Machining method for turbine work blade

A technology of mechanical processing and blades, which is applied in the field of mechanical processing of aero-engines, can solve the problems of low production quality and production efficiency of turbine blades, and achieve the effects of high blade processing quality, reliable positioning, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

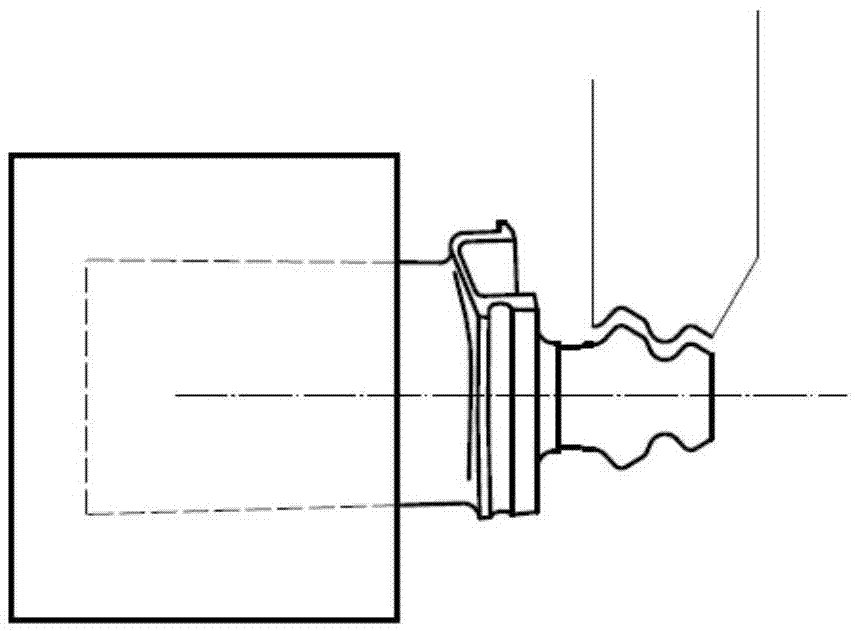

[0025] The turbine blade processing technology of the present invention is as follows: degreasing→blade precise positioning→wax filling→grinding tenon teeth and tooth exhaust side→wax removal→melting low melting point alloy→pollution removal→grinding tenon tooth bottom→grinding edge plate and teeth Air intake side→fluorescent inspection→comprehensive inspection→processing air film holes→cleaning→storage.

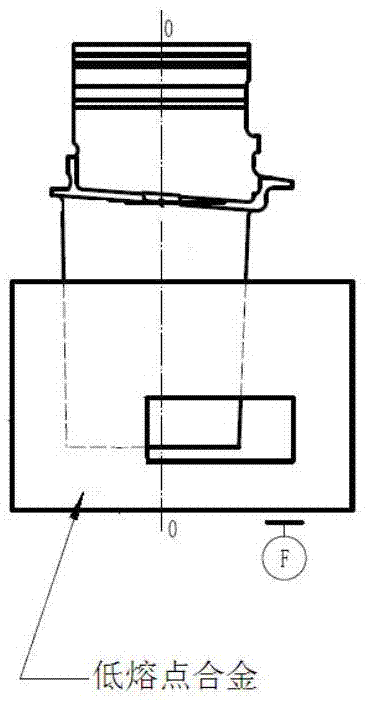

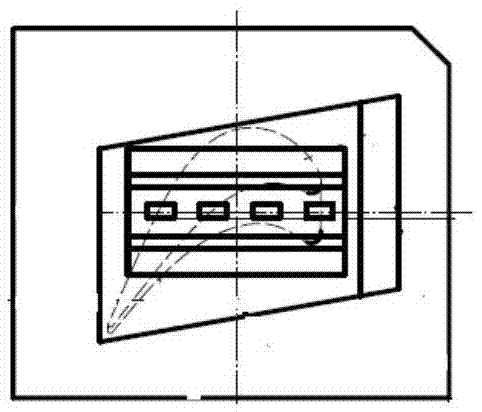

[0026] Degreasing is to clean up the oil stains attached to the wool from the warehouse. see Figure 1a and Figure 1b , the precision positioning of the blade is cast low-melting point alloy, and the six-point positioning reference of the blade body surface is converted to the six-point positioning reference of the casting block. The positioning is reliable and easy to clamp during machining. Adhesive tape seals all the holes on the blade body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com