Drilling component used for drilling technique of hard alloy materials

A technology of cemented carbide and components, applied in the direction of drilling/drilling equipment, parts of boring machine/drilling machine, drilling tool accessories, etc., can solve problems such as inappropriateness, and achieve the effect of improving work efficiency, reducing costs, and smooth processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

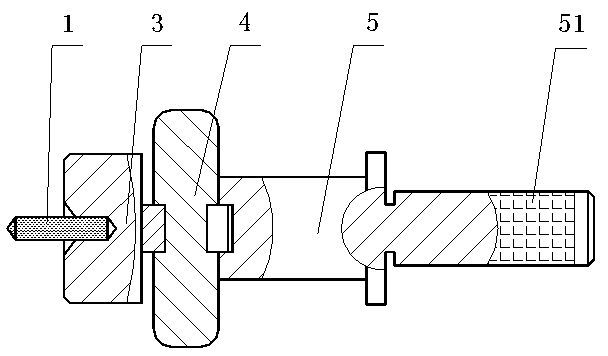

[0032] Such as figure 1 As shown, the present invention discloses a drilling assembly used in the drilling process of cemented carbide materials. The drilling assembly is used for drilling cemented carbide materials with a thickness not greater than 5 mm in the processing of molds in a clamp bed. .

[0033] The drilling assembly includes a coaxially connected drill bit 1 , a tip set 3 and a shaft member 5 . The drill bit 1 and the shaft member 5 are respectively arranged at two ends of the tip casing 3 .

[0034] A snap ring positioning piece 4 is also mechanically connected between the top end sleeve 3 and the shaft member 5 .

[0035] A knurling section 51 is provided on the end of the shaft part 5 opposite to the tip sleeve 3 .

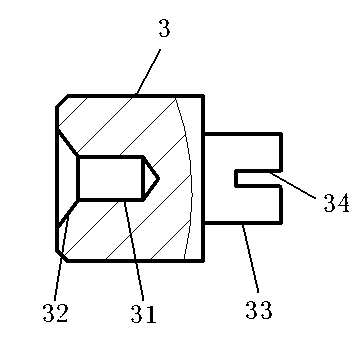

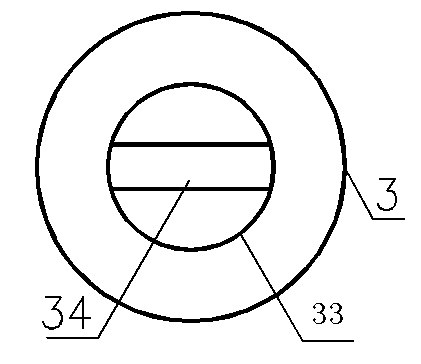

[0036] Such as figure 2 As shown, the top end sleeve 3 is configured as a cylinder, and its two end faces ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com