Dog-cat liquid wet food taking enzymolysis meat as main raw material and preparation method of food

A technology of meat and raw materials, which is applied in the field of liquid wet food for dogs and cats and its preparation, to achieve the effects of easy post-processing, easy feeding, easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

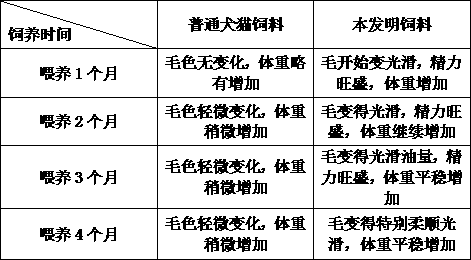

Image

Examples

Embodiment 1

[0024] A liquid wet food for dogs and cats with enzymatically hydrolyzed meat as the main raw material. Sulfonic acid 0.2%, multivitamin 0.5%, multimineral 0.3%, brewer's yeast 0.5%, salt 0.1%, water 49.3%.

[0025] In the above-mentioned embodiment 1, the preparation method of the liquid wet food for dogs and cats with enzymatic meat as the main raw material is characterized in that it comprises the following steps:

[0026] Preparation of fresh meat enzymatic hydrolyzate: put frozen meat into a pulverizer, and pulverize until the diameter is not greater than 3mm;

[0027] Put the crushed minced meat into the reaction kettle, pass steam into the reaction kettle to heat the temperature slowly, and continue for half an hour after reaching about 100 degrees Celsius, and keep stirring the minced meat during the heating process to fully pre-cook the minced meat;

[0028] Reduce the temperature in the reactor to 50 degrees Celsius by water cooling, add sodium hydroxide, adjust the...

Embodiment 2

[0039] A liquid wet food for dogs and cats with enzymatically hydrolyzed meat as the main raw material. 0.2% sulfonic acid, 0.3% multivitamin, 0.5% multimineral, 0.1% beer yeast, 0.2% salt, 42.4% water.

[0040] In the above-mentioned embodiment 2, the preparation method of the liquid wet food for dogs and cats with enzymatic meat as the main raw material is characterized in that it comprises the following steps:

[0041] Preparation of fresh meat enzymatic hydrolyzate: put frozen meat into a pulverizer, and pulverize until the diameter is not greater than 3mm;

[0042] Put the crushed minced meat into the reaction kettle, pass steam into the reaction kettle to heat the temperature slowly, and continue for half an hour after reaching about 100 degrees Celsius, and keep stirring the minced meat during the heating process to fully pre-cook the minced meat;

[0043] Reduce the temperature in the reactor to 60 degrees Celsius by water cooling, add sodium hydroxide, adjust the pH ...

Embodiment 3

[0052] A liquid wet food for dogs and cats with enzymatically hydrolyzed meat as the main raw material. 0.2% sulfonic acid, 0.5% multivitamin, 0.3% multimineral, 0.4% beer yeast, 0.1% salt, 47.6% water.

[0053] In the above-mentioned embodiment 3, the method for preparing liquid wet food for dogs and cats with enzymatic meat as the main raw material is characterized in that it comprises the following steps:

[0054] Preparation of fresh meat enzymatic hydrolyzate: put frozen meat into a pulverizer, and pulverize until the diameter is not greater than 3mm;

[0055] Put the crushed minced meat into the reaction kettle, pass steam into the reaction kettle to heat the temperature slowly, and continue for half an hour after reaching about 100 degrees Celsius, and keep stirring the minced meat during the heating process to fully pre-cook the minced meat;

[0056] Reduce the temperature in the reactor to 55 degrees Celsius by water cooling, add sodium hydroxide, adjust the pH value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com