Precise part machining numerical control machine tool

A technology of precision parts and CNC machine tools, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of product theory and actual difference, affecting the stress effect and service life of parts, and imperfect process effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

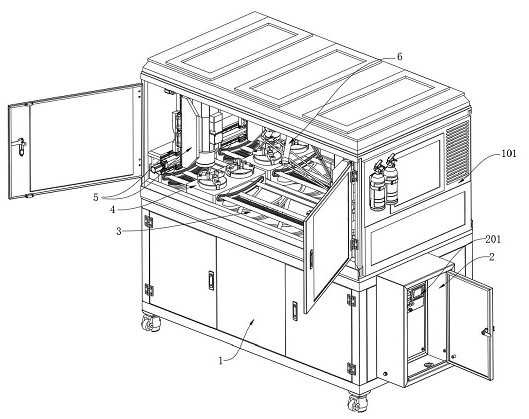

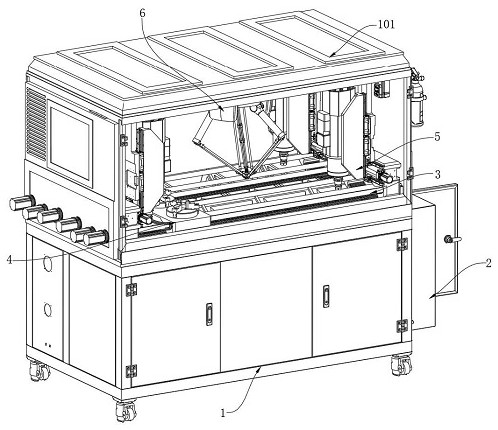

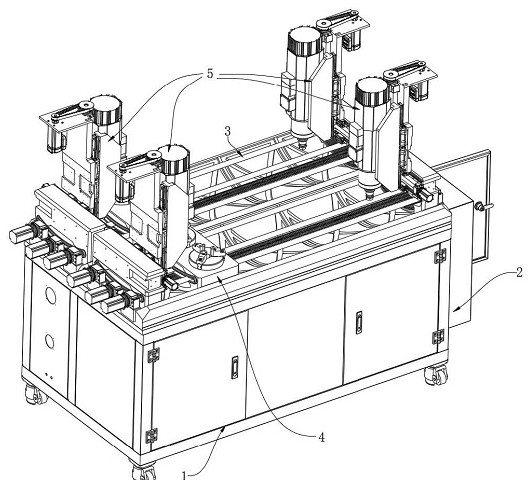

[0047] see Figure 1-8 , the present invention provides a technical solution: CNC machine tools for precision parts processing, including a workbench 1, an electrical box 2, a machine tool mechanism 3 and a servo adjustment claw 6, the electrical box 2 is installed on one side of the workbench 1, and the machine tool mechanism 3 includes two A curved stand 301, six first stepping motors 303, four first ball screws 304, two toothed rollers 305, four servo claws 306, four electric milling cutters 307, two arc slides Bench 4 and four driving mechanisms 5;

[0048] The arc stand 301 is installed on the top of the workbench 1, the outer surface of the first stepper motor 303 is installed on the outer surface of the arc stand 301, the arc sliding stand 4 is installed on the top of the arc stand 301, and the driving mechanism 5 is installed on the top of the arc-shaped stand 301, and the driving mechanism 5 includes a connecting frame 504, a first servo motor 505, a third ball screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com