Machining method of target assembly

A processing method and target technology, applied in the target field, can solve the problems of affecting the conductivity of the target backplane, abnormal discharge, and affecting the quality of the sputtering target, so as to avoid abnormal discharge or power failure, ensure quality, Avoid the effect of conductivity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

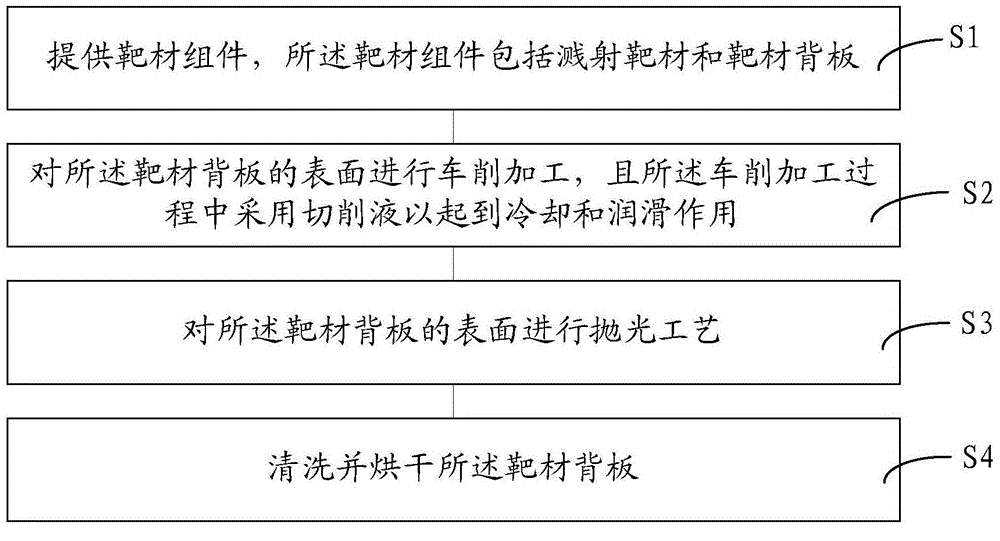

[0025] After analysis by the inventor, it is found that in the existing surface treatment process of the target back plate, there is no other surface treatment after the turning process of the target back plate, and the target back plate after the turning process is easily exposed to the air. Oxidation occurs, and the conductivity of the oxidized target backplane decreases, which in turn causes abnormal discharge or power failure of the sputtering target during the sputtering process, and even affects the final use of the sputtering target

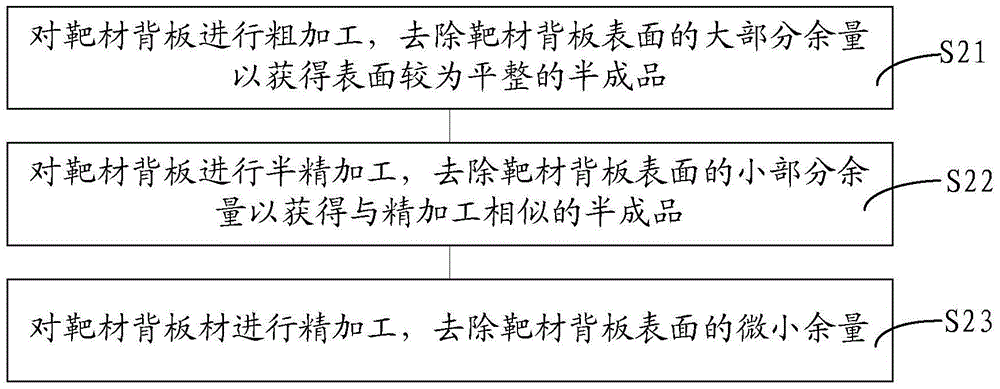

[0026] In order to solve the problem that the target backplane is easily oxidized in the prior art, the inventor of the present invention made further research on the surface treatment process of the target backplane, and found that adding a polishing process after the turning process of the target backplane can solve the problem of target backplane oxidation. The material backplane is easy to oxidize. Through this polishing process, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com