Mechanical interface device of machine tool module

A mechanical interface and machine tool technology, applied in metal processing mechanical parts, large fixed members, metal processing equipment, etc., can solve problems such as geometric accuracy and stiffness adjustment limitations, and the large influence of module joints on the dynamic characteristics of machine tools. Convenience, simple structure, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

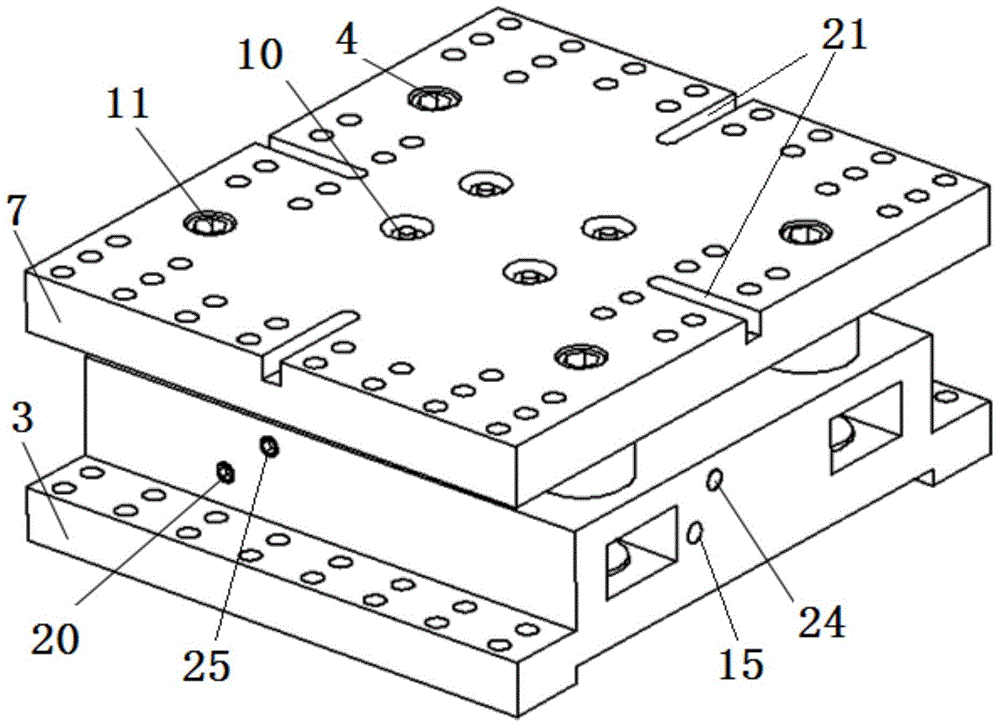

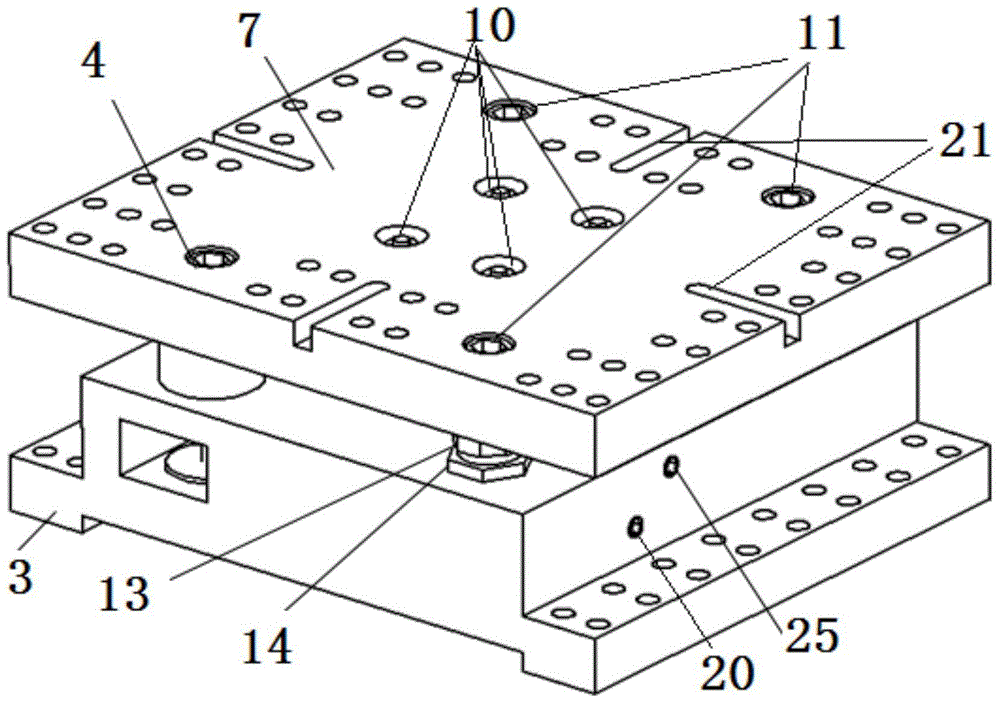

[0040] refer to figure 1 , figure 2 , the structure of the mechanical interface device of the machine tool module of the present invention is to include a base body 3 and an interface connecting plate 7, the interface connecting plate 7 is installed above the base body 3, and an equal pressure tension and compression mechanism is arranged between the base body 3 and the interface connecting plate 7; A U-shaped keyway 21 for positioning is respectively provided on the upper surface of the interface connecting plate 7 along the outer ends of the two centerlines intersecting vertically and horizontally, and each pair in the vertical and horizontal directions is a total of four U-shaped keyways 21;

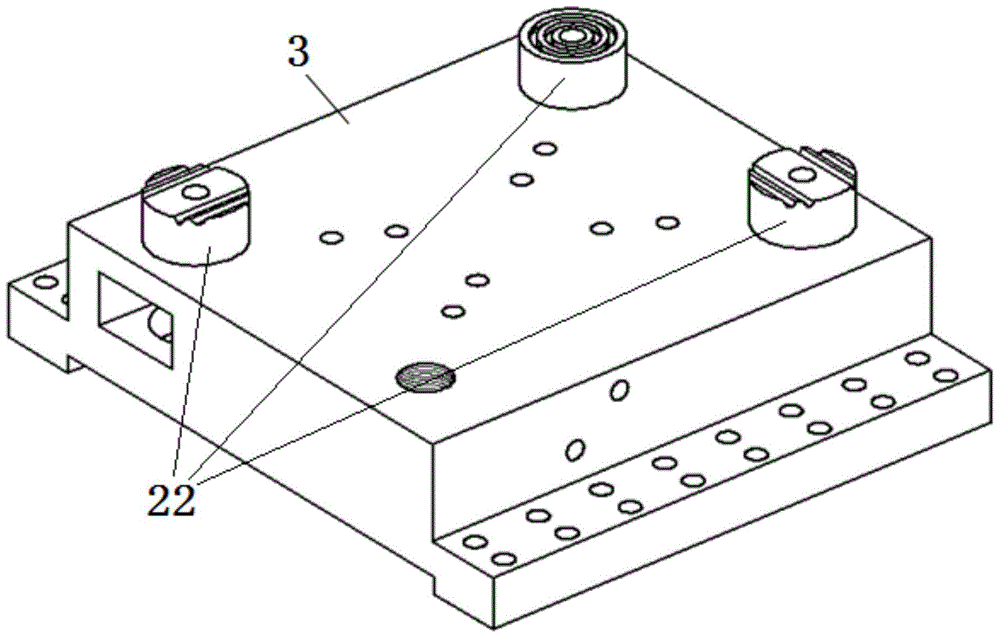

[0041] refer to image 3 , Figure 4 , Figure 5 , between the seat body 3 and the interface connecting plate 7, there are three sets of main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com