Device used for preventing display panel paradoxical discharge and display panel preparation system

A display panel and preparation system technology, applied in the direction of protection against damage caused by electrostatic discharge, static electricity, electrical components, etc., can solve problems such as abnormal discharge, ineffective effect, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

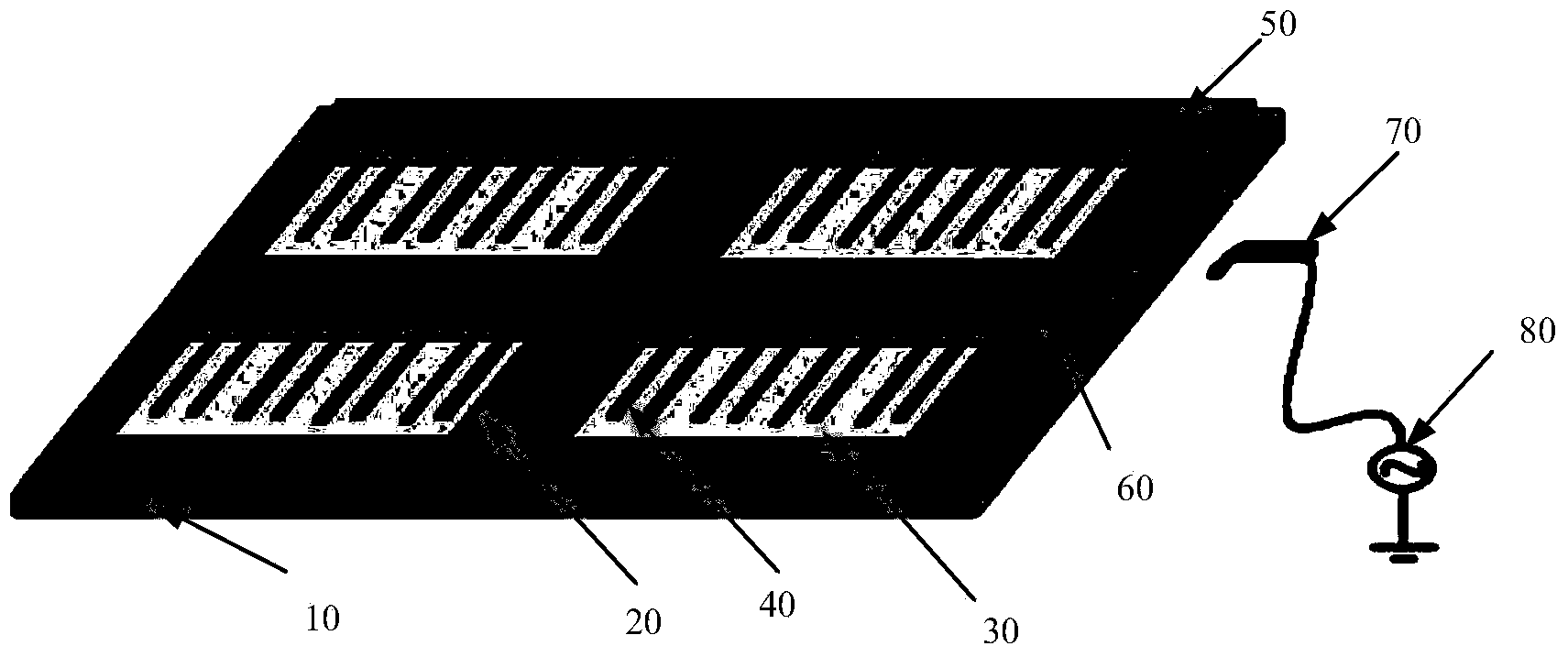

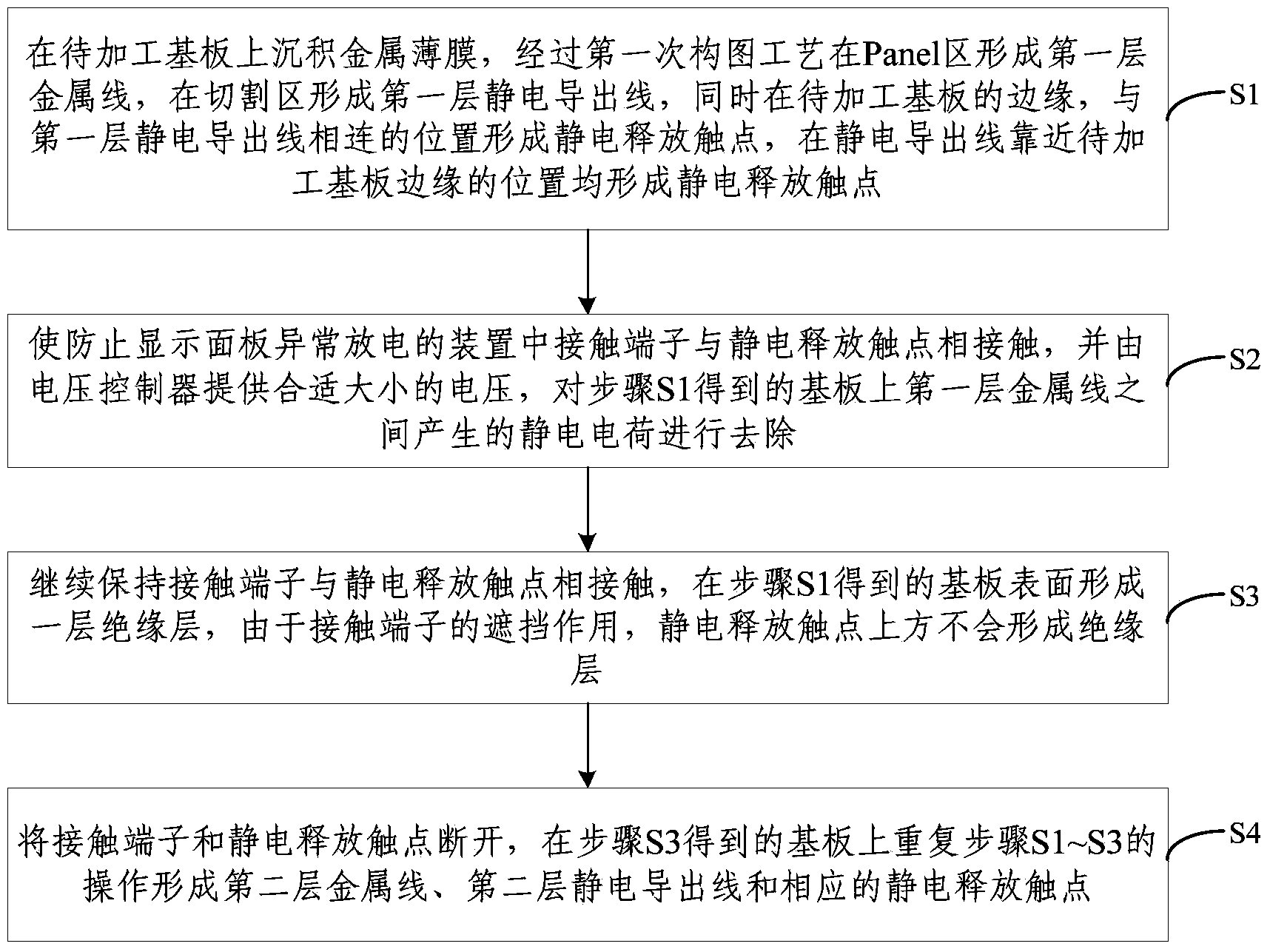

[0028] Based on the above, Embodiment 1 of the present invention proposes a device for preventing abnormal discharge of the display panel, including a contact terminal 70 and a voltage controller 80, the contact terminal 70 is a conductor, and is used to contact the electrostatic discharge contact 60 on the substrate 20 to be processed. To connect, the voltage controller 80 is connected to the contact terminal 70 for adjusting the voltage on the contact terminal 70 to remove static electricity on the substrate 20 to be processed.

[0029] The device is used in the production process of the display panel, wherein the display panel includes an array substrate and a color filter substrate. If the array substrate is taken as an example, it is specifically used to make a metal thin film on a substrate substrate (usually a glass substrate). Forming metal lines (such as grid lines), these metal lines will form charges on the surface of the substrate to be processed. Since the contact ...

Embodiment 2

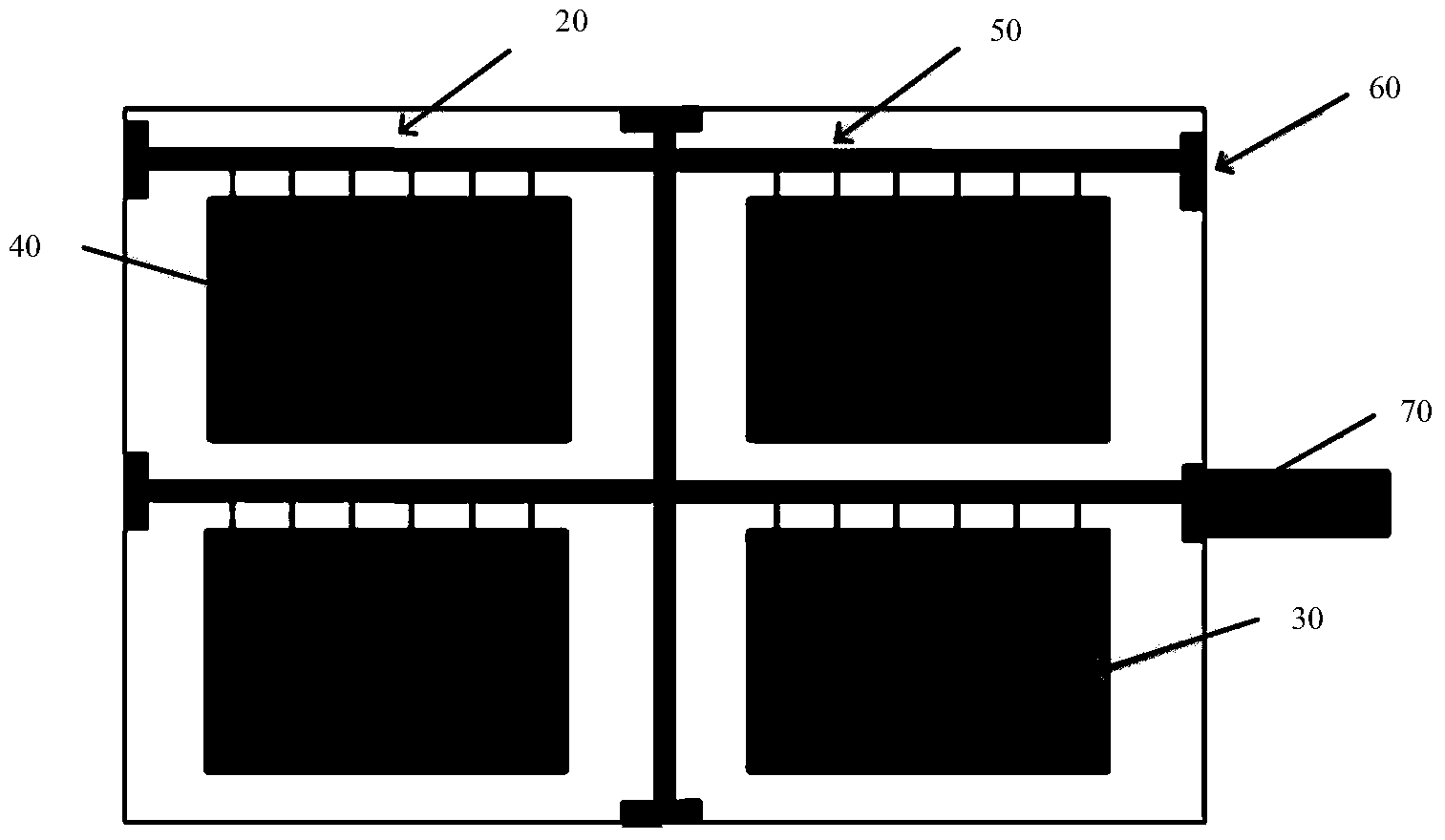

[0033] Embodiment 2 of the present invention also provides a display panel preparation system, which includes, in addition to the device for preventing abnormal discharge of the display panel in Embodiment 1, a substrate 20 to be processed, on which an electrostatic lead-out line 50 is arranged. There is at least one display panel 30 on the processing substrate 20 , the display panel 30 includes a metal wire 40 , one end of the static electricity lead-out wire 50 is connected to the metal wire 40 , and the other end is connected to the static discharge contact 60 .

[0034] Since the cost of the patterning process is relatively high during the manufacture of the display panel 30, generally a plurality of display panels 30 need to be produced on a substrate 20 with a large area to be processed during the processing process, and the patterning process of the same layer of different display panels 30 is the same. Therefore, a plurality of display panels 30 will be fabricated simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com