A kind of cleaning method of bacterial sludge on the inner wall of the inlet pipe of nf/ro membrane unit

A water cleaning and pipeline technology, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problem of insufficient contact between cleaning chemicals and pipes, poor cleaning efficiency and cleaning effect, and easy splashing of cleaning chemicals. and other problems, to achieve good application value and application prospects, low processing cost, and the effect of inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

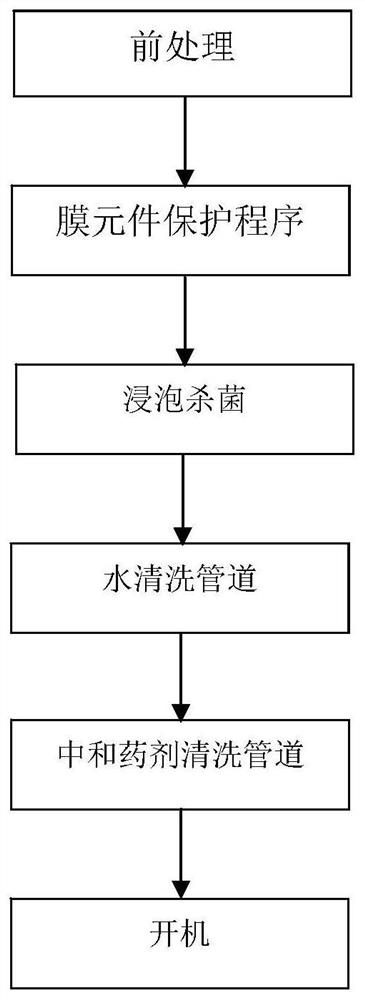

[0035] A kind of cleaning method of the bacterial sludge that breeds on the inner wall of the water inlet pipe of a NF / RO membrane unit, such as figure 1 shown, including the following steps:

[0036]S1, pre-processing. Empty the residual sewage in the water inlet pipe, and wash the inner wall of the water inlet pipe with reclaimed water (outlet of the reverse osmosis membrane system) to clean the inner wall of the pipe until the color of the eluate is less than 10 times, and then stop washing.

[0037] S2. Membrane element protection program. After step S1 is finished, put the sodium bisulfite solution with a concentration of 10000ppm in the ultrafiltrate collection tank, start the cycle cleaning program, and carry out cycle cleaning on the inner wall of the water inlet pipe and the NF / RO membrane unit for 15 minutes, and at the same time make the NF / RO The RO membrane elements are soaked in sodium bisulfite solution to prevent subsequent sodium hypochlorite solution from o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com