Screw type plastic mold

A plastic mold and spiral technology, applied in the field of plastic molds, can solve the problems of accelerated molding, inconvenient extrusion of materials, and lack of collection, and achieve the effect of convenient collection, convenient collection and processing, and avoidance of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

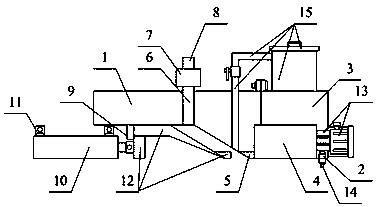

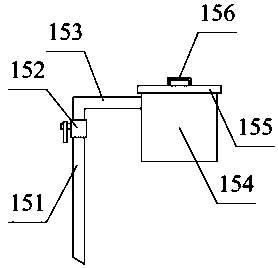

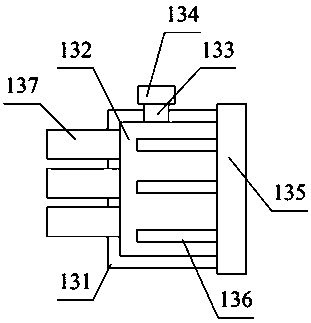

[0033] as attached figure 1 to the attached figure 2As shown, a spiral plastic mold includes a bracket 1, a connecting rectangular block 2, a mold 3, a mold cavity 4, a feeding hole 5, a connecting pipe 6, a connecting sleeve 7, a feeding pipe 8, a clamping block 9, and a cylinder 10. , the mounting seat 11, the push plate structure 12, the heat conduction box structure 13, the connecting bolts 14 and the collecting box structure 15, the connecting rectangular blocks 2 are respectively welded on the right side of the front surface of the bracket 1 and the left side and the lower part of the front surface of the mold 3 At the same time, there are connecting bolts 14 internally threaded; the mold cavity 4 is opened on the lower left side of the mold 3; the feed hole 5 is opened on the lower right side of the bracket 1; the connecting pipe 6 is inlaid A connecting sleeve 7 is threadedly connected to the upper part of the inner part of the bracket 1; the feed pipe 8 is threadedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com