Real-time flexible acceleration and deceleration control algorithm based on adaptive forward-looking and predictive correction

A technology of acceleration and deceleration control, predictive correction, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problem that the CNC machine tool cannot respond in time, cannot meet the processing requirements well, and realizes complicated processes etc. to achieve real-time flexible acceleration and deceleration control, realize real-time optimal speed planning, and improve processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described in detail below in conjunction with the examples.

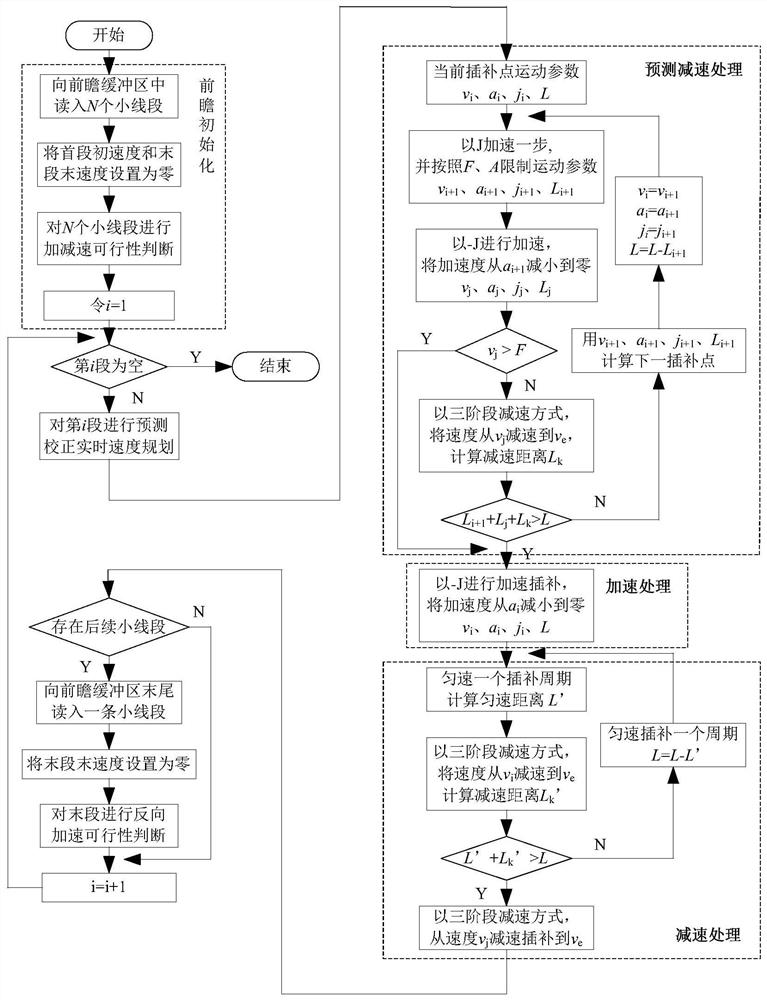

[0076] A real-time flexible acceleration and deceleration control algorithm based on adaptive forward-looking and predictive correction, including the following steps:

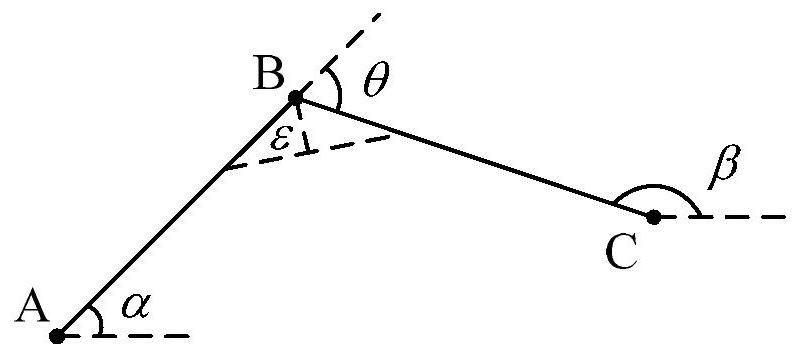

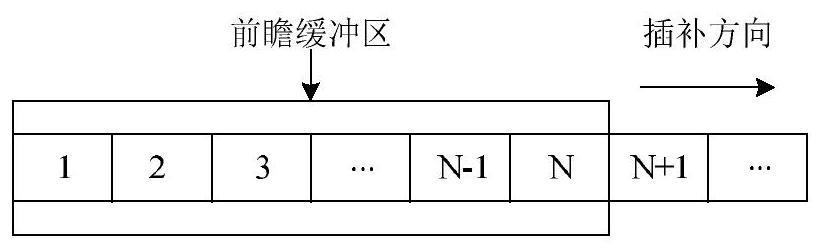

[0077] Forward-looking processing, determine the maximum feed speed at the corner of the adjacent small line segment in the processing path, to ensure the accessibility of the speed at both ends of the small line segment;

[0078] Predict and correct real-time speed planning, use forward-looking processing to calculate the feed speed of the next interpolation cycle in a predictive way, and correct the speed, acceleration and jerk of the next interpolation cycle according to the dynamic performance of the machine tool to ensure flexible speed planning;

[0079] Dynamic adjustment processing, under the premise of satisfying the dynamic performance of the machine tool, adjusts the current forward-looking pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com