Continuous position correction mechanism for fluid product bag

A technology of fluid products and alignment, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as large amount of glue used, the handle cannot be installed in the designated position, and the milk is easy to shake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

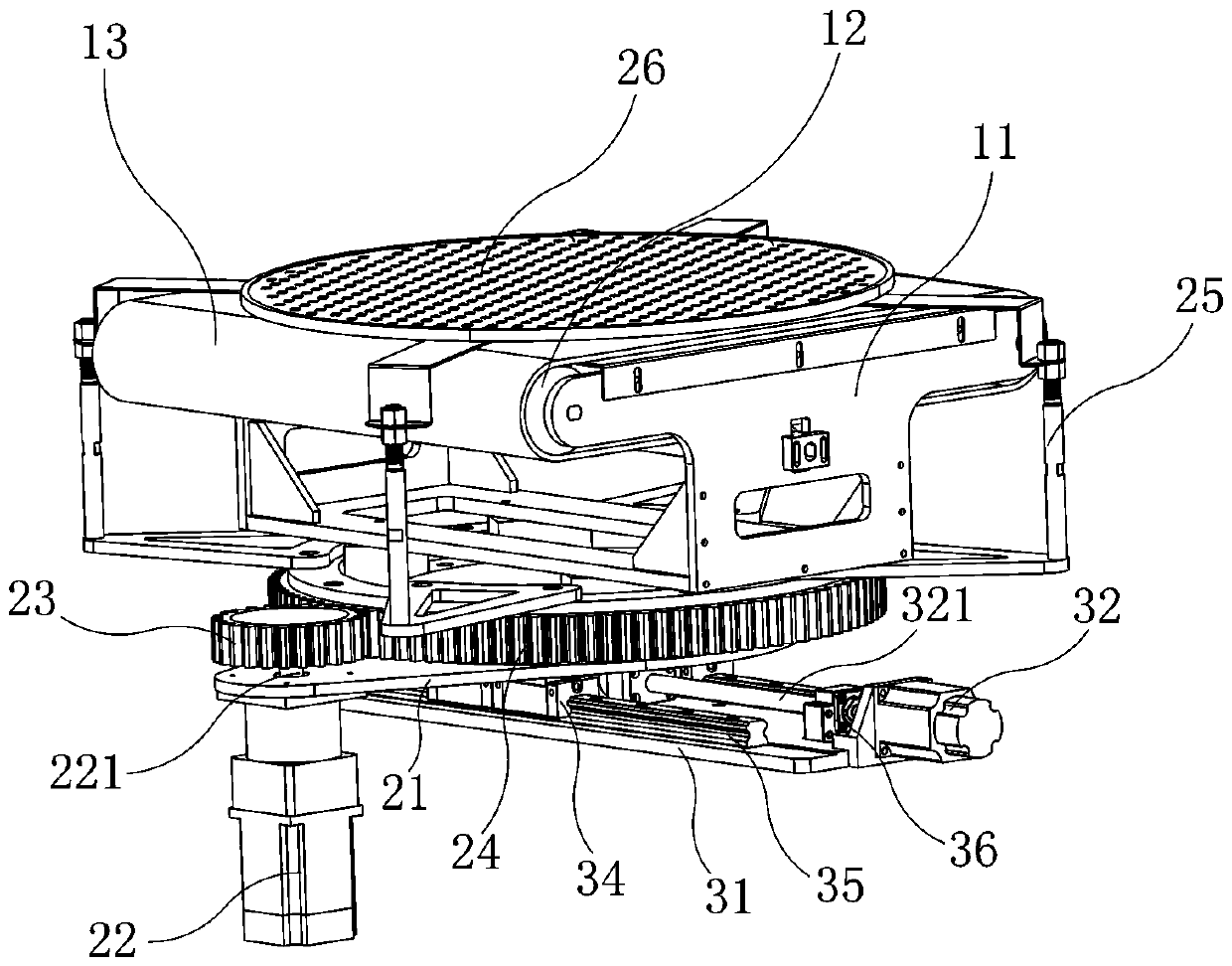

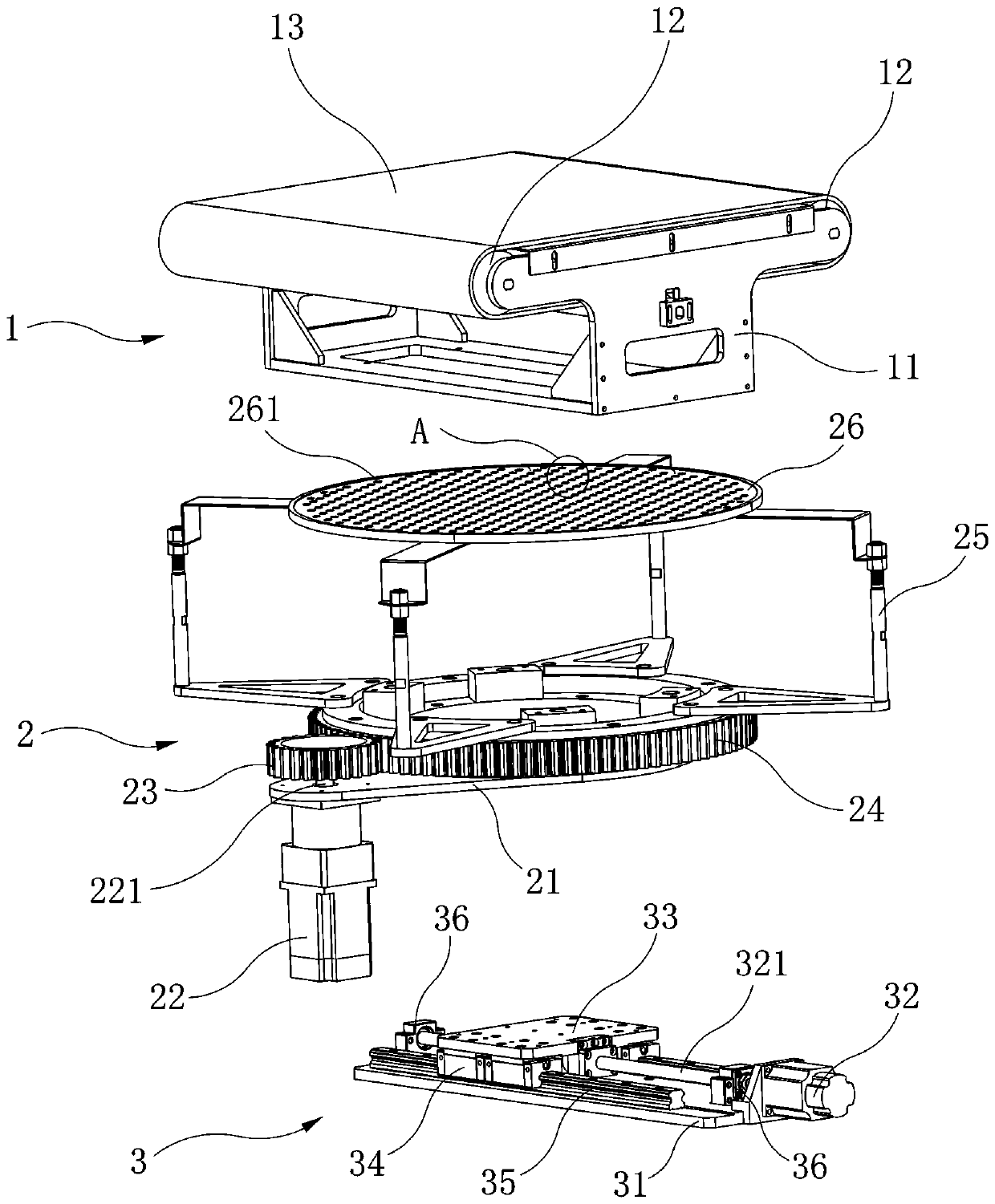

[0019] like Figure 1 to Figure 4 As shown, it is a preferred embodiment of a fluid product bag continuous alignment mechanism of the present invention, which includes a transmission mechanism 1, a rotary mechanism 2 and a translation mechanism 3, and the rotary mechanism 2 is fixedly connected to the transmission mechanism 1 and the translation mechanism 3 respectively.

[0020] The above-mentioned transmission mechanism 1 includes a base 11 , an electric drum 12 and a conveyor belt 13 .

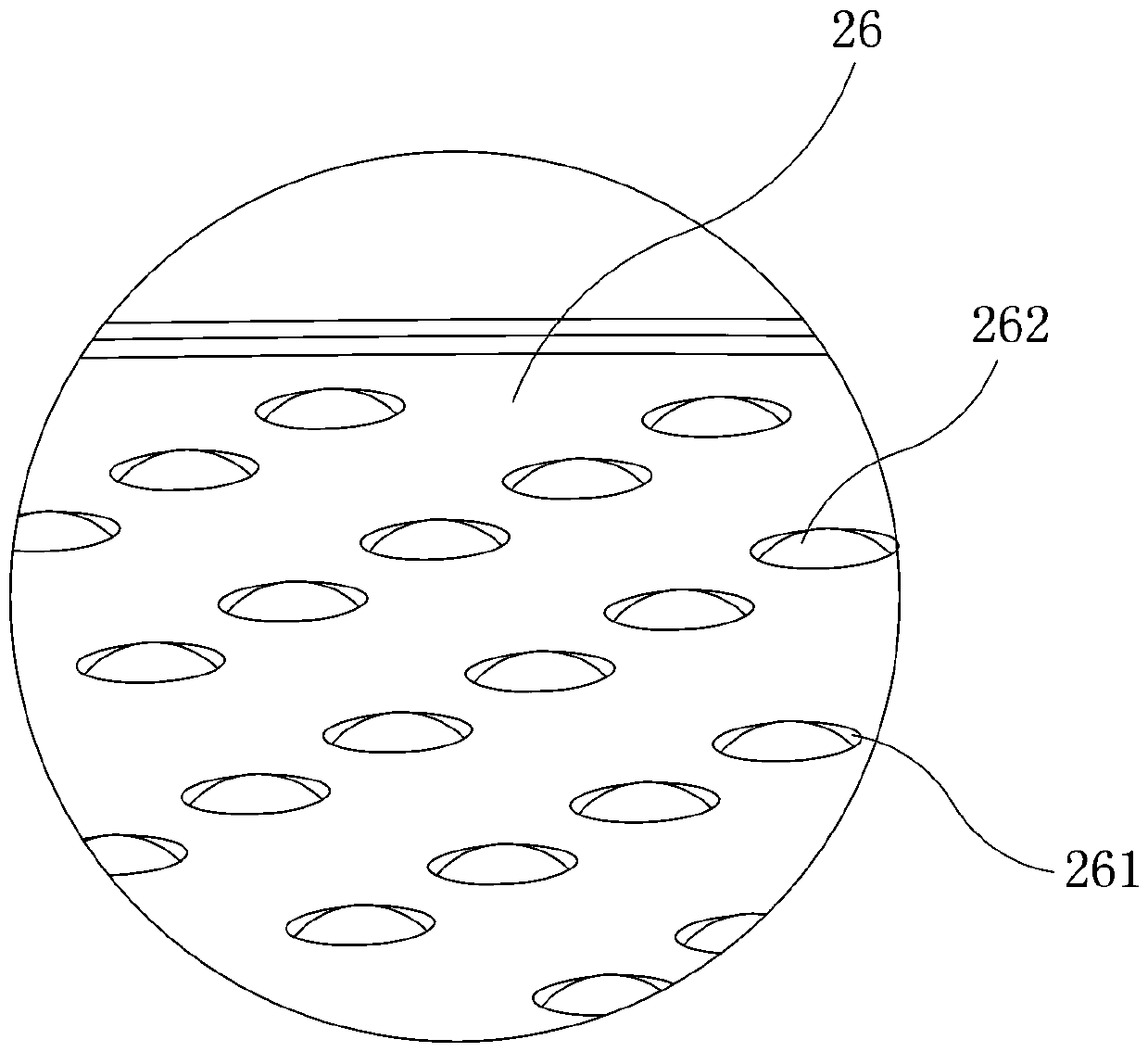

[0021] The above-mentioned rotating mechanism 2 includes a first fixed seat 21, a servo motor 22 provided with a rotating shaft 221, a driving wheel 23, a driven wheel 24, a rotating support 25 and a turntable 26, and the servo motor 22 is fixedly installed on the first fixed seat 21. The driving wheel 23 is fixedly mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com