Spiral exhaust type continuous feeding device and method for thermal cracking of waste tires

A technology for waste tires and feeding devices, which is applied in the directions of transportation and packaging, loading/unloading, and special dry distillation. Improve material work efficiency, ensure safety and environmental protection, and ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

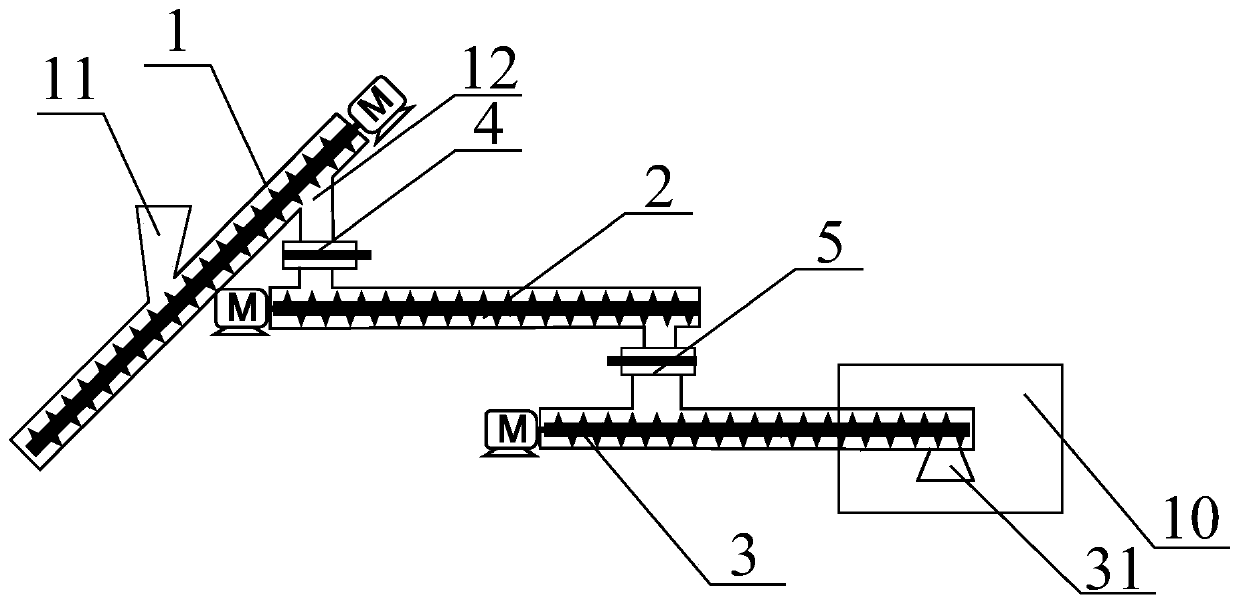

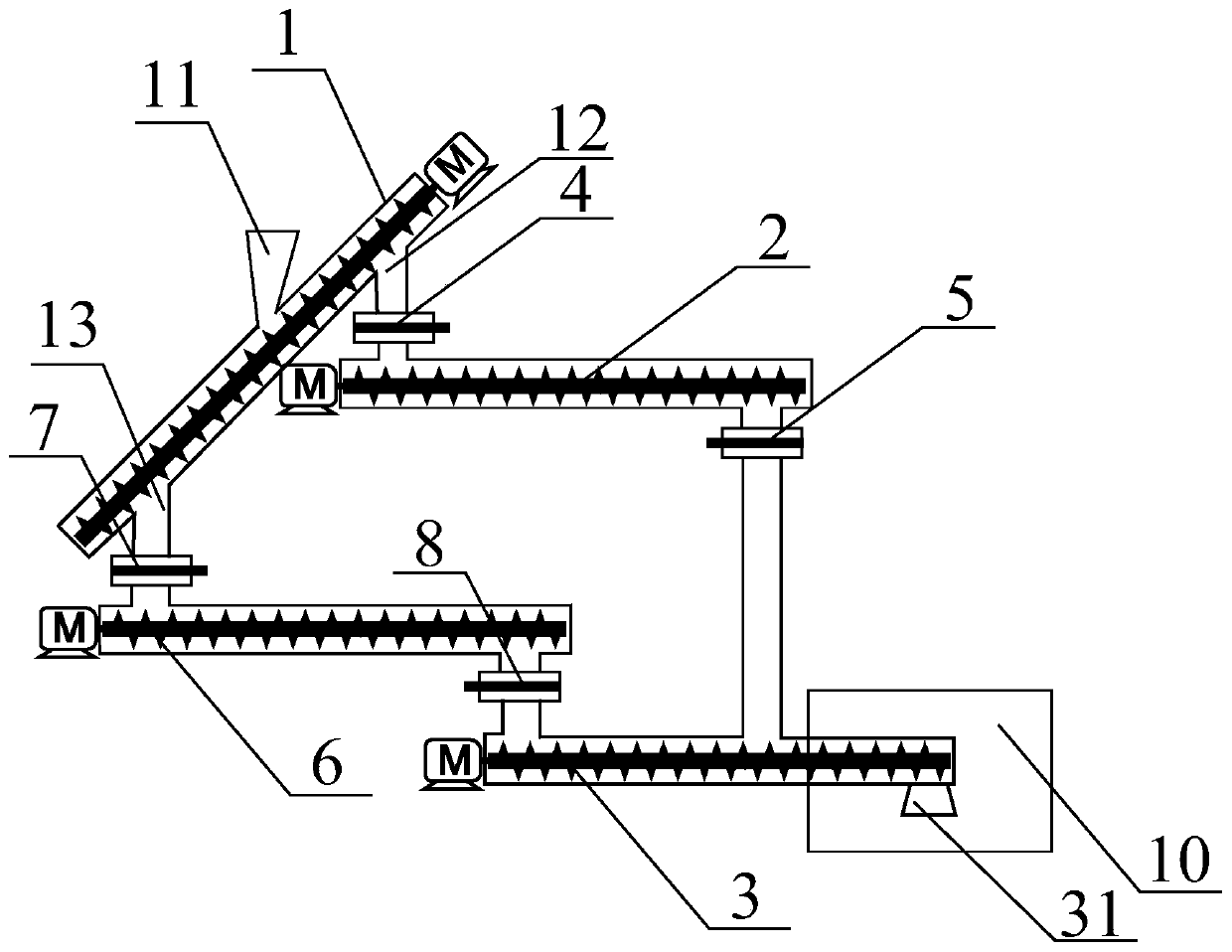

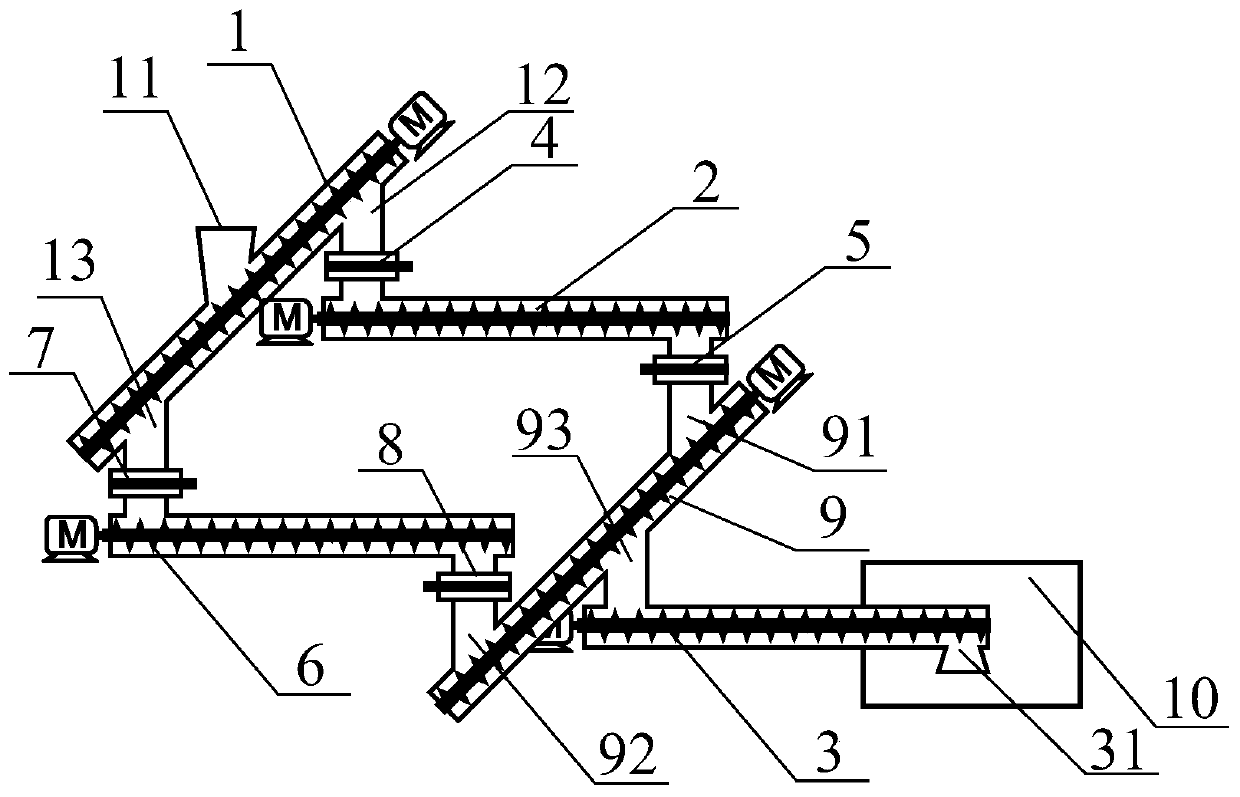

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a continuous feeding device for pyrolysis of waste tires, which includes a distributing screw conveyor 1, a first screw exhaust conveyor 2 and a feeding screw conveyor 3 connected in sequence. The feed screw conveyor 1 is provided with a first feed port 11 and a first discharge port 12, and the feed screw conveyor 3 is provided with a third discharge port 31 communicated with the thermal cracking reactor 10; The first discharge port 12 of the distribution screw conveyor 1 communicates with the feed end of the first screw exhaust conveyor 2, and there is a seal between the two for sealing the first screw exhaust conveyor 2. The first gate valve 4 at the feed end, the discharge end of the first screw exhaust conveyor 2 is communicated with the feed end of the feed screw conveyor 3, and a device for sealing the first screw conveyor is arranged between the two. A second slide valve 5 at the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com