Integrated furnace chains and heating heads

A heating head, integrated technology, applied in the field of integrated furnace chain and heating head, can solve the problems of incapable of preform protection, prone to waste bottles, low production efficiency, etc., to achieve a simple and compact overall structure, satisfying processing demand, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

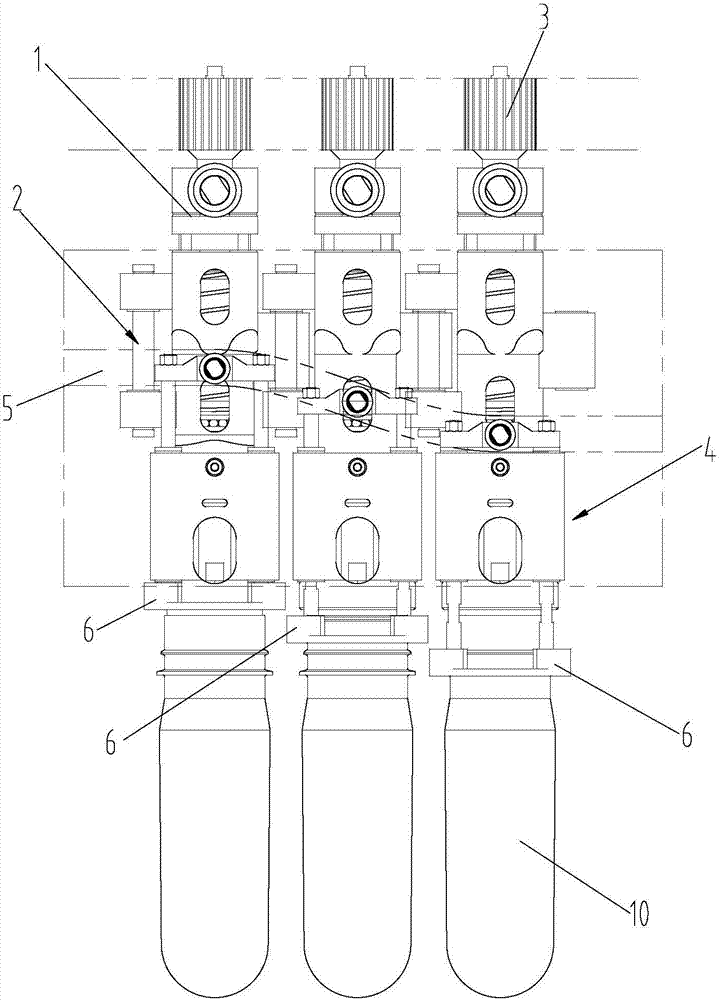

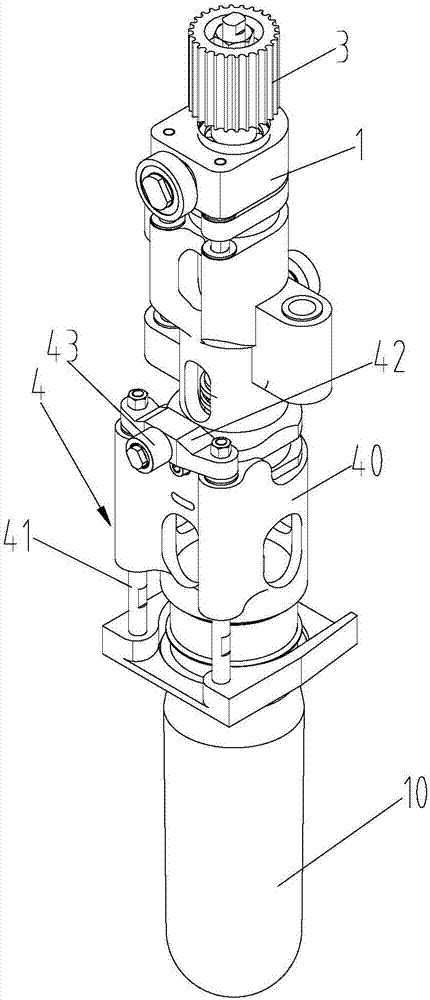

[0015] as attached Figure 1-2 The shown integrated furnace chain and heating head of the present invention include a heating head device 1, a furnace chain 2, a mandrel pulley 3, a nut (not shown in the figure), a timing belt (not shown in the figure) shown), a lifting device 4, a lifting track 5 and a light barrier 6; a plurality of the heating head devices 1 are sequentially arranged on the furnace chain 2; the mandrel pulley 3 is inserted into the upper end of the heating head device 1, and passed through Nuts are fixed; a plurality of the mandrel pulleys 3 are arranged in the synchronous belt; the lower part of the heating head device 1 is provided with a lifting device 4, and the above-mentioned lifting device 4 is slidably arranged on the heating head device 4 Inside the lifting track 5 on one side; the lower end of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com