Washing dryer

A technology for washing and drying machines and washing tanks, which is applied to washing devices, household clothes dryers, washing machines with containers, etc., and can solve problems such as abnormal discharges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

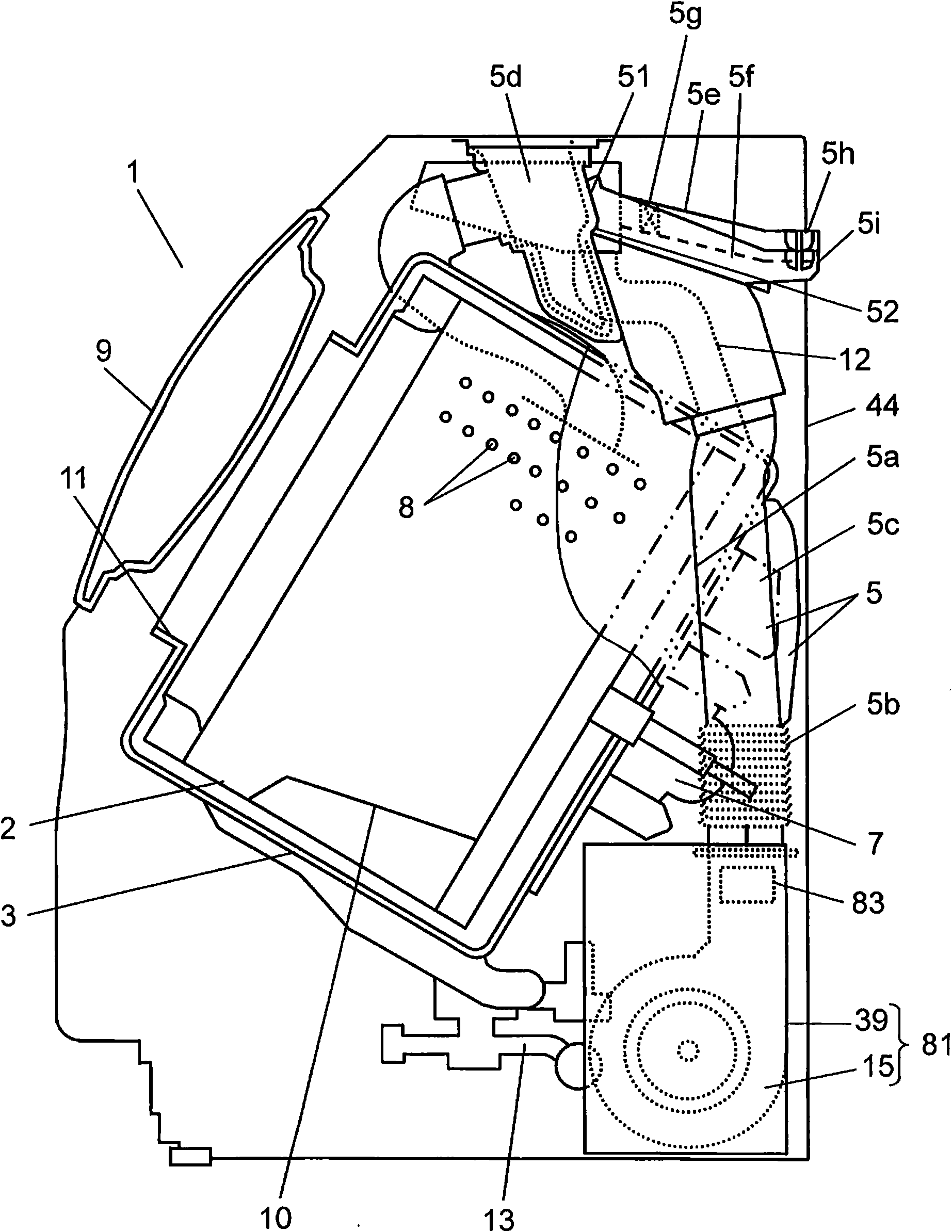

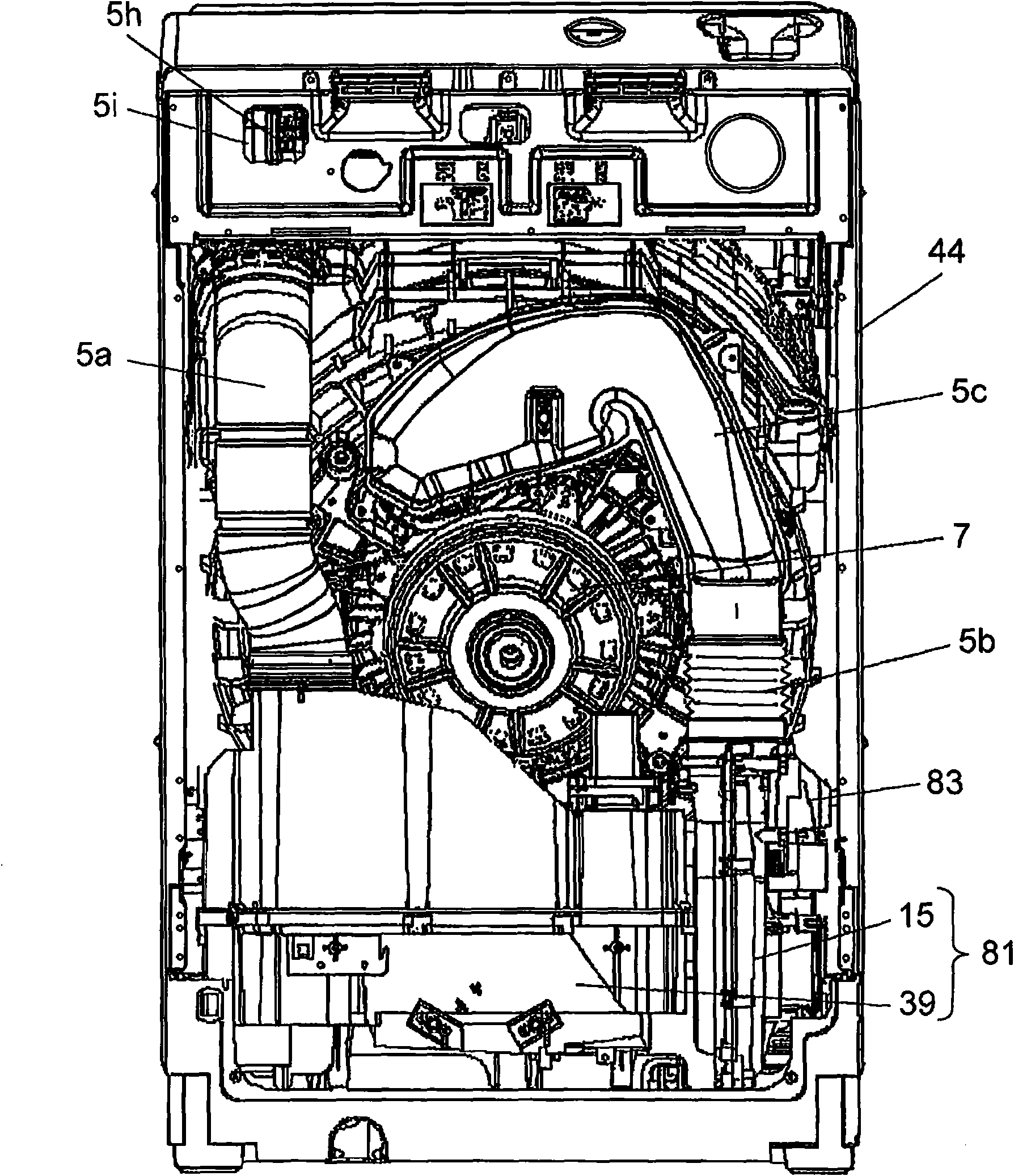

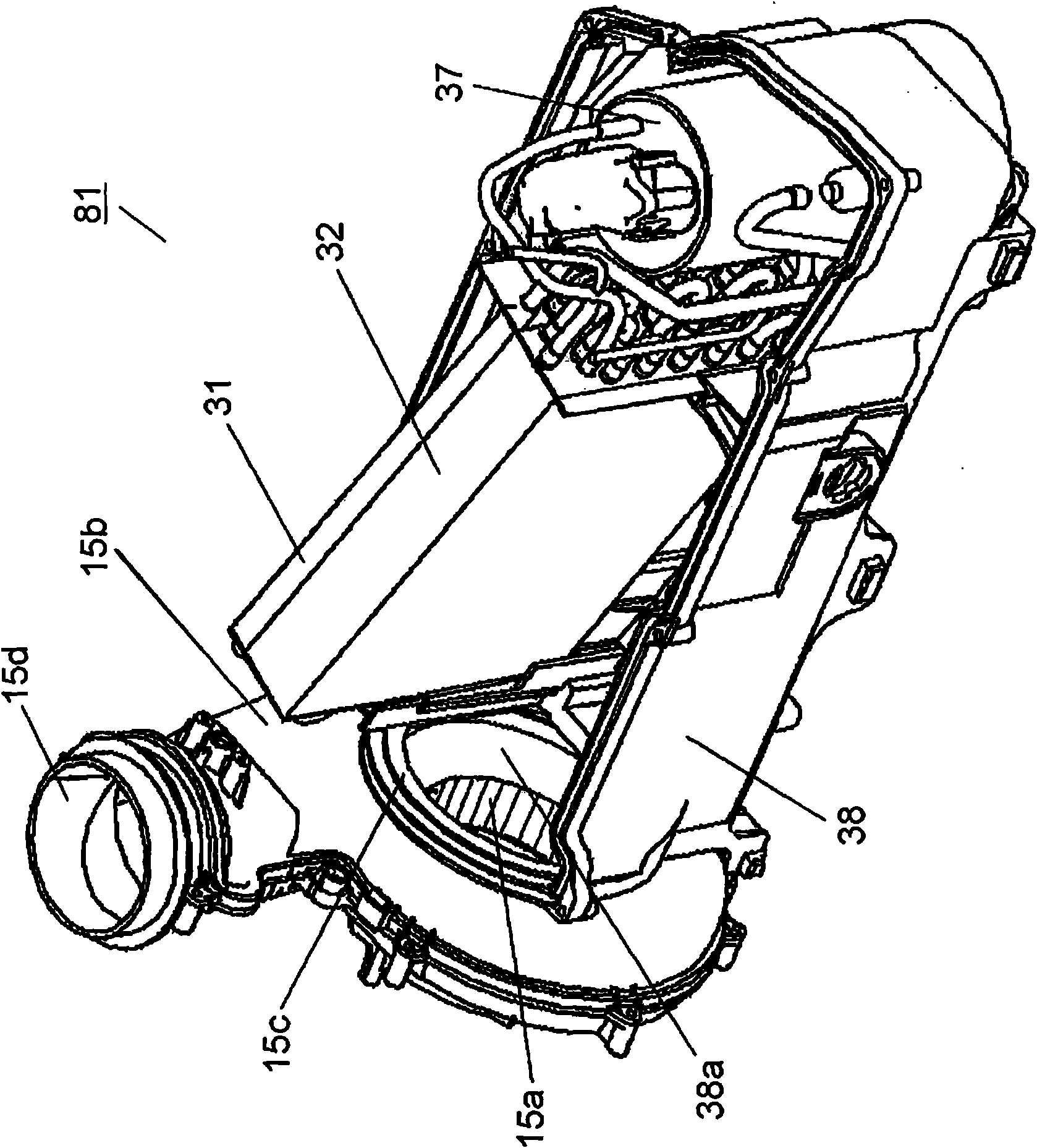

[0028] figure 1 It is a sectional view showing the structure of main parts of the washing and drying machine according to Embodiment 1 of the present invention, figure 2 is an internal rear view showing the circulating air supply path and the back of the outer tank of the washing and drying machine, image 3 It is a perspective view which shows the inside of the heat pump ventilation unit of this washing and drying machine.

[0029] Such as Figure 1 ~ Figure 3 As shown, in the washing and drying machine 1 , the washing tank 2 for accommodating laundry can be rotatably arranged in the outer tank 3 in such a way that its rotation axis direction is horizontal or inclined downward relative to the horizontal direction toward the rear. The washing and drying machine 1 has a drying process in addition to the processes of washing, rinsing, and dehydration.

[0030] The drying process is a process of repeating the following work to dry the laundry. The above work refers to: using ...

Embodiment approach 2

[0062] Figure 8 It is a longitudinal sectional view of the washing and drying machine according to Embodiment 2 of the present invention. In Embodiment 2 of the present invention, description of the same configuration, operation, and effect as Embodiment 1 will be omitted, and only differences will be described.

[0063] Such as Figure 8 As shown, the rotary drum 121 as the washing tank of the drum type washing and drying machine is formed in a bottomed cylindrical shape, and a plurality of through holes 122 are provided on the entire surface of the outer periphery thereof, and the rotary drum 121 is freely rotatably disposed on the Inside the bucket tank 123 as the outer tank. The rotating shaft 124 is provided at the center of rotation of the rotating drum 121 obliquely with respect to the horizontal direction, and the axial center direction of the rotating drum 121 is inclined downward from the front side toward the rear side. The rotating shaft 124 is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com