Patents

Literature

44results about How to "Play the role of conveying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

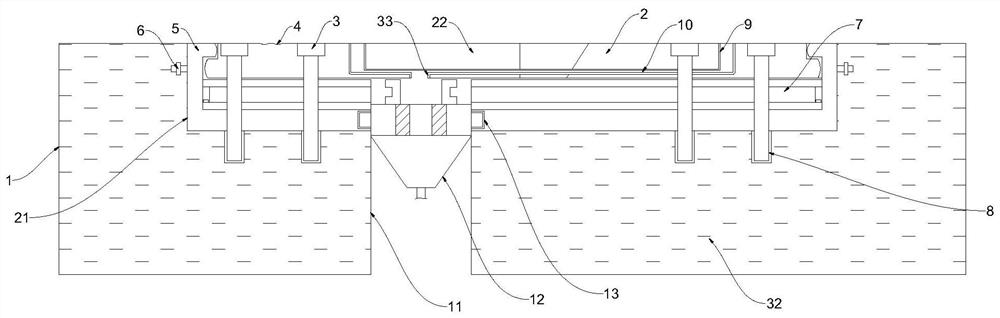

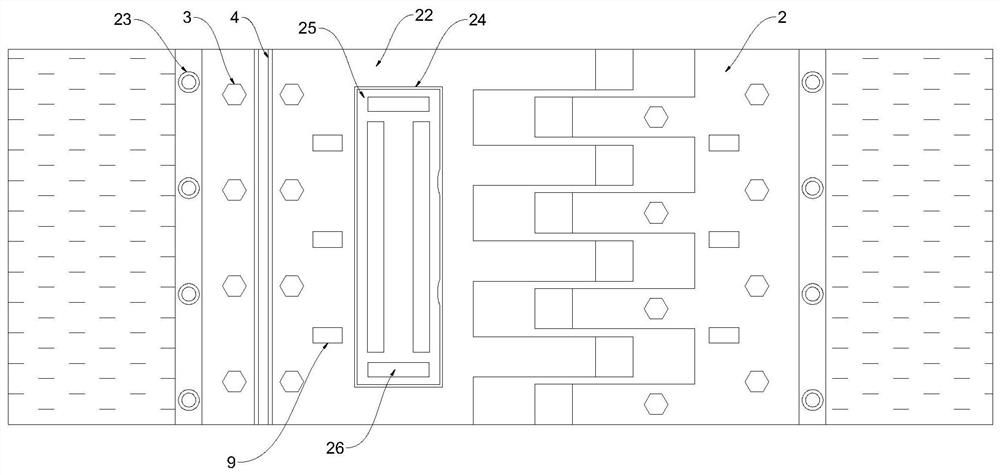

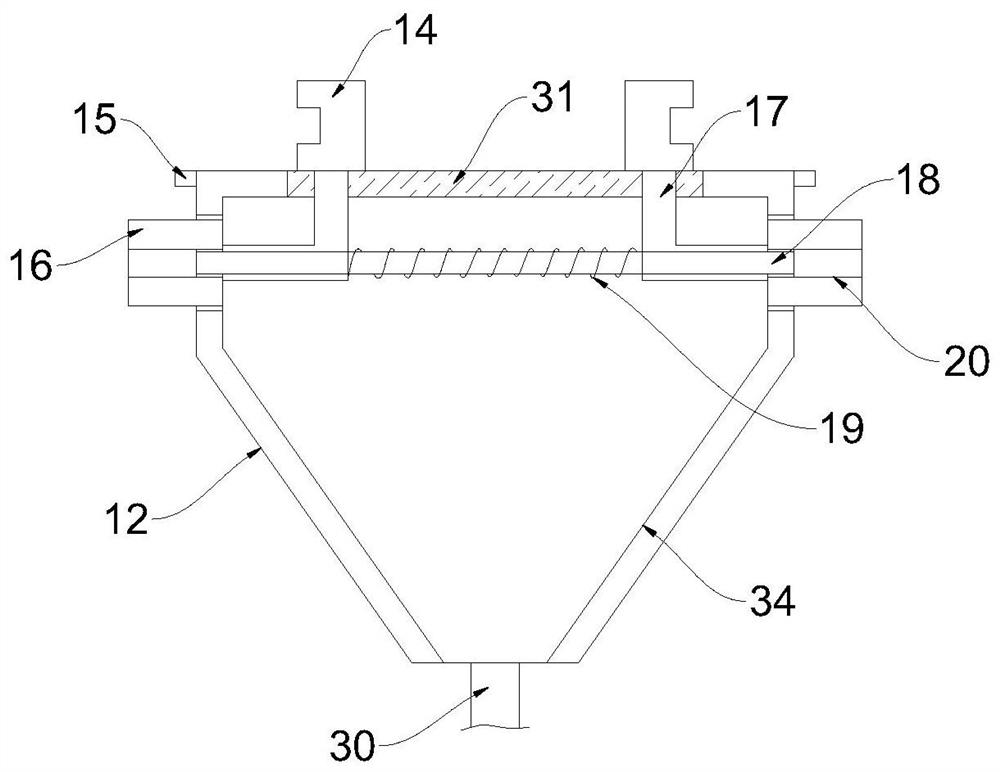

Comb-type bridge expansion joint plate structure and cleaning device thereof

InactiveCN112064498ALarge displacementPlay the role of anti-looseningBridge structural detailsRoad cleaningExpansion jointRivet

The invention discloses a comb-type bridge expansion joint plate structure and a cleaning device thereof. The comb-type bridge expansion joint plate structure comprises a first beam body, a second beam body arranged on one side of the first beam body, a comb plate supporting plate and a first comb-type expansion joint plate, wherein preformed grooves are formed in the first beam body and the second beam body respectively; an expansion joint is arranged between the first beam body and the second beam body; the comb plate supporting plate is arranged in the preformed grooves; the comb plate supporting plate is fixedly connected with the first beam body and the second beam body through fixing rivets; the first comb-type expansion joint plate is arranged in the comb plate supporting plate; anda second comb-type expansion joint plate is arranged on one side of the first comb-type expansion joint plate. The comb-type bridge expansion joint plate structure achieves the anti-seismic bufferingfunction; the strength of the structure at the expansion joint is improved; accumulated water and dust in the expansion joint are convenient to clean away; the internal structures of the expansion joint are prevented from being affected by the accumulated water; and the problem is solved that the first beam body and the second beam body squeeze each other to cause potential safety risks.

Owner:蒋明敏

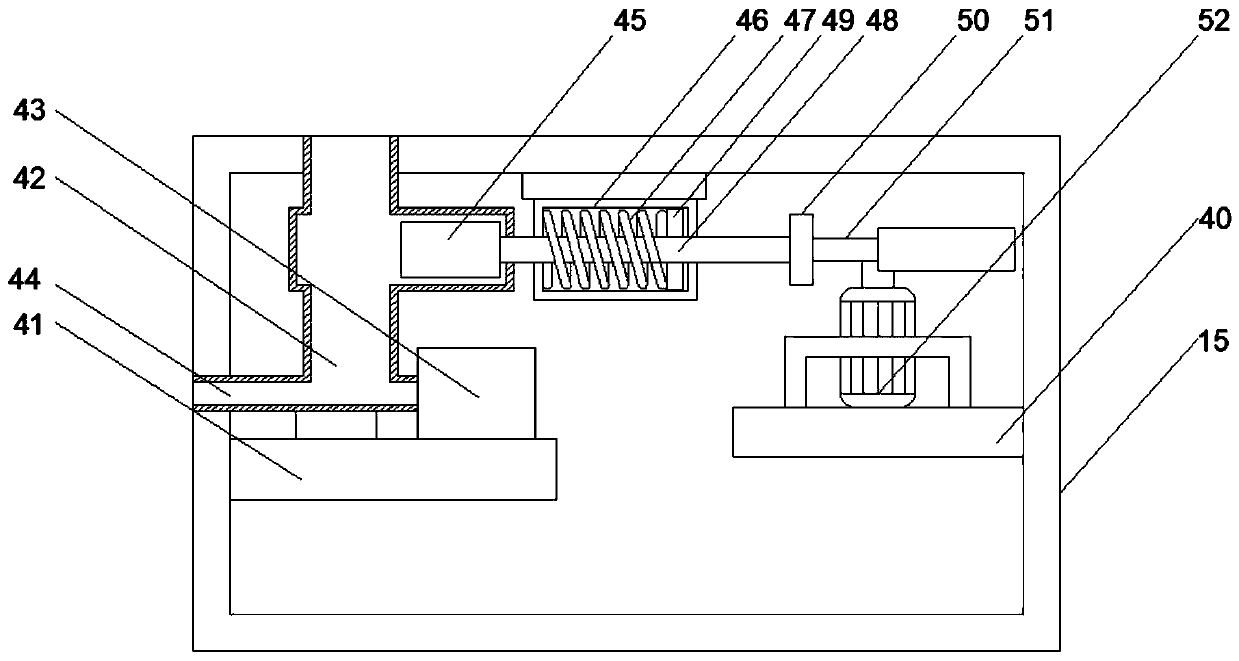

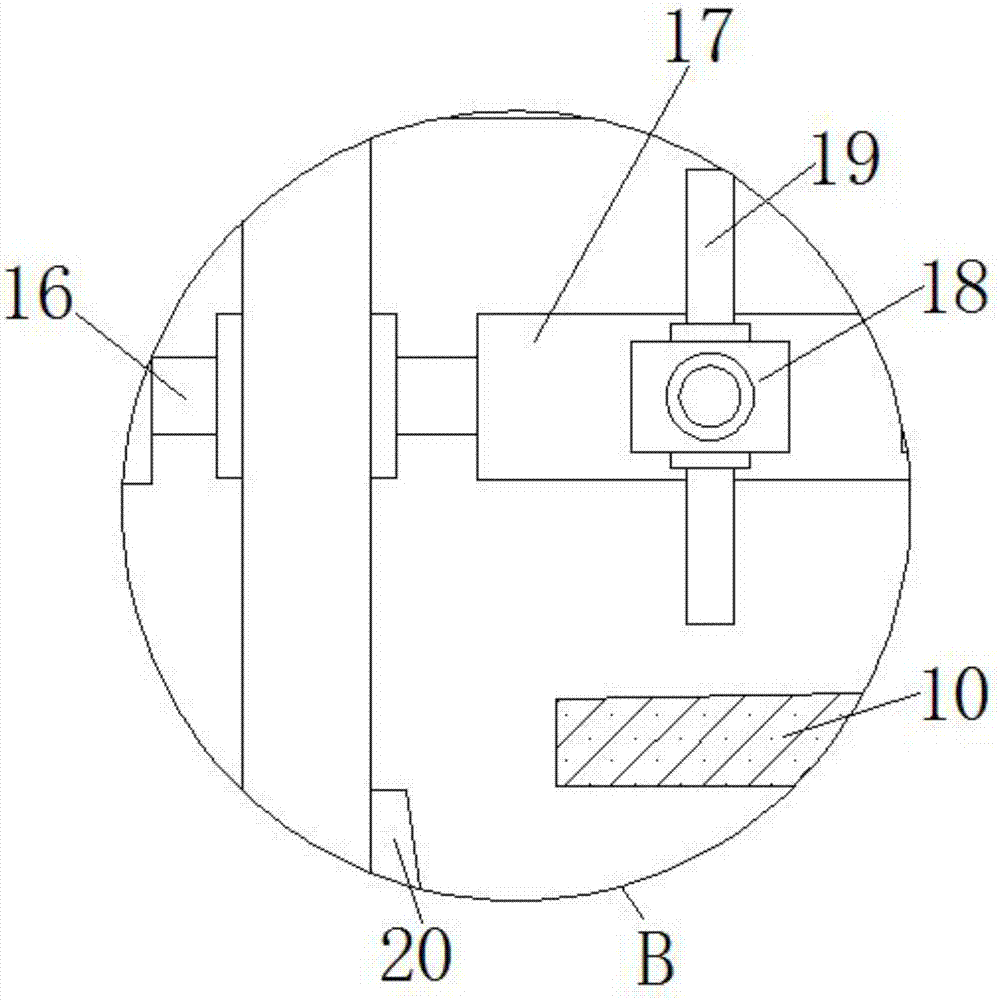

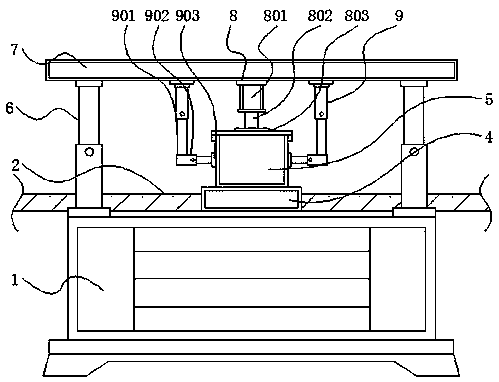

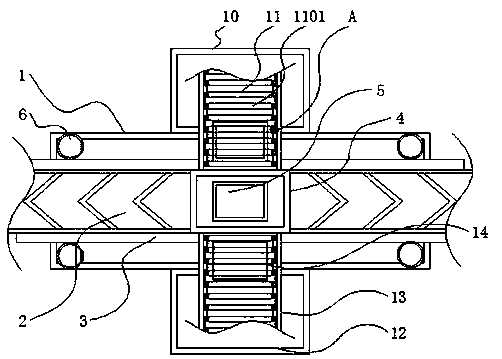

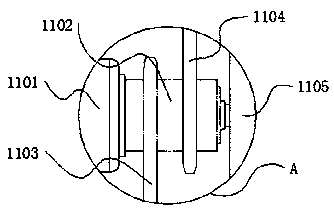

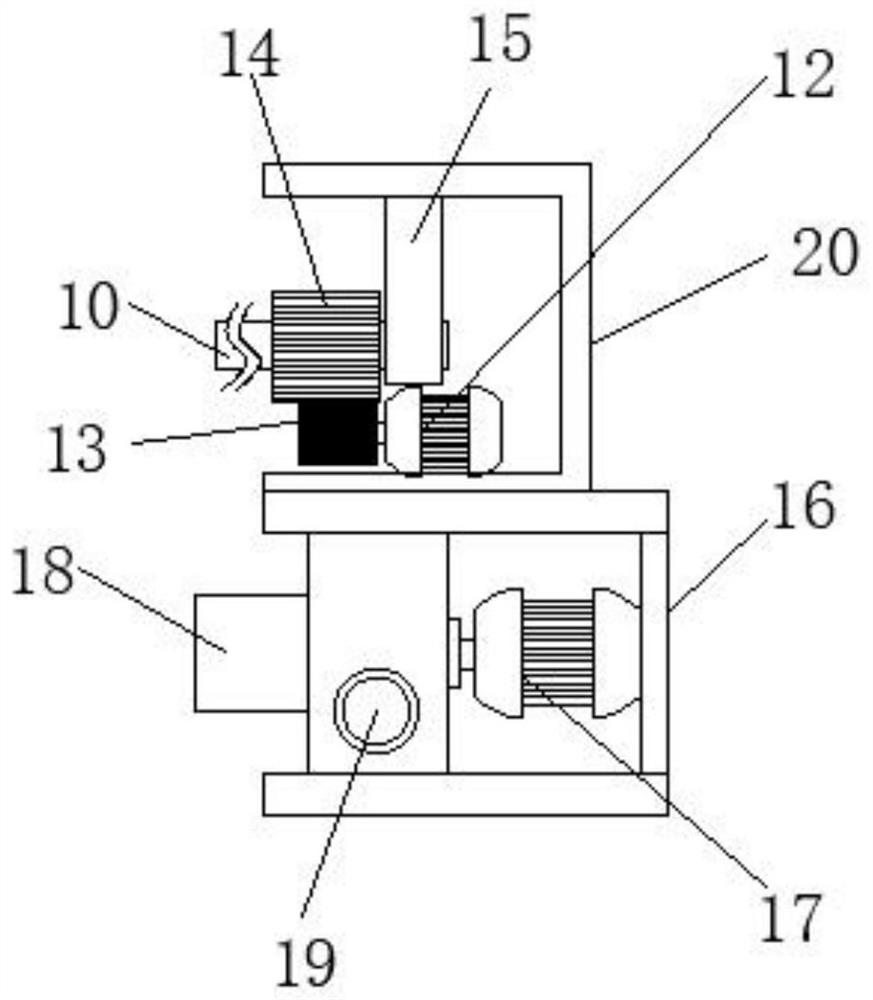

Equipment for detecting computer case finished product by utilizing punching pressure

ActiveCN110954399AChange the clamping forceAchieve the effect of clearingStrength propertiesComputer caseDeflection angle

The invention relates to the technical field of computer case punching and detection and further discloses equipment for detecting the computer case finished product by utilizing the punching pressure. The equipment comprises a shell, a rotating shaft is movably connected into the shell, a meshing block is movably connected to the surface of the rotating shaft, a sliding rod is movably connected to the surface of the meshing block, a punching part is movably connected to the end, away from the meshing block, of the sliding rod, a lever is slidably connected to the surface of the sliding rod, and an air bag is movably connected to the surface of the lever. The rotating shaft rotates to drive the meshing block to move from the surface to the center of the shell. In the process that the meshing block moves towards the center of the shell, the sliding rod is driven to move away from the rotating shaft; the clamping rods are guided by the guide wheels to be clamped on the upper portion andthe side face of the case plate respectively, the clamping rods can pull the ropes to compress the springs, and due to the fact that the movement displacement of the rods of the detection rods is related to the deflection angle of the lever, the effect that the clamping force changes along with the change of the punching force is achieved.

Owner:广州嘉泰电脑设备有限公司

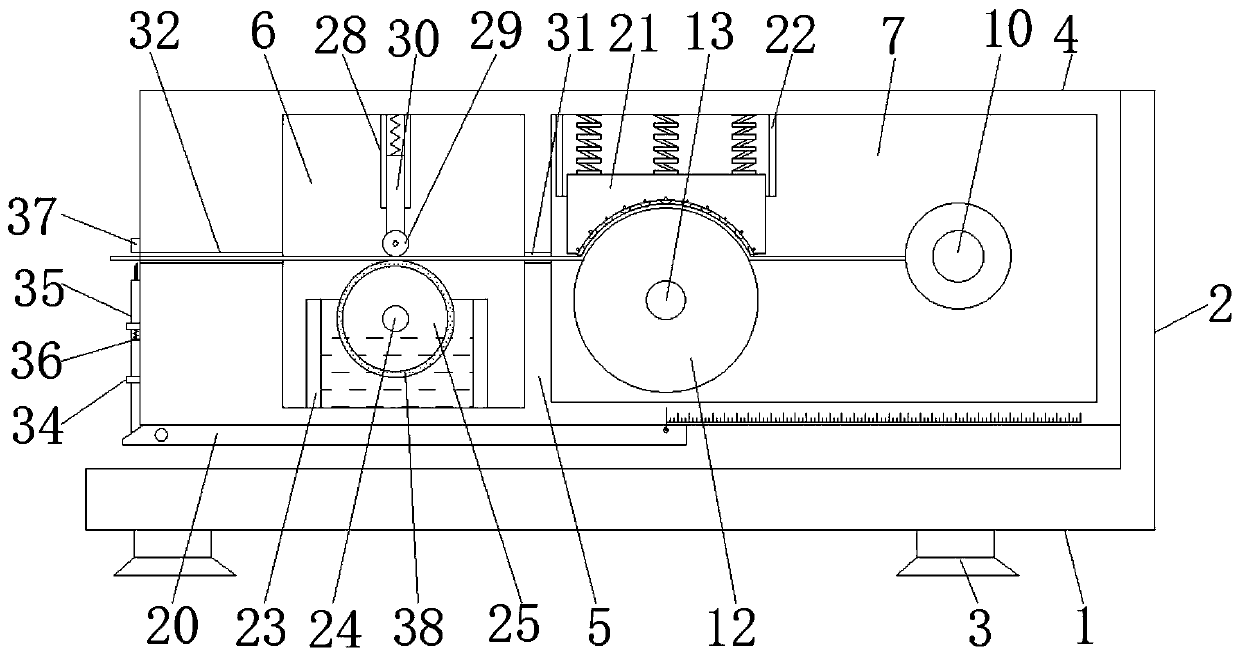

Surgical suture fixing box for operating room nursing

InactiveCN110584731AMobile will notKeep moistSuture equipmentsSurgical needlesLiquid storage tankOperating theatres

The invention discloses a surgical suture fixing box for operating room nursing. The fixing box comprises a base and a shell; a partition plate is vertically fixed in the shell; the partition plate divides the interior of the shell into a left cavity and a right cavity from left to right; a winding roller and a pay-off reel are sequentially fixed to the right cavity from right to left; one end ofa first fixing shaft horizontally extends out of the side wall of the shell and is fixedly provided with a first gear and a first belt wheel; the first gear is fixed to a first fixing shaft through aone-way bearing; a second fixing shaft is fixed to the outer side wall of the shell; a second gear matched with the first gear is fixed on the second fixing shaft; a liquid storage tank is fixed on the bottom end face of the left cavity; a third fixing shaft is fixed into the liquid storage tank through a bearing; and the third fixing shaft is sleeved with a wetting roller. The fixing box is reasonable in structure, medical staff can accurately and quickly take out surgical sutures with the required length from the surgical suture fixing box when preparing the surgical sutures, the working efficiency is improved, and the surgical sutures can be wetted when being taken out so as to guaranteed that the surgical sutures are always kept wet in the wound suturing process.

Owner:李荣荣

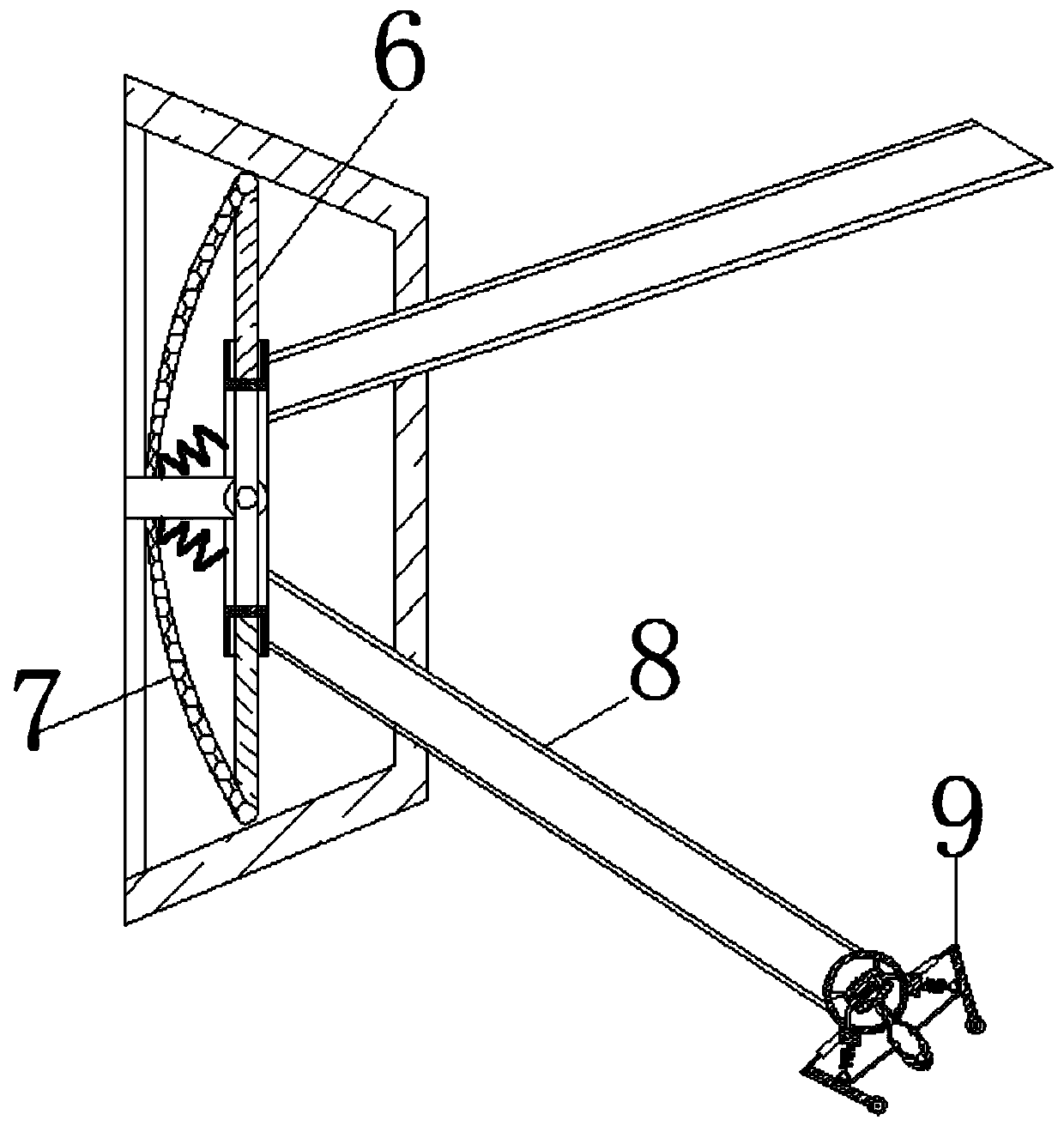

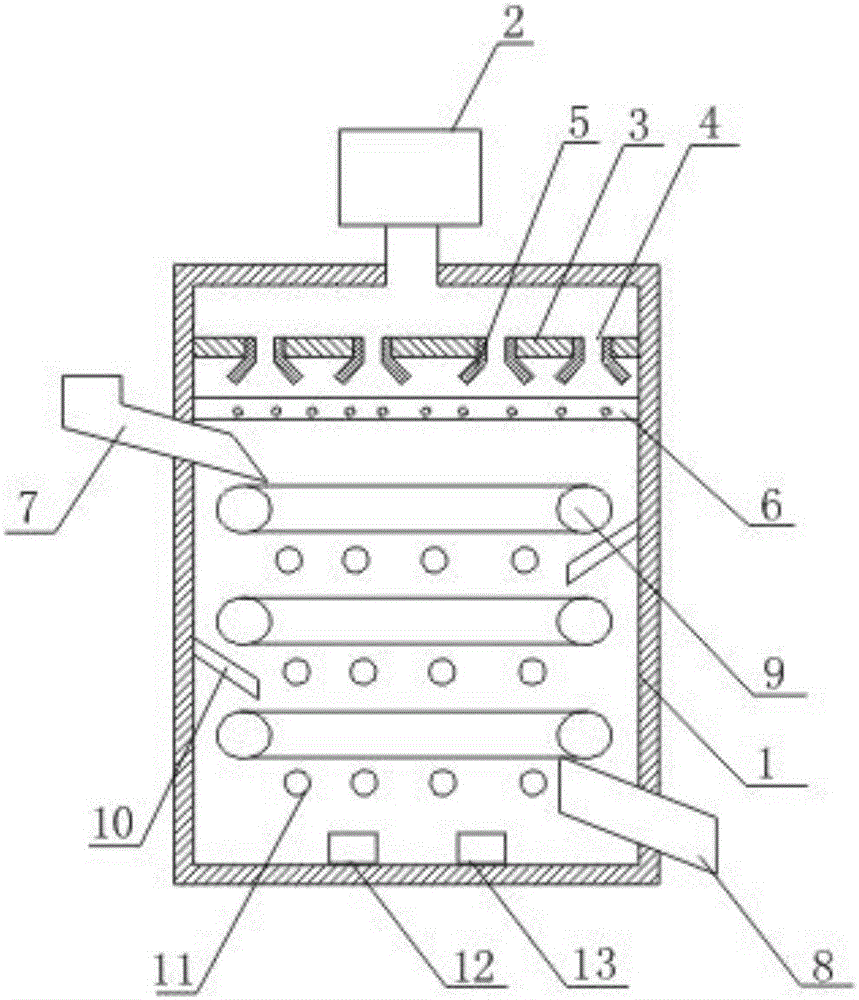

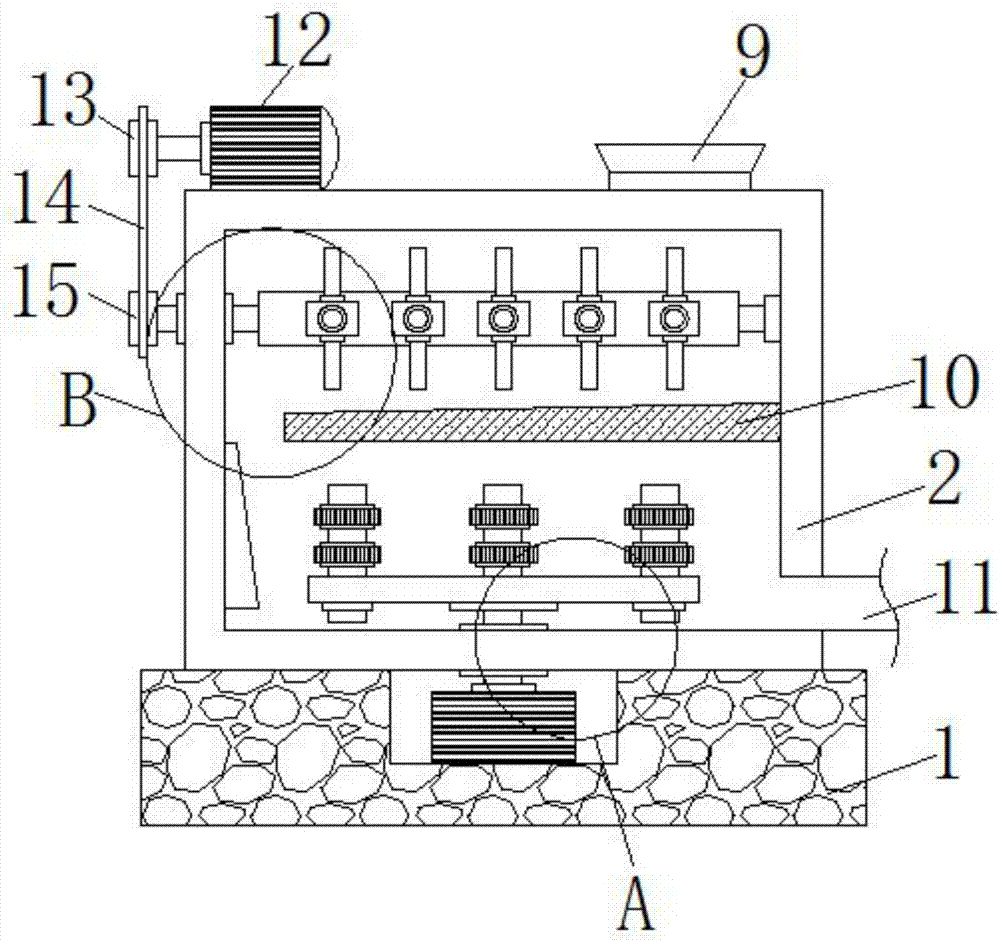

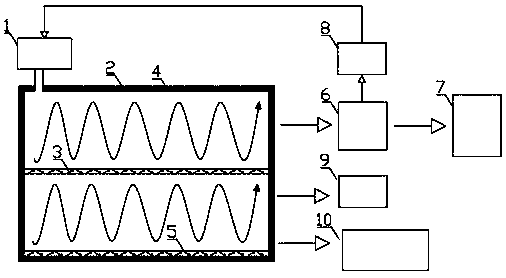

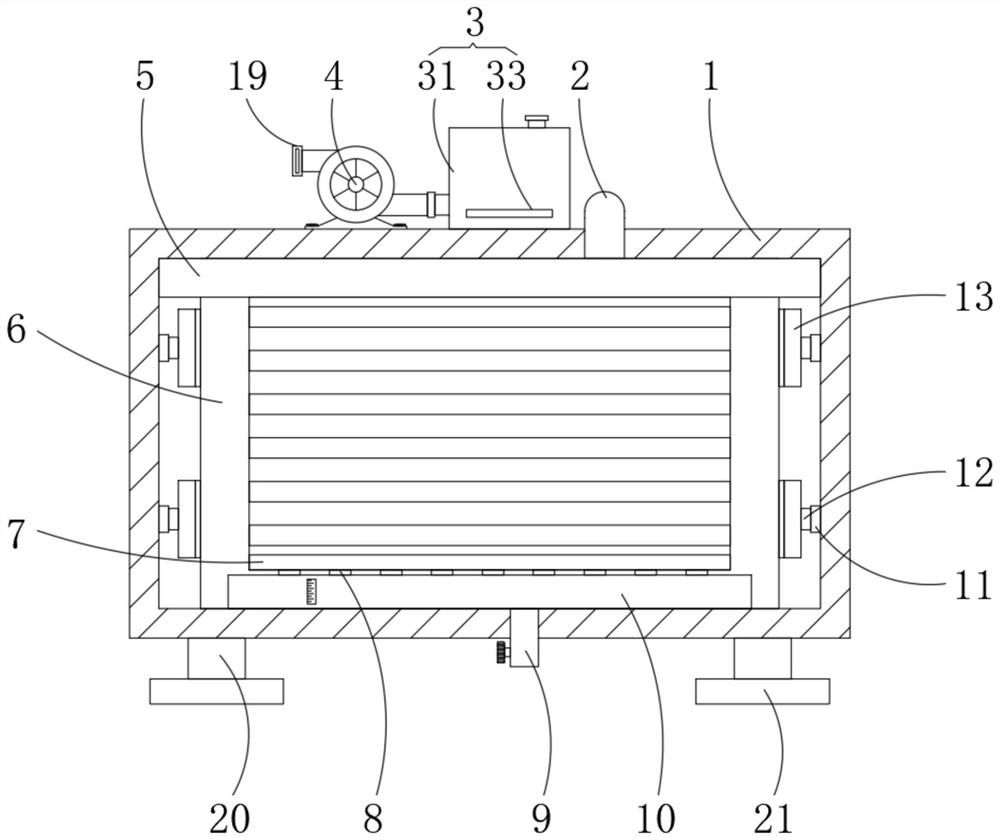

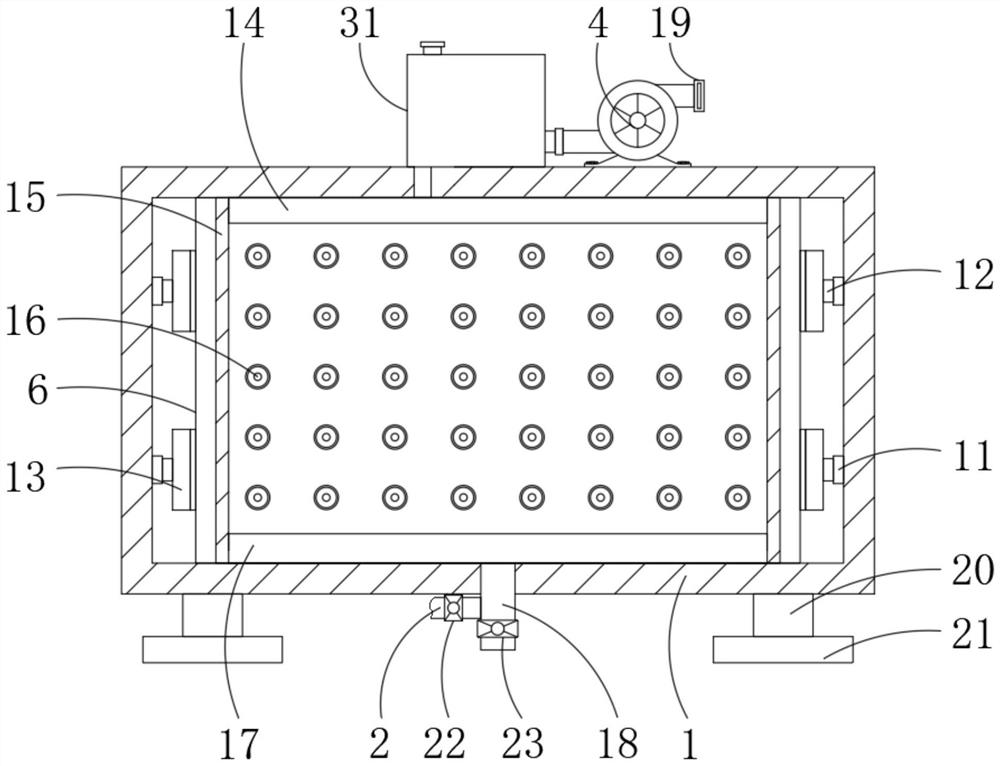

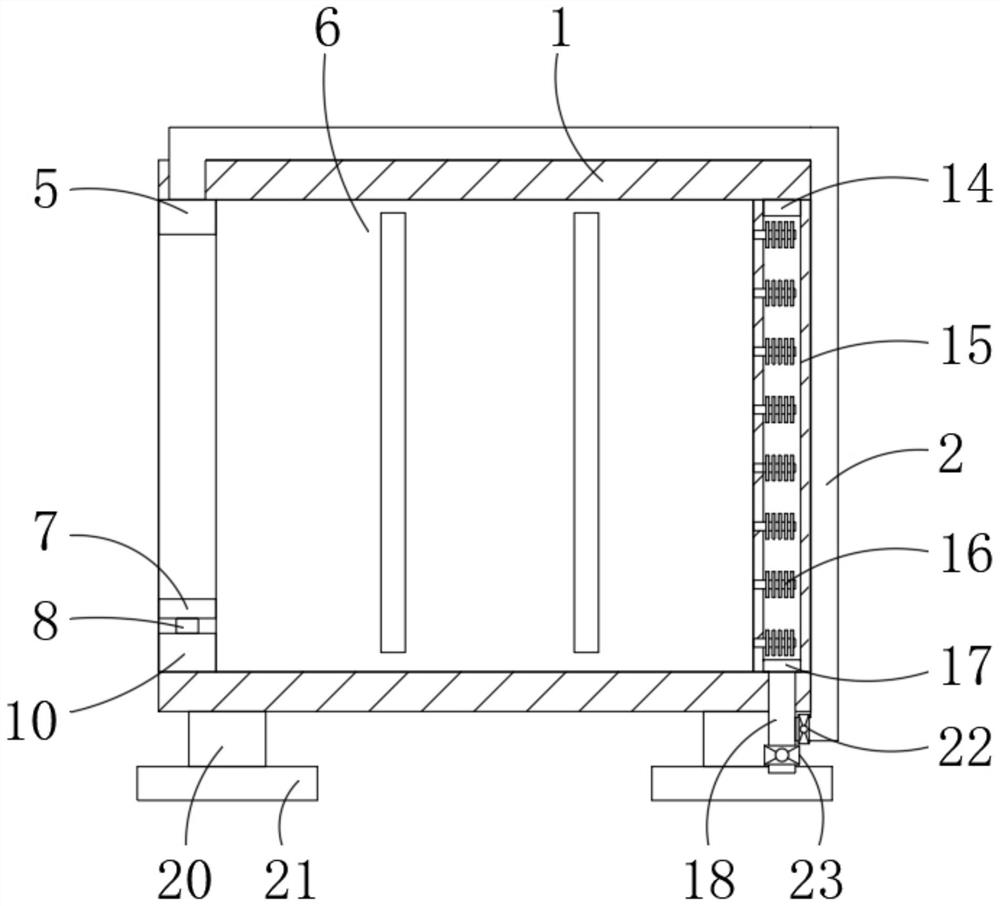

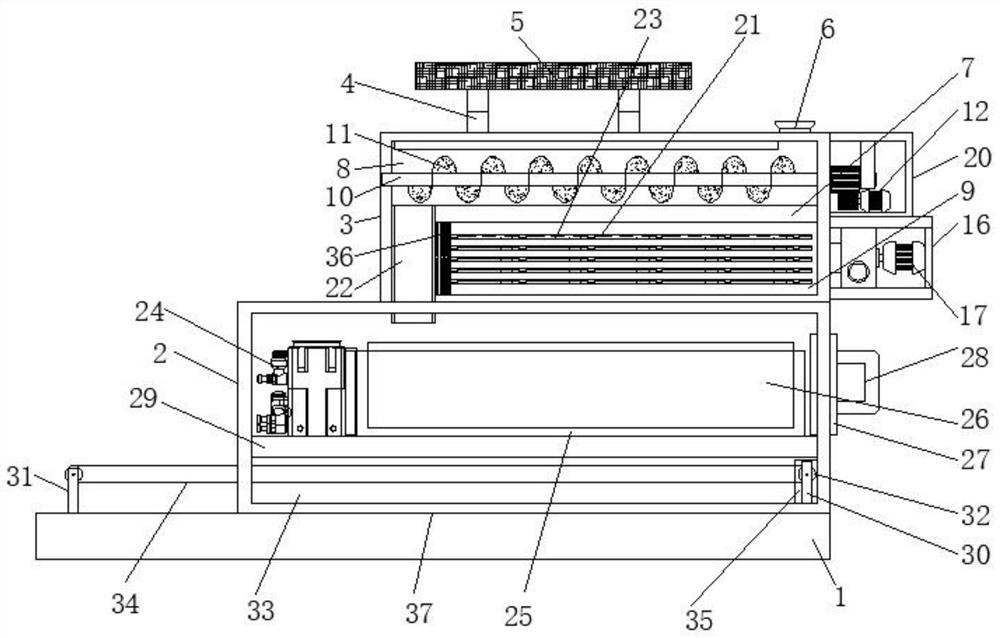

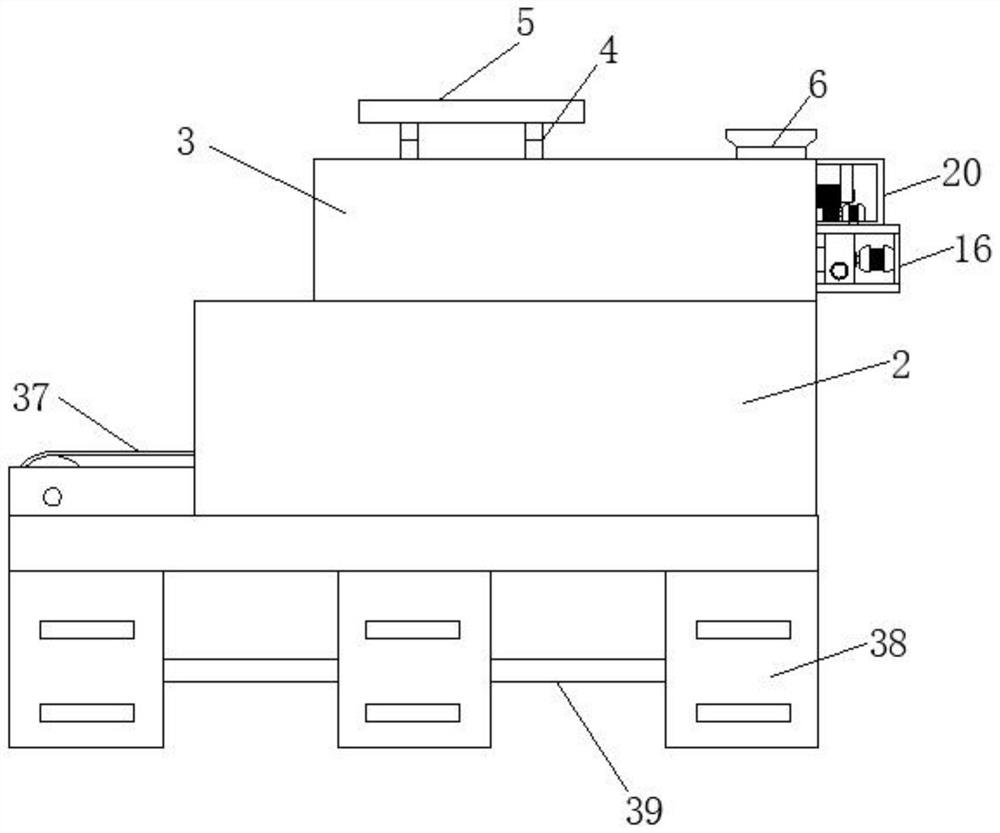

Device for evenly drying objects

InactiveCN106174646APlay the role of evenly distributed diversionPlay a buffer roleFood treatmentFruits/vegetable preservation by dehydrationEngineeringDried fruits

The invention discloses a device for evenly drying objects. The device comprises a drying box, the upper end of the drying box is connected with an air heater, a baffle A is arranged on the upper portion of an inner cavity of the drying box, ventilation openings are evenly distributed in the baffle A, and flow guide sheets are arranged on the two sides of the ventilation openings respectively. A porous separation plate is arranged below the baffle A, and a hot air buffer area is formed between the porous separation plate and the upper surface of the drying box. A feeding channel is formed in the top of one side face of the drying box, a discharging channel is arranged at the bottom of the other side face of the drying box, a conveying device is further arranged in the drying box and located below the porous separation plate, the feeding channel extends to the upper surface of the feeding end of the conveying device, and the discharging channel is in contact with the discharging end of the conveying device. The arranged hot air buffer area achieves a buffer function on hot air, the hot air can slowly dry fruits and vegetables after passing through the porous separation plate, and the situation that hot air suddenly enters the upper surfaces of the fruits and vegetables for strong drying, and the lower surfaces of the fruits and vegetables are not heated is avoided.

Owner:成都元始信息科技有限公司

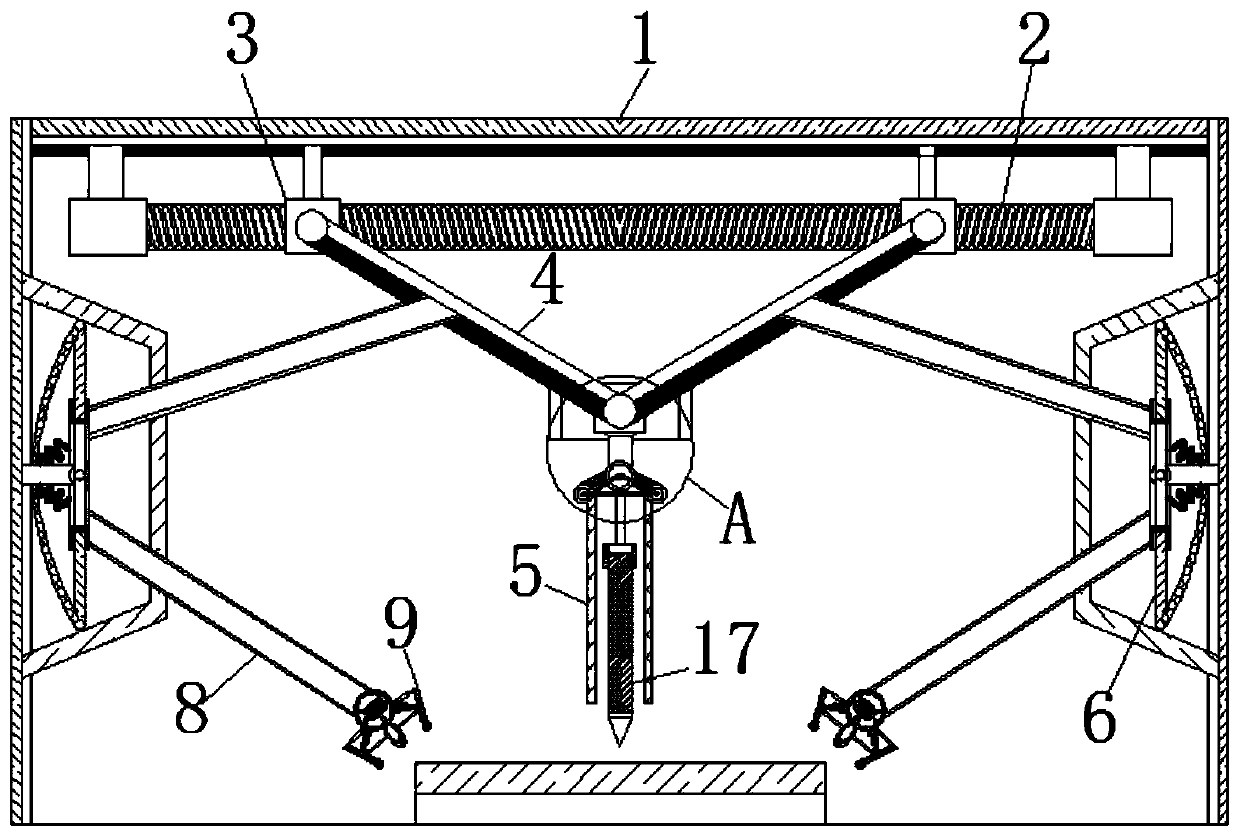

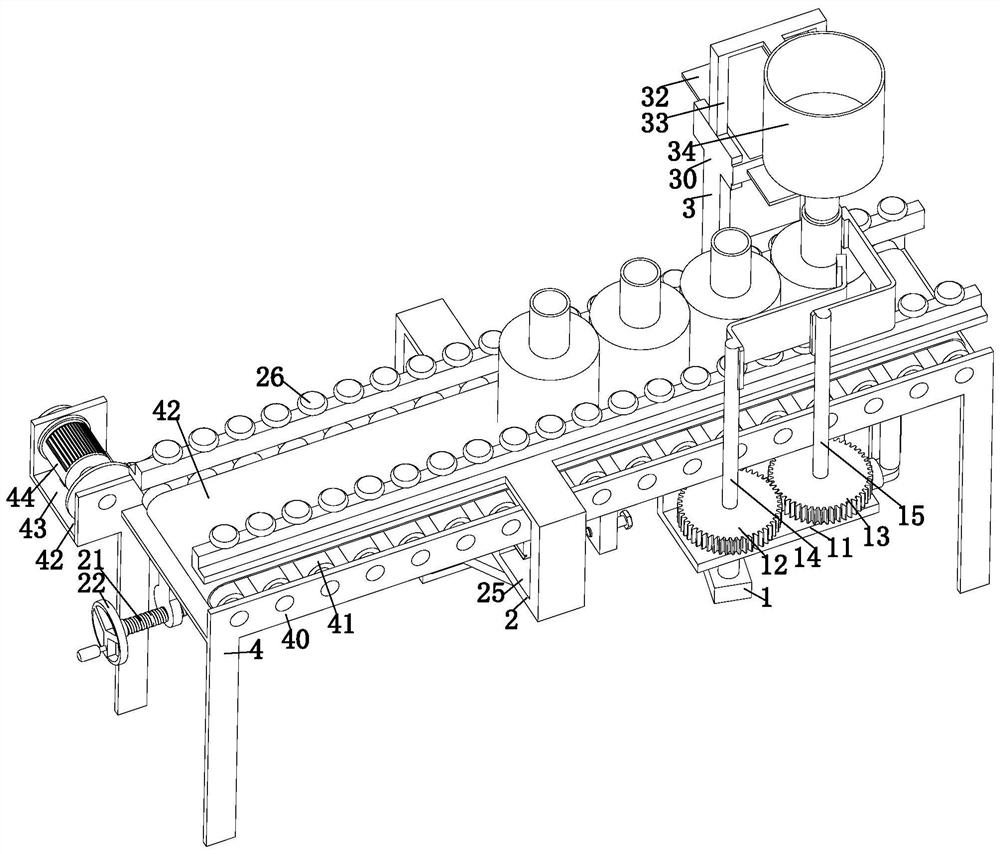

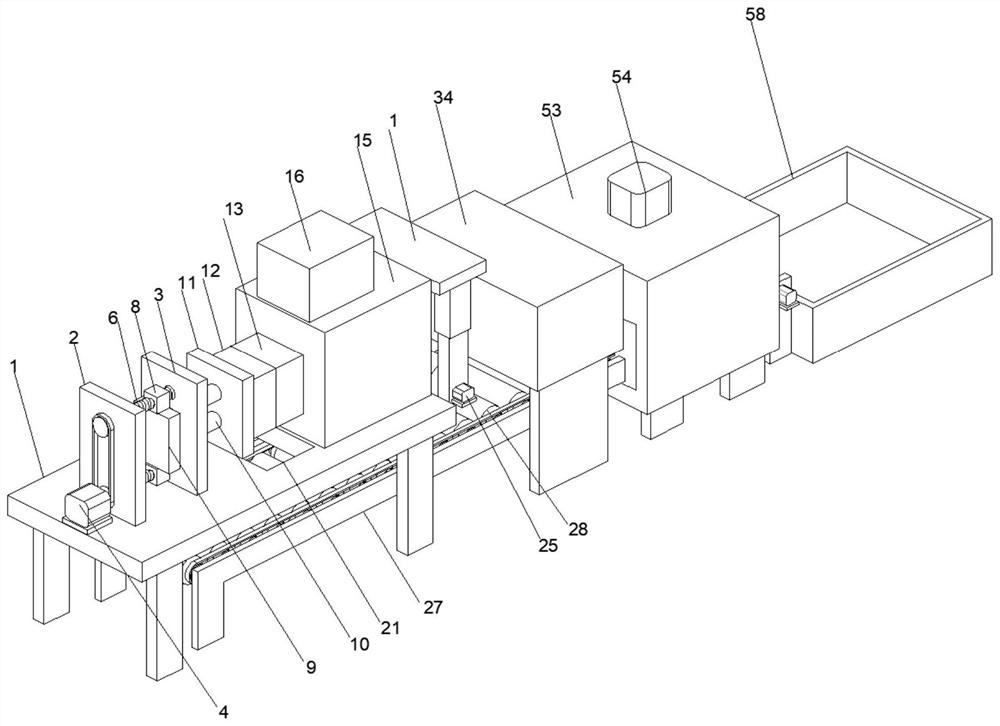

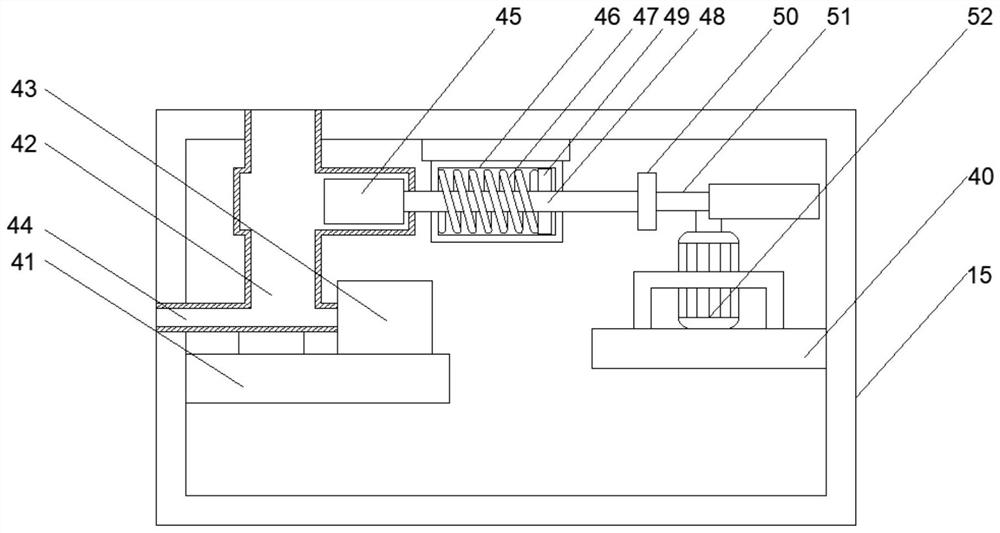

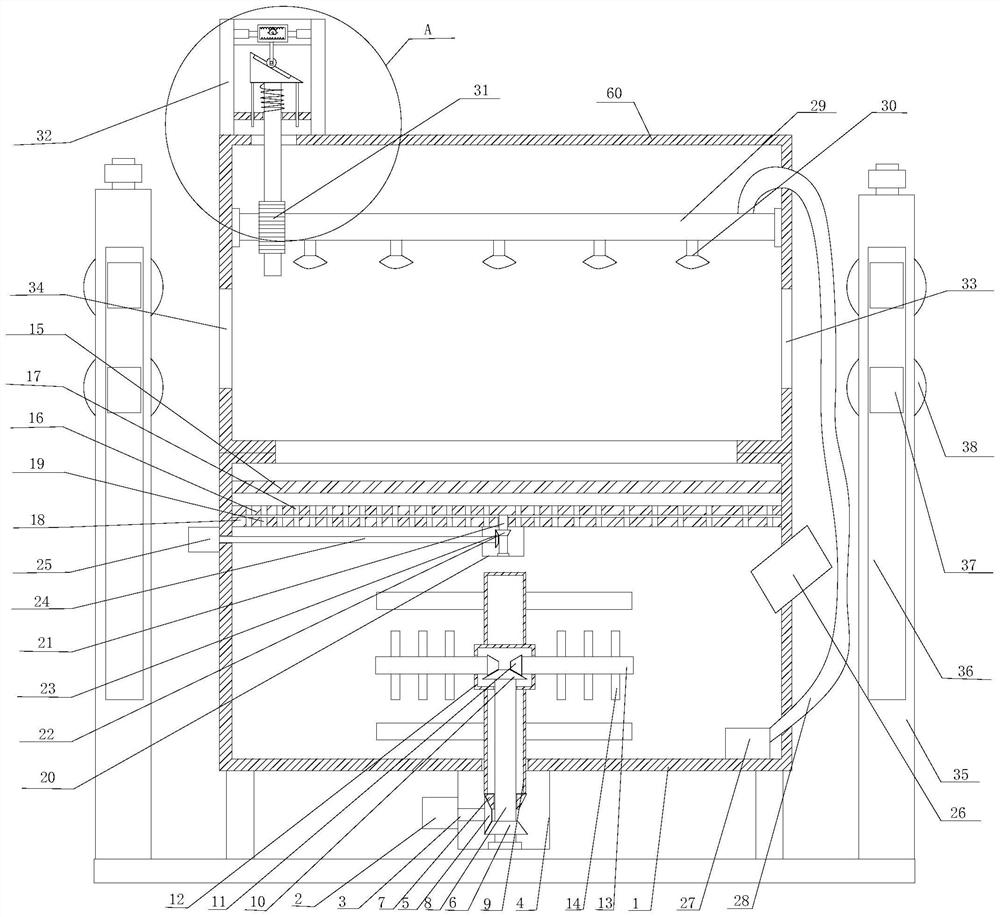

Integrated machining equipment of die-casting machine for button machining

The invention discloses integrated machining equipment of a die-casting machine for button machining. The integrated machining equipment of the die-casting machine for button machining comprises a rack, wherein a first fixed plate, a second fixed plate and a first motor are fixedly installed at the upper side of the rack; a first thread is fixedly connected to an output end of the first motor; a second thread rod is connected to the first motor in a transmission manner and through a first chain; moving blocks are connected to the surfaces of the first thread and the second thread through threads separately, and a moving plate is fixedly connected between the two moving blocks; a support rod is fixedly connected to the right side of the moving plate; the support rod is slidably connected with the second fixed plate; and a connection plate is fixedly installed at the other end of the support rod. According to the integrated machining equipment of the die-casting machine for button machining, through arrangement of a stirring box, molten liquid metal is temporarily stored, and continuous multiple die-casting operation can be carried out; through arrangement of a quantification device,the metal liquid needed for completing one die-casting can be regularly and quantitatively conveyed, so that waste for materials is avoided, time and labor are saved, the labor intensity of working personnel is reduced, and the die-casting efficiency of the die-casting machine is increased.

Owner:东莞市恒兴隆实业有限公司

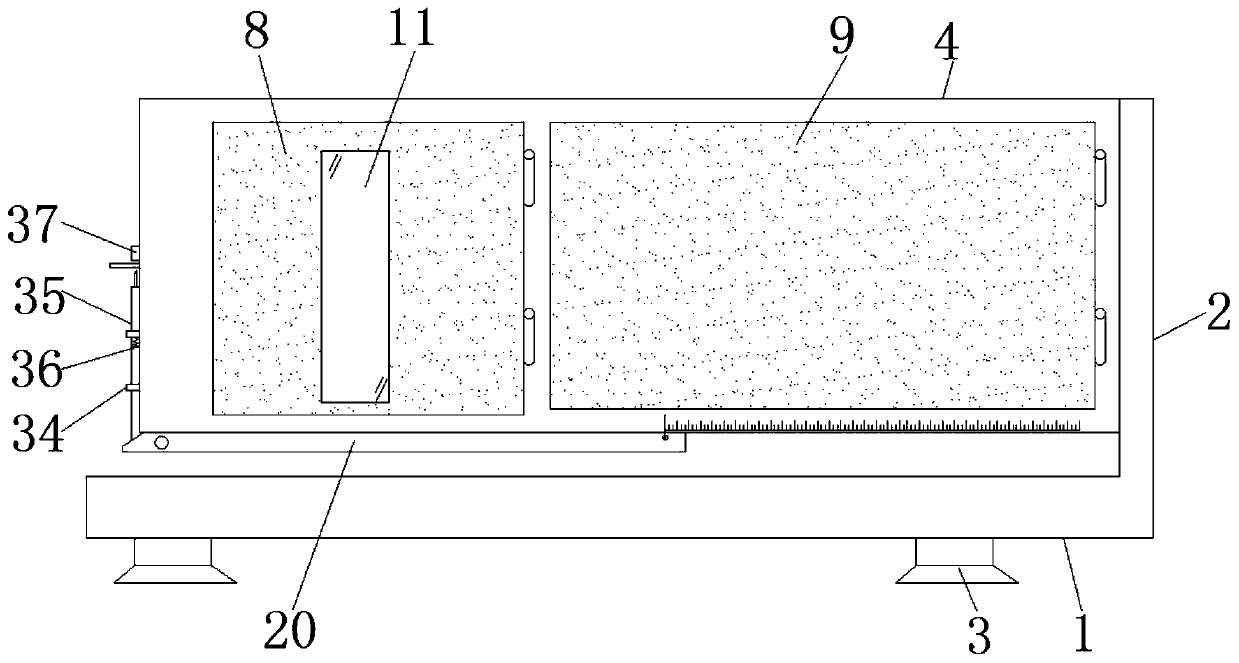

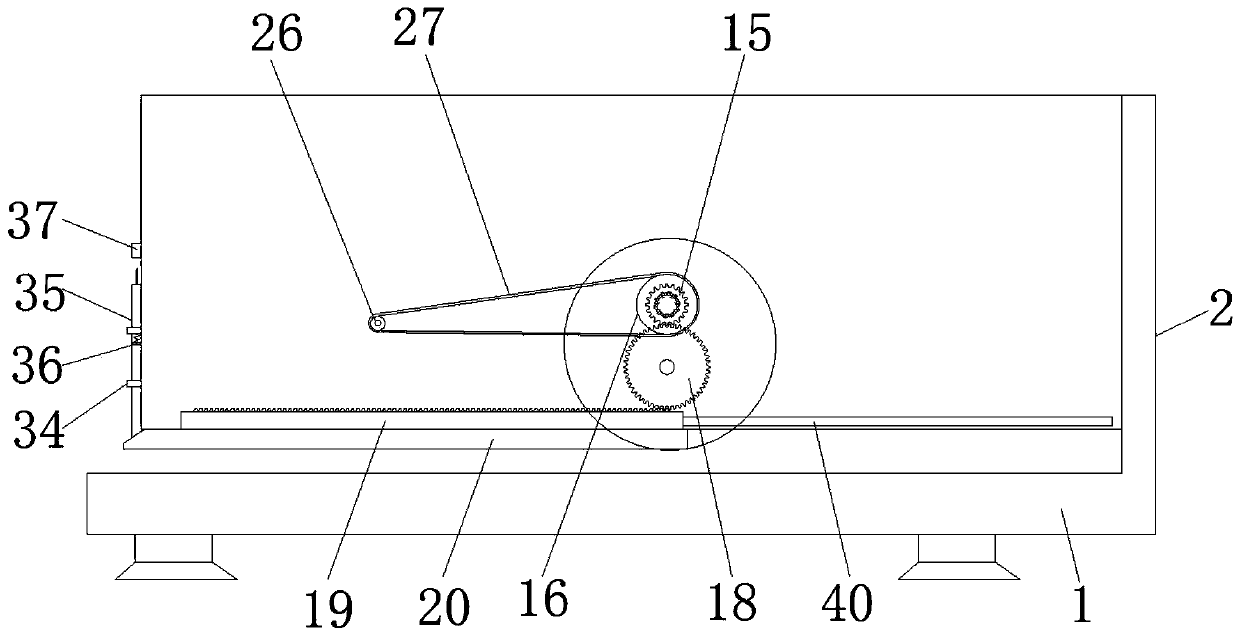

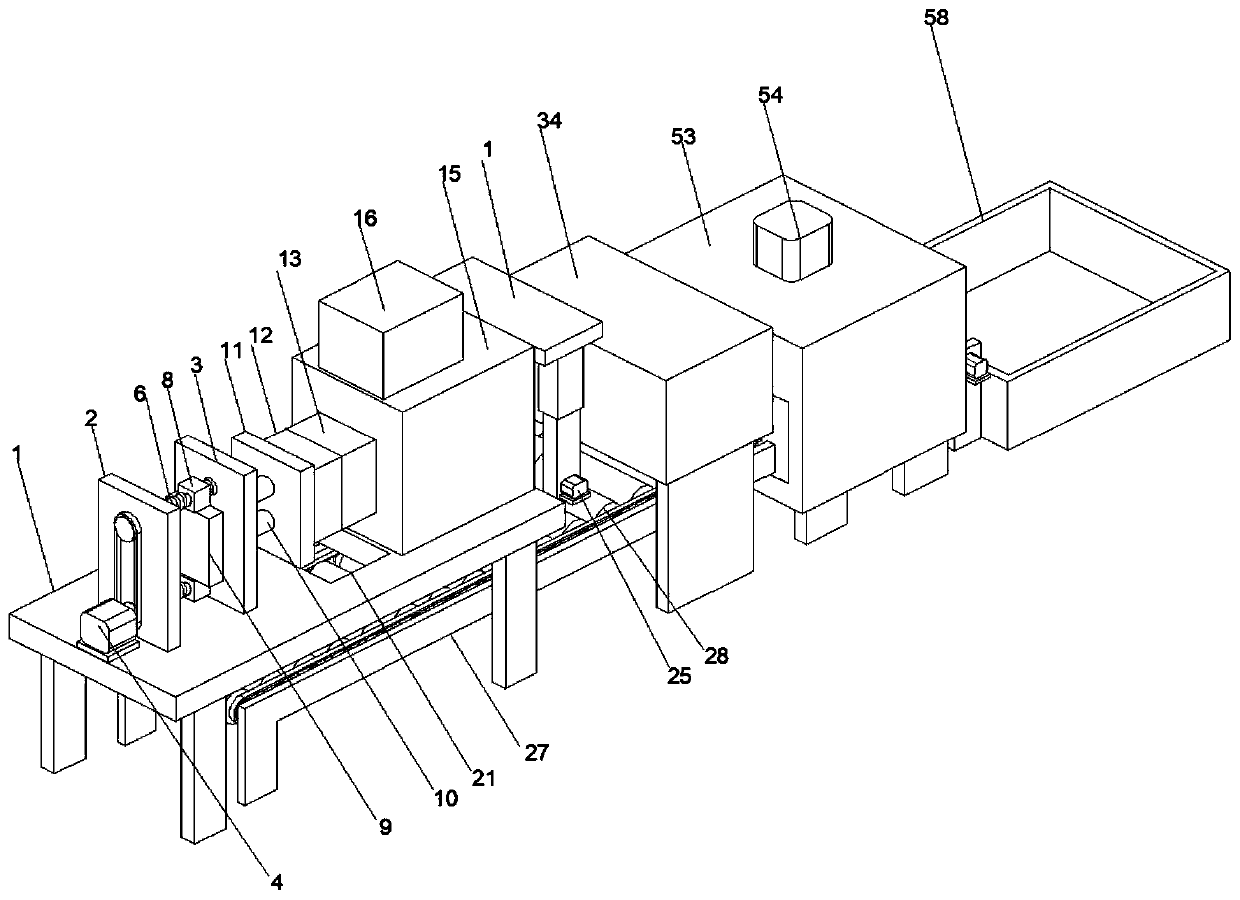

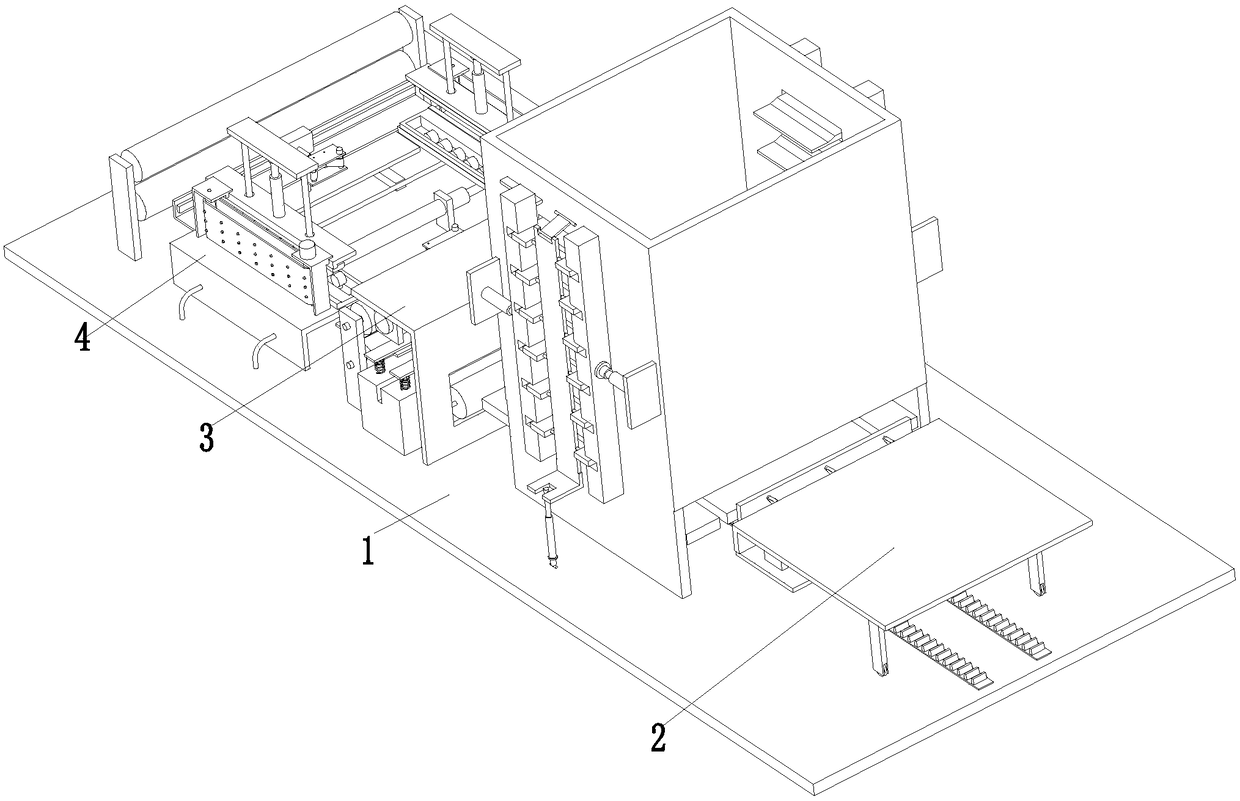

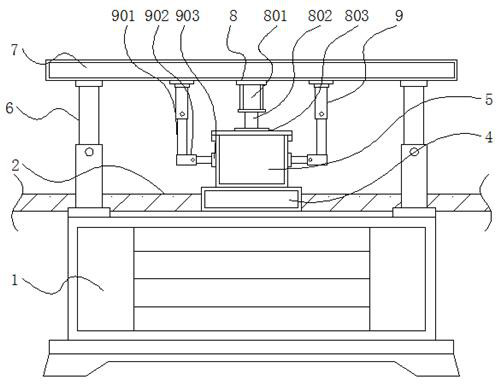

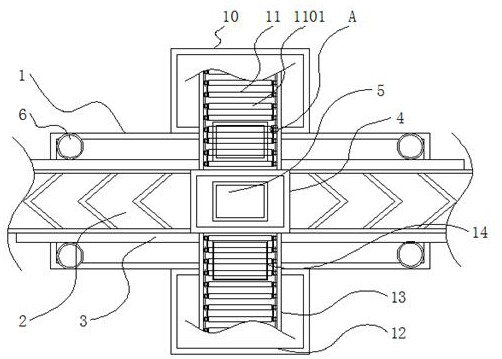

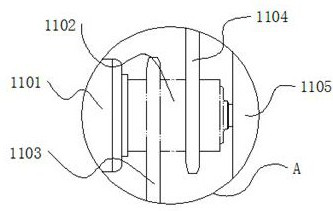

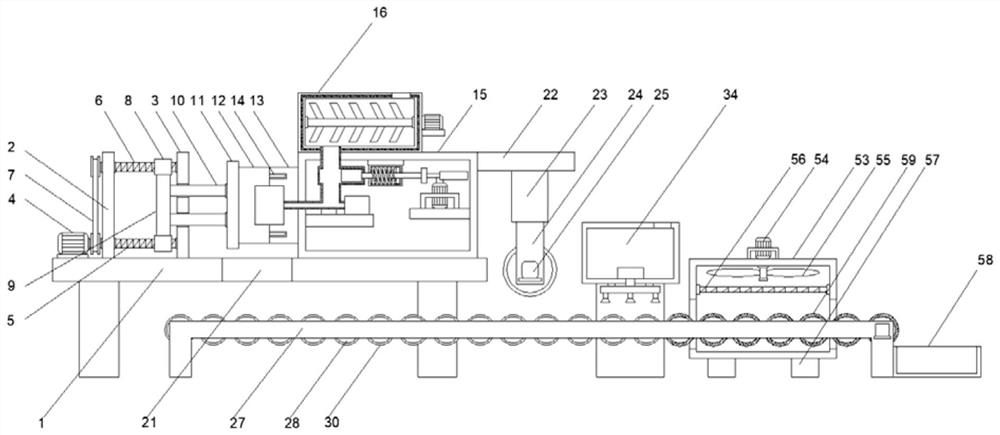

Environment-friendly processing assembly line for building materials

InactiveCN108466350AReduce processing efficiencyRealize the function of automatic processingEdge grinding machinesGrinding carriagesProcess efficiencyEngineering

The invention relates to an environment-friendly processing assembly line for building materials. The environment-friendly processing assembly line comprises a bottom plate, wherein a limiting and pushing device, a stable cutting device and a grinding conveying device which are sequentially mounted on the bottom plate from front to rear; the limiting and pushing device comprises a limiting workingframe mounted on the bottom plate; a pushing inlet is formed in the rear side of the lower end of the limiting working frame; and two limiting auxiliary mechanisms are arranged on the limiting working frame. The environment-friendly processing assembly line for the building materials can solve the problems that material waste is caused, processing efficiency of straw tiles is reduced, manual straw tile cutting is unstable, straw tiles quickly vibrate in a cutting process and need to manually fix, operations are complex and cutting precision is low and poor as the straw tiles need to manuallycut and process, corners of the straw tiles need to grind, processing number of the straw tiles needs to manually control, and manual controlling and processing number is inaccurate in an existing process of manually processing and processing straw tiles.

Owner:王冰建

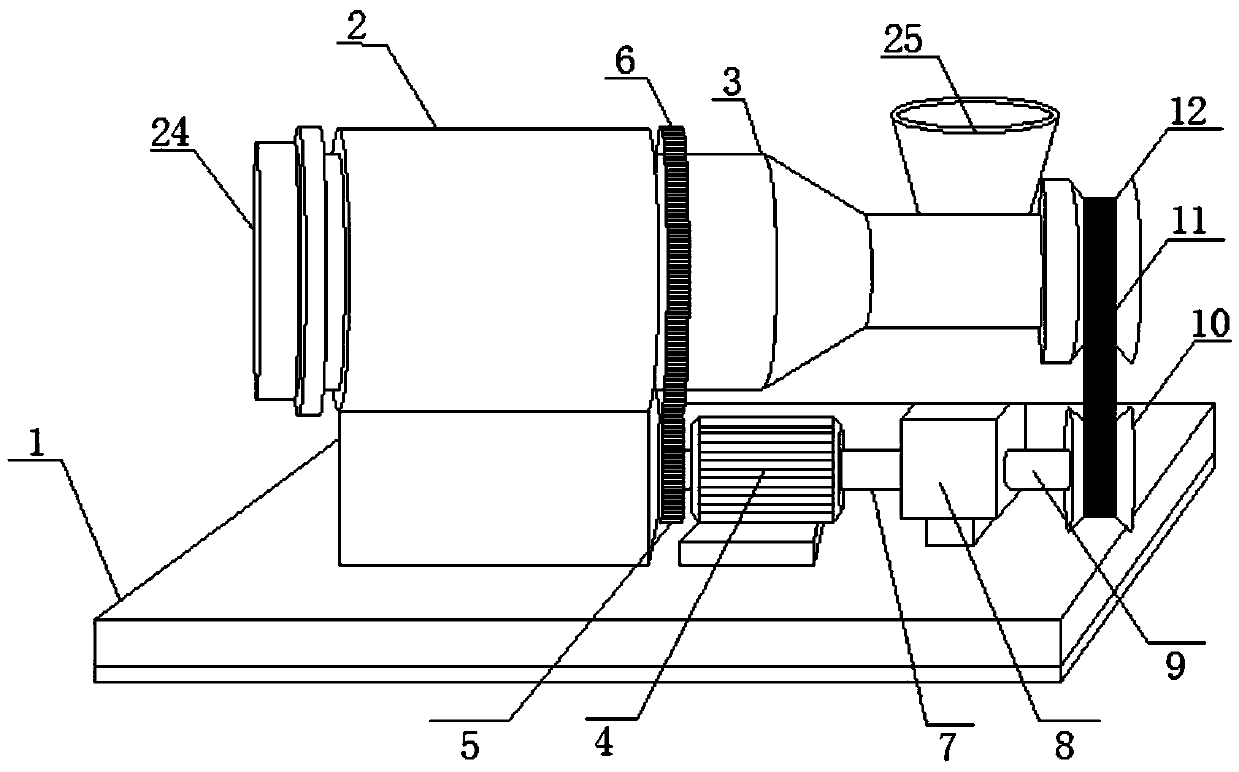

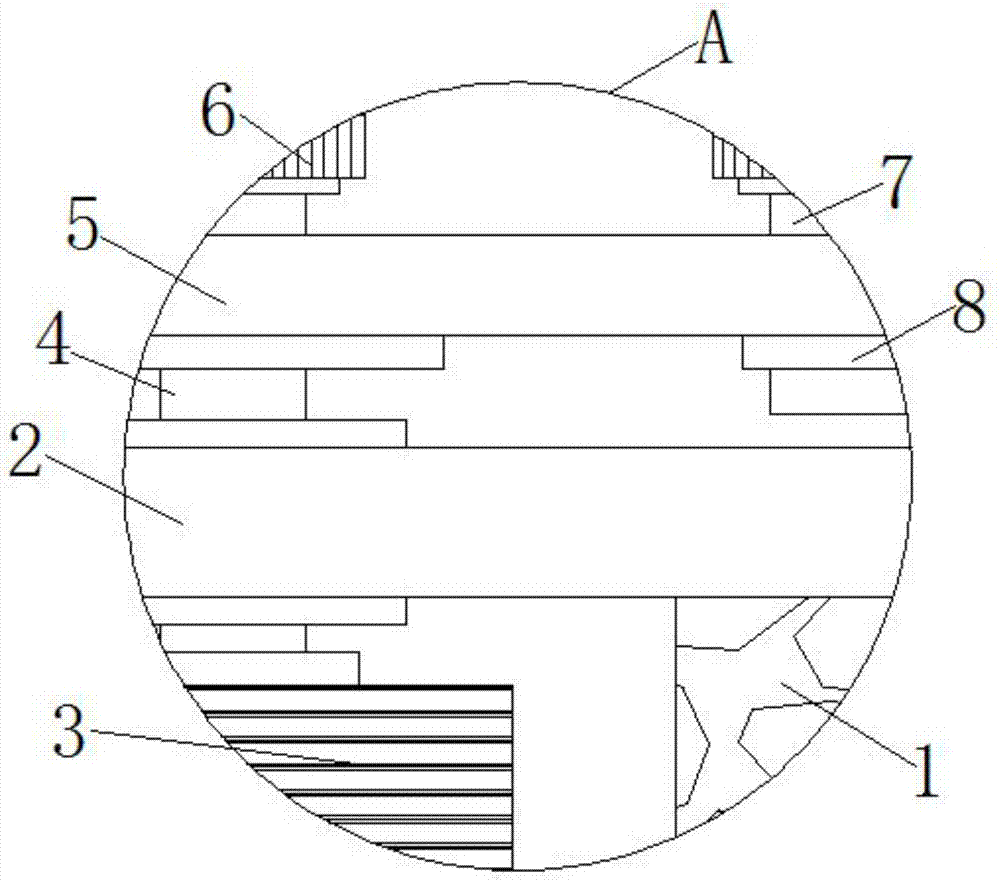

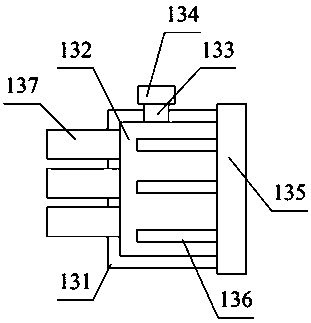

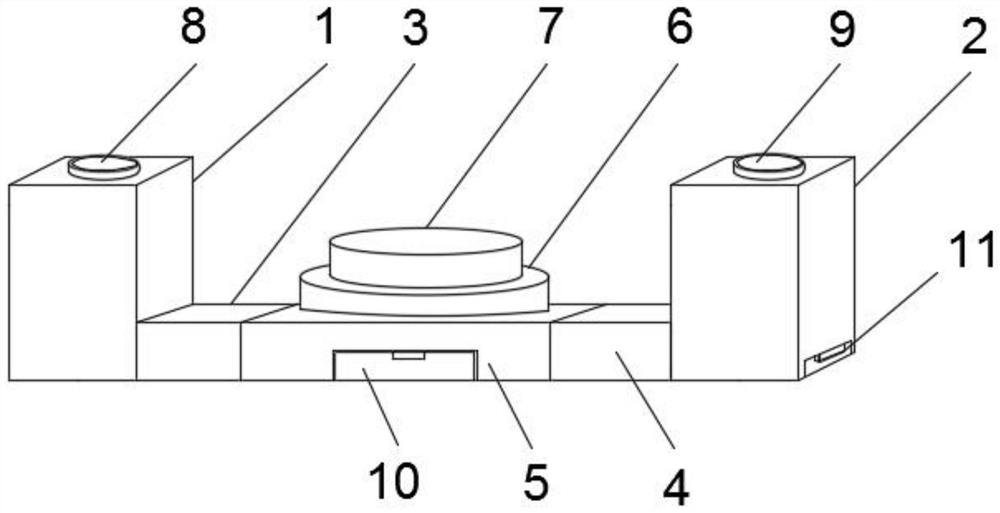

Novel electro-optical ceramic processing grinding device

InactiveCN109531395AWell groundPlay the role of conveyingEdge grinding machinesGrinding carriagesEngineeringRaw material

The invention discloses a novel electro-optical ceramic processing grinding device. The novel electro-optical ceramic processing grinding device comprises a base, a supporting block, a grinding box and a motor. The supporting block is fixedly connected to the upper end of the base. The grinding box is movably inserted and connected in the supporting block. The motor is fixedly connected to the upper end of the base. A gear is fixedly connected to one output end of the motor and is in meshing connection with a gear ring. The gear ring is fixedly in cup joint to the outer side wall of the grinding box. The side wall of one end of the grinding box is in penetrating connection with a feeding port. Electro-optical ceramic raw materials are poured in from the feeding port, the grinding box rotates along with running of the motor, a spiral conveying paddle rotates, then under driving of the spiral conveying paddle, the materials are conveyed to the positions of grinding balls, the spiral conveying paddle can achieve a conveying function at the time, and the pulverizing function can be achieved as well.

Owner:合肥易美特建材有限公司

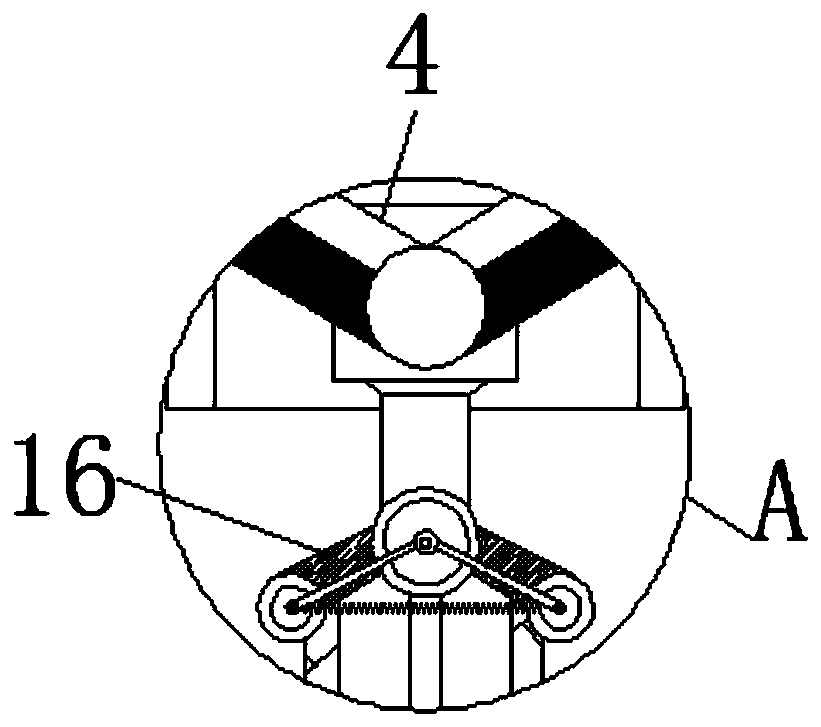

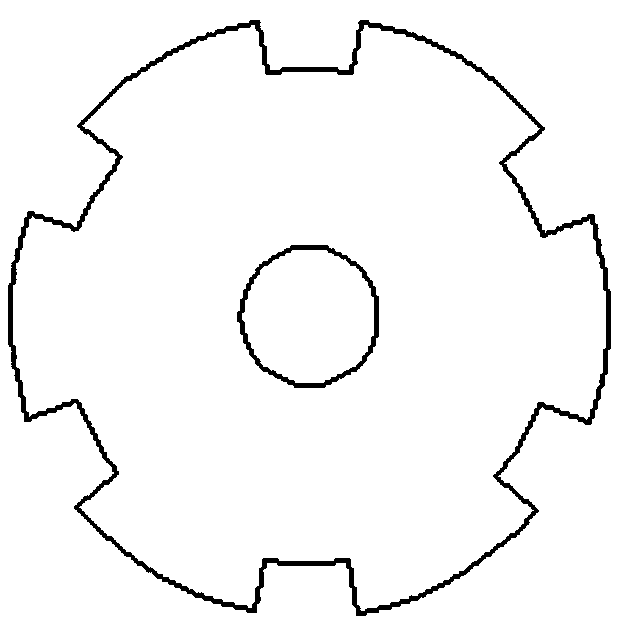

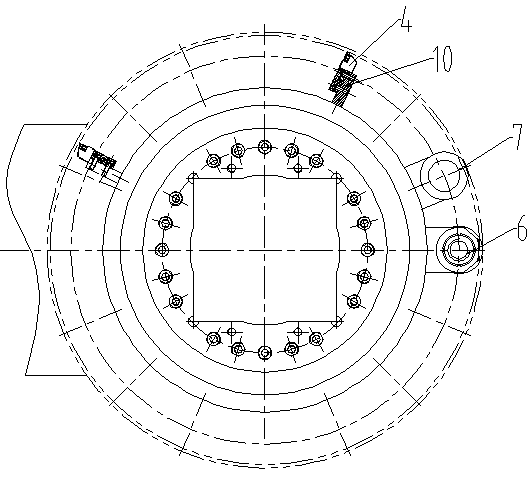

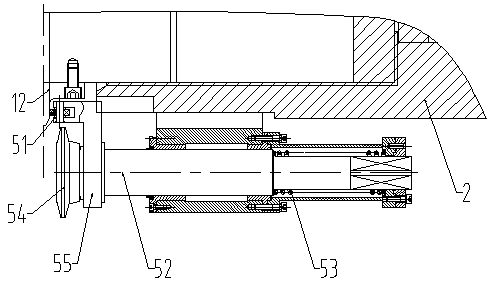

Rectangle hard rock shield cutter head

The invention discloses a rectangular hard rock shield cutter head. The cutter head solves the problems that in the prior art, cutter heads applied to rectangular tunnel construction are complex in structure, complicated in preparation work, large in impact force and the like. According to the technical scheme, the rectangular hard rock shield cutter head comprises a supporting frame, a roller cutter head body and a cutter set, the roller cutter head body is connected with a deceleration device mounted on the supporting frame, and the cutter set is mounted on the roller wall of the roller cutter head body; the cutter set comprises a hobbing cutter, a cutter and retractable cutters, the hobbing cutter is circumferentially arranged on the roller wall of the roller cutter head body, the cutter is radially arranged on the roller wall of the roller cutter head body, and the retractable cutters are symmetrically arranged on the roller wall of the roller cutter head body. According to the rectangular hard rock shield cutter head, the propulsion force and the cutting rotation power are relatively low, the fluctuation angle of the cutting force is small, and impact and vibration on equipment are weak. By adjusting the axial length of the cutting equipment and the supporting mode of a bracket, the cutter head can adapt to tunneling of partial sections and a whole section.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

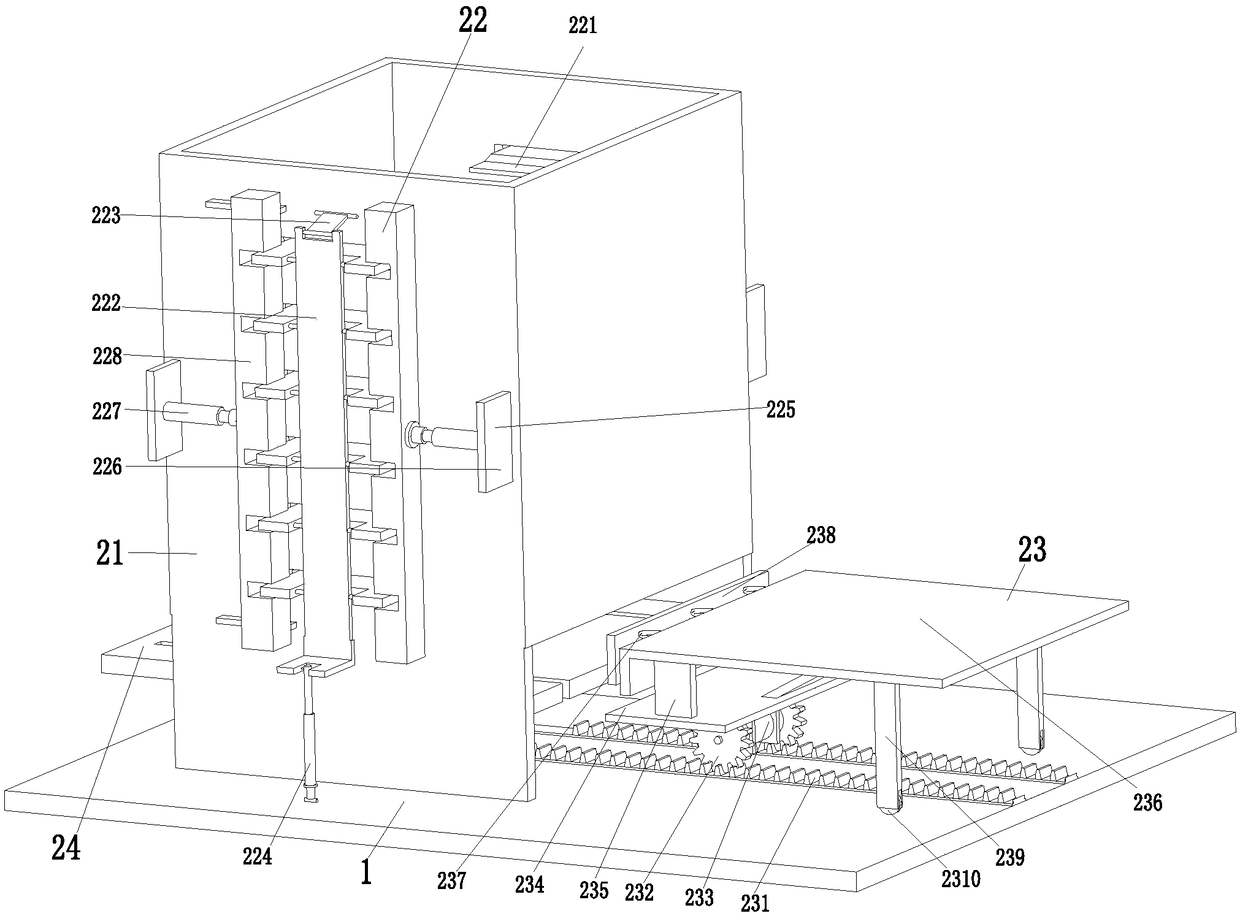

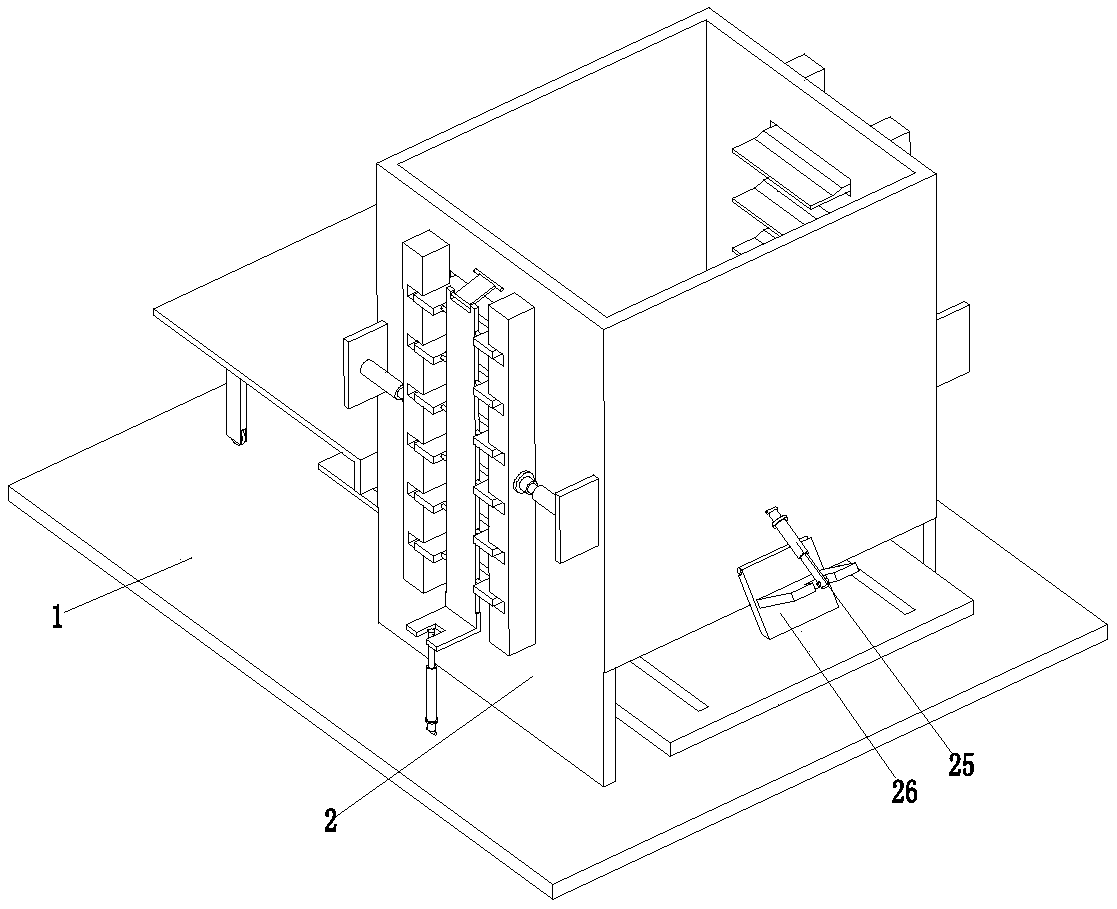

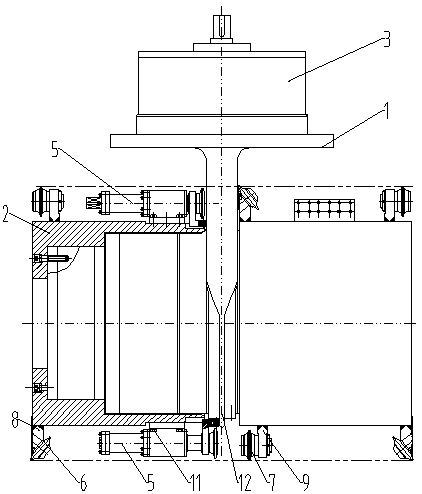

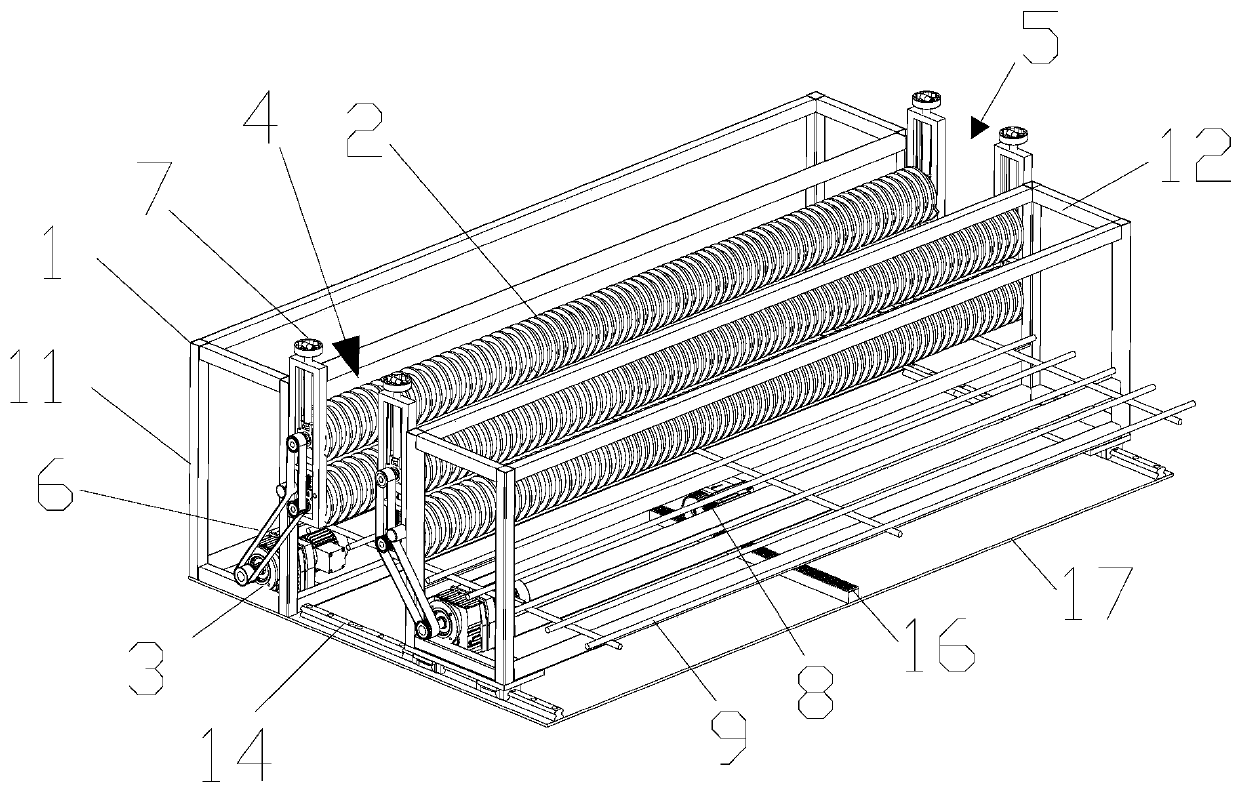

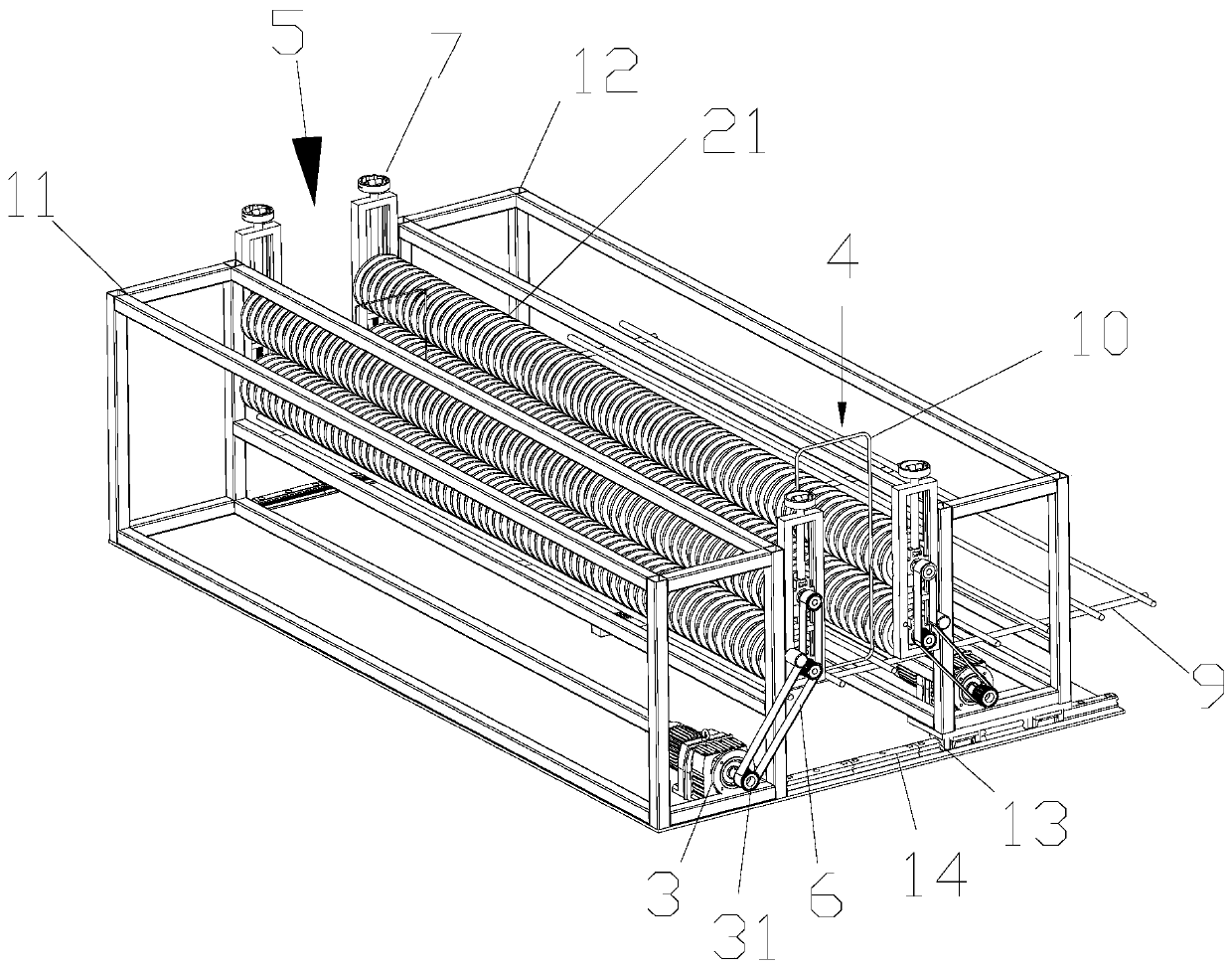

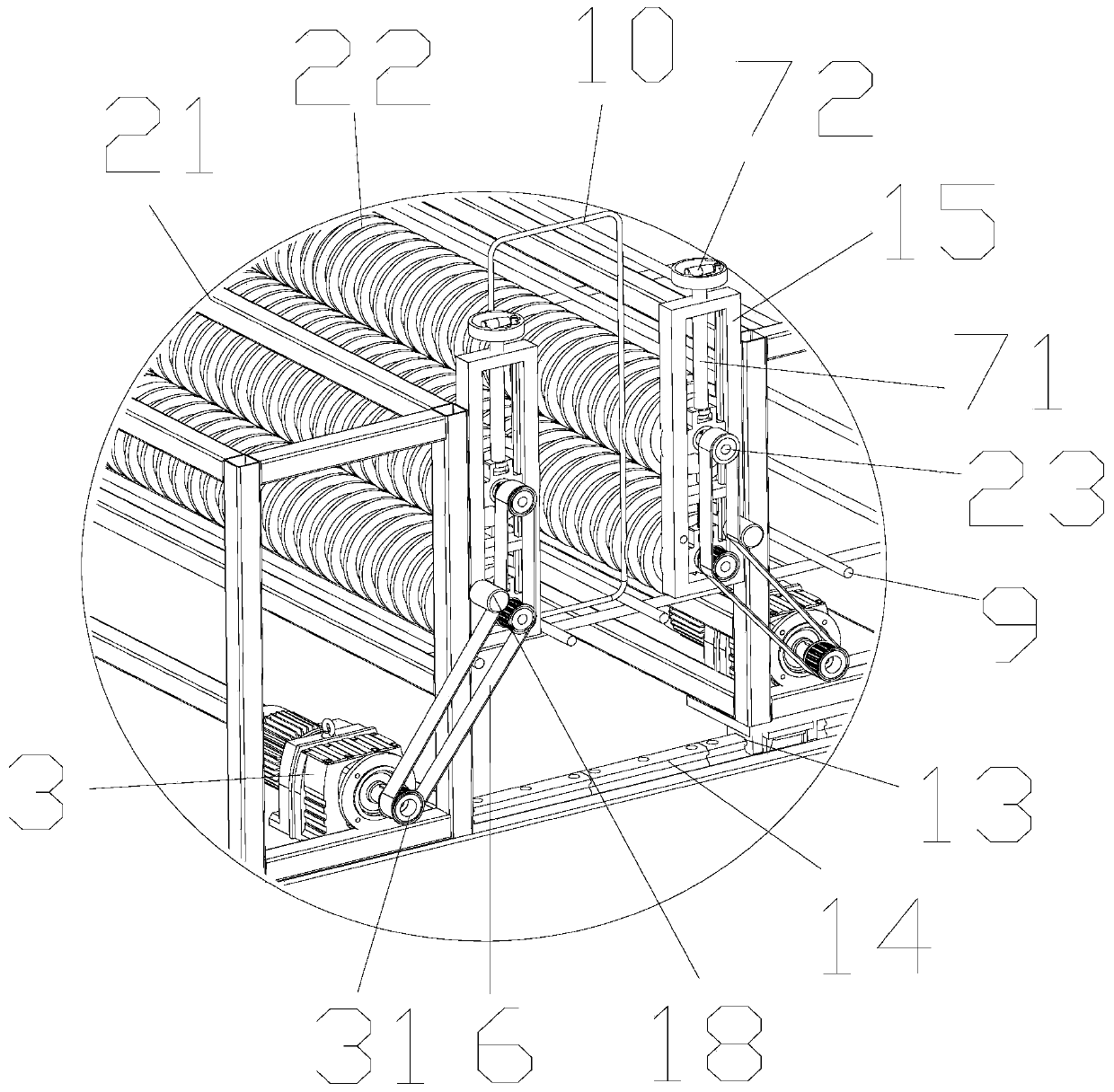

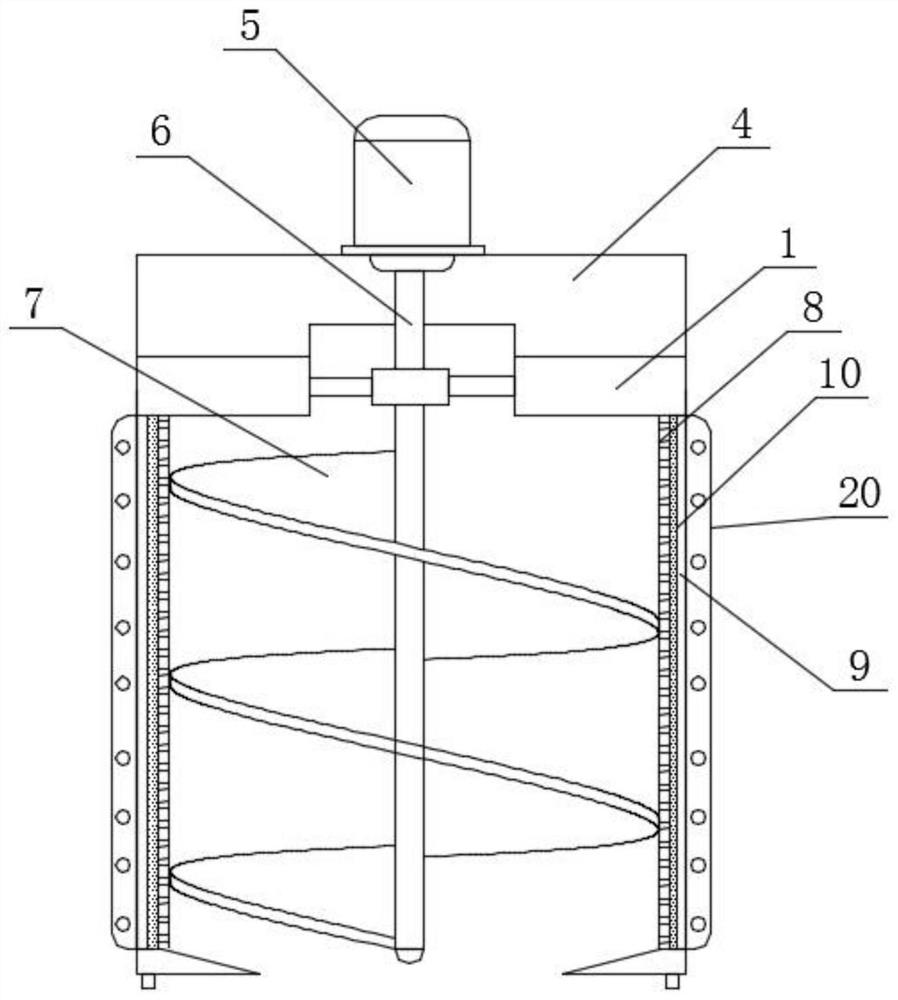

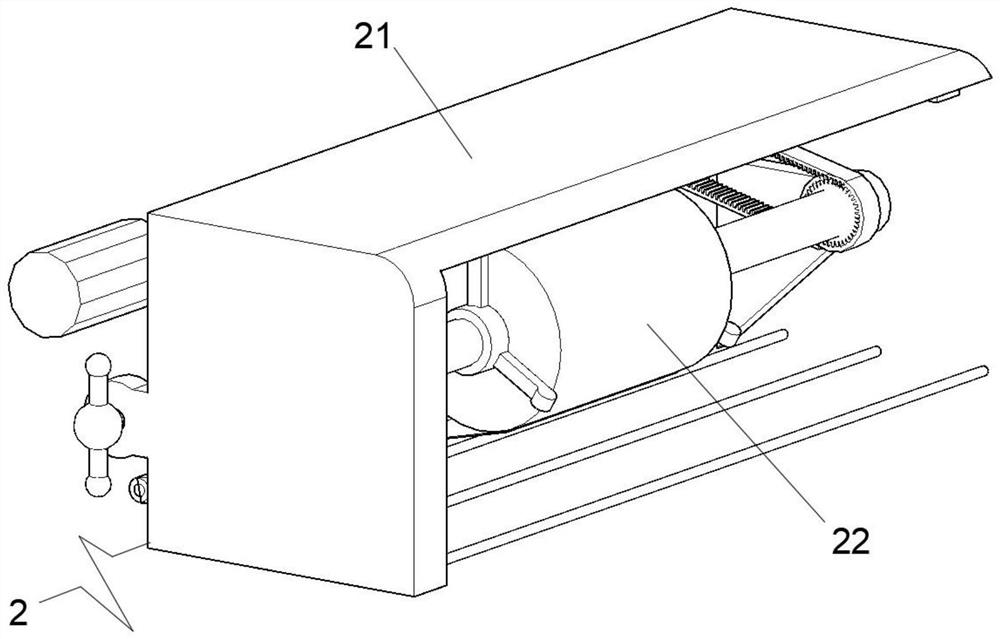

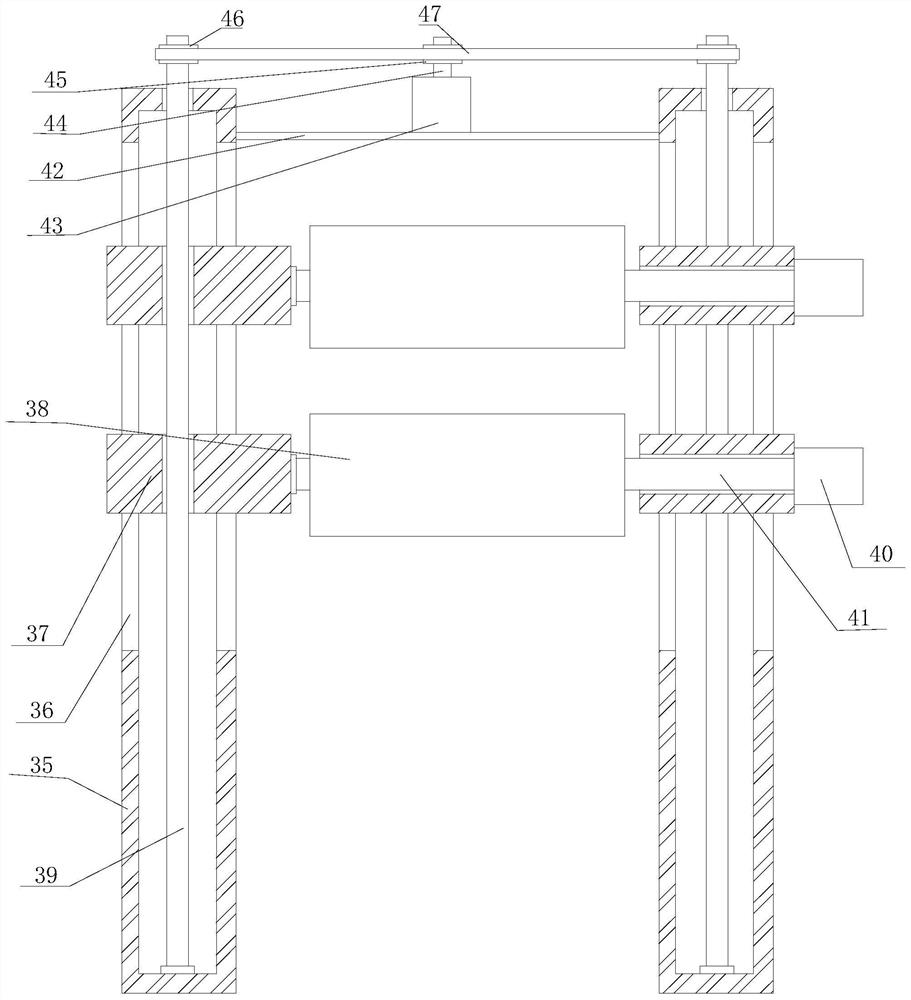

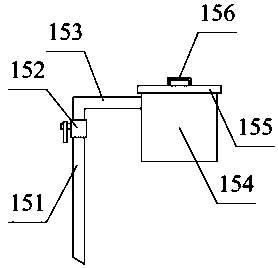

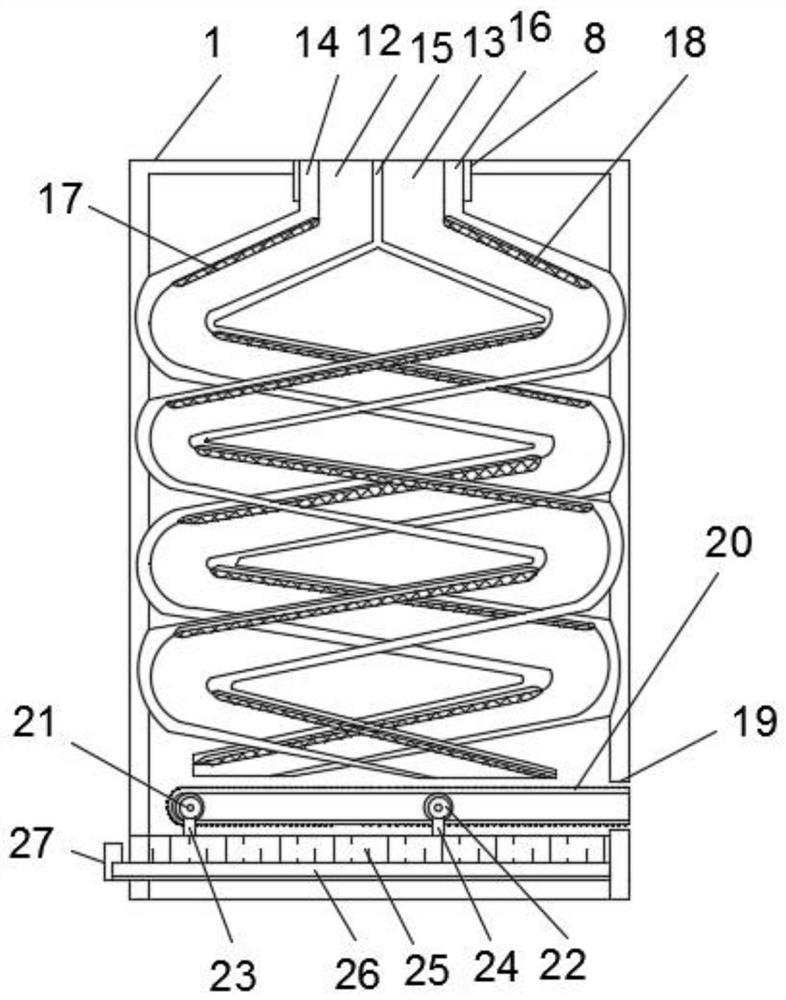

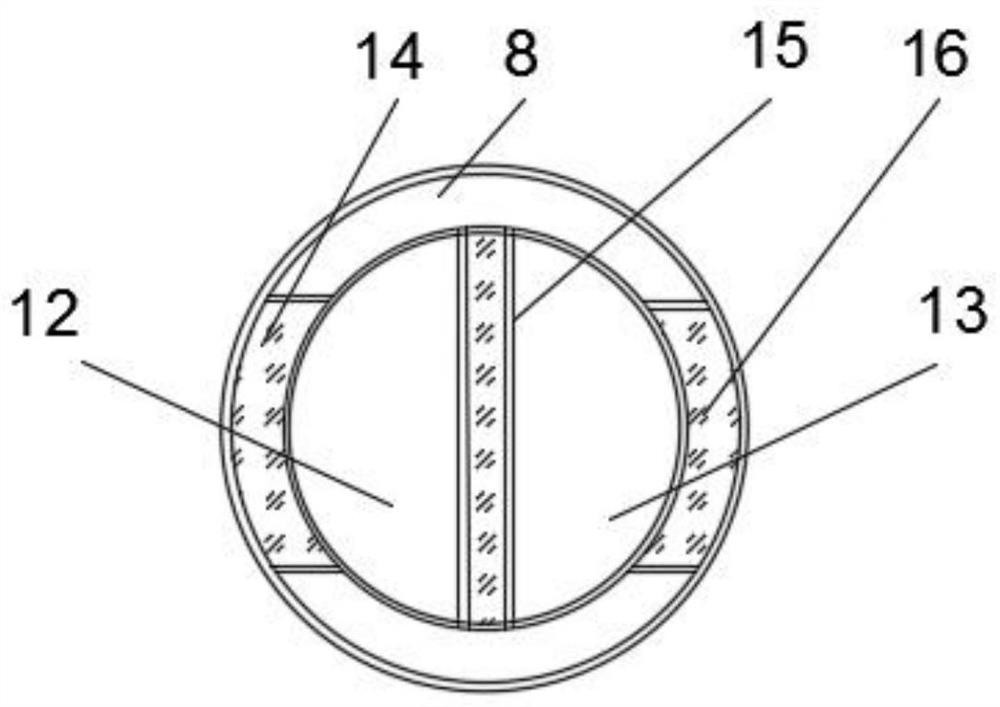

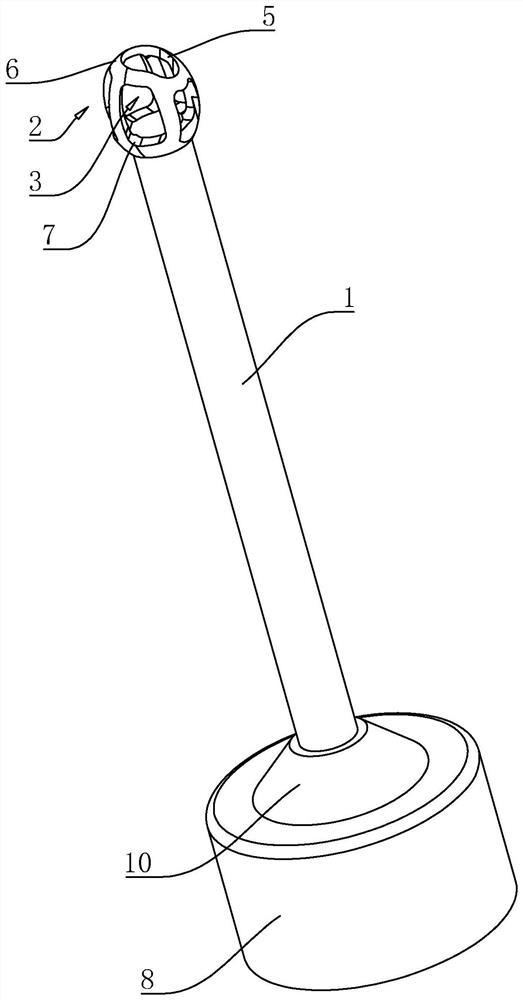

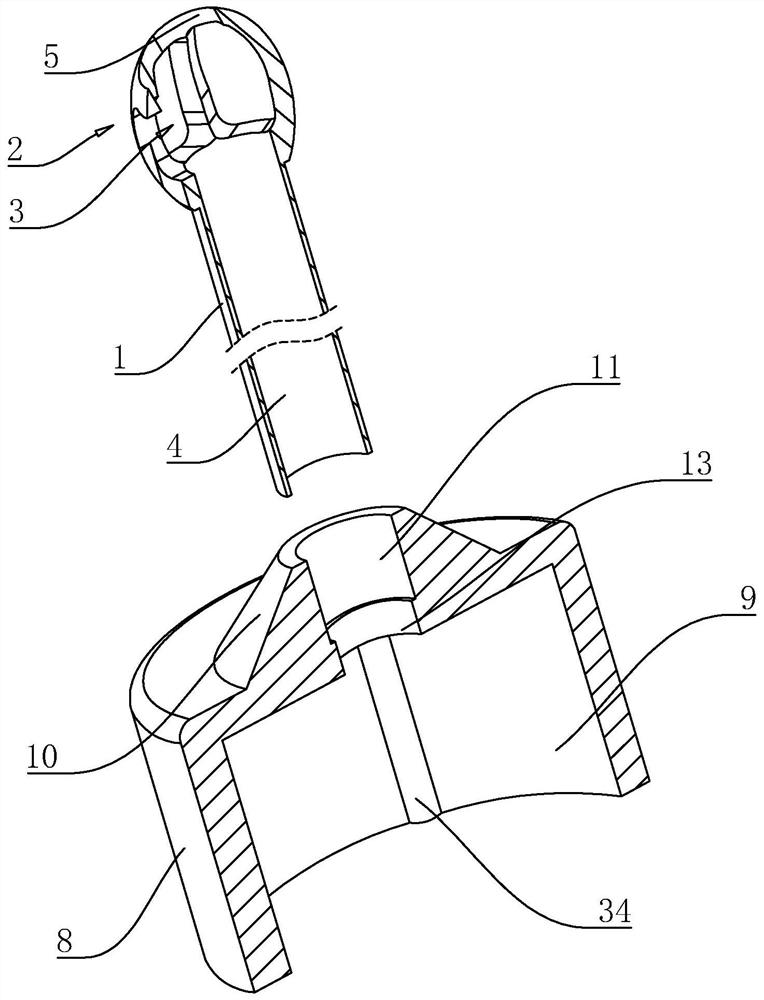

Stirrup feeding device for welding steel reinforcement cages

InactiveCN109834205APlay the role of conveyingRealize transportationWire networkScrew conveyorSpiral line

The invention discloses a stirrup feeding device for welding steel reinforcement cages. The stirrup feeding device includes a base, a screw conveying device and a driving device, the screw conveying device includes two groups of screw rods which are oppositely arranged and have a certain interval in the middle, spiral clamping grooves are formed in the surfaces of the screw rods, rotating shafts are arranged at the two ends of the screw rods, and the rotating shafts are fixed to the base; and the driving device is fixed to the base, and the driving device drives the rotating shafts to rotate.The stirrup feeding device for welding the steel reinforcement cages can be used as a stirrup material caching and equidistant conveying device, the spiral clamping grooves of screw conveying deviceson the left side and the right side are fully used for restraining stirrups, the driving device drives the stirrups to move in a straight line along a spiral line when driving the screw conveyors to rotate, and thus transport and feeding of the stirrups are achieved.

Owner:CHINA MINSHENG ZHUYOU

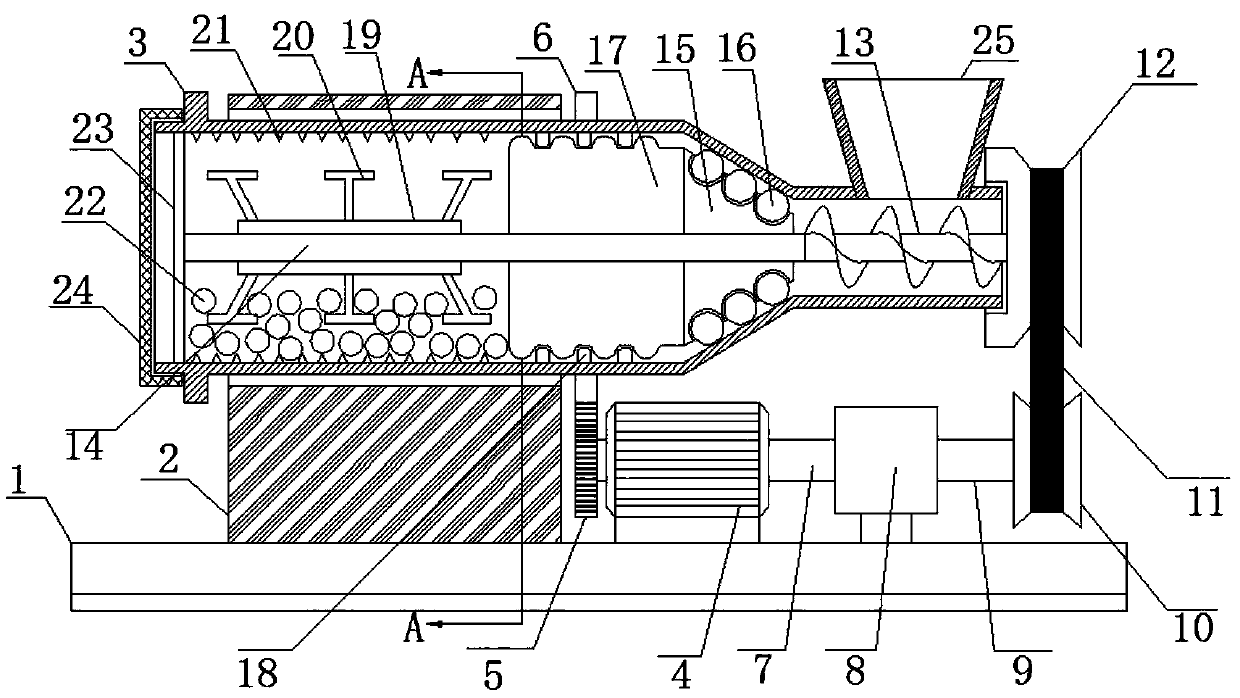

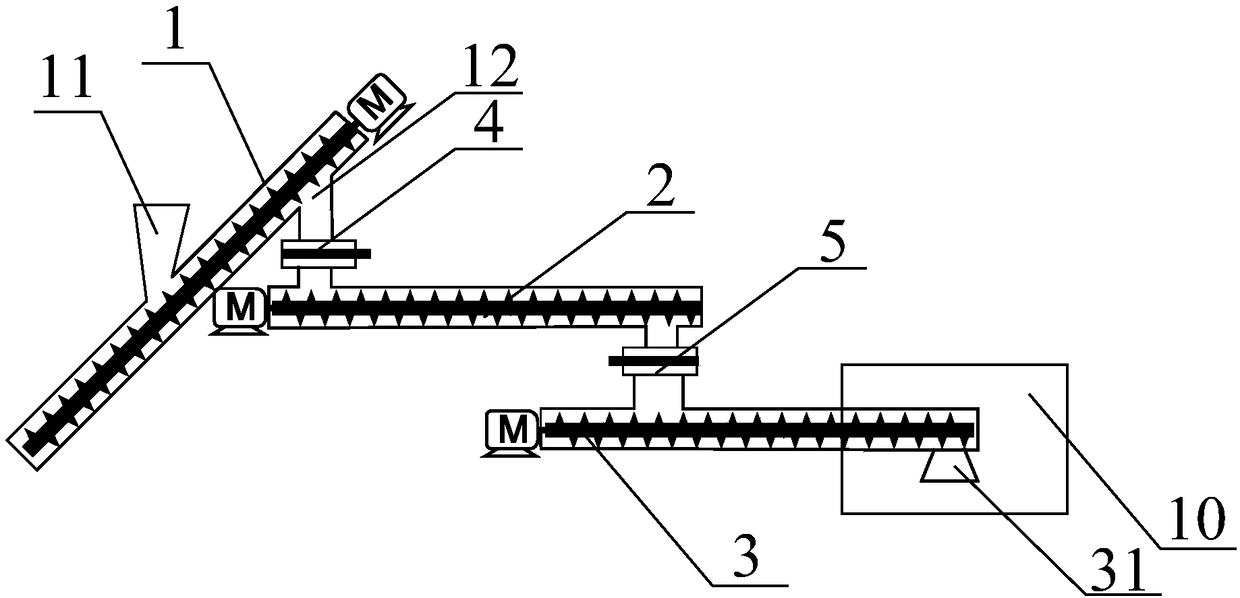

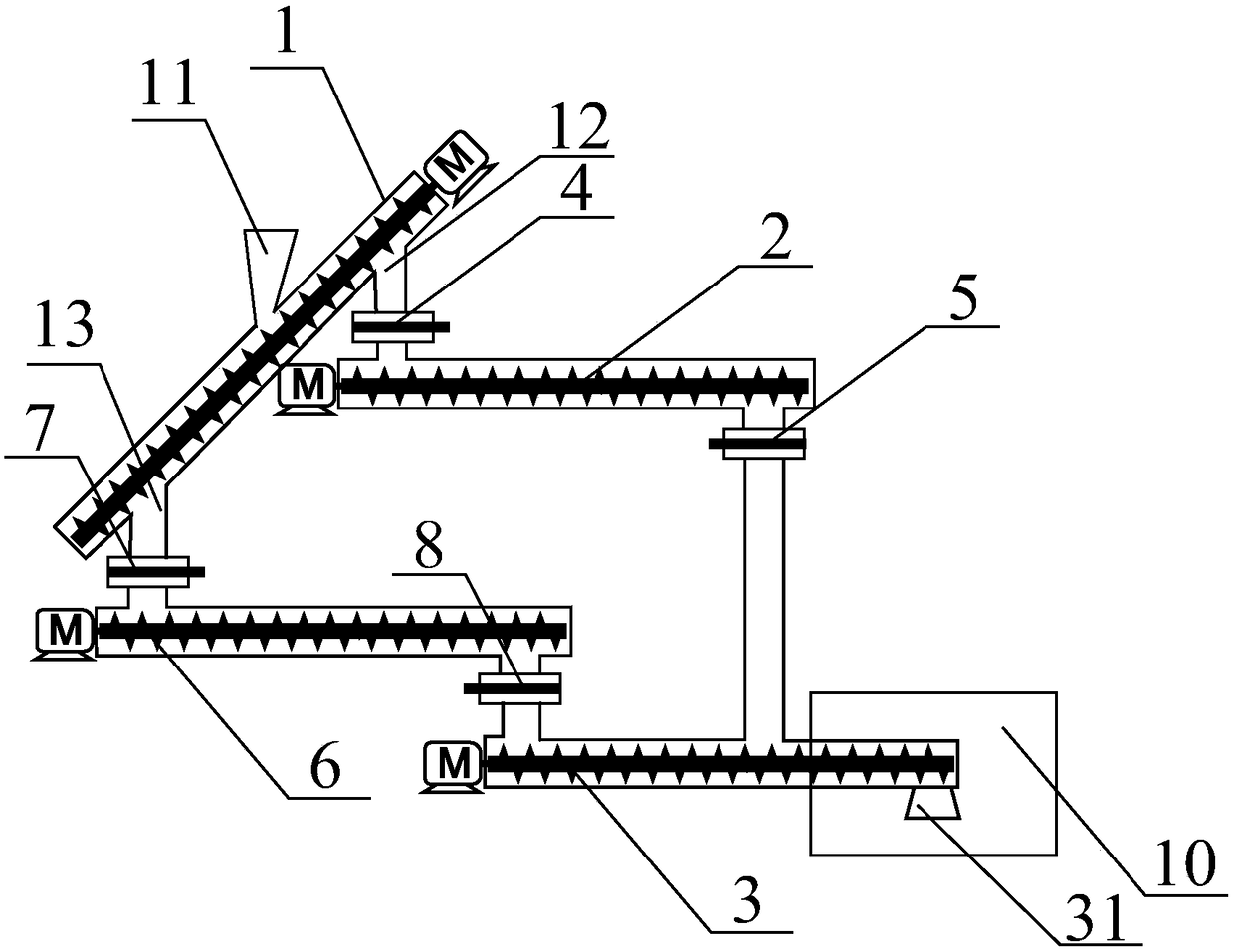

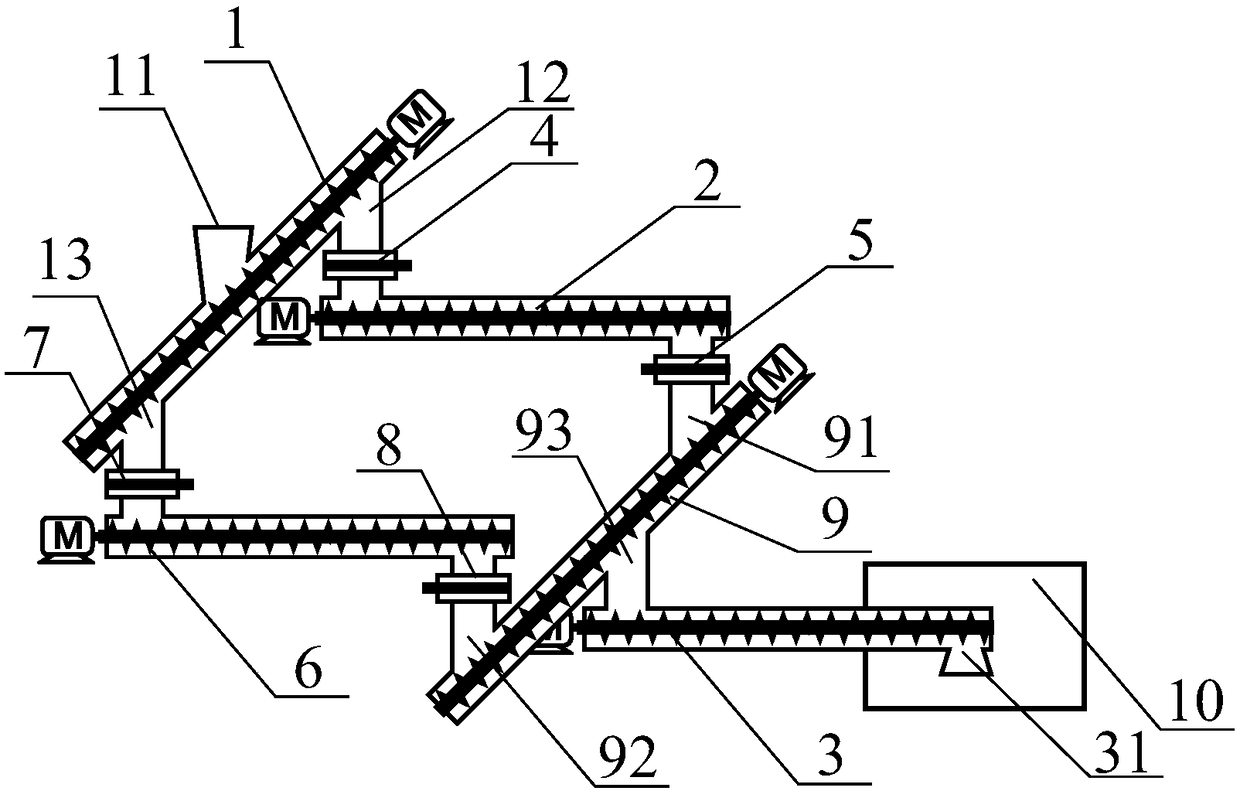

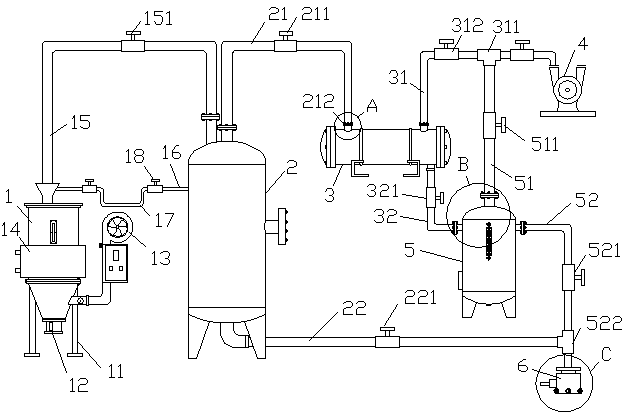

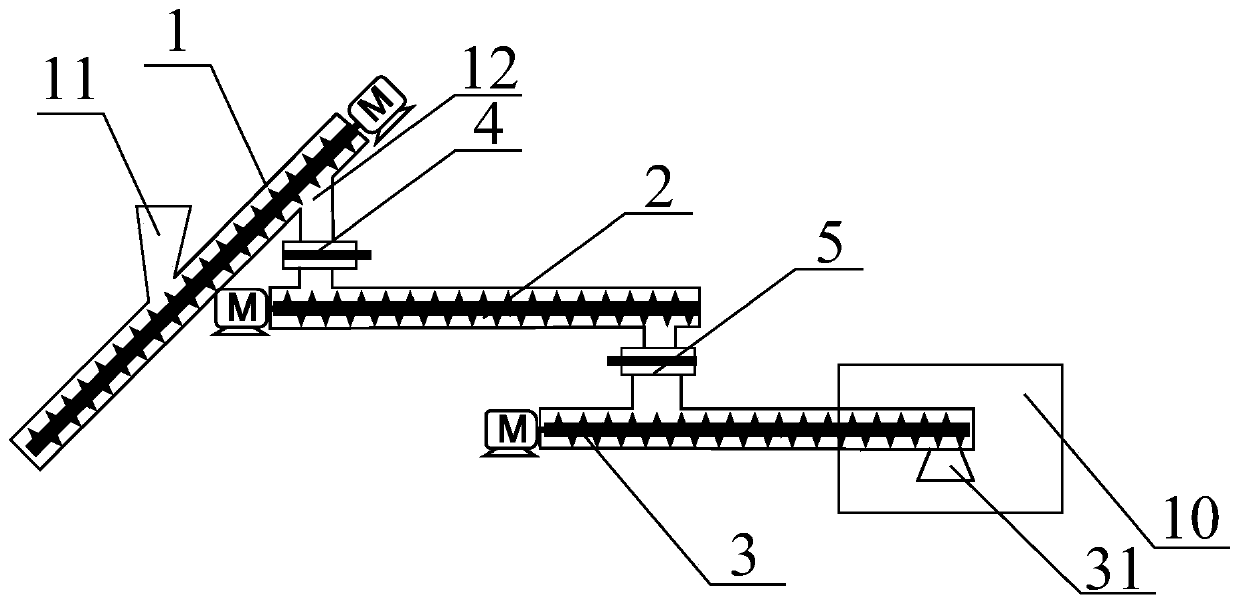

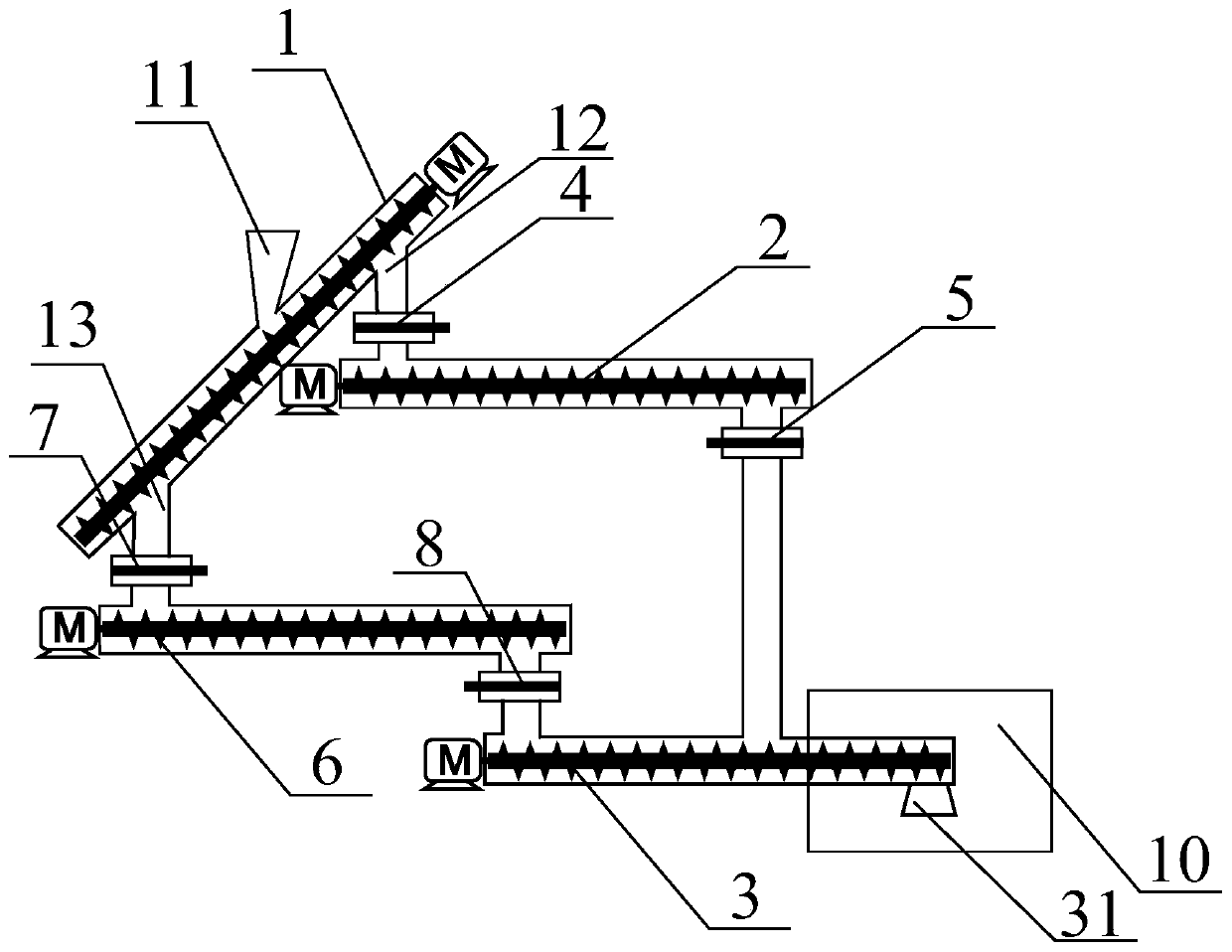

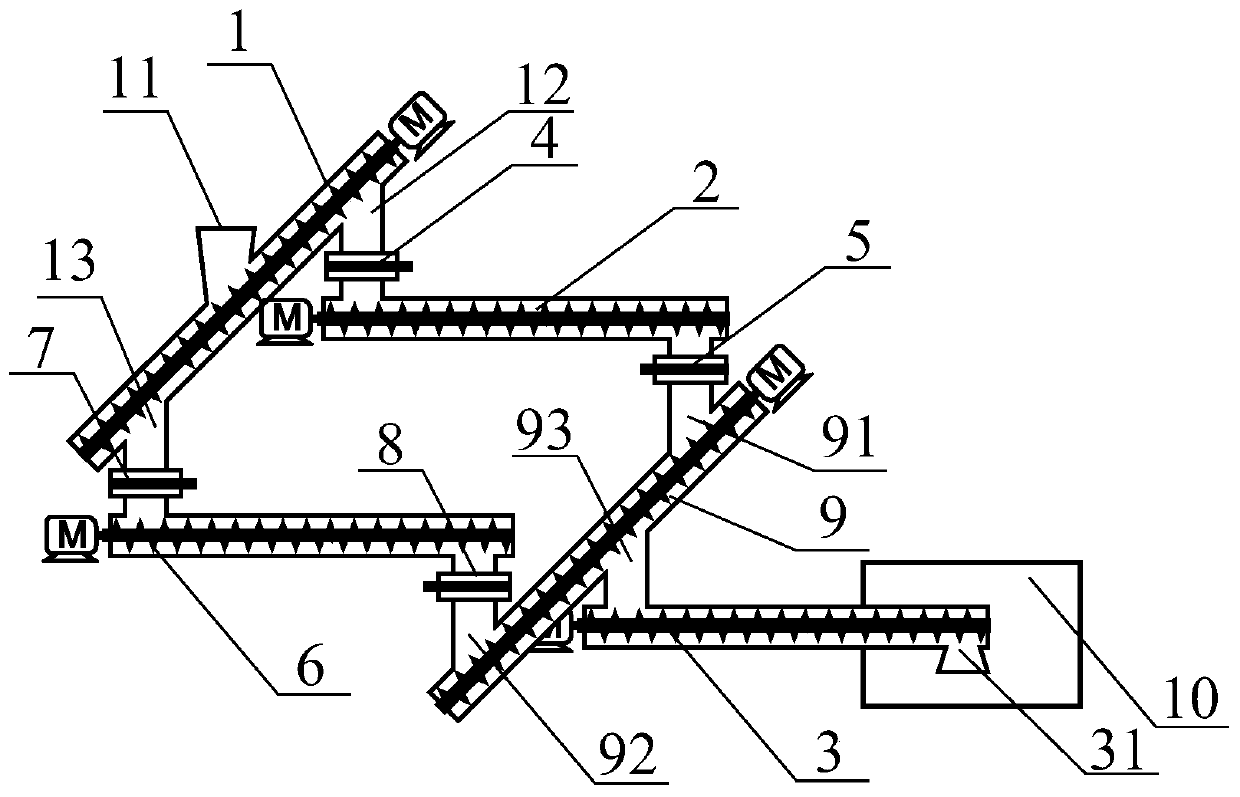

Spiral exhaust continuous feeding device and method for thermal cracking of waste tires

The invention provides a spiral exhaust continuous feeding device and method for thermal cracking of waste tires. The continuous feeding device comprises a sub-feed screw conveyor, a first spiral exhaust conveyor and a feeding screw conveyor which are sequentially connected, a first feeding port and a first discharging port are formed in the sub-feed screw conveyor, a third discharging port communicated with a thermal cracking reactor is formed in the feeding screw conveyor, and the discharge end and the feed end of the first spiral exhaust conveyor are respectively provided with a first plugvalve and a second plug valve for sealing the first spiral exhaust conveyor. According to the continuous feeding device and the method, the sealing between the continuous feeding device and the thermal cracking reactor is achieved, compared with the sealing by pressing and crushing tires, the safety and environmental protection of thermal cracking are ensured, oxygen in the air can be effectivelyprevented from entering the reactor or high temperature oil and gas in the reactor can be effectively prevented from being leaked into the air.

Owner:QINGDAO EXCEL INTELLIGENT EQUIP CO LTD

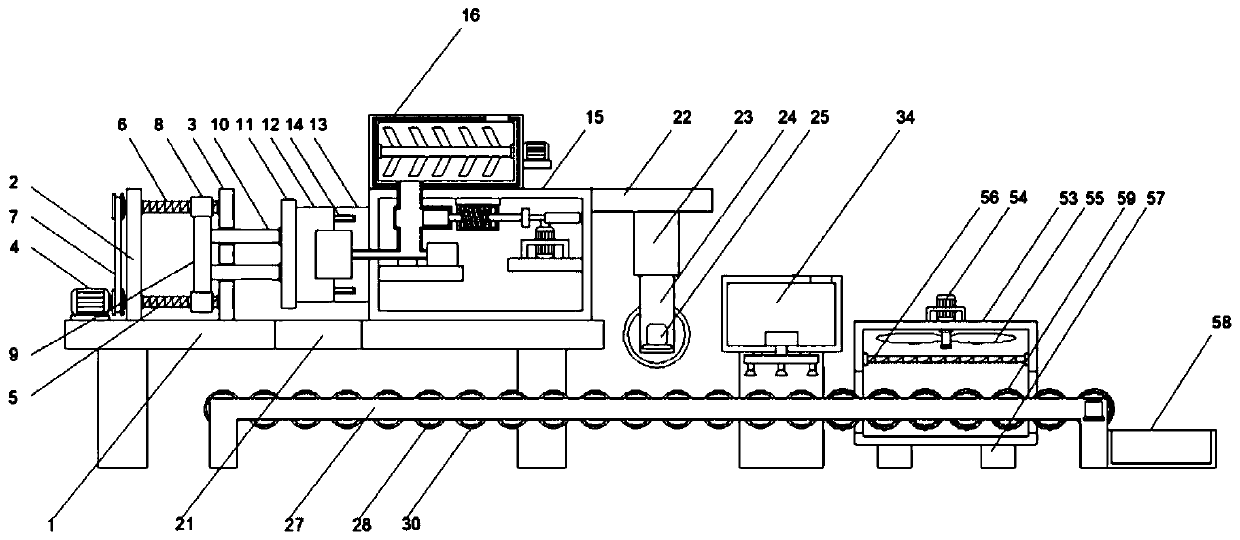

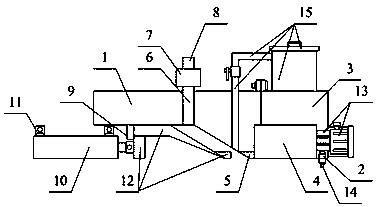

Mechanized processing device special for slicing making process of traditional Chinese medicinal material achyranthes bidentata

InactiveCN107718078ARealize the function of mechanized processingReduce labor intensityMetal working apparatusEngineeringAchyranthes bidentata

The invention relates to a special mechanized processing device for the slice production process of Chinese medicinal material Achyranthes bidentata. article processing agency. The present invention can solve the problem that existing small workshops need to manually slice the Achyranthes bidentata fruit with the help of tools. When cutting into strips is required, there is a potential safety hazard in processing the Achyranthes bidentata fruit manually with the help of tools. It is easy to hurt the staff, need to collect the sliced fruit, cumbersome process, repetitive work, high labor intensity and low work efficiency, etc., can realize the function of mechanized processing of Achyranthes bidentata fruit.

Owner:王辉

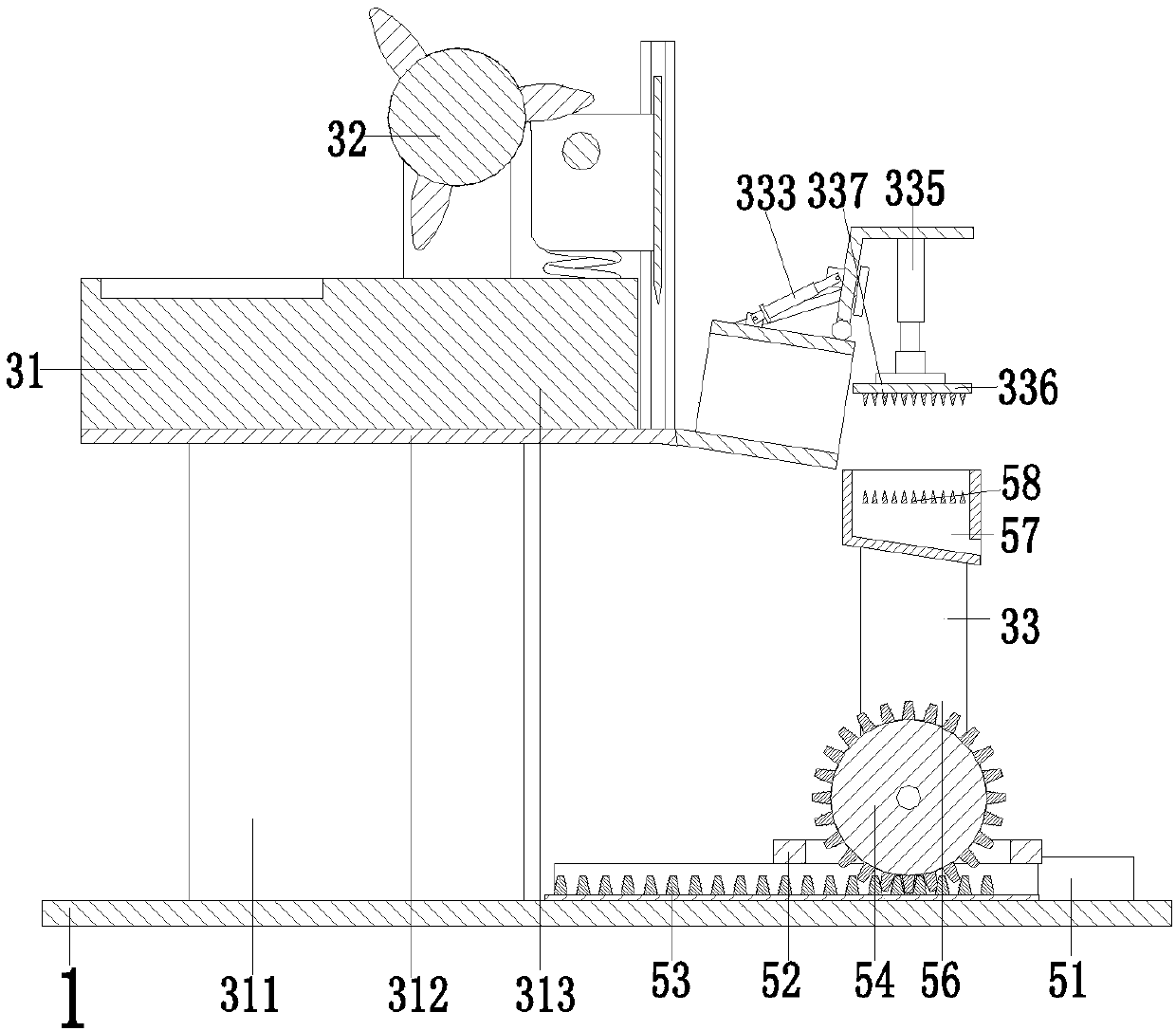

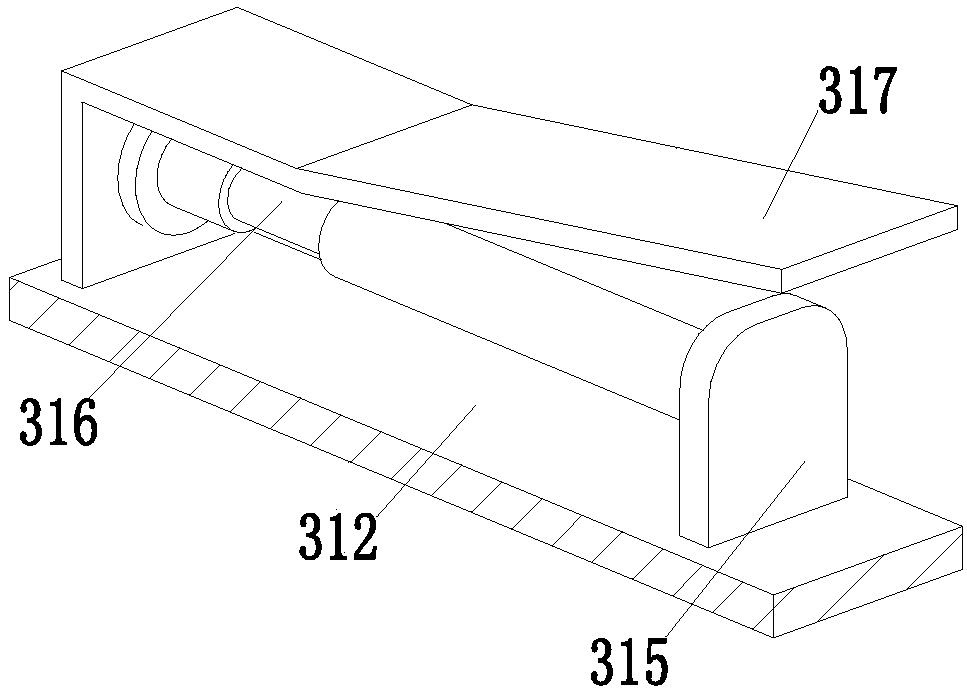

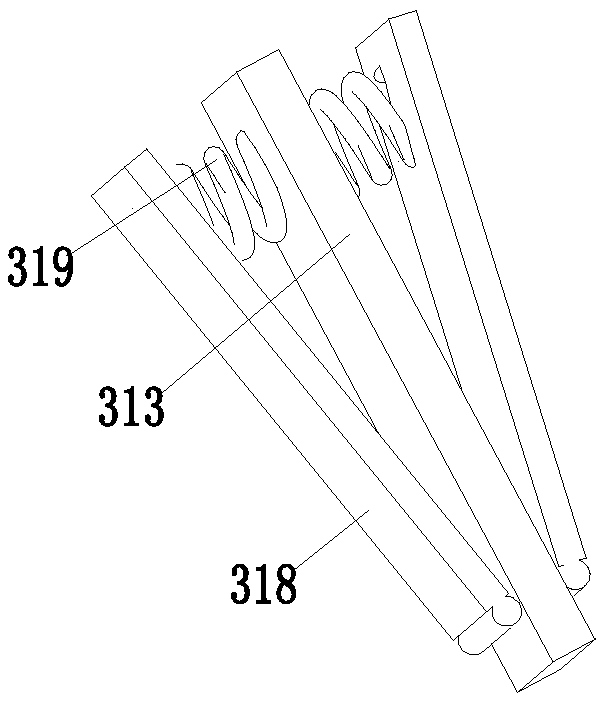

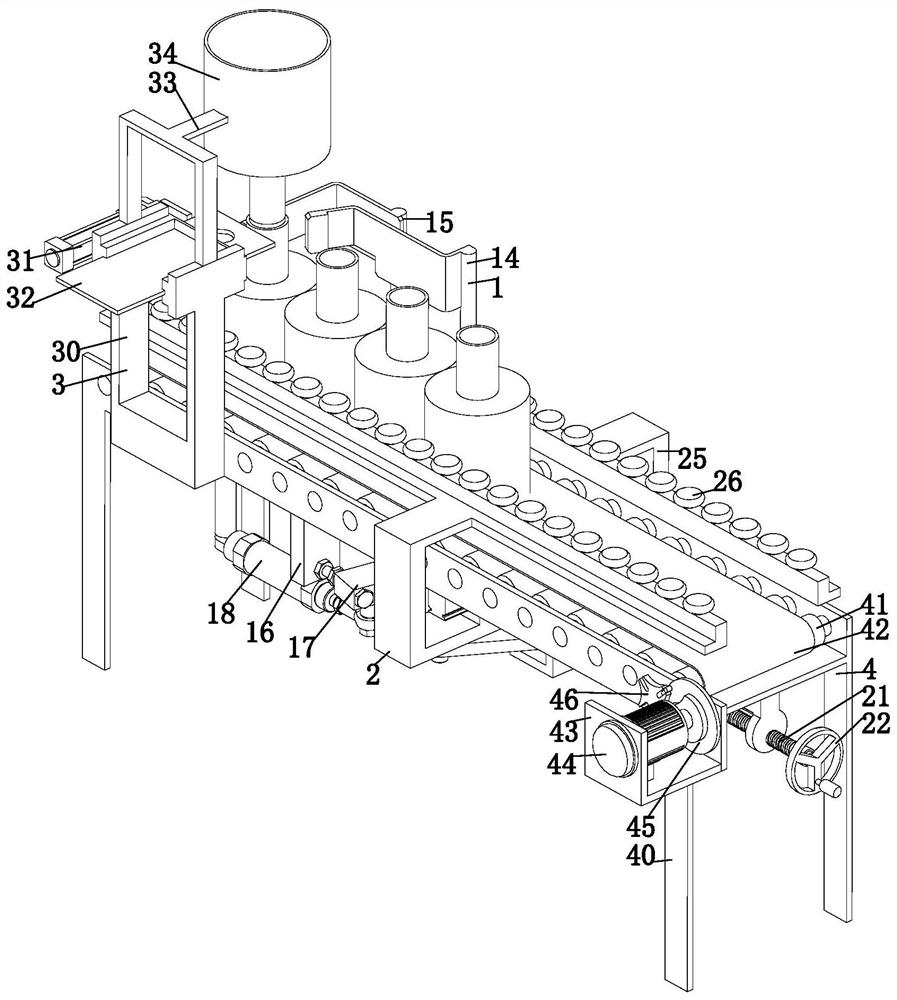

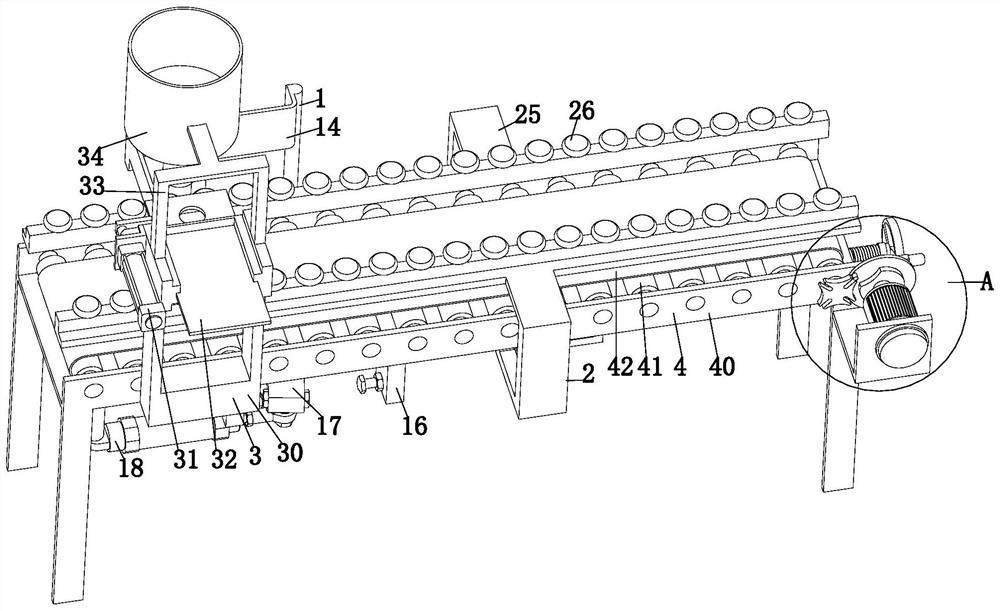

Automatic medicine bottle canning assembly line

InactiveCN112591213APlay the role of guiding pinchEasy to stop deliveryPackagingEngineeringMechanical engineering

The invention provides an automatic medicine bottle canning assembly line. The automatic medicine bottle canning assembly line comprises a positioning mechanism, a guiding mechanism, a discharging mechanism and a conveying mechanism, wherein the guiding mechanism is arranged on the bottom wall of the conveying mechanism, the positioning mechanism is arranged right in front of the guiding mechanism, and the positioning mechanism is arranged on the bottom wall of the conveying mechanism; and the discharging mechanism is arranged over the positioning mechanism, arranged on the outer wall of the conveying mechanism and located over the conveying mechanism. The automatic medicine bottle canning assembly line solves the problems that the cost is wasted due to the fact that medicine particles areprone to fall out due to the fact that the positioning precision of a positioning device used for positioning a medicine bottle is not high in the medicine particle canning production process, medicine bottles with different types need to be positioned through different positioning devices due to the fact that the positioning device is poor in compatibility with medicine bottle containers with different types, and the medicine particles cannot be accurately canned and the medicine bottles after medicine particle canning is completed cannot be moved out due to the fact that stopping conveyingof the medicine bottles cannot be accurately controlled due to complex structure and high cost of the positioning device.

Owner:安徽一首工业设计有限公司

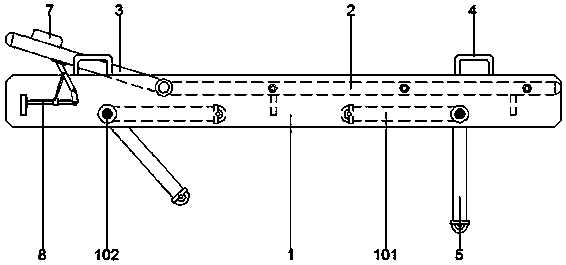

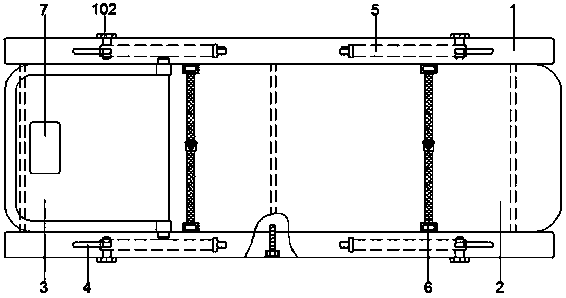

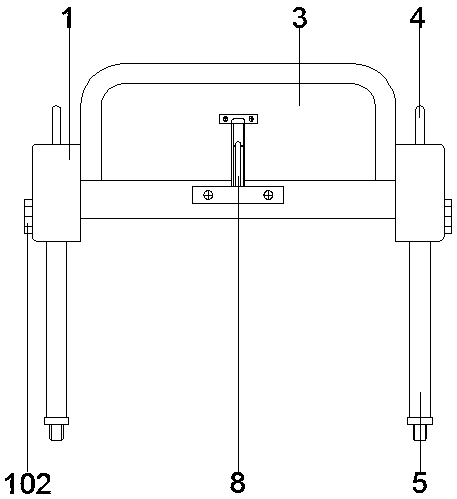

Rescue medical bed used for air transportation of patients in medical institutions

The invention relates to the technical field of medical beds, in particular to a rescue medical bed used for air transportation of patients in medical institutions. The rescue medical bed comprises abedstead, a bed body and a bed head, wherein the bed body is arranged in the middle of the bedstead, and the bed body and the bedstead are connected in a bolt fixing manner; the bed head is arranged at one end of the bed body and the bed head is connected with the bed body through a rotating shaft; and handles are arranged on two sides of the bedstead and connected with the bedstead in a welding manner. By improvement of the structure, the rescue medical bed has a corresponding height adjustment function according to required lying postures of patients with different diseases, has patient transportation and protection functions and cannot do harm to patients, and the rescue medical bed has a rapid ground transportation effect and has the advantages of fully saving inner space of a cabin due to a bed leg folding function, so that the problems and defects of existing devices are effectively solved.

Owner:TIANJIN KANGLI MEDICAL INSTR

High efficiency intelligent chemical fertilizer mixing device

InactiveCN107261897AImprove efficiencyPlay the role of conveyingRotary stirring mixersTransportation and packagingDrive wheelEngineering

The present invention relates to the technical field of chemical fertilizer processing equipment, and discloses a high efficiency intelligent chemical fertilizer mixing device which comprises a base, the top of the base is fixedly provided with a box, the other side of the top of the box is fixedly provided with a second motor, one end of the output shaft of the second motor is fixedly connected with a driving wheel, the outer surface of the driving wheel is in transmission connection with the outer surface of a driven wheel by a belt, the axis of the driven wheel is sleeved with a rotating shaft, one end of the rotating shaft passes through one side of the box and is fixedly connected with one side of the inner wall of the box, the outer surface of the rotating shaft is sheathed with a sleeve, and the outer surface of the sleeve is fixedly connected with a positioning seat, and the top and bottom of the positioning seat are fixedly connected with mixing blades. The second motor is arranged to drive the driving wheel, the belt and the driven wheel to rotate so as to drive the rotation of the rotating shaft and the sleeve, when the sleeve rotates, the positioning seat and the mixing blades also rotate, and processing quality and effect of fertilizer raw materials can be guaranteed.

Owner:赖海燕

Packaging equipment used for metal wire drawing lubricating powder production and provided with feeding mechanism

ActiveCN110228617AFacilitate automatic cappingIncrease weightPackaging automatic controlSolid materialConveyor beltEquipment use

The invention discloses packaging equipment used for metal wire drawing lubricating powder production and provided with a feeding mechanism, and relates to the technical field of metal wire drawing lubricating powder. The packaging equipment comprises a machine body, a packaging capping mechanism and an unloading mechanism, wherein conveyor belts are erected at the two sides above the machine body; protective side plates are mounted at the outer sides of the conveyor belts; a weighing table is mounted on the middle part above the machine body; a packaging box is arranged above the weighing table; supporting columns are fixedly arranged on four corners above the machine body; a top plate is mounted above the supporting columns; the packaging capping mechanism is mounted above the weighing table; the packaging capping mechanism is fixedly connected to the top plate; the two sides of the packaging capping mechanism are equipped with positioning pushing structures; and the positioning pushing structures are in bolt connection to the top plate. The packaging equipment has the beneficial effects that automatic capping packaging is conveniently performed on the packaging box through the packaging capping mechanism, so that the packaging box is sealed.

Owner:南京华舜润滑制品有限公司

Indirect thermal desorption and drip washing technology coupling device

InactiveCN108080406AAvoid secondary pollutionFully contactedContaminated soil reclamationCouplingPollution soil

The invention discloses an indirect thermal desorption and drip washing technology coupling device. The indirect thermal desorption and drip washing technology coupling device comprises a roller bodyand a pollutant treatment device; a drip washing roller and a thermal desorption roller are arranged in the roller body in a spaced manner, a heat preservation layer is arranged outside the roller body, hot airflow layers are arranged between the thermal desorption roller and the drip washing roller and on the lower portion of the thermal desorption roller, and are used for thermal desorption treatment of soil polluted by organic matter in the thermal desorption roller, the drip washing roller is arranged on the upper portion of the thermal desorption roller and is used for drip washing treatment and indirect thermal desorption treatment of the soil polluted by heavy metal and organic matter. The tails of the drip washing roller and the thermal desorption roller are connected with a pollutant treatment device and are used for drip washing and thermal desorption of pollutants. The indirect thermal desorption and drip washing technology coupling device is simple in structure, efficient and suitable for heavy metal and organic matter composite pollution soil.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

A kind of packaging equipment with feeding mechanism for the production of metal wire drawing lubricant powder

ActiveCN110228617BFacilitate automatic cappingIncrease weightSolid materialPackaging automatic controlConveyor beltMaterials science

The invention discloses packaging equipment used for metal wire drawing lubricating powder production and provided with a feeding mechanism, and relates to the technical field of metal wire drawing lubricating powder. The packaging equipment comprises a machine body, a packaging capping mechanism and an unloading mechanism, wherein conveyor belts are erected at the two sides above the machine body; protective side plates are mounted at the outer sides of the conveyor belts; a weighing table is mounted on the middle part above the machine body; a packaging box is arranged above the weighing table; supporting columns are fixedly arranged on four corners above the machine body; a top plate is mounted above the supporting columns; the packaging capping mechanism is mounted above the weighing table; the packaging capping mechanism is fixedly connected to the top plate; the two sides of the packaging capping mechanism are equipped with positioning pushing structures; and the positioning pushing structures are in bolt connection to the top plate. The packaging equipment has the beneficial effects that automatic capping packaging is conveniently performed on the packaging box through the packaging capping mechanism, so that the packaging box is sealed.

Owner:南京华舜润滑制品有限公司

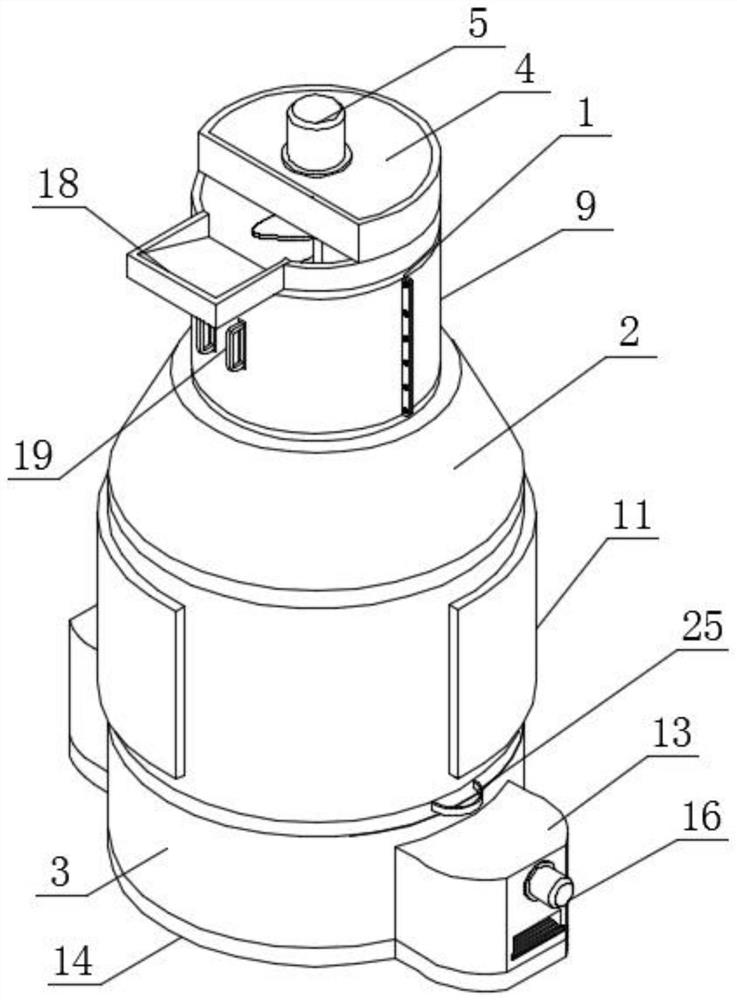

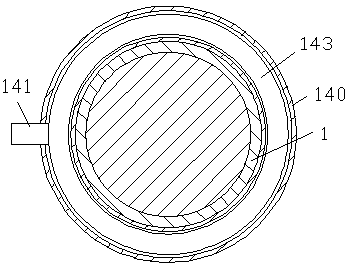

Drying device with heating pretreatment function for white carbon black processing

PendingCN114251925AImprove detachabilityEasy to clean upSilicaMagnetic separationMagnetic effectIron removal

The invention discloses a white carbon black processing drying device with heating pretreatment, which comprises a limiting barrel, a heating barrel and a base, the bottom of the limiting barrel is connected with the heating barrel, the bottom of the heating barrel is in threaded connection with the base, the top of the limiting barrel is in threaded connection with a limiting seat, the top of the limiting seat is provided with a driving motor, and the driving motor is in threaded connection with the base. A driving rod is installed at the output end of the driving motor, a stirring frame is arranged on the outer surface of the driving rod, a supporting frame is arranged on the inner wall of the limiting barrel, a connecting plate is connected to the outer surface of the limiting barrel in an embedded mode, and a magnetic suction pad is arranged on the inner wall of the connecting plate. Through the arrangement of the limiting barrel, the limiting seat, the feeding plate, the driving motor, the driving rod, the stirring frame, the connecting plate and a magnetic suction pad, a certain iron removal effect is achieved on raw materials through the magnetic effect of the magnetic suction pad, the connecting plate has good convenience in disassembly, so that the magnetic suction pad is conveniently cleaned, and the efficient usability of the device is kept.

Owner:WUXI HENGCHENG SILICON IND CO LTD

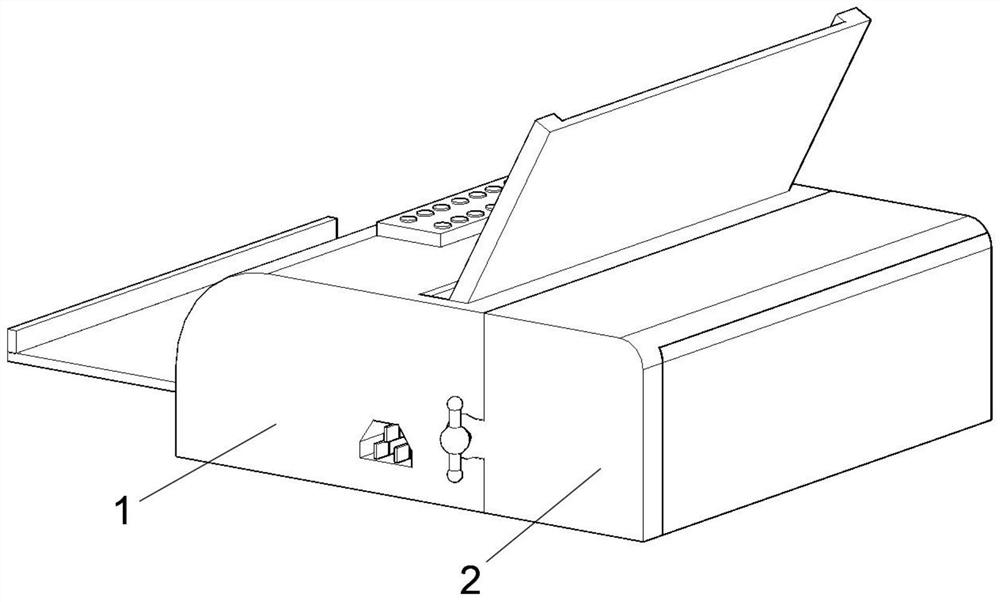

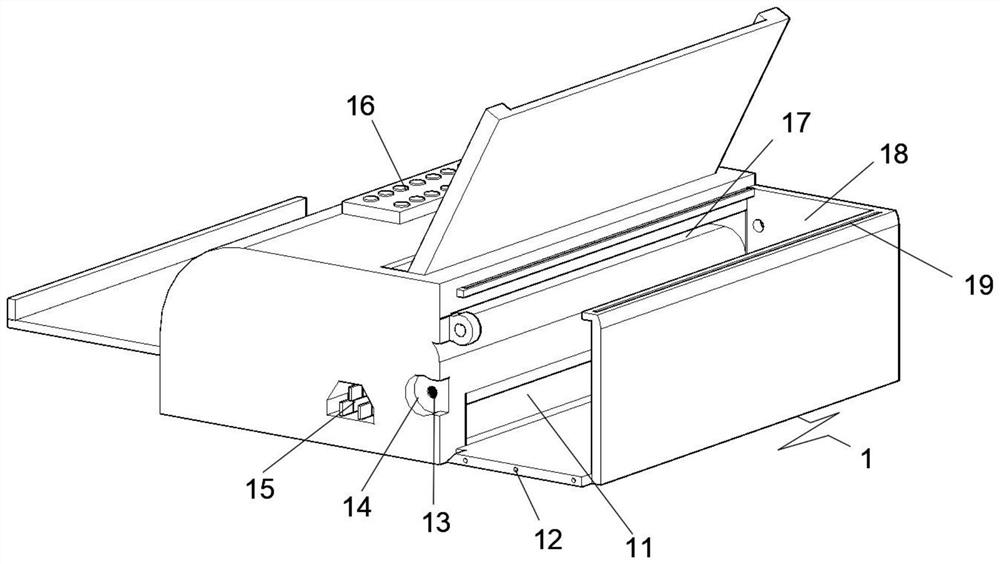

Printed electronic ink-jet printer

ActiveCN112297661APlay a protective effectPlay a supporting roleOther printing apparatusComputer printingMechanical engineering

Owner:佛山市超国达科技有限公司

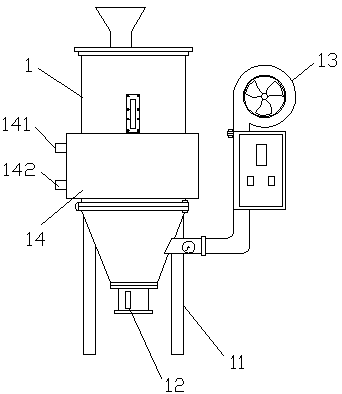

Solid waste integrated drying system based on environmental protection

PendingCN109307407AImprove work efficiencyPlay the role of recycling and reprocessingDrying gas arrangementsDrying solid materialsLiquid wastePulp and paper industry

The invention relates to the technical field of solid waste drying, and discloses a solid waste integrated drying system based on environmental protection. According to the system, solid waste and liquid waste can be effectively separated, and effective components in liquid can be recycled. The solid waste integrated drying system structurally comprises a drying machine, wherein a fan is connectedto one side of the drying machine, a discharge opening is formed in the bottom, an auxiliary heating device wraps the outer side of the drying machine, the auxiliary heating device comprises an annular box body which wraps the outer side of the drying machine, a conduction oil coil is wound in the annular box body, an oil inlet and an oil outlet of the conduction oil coil respectively protrude from one side of the annular box body and are connected with the heating device, the top of the drying machine is connected with the top of a vapor and liquid separation tank by virtue of a first connecting pipe, a first ball valve is arranged on the first connecting pipe, and a liquid recovery pipe is further arranged between the vapor and liquid separation tank and the drying machine. The solid waste integrated drying system has the advantages of simplicity in operation and convenience in use and can be used in various places.

Owner:ZHEJIANG EUCHEM CHEM

Evaporative cold air source heat pump unit

InactiveCN112762638ASolve the phenomenon of frost and fogPlay the role of conveyingMechanical apparatusHeat pumpsCold airAir pump

The invention discloses an evaporative cold air source heat pump unit which comprises a shell. An air source heat pump unit body is fixedly installed in an inner cavity of the shell, an air pump is fixedly installed on one side of the top of the shell, and a refrigeration mechanism is fixedly installed at the air outlet end of the air pump. Through the arrangement of the air pump, when the air pump works, the air outlet end of the air pump conveys air to an inner cavity of a second air dispersion plate through the refrigeration mechanism, heat dissipation fins absorb heat generated by working of the air source heat pump unit body, the second air dispersion plate blows the heat dissipation fins, and then heat on the surfaces of the heat dissipation fins is taken away. The air with heat enters an inner cavity of an air collection plate and then is conveyed to an inner cavity of an air conveying pipe through an exhaust pipe, the air conveying pipe conveys the hot air to an inner cavity of a first air dispersion plate, the first air dispersion plate enables the hot air to blow the air inlet part on the front face of the air source heat pump unit body, and then frost at the air inlet part of the air source heat pump unit body is removed.

Owner:杭州美奇餐饮服务有限公司

A die-casting machine integrated processing equipment for button processing

The invention discloses an integrated die-casting machine processing equipment for button processing, which comprises a frame, a first fixed plate, a second fixed plate and a first motor are fixedly installed on the upper side of the frame, and the output end of the first motor is fixedly connected to the There is a first threaded rod, the first motor is connected to the second threaded rod through the first chain transmission, the surfaces of the first threaded rod and the second threaded rod are threaded with moving blocks, and a moving block is fixedly connected between the two moving blocks. plate, the right side of the moving plate is fixedly connected to the support bar, the support bar is slidingly connected to the second fixed plate, and the other end of the support bar is fixedly installed with a connecting plate. In the present invention, the molten liquid metal is temporarily stored by setting a stirring box, and multiple die-casting operations can be carried out without interruption. By setting a quantitative device, the metal liquid required for one die-casting can be delivered regularly and quantitatively, which avoids the waste of materials and saves time and effort. , Reduce the labor intensity of the staff, and improve the die-casting efficiency of the die-casting machine.

Owner:东莞市恒兴隆实业有限公司

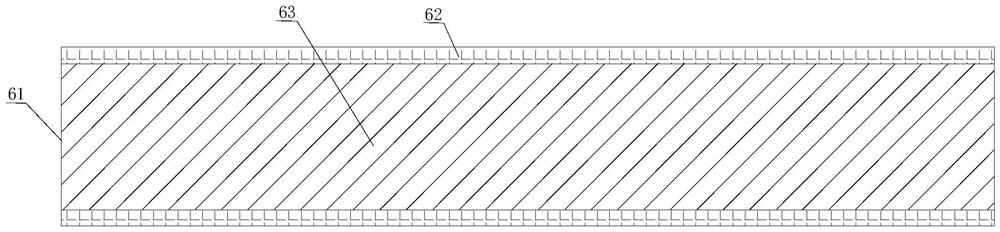

Crease-resistant curtain fabric

ActiveCN114642347APlay a filtering roleImprove purityTextile treatment machine arrangementsCurtainsPolymer sciencePolymer chemistry

The invention discloses an anti-wrinkle curtain fabric, which comprises a fabric body, the fabric body comprises a base fabric and a TPU film, the TPU film is compounded on the outer surface of the base fabric, carbon black particles are arranged in the TPU film, and the thickness of the TPU is between 1 silk and 3 silk.

Owner:HOMEX SOFT FURNISHINGS HANGZHOU LTD

Spiral exhaust type continuous feeding device and method for thermal cracking of waste tires

The invention provides a spiral exhaust continuous feeding device and method for thermal cracking of waste tires. The continuous feeding device comprises a sub-feed screw conveyor, a first spiral exhaust conveyor and a feeding screw conveyor which are sequentially connected, a first feeding port and a first discharging port are formed in the sub-feed screw conveyor, a third discharging port communicated with a thermal cracking reactor is formed in the feeding screw conveyor, and the discharge end and the feed end of the first spiral exhaust conveyor are respectively provided with a first plugvalve and a second plug valve for sealing the first spiral exhaust conveyor. According to the continuous feeding device and the method, the sealing between the continuous feeding device and the thermal cracking reactor is achieved, compared with the sealing by pressing and crushing tires, the safety and environmental protection of thermal cracking are ensured, oxygen in the air can be effectivelyprevented from entering the reactor or high temperature oil and gas in the reactor can be effectively prevented from being leaked into the air.

Owner:QINGDAO EXCEL INTELLIGENT EQUIP CO LTD

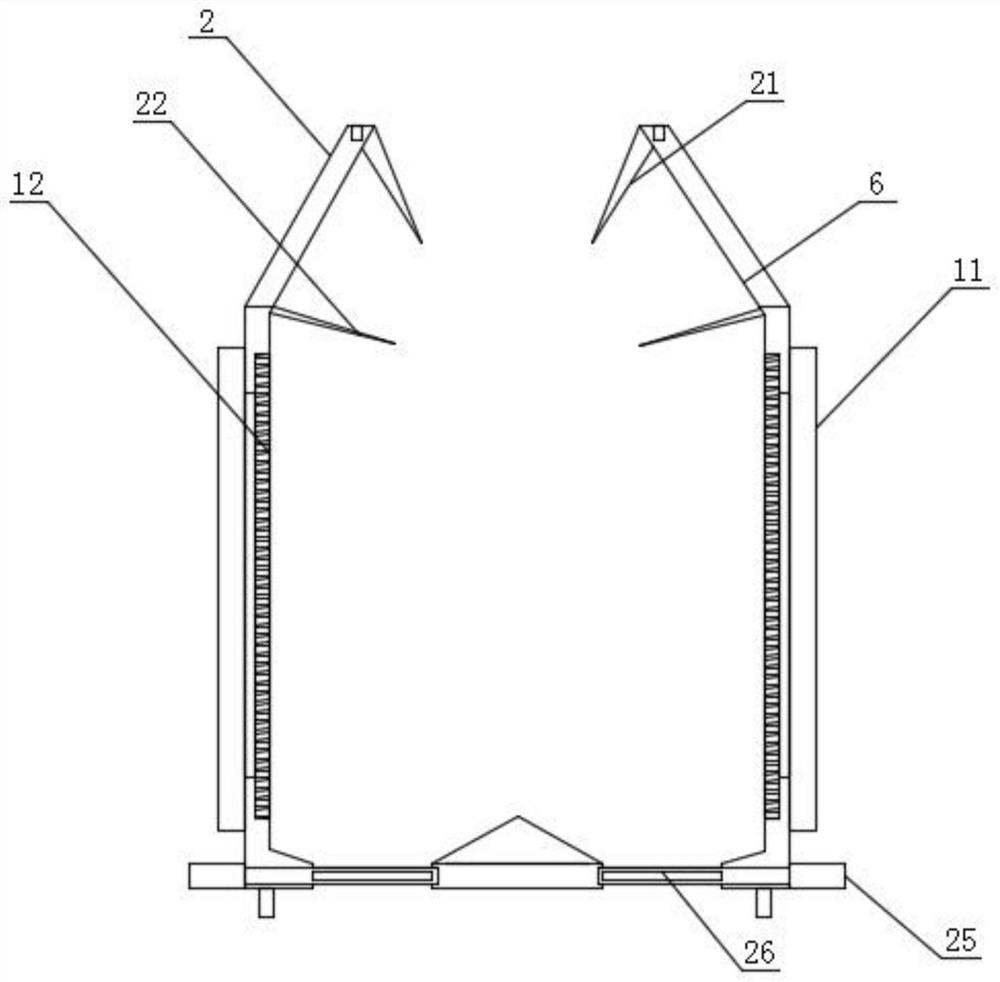

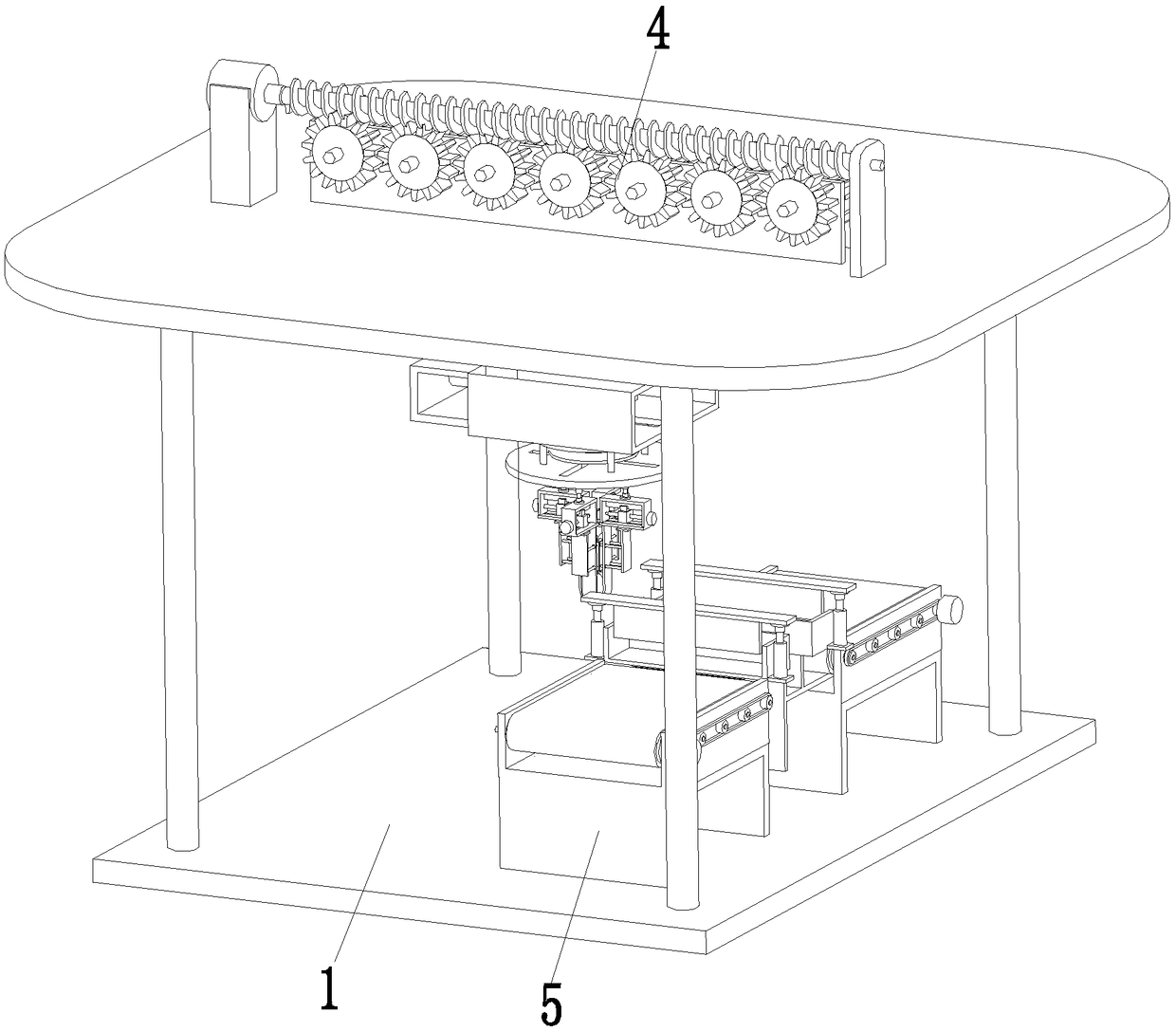

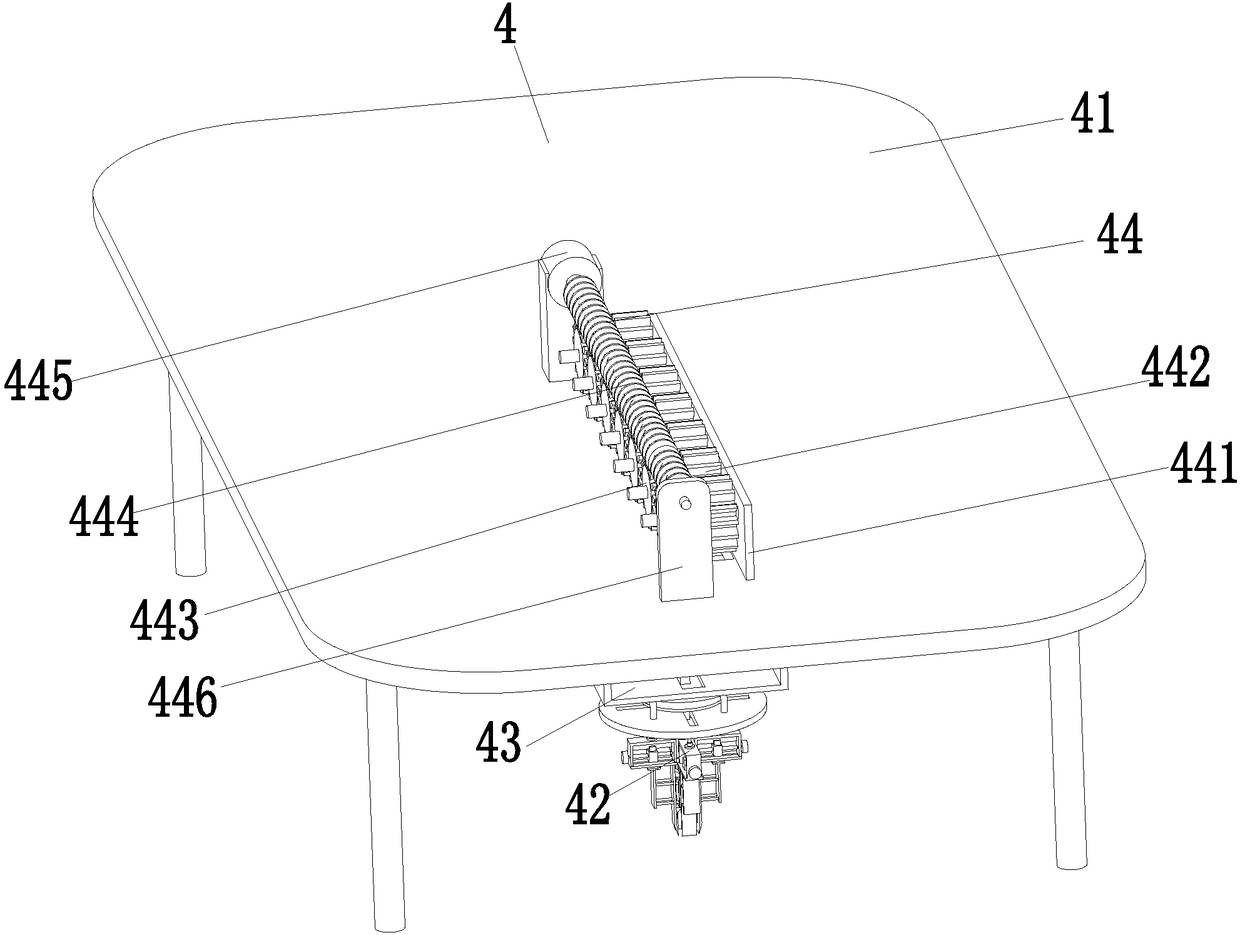

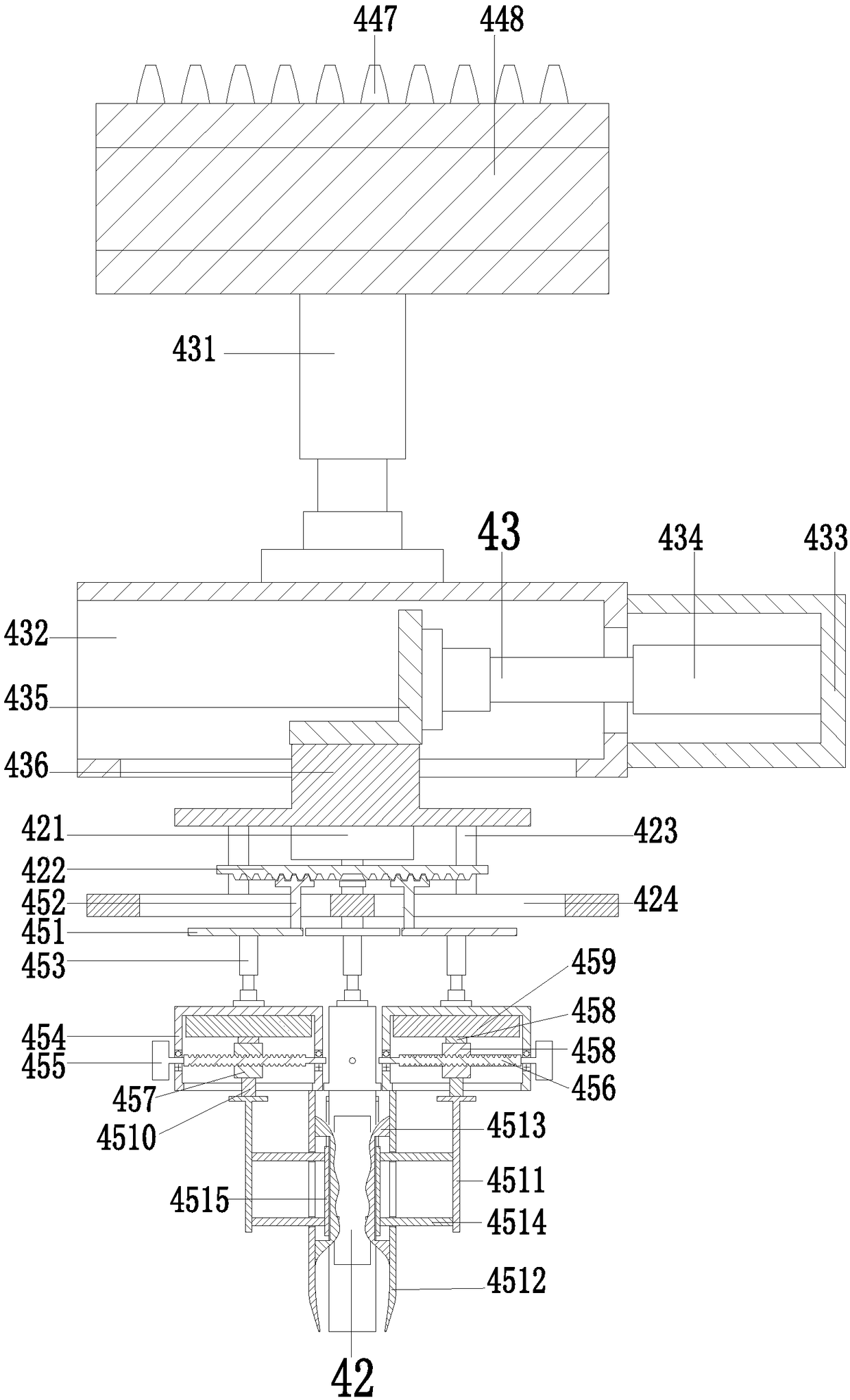

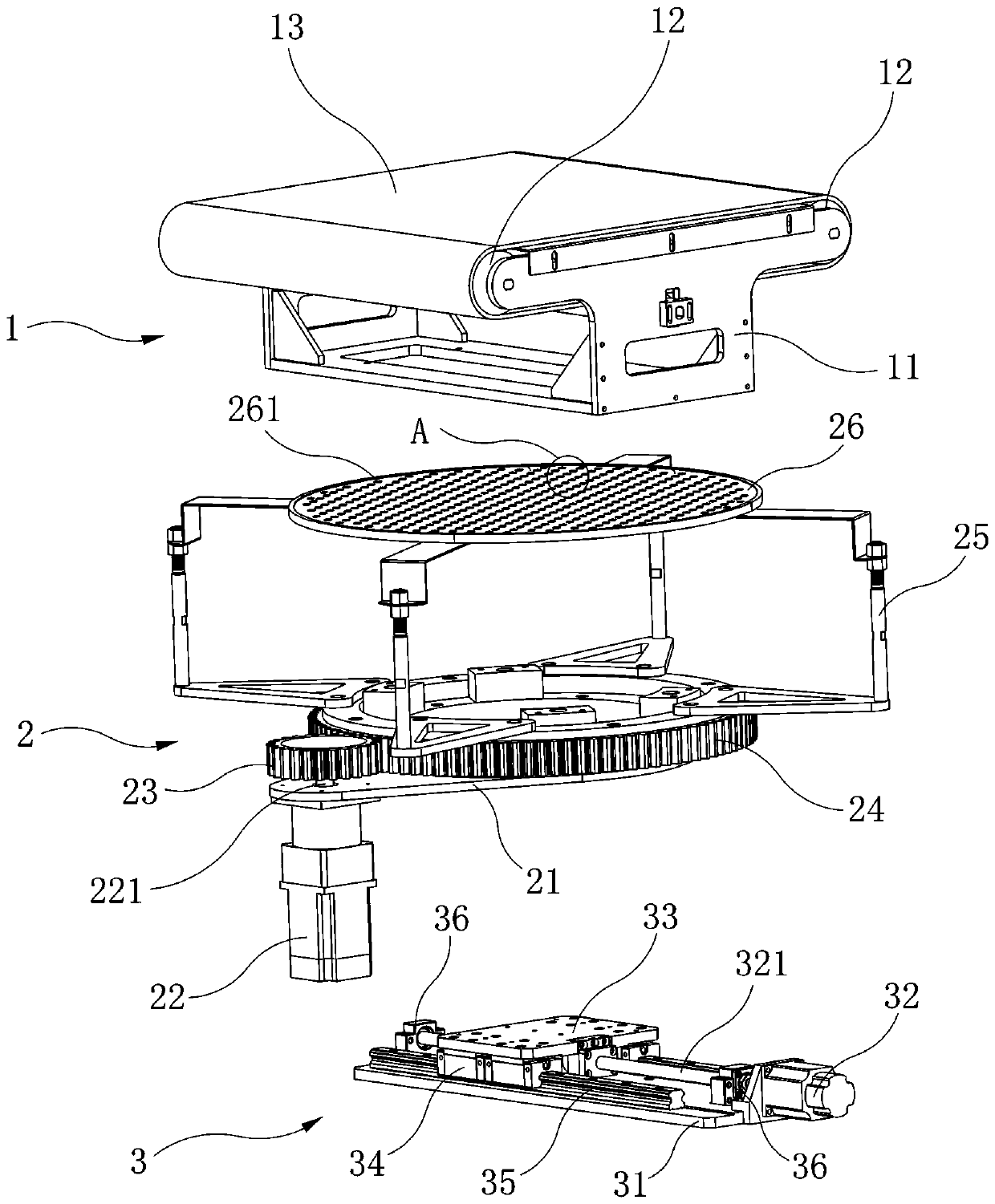

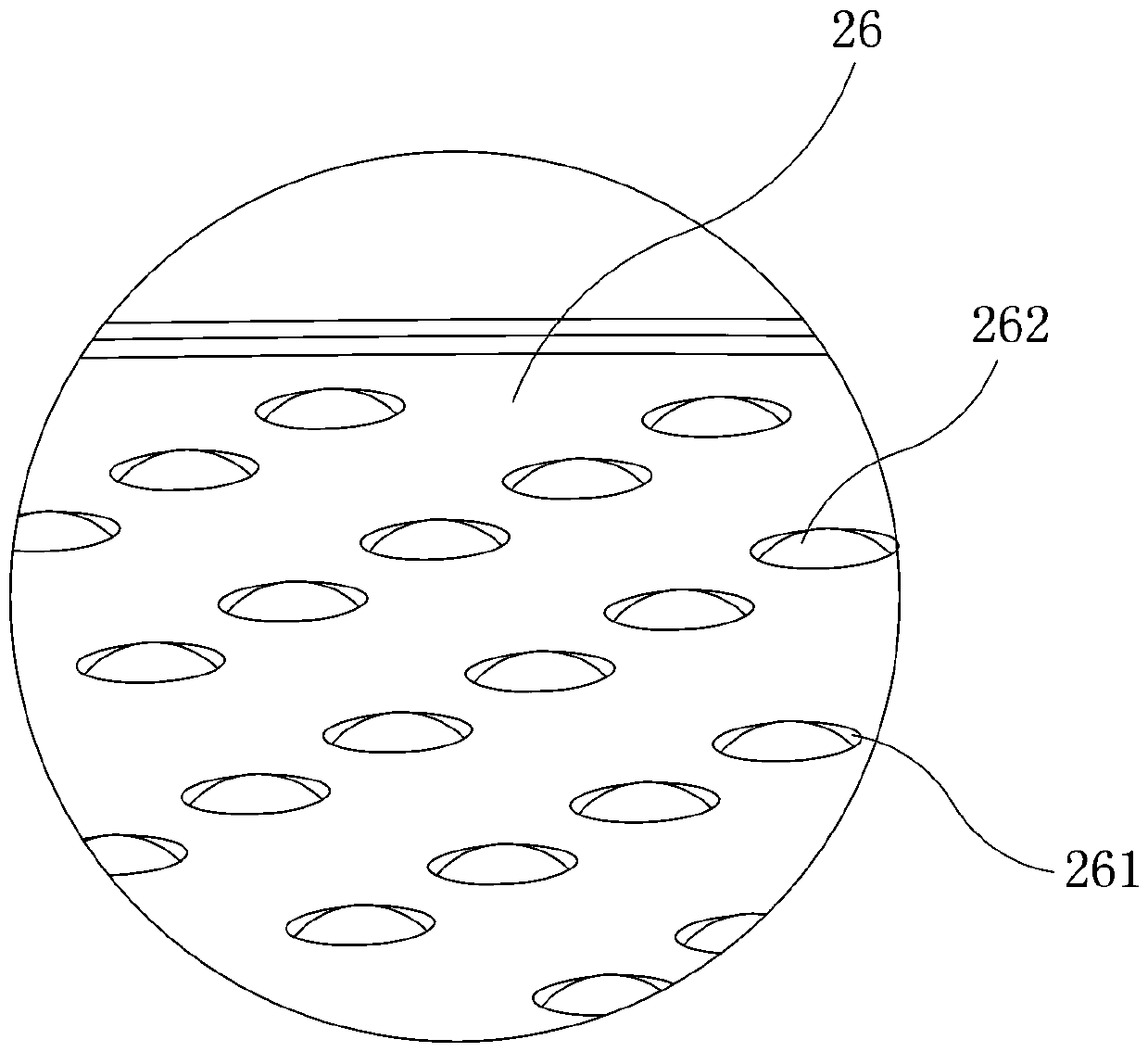

Vehicle-mounted power battery automatic replacing robot special for new energy electric vehicle

InactiveCN108189813AAccurate clamping and conveyingReduce labor intensityElectric propulsion mountingVehicle servicing/repairingPower batteryNew energy

The invention relates to a vehicle-mounted power battery automatic replacing robot special for a new energy electric vehicle. The robot comprises a working table. A detaching device is installed at the upper end of the working table. A battery conveying device is arranged at the front end of the working table. The detaching device comprises a detaching positioning frame installed on the working table. A detaching movement groove is formed in the front end of the detaching positioning frame and internally provided with a detaching movement mechanism. A detaching driving mechanism is arranged onthe lower side of the detaching movement mechanism. A detaching clamping mechanism is installed at the lower end of the detaching driving mechanism. By means of the robot, the problems are solved that existing hoisting tools need to be used for installing and detaching batteries of the new energy electric vehicle in the existing new energy electric vehicle replacing process, the new energy batteries need to be manually conveyed, and when the new energy electric vehicle is manually installed and detached, abrasion is easily caused to the batteries of the new energy electric vehicle, labor intensity is high, operation complexity is high, and work efficiency is low.

Owner:吴凡

Screw type plastic mold

The invention provides a screw type plastic mold. The screw type plastic mold comprises a support, a connecting rectangular block, a mold, a mold cavity, a feed opening, a connecting pipe, a connecting sleeve, a feed pipe, a fixture block, a cylinder, a mounting base, a push plate structure, a heat conduction box structure, a connecting bolt and a collection box structure, wherein the connecting rectangular block is welded to the right side of the front surface of the support and the left side and lower part of the front surface of the mold respectively, and simultaneously is internally in threaded connection with the connecting bolt; the mold cavity is formed in the left lower side of the interior of the mold; the feed opening is formed in the right lower side of the interior of the support; the connecting pipe is embedded into the middle part of the interior of the support, and the upper part of the connecting pipe is in threaded connection with the connecting sleeve. The screw typeplastic mold has the benefits that materials inside a second connecting pipe are conveniently collected through the arrangement of the collection box structure, and then materials inside a storage tank are conveniently collected and treated, and the problem that a part of the materials cannot be used and are wasted is further avoided.

Owner:XUZHOU TIANLI DIE MFG

Energy-saving ginkgo leaf fixation dryer

PendingCN111888382AReach deliveryTo achieve the effect of removing impuritiesGinkgophyta medical ingredientsPlant ingredientsAgricultural engineeringGinkgo biloba

The invention discloses an energy-saving ginkgo leaf fixation dryer. The dryer comprises a bearing plate, a second box body is fixedly mounted at the upper part of the bearing plate, a first box bodyis fixedly mounted at the upper part of the second box body, a liftable adjusting bracket is fixedly mounted at the upper part of the first box body, a solar panel is arranged at the upper part of theadjusting bracket, a feeding port is formed in the upper portion of the first box body and located in the right side of the adjusting bracket, a grid plate is fixedly installed in the first box bodyand divides the first box body into a material conveying cavity and a temperature control cavity, a rotating rod is rotatably installed in the material conveying cavity, and a transmission blade is arranged outside the rotating rod. The invention relates to the technical field of ginkgo leaf processing. The energy-saving ginkgo leaf fixation dryer is good in drying effect, resources are reasonablyutilized, the energy-saving effect is achieved, impurities on ginkgo leaves are removed, and the effect of the ginkgo leaf fixation drying machine is better.

Owner:JIANGSU BESCON PHARMA

Breakage-proof quick-freezing device for quick-frozen dumplings, and working method of breakage-proof quick-freezing device

ActiveCN112021491ASolve the problem of poor effect of damage preventionSolve the problem of low freezing efficiencyFood preservationStructural engineeringIndustrial engineering

The invention discloses a breakage-proof quick-freezing device for quick-frozen dumplings, and a working method of the breakage-proof quick-freezing device. A first drying pipe, a second drying pipe,a third drying pipe, a first drying strip and a second drying strip are arranged and used in cooperation, so that the breakage-proof effect during quick-freezing of the dumplings can be improved; a driving column rotates so as to drive a conveying belt in the first drying pipe and a conveying belt in the second drying pipe to rotate oppositely; the dumplings are conveyed onto a storage base through the conveying belts; the problem that the breakage-proof effect is poor during quick-freezing of the dumplings in the existing scheme is solved; a first conveying box, a second conveying box, a freezing box and a refrigerating base are arranged and used in cooperation, so that the quick-freezing efficiency of the dumplings can be improved; the dumplings roll on a first storage inclined plate anda second storage inclined plate respectively, and roll onto a third storage inclined plate to be accumulated and quickly frozen; after quick-freezing is finished, the dumplings on the third storage inclined plate are collected through a first pull plate; and therefore, the problem of low quick-freezing efficiency of the dumplings in the existing scheme is overcome.

Owner:安徽昊晨食品股份有限公司

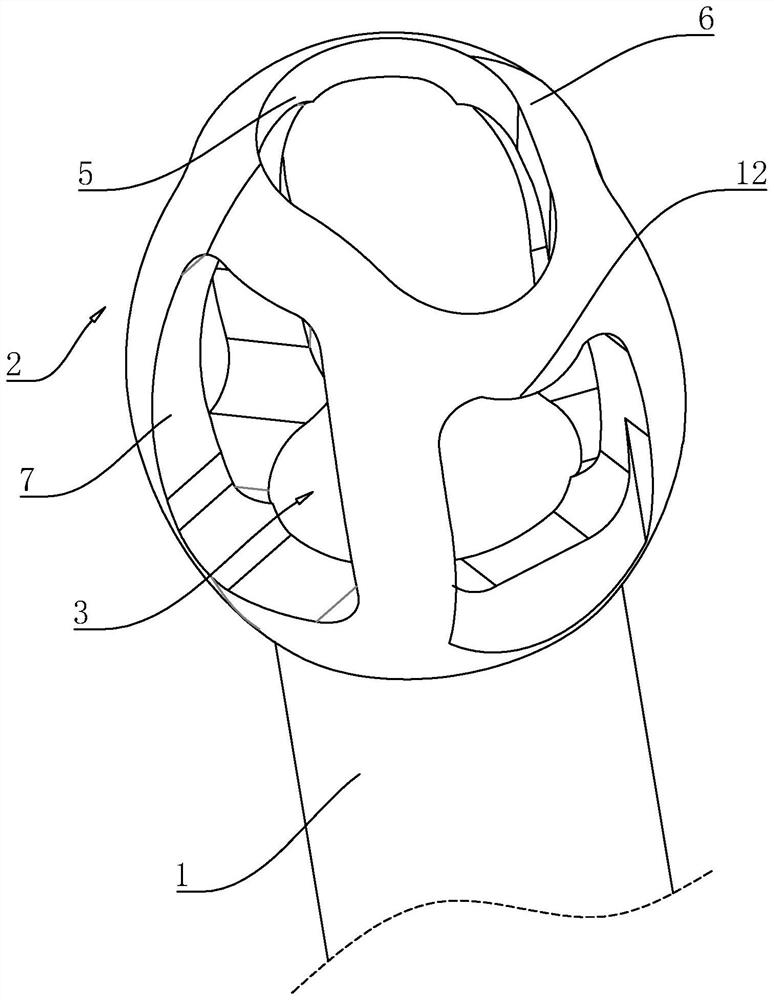

Ear cleaning head of hollow structure and ear cleaning device

ActiveCN113057797ASent out in timeReduce the possibilityEar treatmentFinal product manufactureEngineeringMechanical engineering

The invention relates to the field of ear canal cleaning, in particular to an ear cleaning head of a hollow structure. The ear cleaning head comprises a connecting rod and a cleaning end arranged on the end face of one end of the connecting rod, the outer wall of the cleaning end is a convex arc-shaped wall, and a pre-storage cavity is arranged in the cleaning end in a hollow manner. The connecting rod is provided with a pre-storage cavity in a penetrating mode, the connecting rod is provided with a conveying cavity communicating with the pre-storage cavity in a penetrating mode, the end, away from the connecting rod, of the cleaning end is provided with a collecting groove communicating with the pre-storage cavity, the cleaning end is provided with a side groove communicating with the pre-storage cavity in a hollowed-out mode, and the cleaning end is in a hollowed-out shape and communicates with the conveying cavity. The ear cleaning head has the effect of reducing the possibility that granular earwax in the ear canal is pushed to the outer ear in the ear canal cleaning process.

Owner:SHENZHEN GLOBAL GENERAL MASCH CO LTD

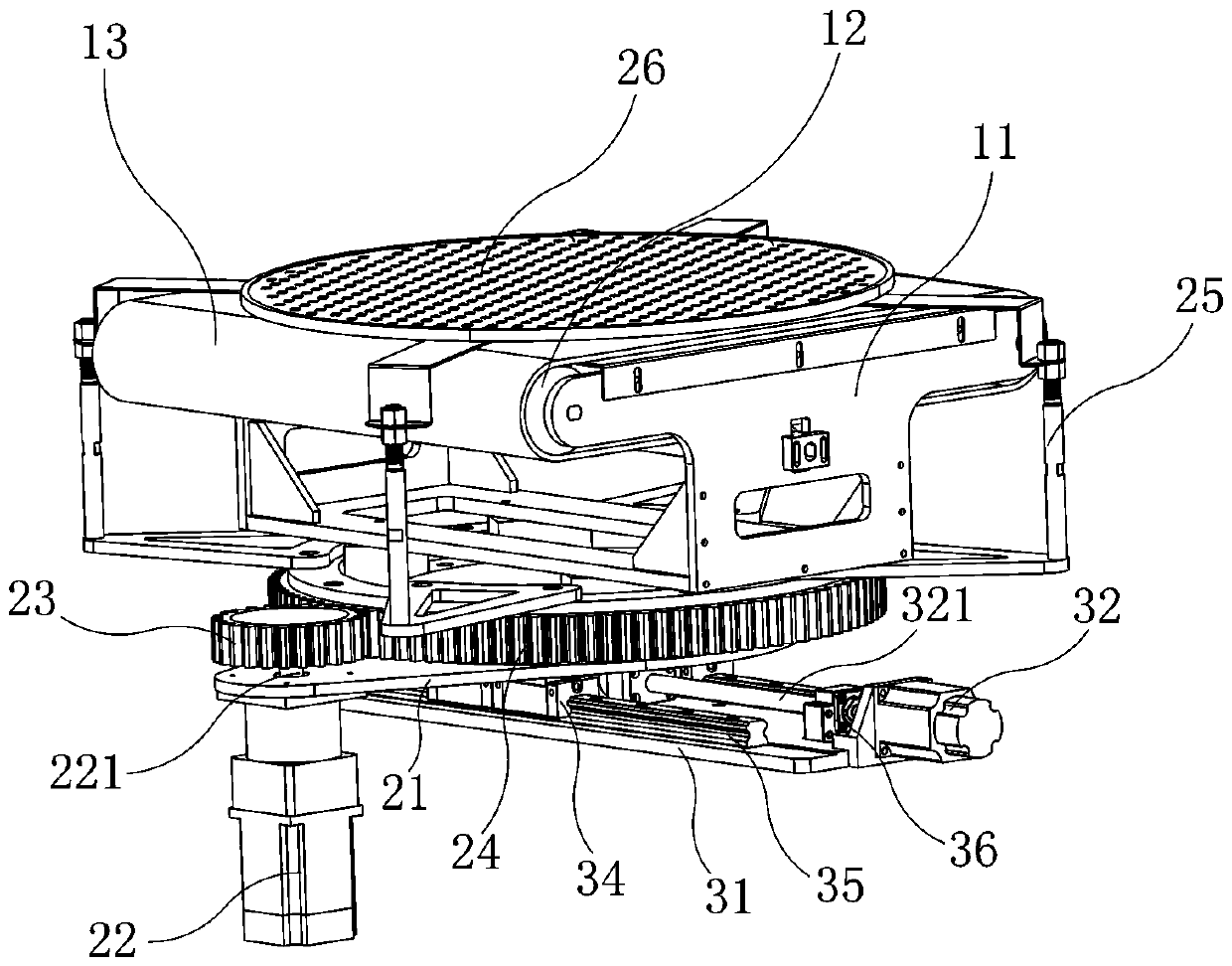

Continuous position correction mechanism for fluid product bag

The invention discloses a continuous position correction mechanism for a fluid product bag. The continuous position correction mechanism for the fluid product bag comprises a conveying mechanism, a rotating mechanism and a horizontal moving mechanism, wherein the conveying mechanism comprises a base, an electric roller and a conveyor belt; the rotating mechanism comprises a first fixed seat, a servo motor provided with a rotary shaft, a driving wheel, a driven wheel, a rotating support and a rotary plate; and the horizontal moving mechanism comprises a second fixed seat, a drive motor provided with a drive shaft, a connecting plate, a sliding seat and a sliding rail. When the continuous position correction mechanism for the fluid product bag provided by the invention is used for conveying the fluid product bag filled with a fluid product, through arranging the rotating mechanism and the horizontal moving mechanism, when the fluid product bag is continuously conveyed, the position of the fluid product bag in a circumferential direction and the position of the fluid product bag in a horizontal direction along a direction perpendicular to the conveyor belt can be continuously adjusted, so that the position of the fluid product bag is ensured to stay the same in the conveying process.

Owner:XIAMEN AUTOMACTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com