A sorting table with a circular picking structure

A sorting table and sorting column technology, applied in grain processing, solid separation, etc., can solve the problems of human body influence, increase of labor cost, and influence of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

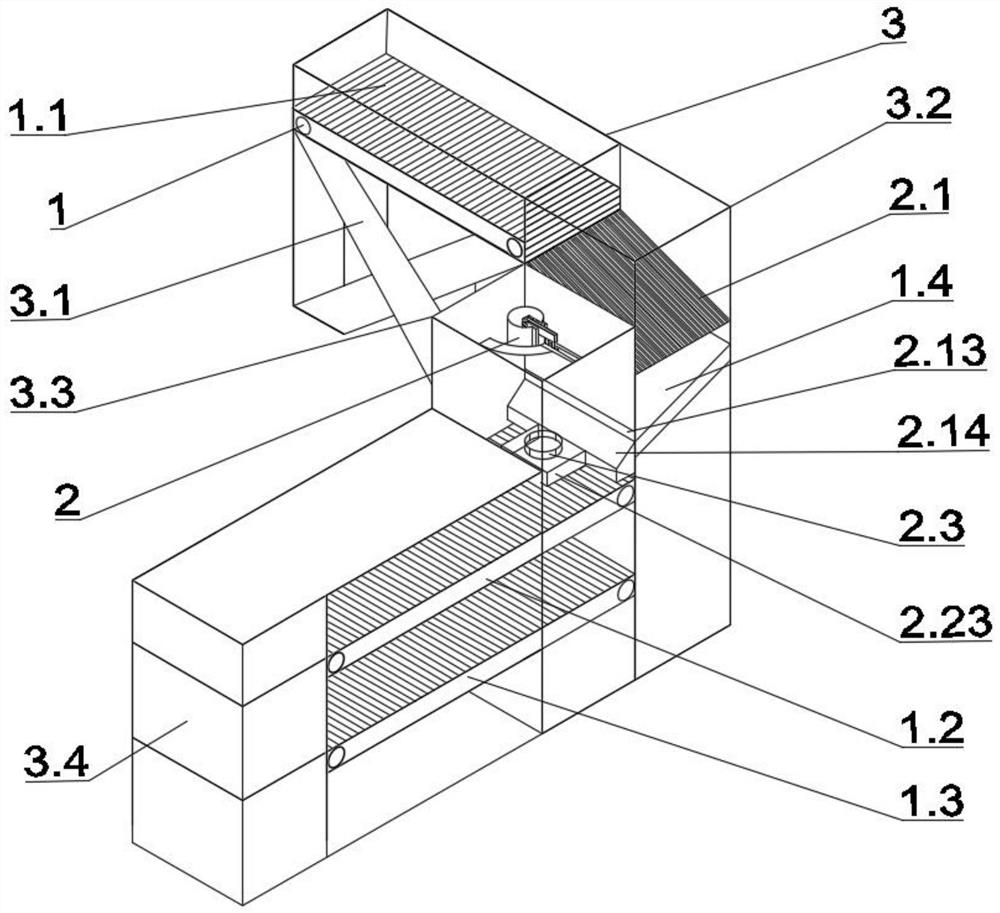

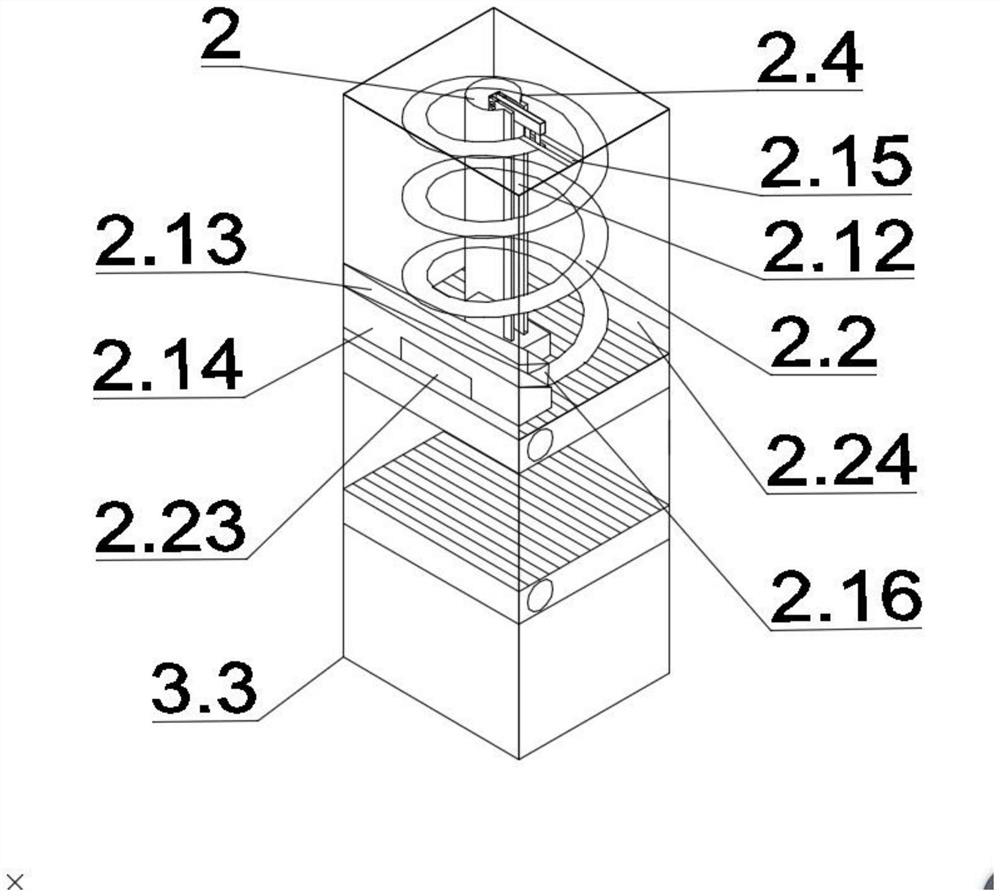

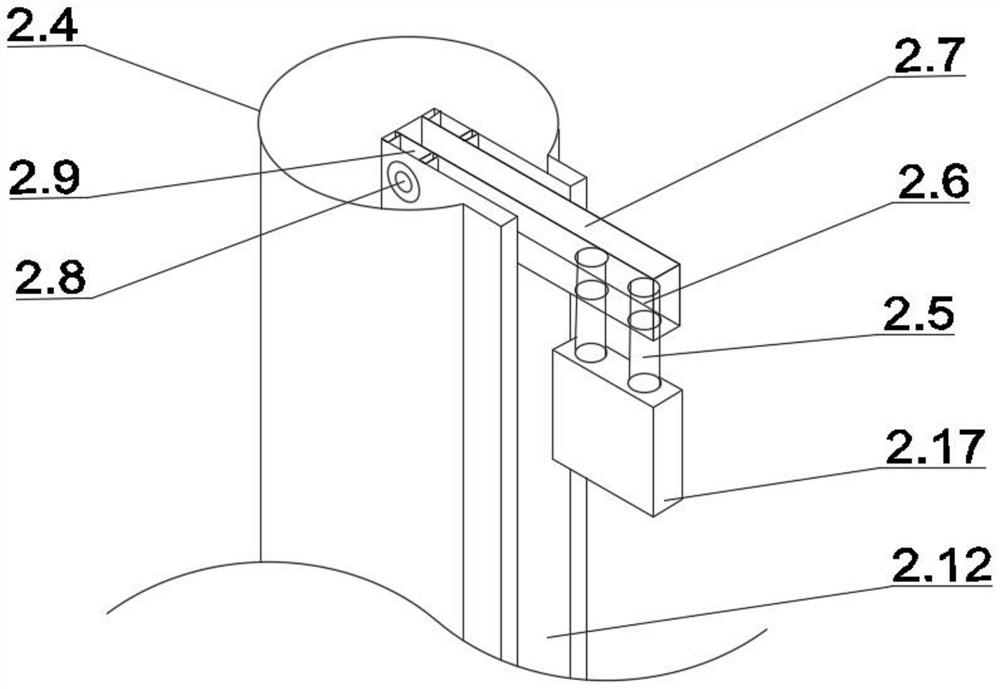

[0042] As shown in the figure, a sorting platform with a circular picking structure includes a conveying mechanism 1, a picking mechanism 2, and a limit mechanism 3. The conveying mechanism 1 is arranged in the limit mechanism 3, and the picking mechanism 2 is arranged in the Inside the limit mechanism 3. The limiting mechanism 3 includes a feeding platform 3.1, a first-level sorting column 3.2, a second-level sorting column 3.3, and a limiting column 3.4. The bottom end of the feeding platform 3.1 is connected with the first-level sorting column 3.2, and the feeding platform 3.1 is vertically connected with the first-level sorting column 3.2, the second-level sorting column 3.3 is installed on the side of the first-level sorting column 3.2, the second-level sorting column 3.3 is arranged side by side with the first-level sorting column 3.2, and the limit column 3.4 is installed on the On the side of the secondary sorting column 3.3, the limit column 3.4 is arranged side by si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com