Manufacturing method of steel-rolling cooling bed roller-oriented support platform

A technology of support table and roller table, applied in cooling bed, metal rolling, metal rolling and other directions, can solve the problem of time-consuming and laborious, and achieve the effect of broadening process ideas, convenient operation and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

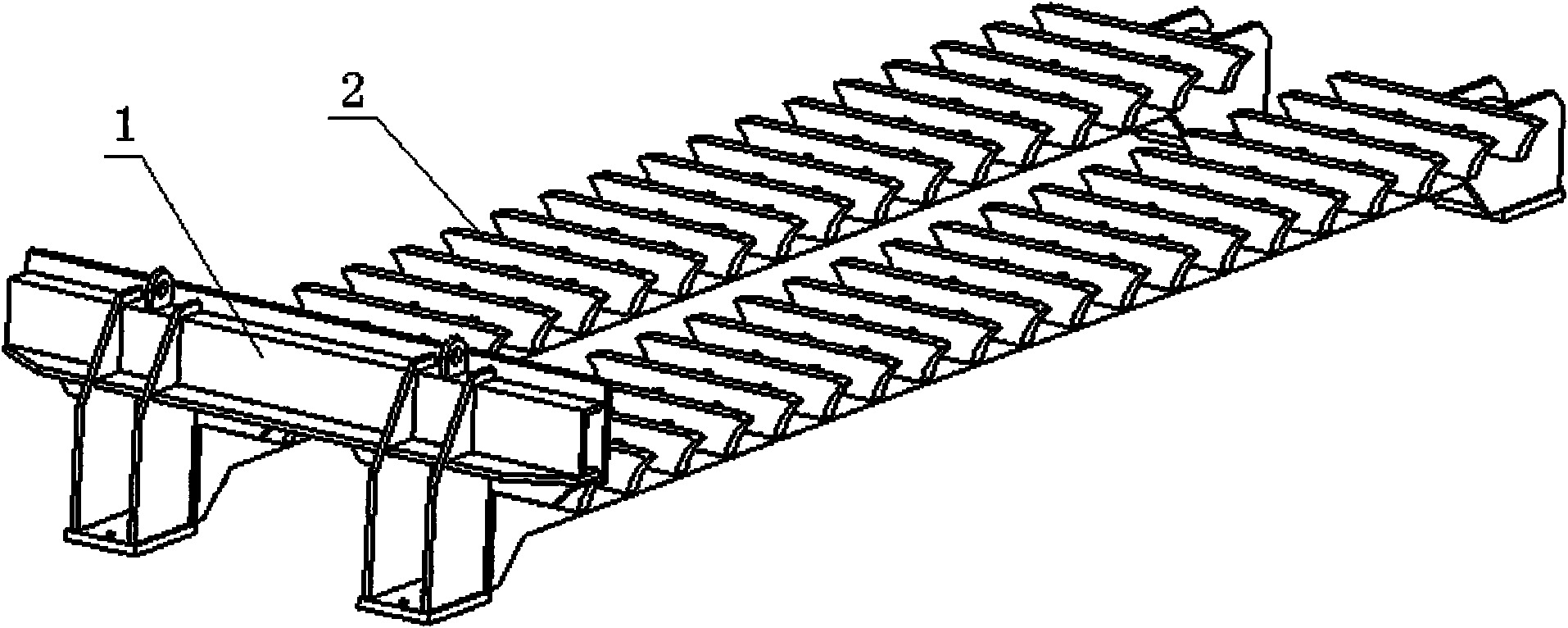

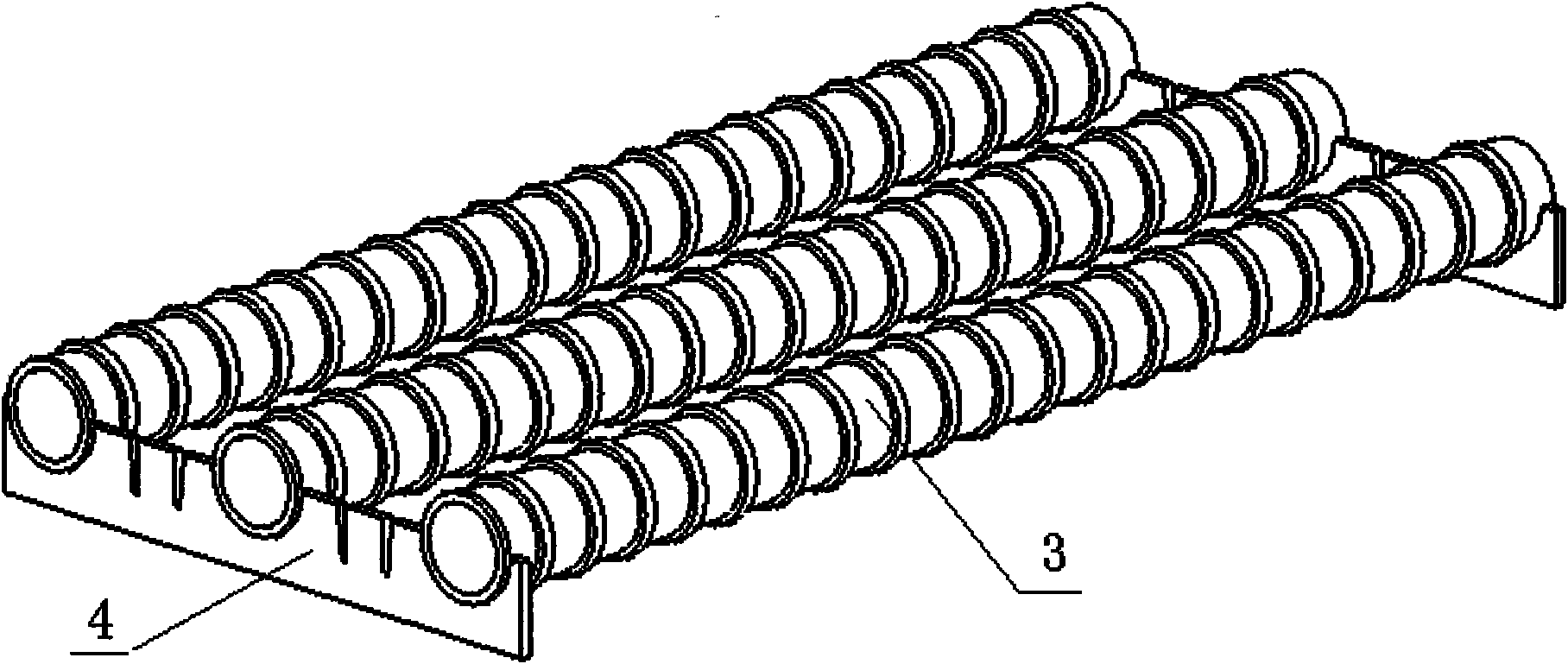

[0027] A method for preparing a roller table guide support platform of a steel rolling cooling bed, comprising the following process steps:

[0028] 1) Blanking: cutting the required pieces of the guide support table; when cutting the material, use the flame cutting to assemble and weld the pieces required for the guide support table. Perpendicularity in the thickness direction.

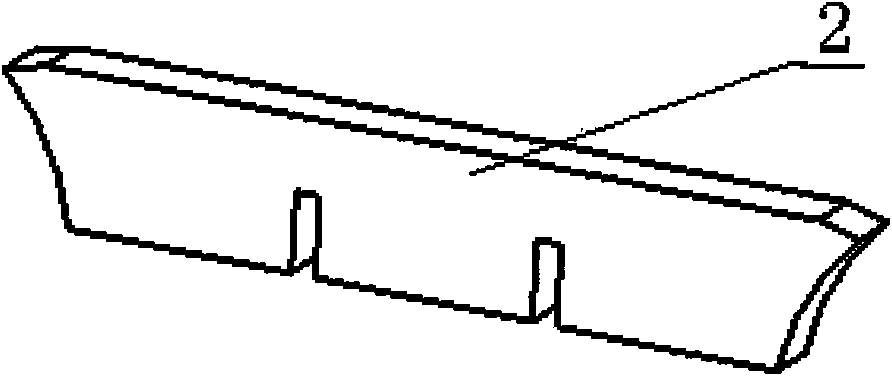

[0029] 2) Assembling: After cutting the material, use tooling to precisely fix the flying spur position, and assemble each piece to ensure the assembly relationship. The tooling of the guide support table is composed of a support plate and a round tube, and the round tube is fixed on the support plate and welded firmly after being fixed accurately. When assembling, insert the skeleton of the flying spurs into the gap of the supporting plate of the tooling, fix it firmly with a wedge iron, and then assemble the flying spurs according to the arc position of the tooling.

[0030] 3) Welding: After pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com