Multi-stage angle-variable machining tool

A corner processing and tooling technology, applied in the field of multi-level variable-angle processing tooling, can solve problems such as unbalanced tasks of CNC machining equipment, uneven production scheduling, waste of equipment utilization, etc., to improve equipment utilization and simple structure , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

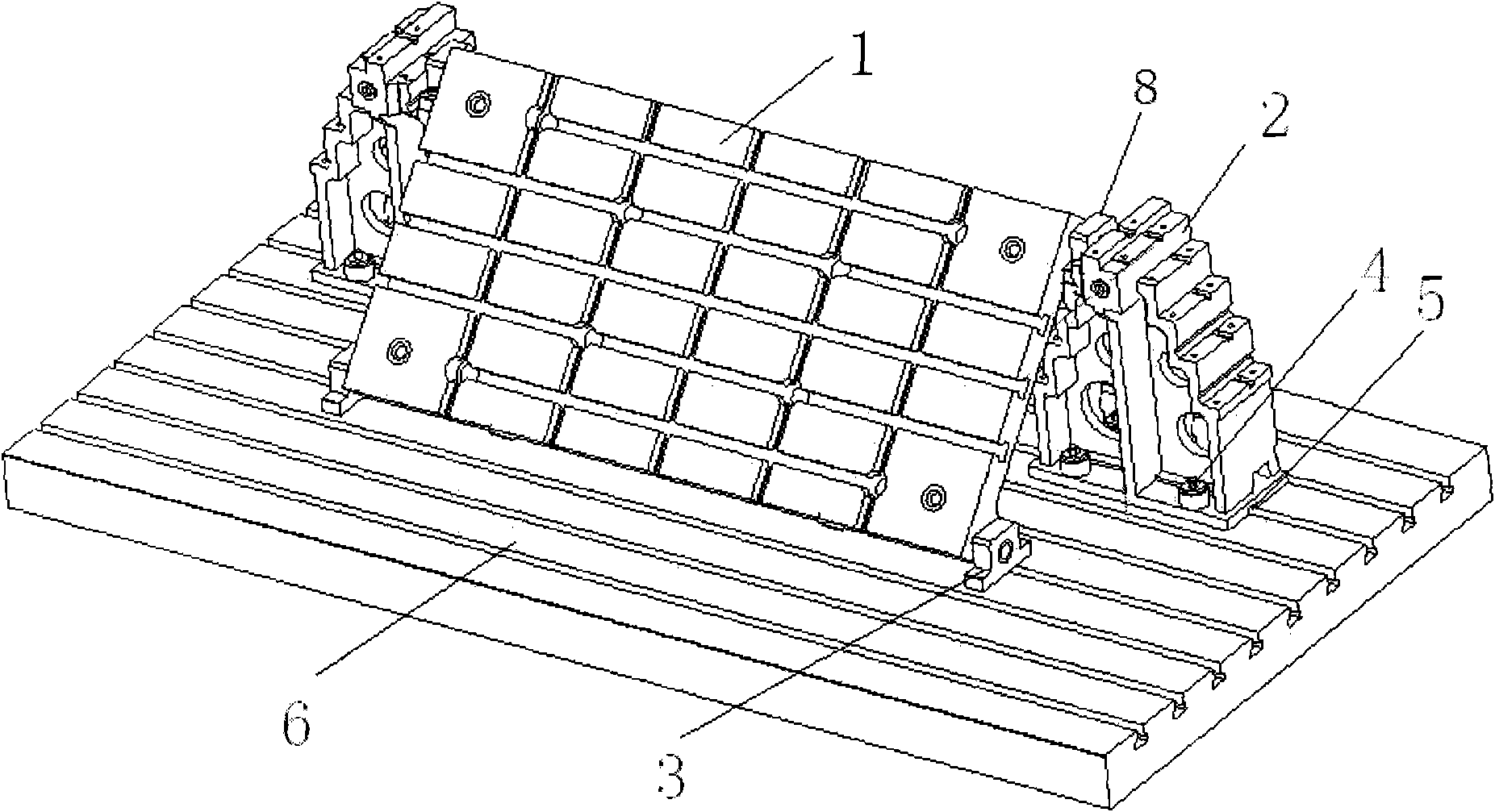

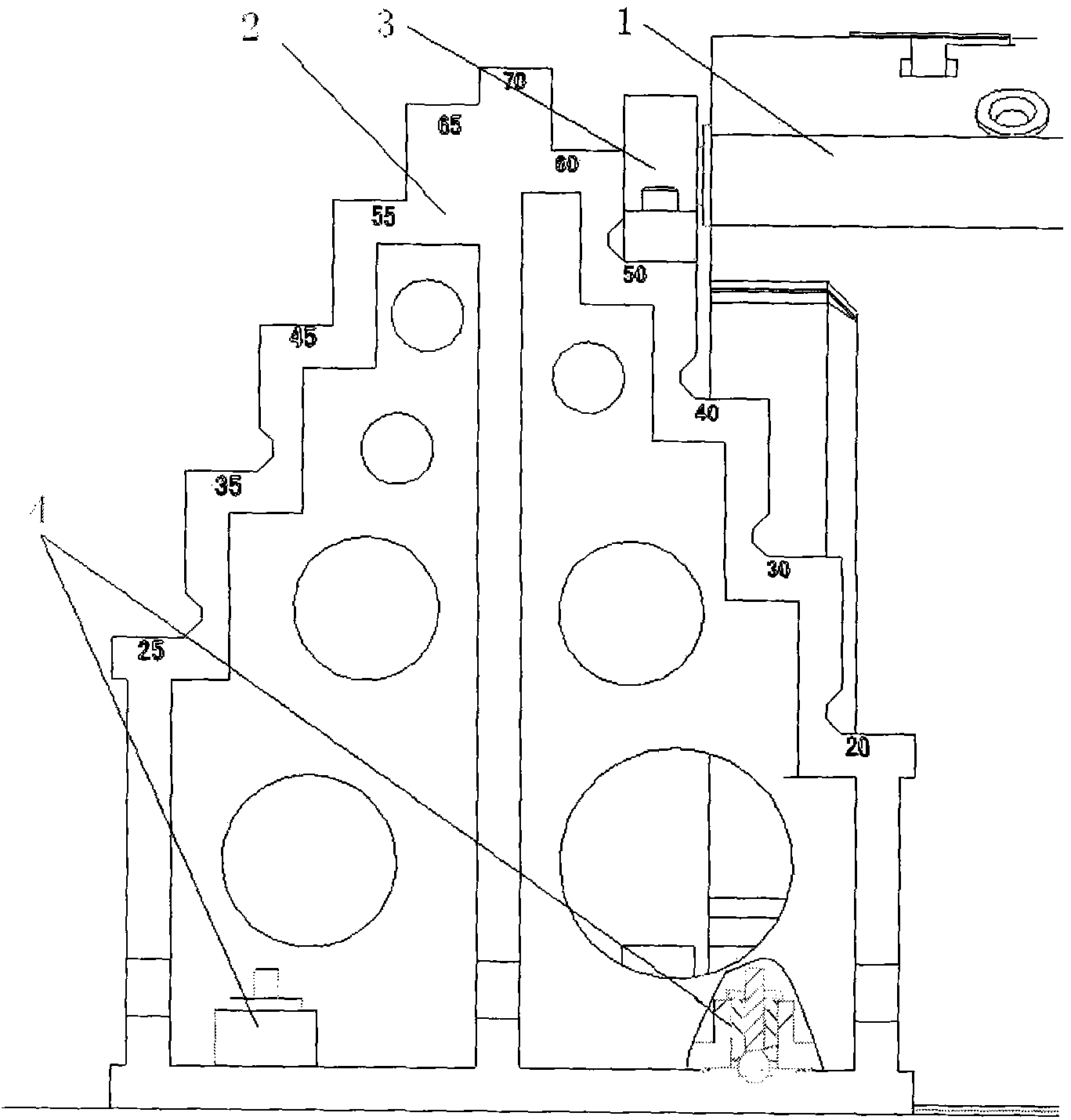

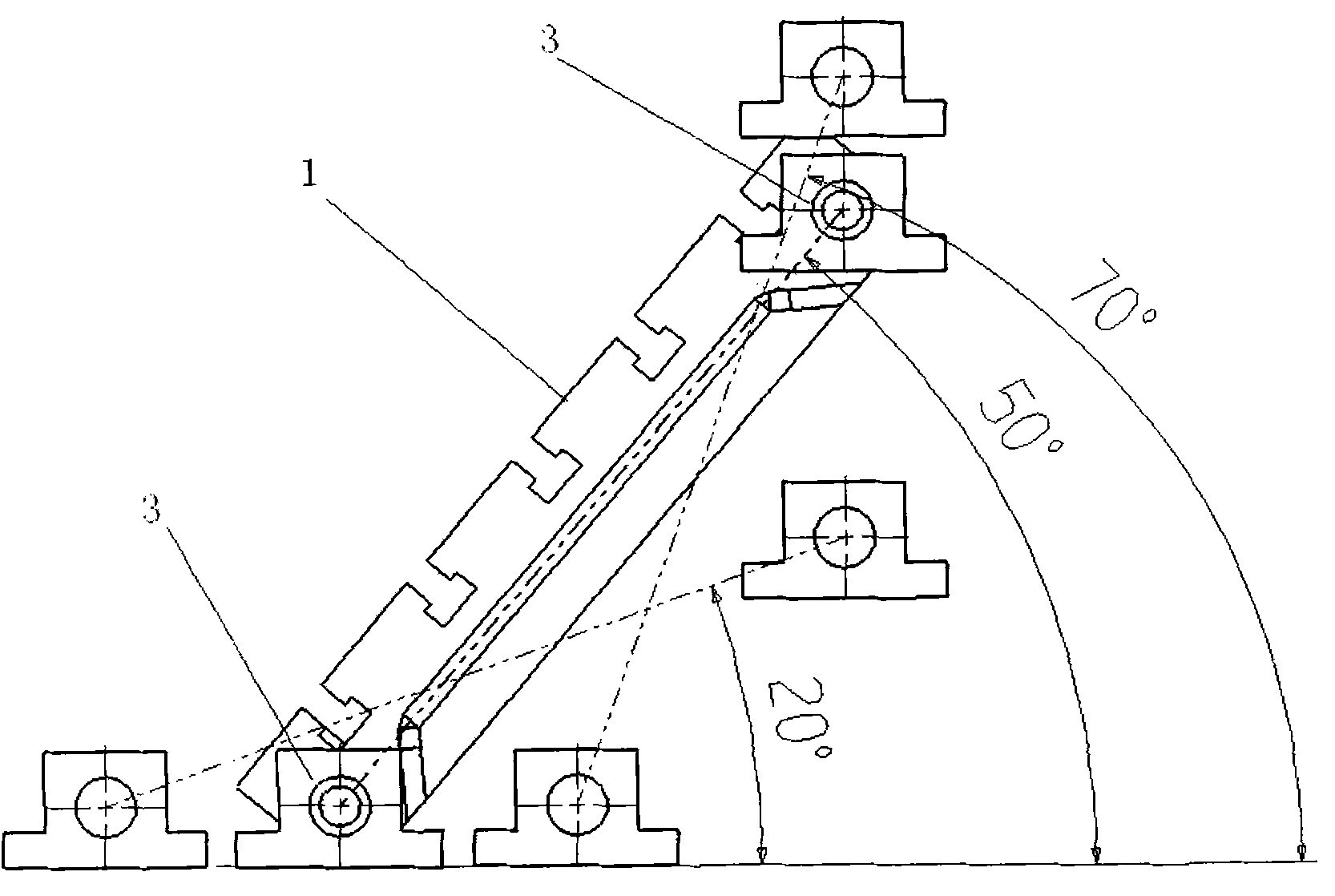

[0016] refer to figure 1 . In a preferred embodiment of the multi-stage variable-angle processing tool described in the figure, the entire multi-stage variable-angle processing tool includes a swing angle table 1, two symmetrical stepped boss support seats 2, a fixed seat 3, and a rolling device 4 and the positioning key 5. The swing angle workbench 1 is a rectangular plate formed with inverted T-shaped installation grooves parallel to each other in the vertical and horizontal directions. The upper and lower ends of the swing angle workbench 1 both sides are shaped on rotating shafts connected with mounting holes. The rotating shaft on both sides of the lower end of the pendulum table 1 is rotatably connected in the fixing seat 3 rotating shaft holes through the fixing seat 3 rotating shaft holes fixedly connected to the CNC machine tool 6 table tops. The rotating shafts on both sides of the free end of the pendulum table 1 are connected in the rotating shaft hole of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com