Plasma processing device and method of operating the same

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as device damage and component damage, and achieve the effects of preventing abnormal discharge and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach ]

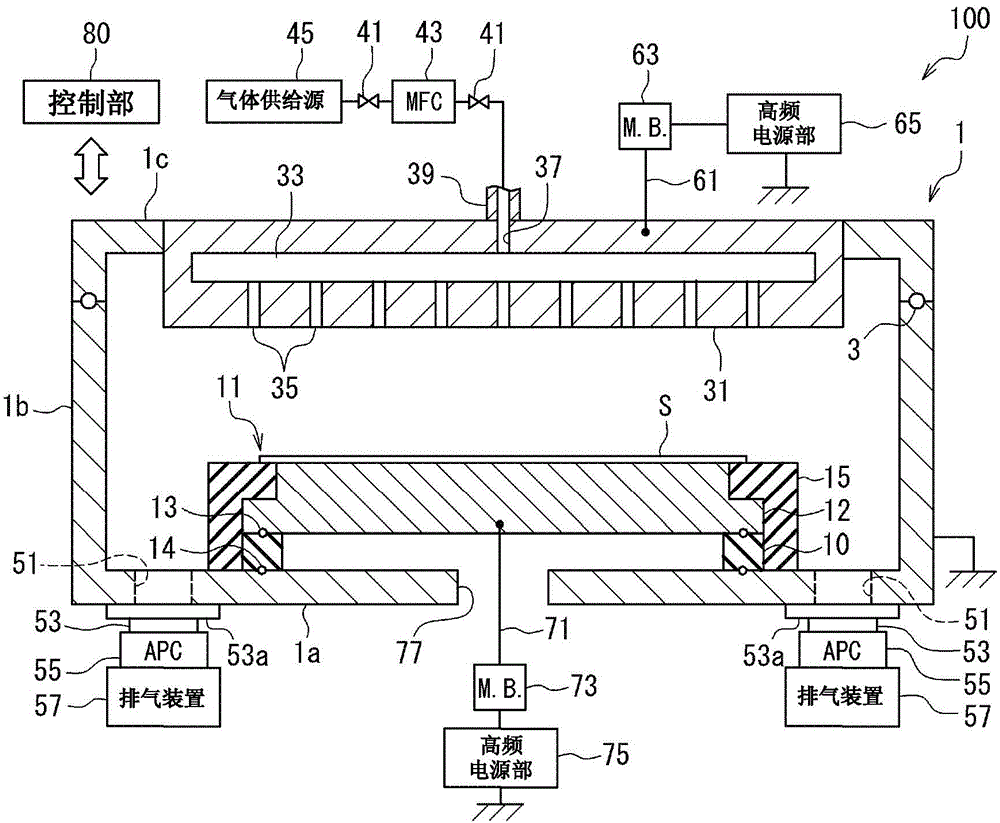

[0038] figure 1 It is a cross-sectional view showing a schematic configuration of a plasma etching apparatus as the first embodiment of the processing apparatus of the present invention. Such as figure 1 As shown, the plasma etching apparatus 100 is configured as a capacitive coupling type parallel plate plasma etching apparatus that etches a glass substrate (hereinafter, abbreviated as “substrate”) S for an FPD as a processed object, for example. In addition, as the FPD, a liquid crystal display (LCD), an electroluminescence (Electro Luminescence; EL) display, a plasma display panel (PDP), etc. can be exemplified.

[0039] This plasma etching apparatus 100 has a processing container 1 formed of aluminum whose inner side is anodized (aluminum oxide film processing) and formed into a rectangular tube shape. The main body (container main body) of the processing container 1 is composed of a bottom wall 1 a and four side walls 1 b (only two are shown). In addition, a lid 1c is joine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com