applied in the direction of chemical vapor deposition coating, electric discharge tube, coating, etc., can solve the problems of difficult to produce high density plasma at relatively low pressure in the rf plasma apparatus, low etching rate, and more damage to device elements on the wafer, so as to improve the performance or quality of the plasma process, improve the uniformity and controllability of plasma density, and be easily monitored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

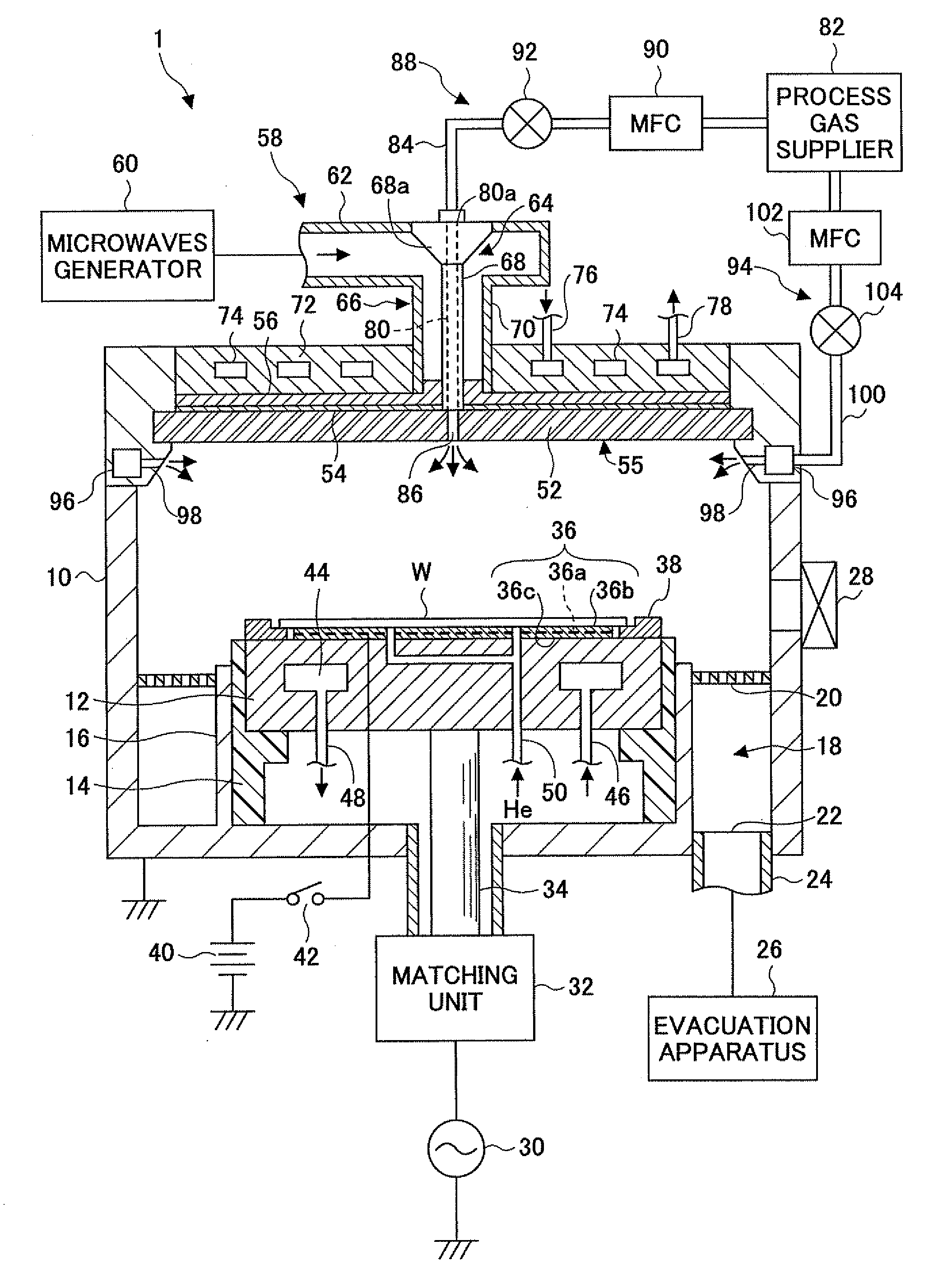

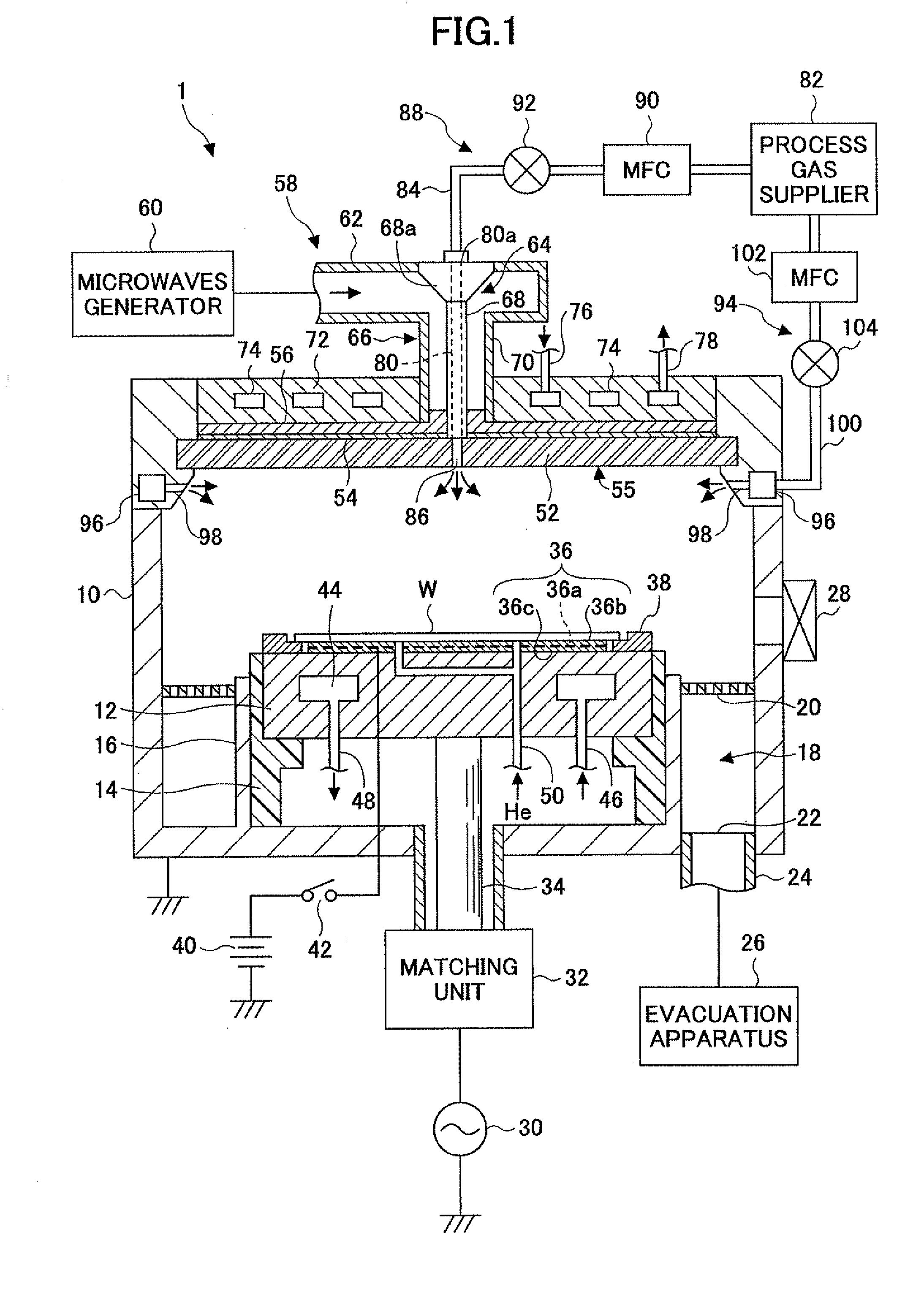

[0047]FIG. 1 is a schematic cut-open view of a microwave plasma etching apparatus 1 according to a first embodiment of the present invention. The microwave plasma etching apparatus 1, which is configured as a planar SWP type plasma process apparatus, has a cylinder-shaped chamber (process chamber) 10 made of metal such as aluminum or stainless steel. The chamber 10 is grounded for security reasons.

[0048]First, components or members, which do not directly contribute to generating the microwave plasma in the chamber 10 of the microwave plasma etching apparatus 1, are described.

[0049]In a lower center portion of the chamber 10, there is a susceptor 12 on which a semiconductor wafer W (referred to as a wafer W below) is placed. The susceptor 12 is horizontally supported by a cylindrical supporting portion 14 extending upward from the bottom of the chamber 10. The cylindrical supporting portion 14 is made of an insulating material. Additionally, the susceptor 12 is shaped into a circular...

second embodiment

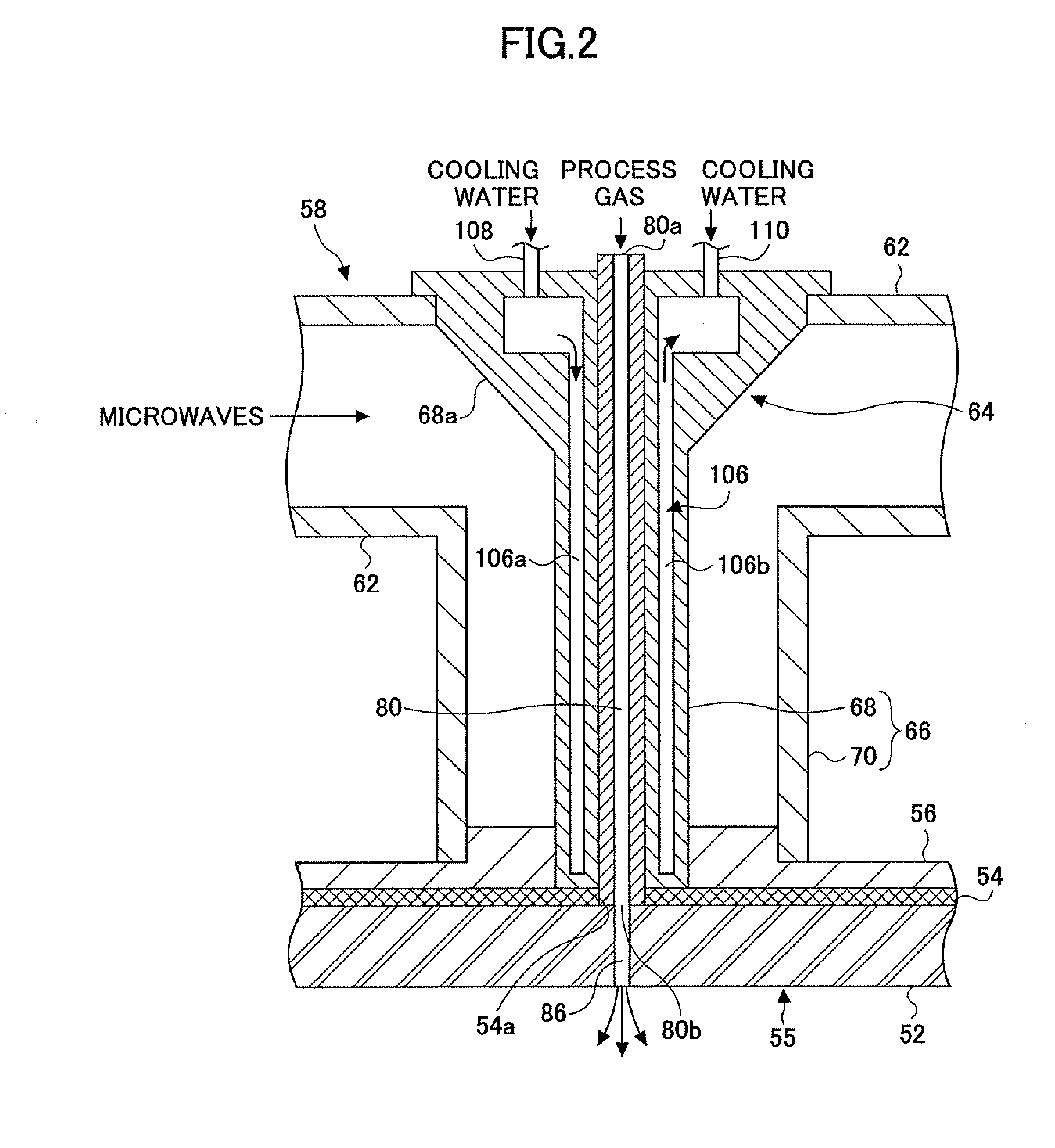

[0078]Referring to FIGS. 6 through 9, a plasma process apparatus according to a second embodiment of the present invention is described. FIG. 6 is a schematic cut-open view of the plasma process apparatus 2 according to the second embodiment of the present invention. While the plasma process apparatus 2 according to the second embodiment is operated, when etching the wafer W in substantially the same manner as the plasma process apparatus 1 according to the first embodiment, the plasma process apparatus 2 is different in a gas ejection configuration at the top center portion of the chamber 10 from the plasma process apparatus 1 according to the first embodiment of the present invention. The following explanation is focused on the difference.

[0079]As shown in FIG. 6, the gas conduit 80 goes through the inner conductor 68 of the coaxial pipe 66, and the top portion of the gas conduit 80 is connected to the process gas supplier 82 through the first gas supplying pipe 84, which places t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com