Aluminum-scandium alloy target blank, and preparation method and application thereof

An alloy target and aluminum-scandium technology, applied in the field of aluminum-scandium alloys, can solve the problems affecting the use effect of scandium-aluminum alloy target blanks, the segregation of aluminum-scandium alloy ingots, affecting the use effect of target materials, etc., so as to achieve uniform microstructure and agglomerates. Less, the effect of stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

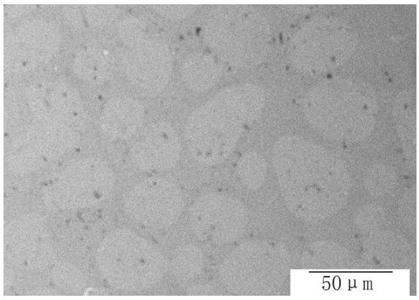

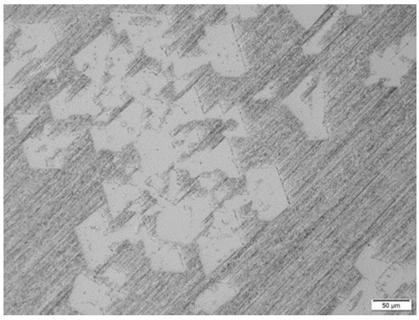

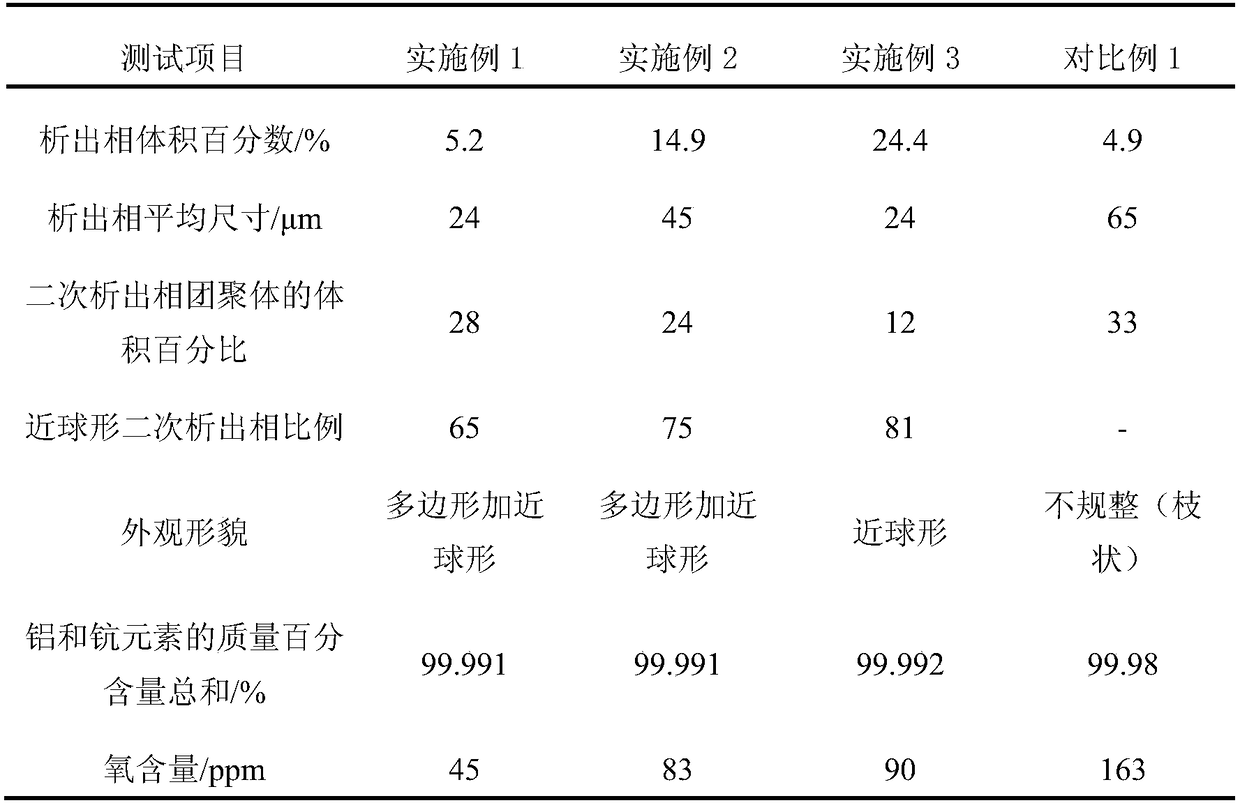

Examples

Embodiment 1

[0028] The smelting equipment adopts a 10kg vacuum suspension furnace, and the induction power supply is a real-time dual output power supply of 8kHz intermediate frequency and 200kHz high frequency.

[0029] According to the composition ratio of aluminum-scandium alloy, weigh 500g of metal scandium (purity is 99.98%), metal aluminum ingot 5700g (purity is 99.995%), then place the metal aluminum on the bottom of the water-cooled copper crucible, and then place the metal scandium on the metal On the aluminum block; close the furnace cover and vacuumize. When the vacuum reaches 0.5Pa, close the vacuum pumping valve, fill in high-purity argon to 0.07MPa, and close the argon valve; then open the vacuum valve and pump to 0.1Pa. , continue to fill with argon to 0.07MPa, start to heat up, gradually increase the power to the melting temperature of 1060°C, keep it at this temperature for 10 minutes, then reduce the power to make the molten metal temperature 970°C, set the output time of...

Embodiment 2

[0031] The smelting equipment adopts a 10kg vacuum suspension furnace, and the induction power supply is a real-time dual output power supply of 8kHz intermediate frequency and 200kHz high frequency.

[0032] According to the composition ratio of aluminum-scandium alloy, weigh 1500g metal scandium (purity is 99.98%), metal aluminum ingot 5000g (purity is 99.995%), then put the metal aluminum on the bottom of the water-cooled copper crucible, and then place the metal scandium on the metal On the aluminum block; close the furnace cover and vacuumize. When the vacuum reaches 0.06Pa, close the vacuum pumping valve, fill in high-purity argon to 0.07MPa, and close the argon valve; then open the vacuum pumping valve and vacuumize to 0.2Pa. , continue to fill with argon to 0.06MPa, start to heat up, gradually increase the power to the melting temperature of 1330°C, keep it at this temperature for 15 minutes, then reduce the power so that the temperature of the molten metal is 1220°C, s...

Embodiment 3

[0034] The smelting equipment adopts a 10kg vacuum suspension furnace, and the induction power supply is a real-time dual output power supply of 8kHz intermediate frequency and 200kHz high frequency.

[0035] According to the composition ratio of aluminum-scandium alloy, weigh 545g of scandium-containing master alloy with a stoichiometric ratio of Al-87Sc, and 5650g of metal aluminum ingot (purity is 99.995%), then place the metal aluminum on the bottom of the water-cooled copper crucible, and then put the aluminum Put the scandium master alloy on the metal aluminum block; close the furnace cover and vacuumize, when the vacuum reaches 0.5Pa, close the vacuum valve, fill high-purity argon to 0.07MPa, close the argon valve; then open the vacuum valve , evacuate to 0.1Pa, continue to fill with argon gas to 0.07MPa, start to heat up, gradually increase the power to the melting temperature of 1060°C, keep it at this temperature for 20min, reduce the power so that the temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com