Stirrup feeding device for welding steel reinforcement cages

A technology of feeding device and reinforcing cage, applied in the field of stirrup feeding device, can solve the problems of high labor cost and low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

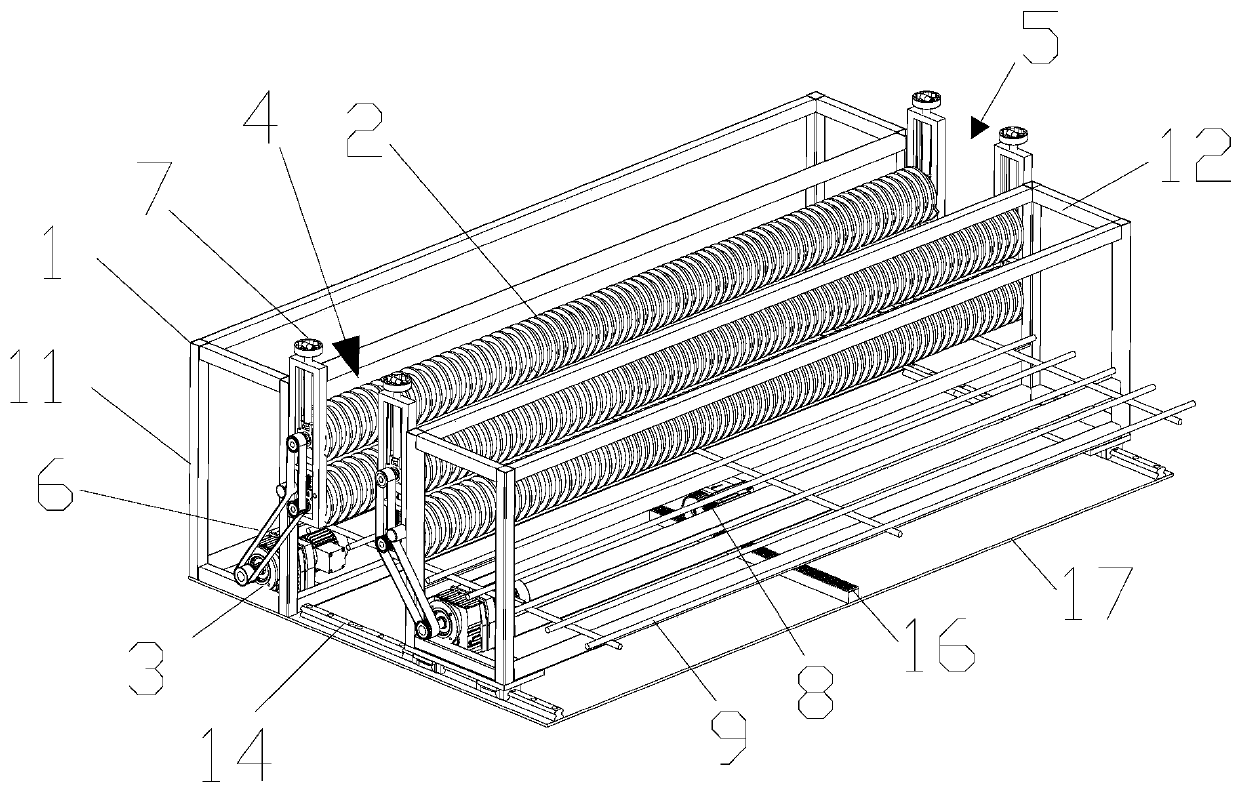

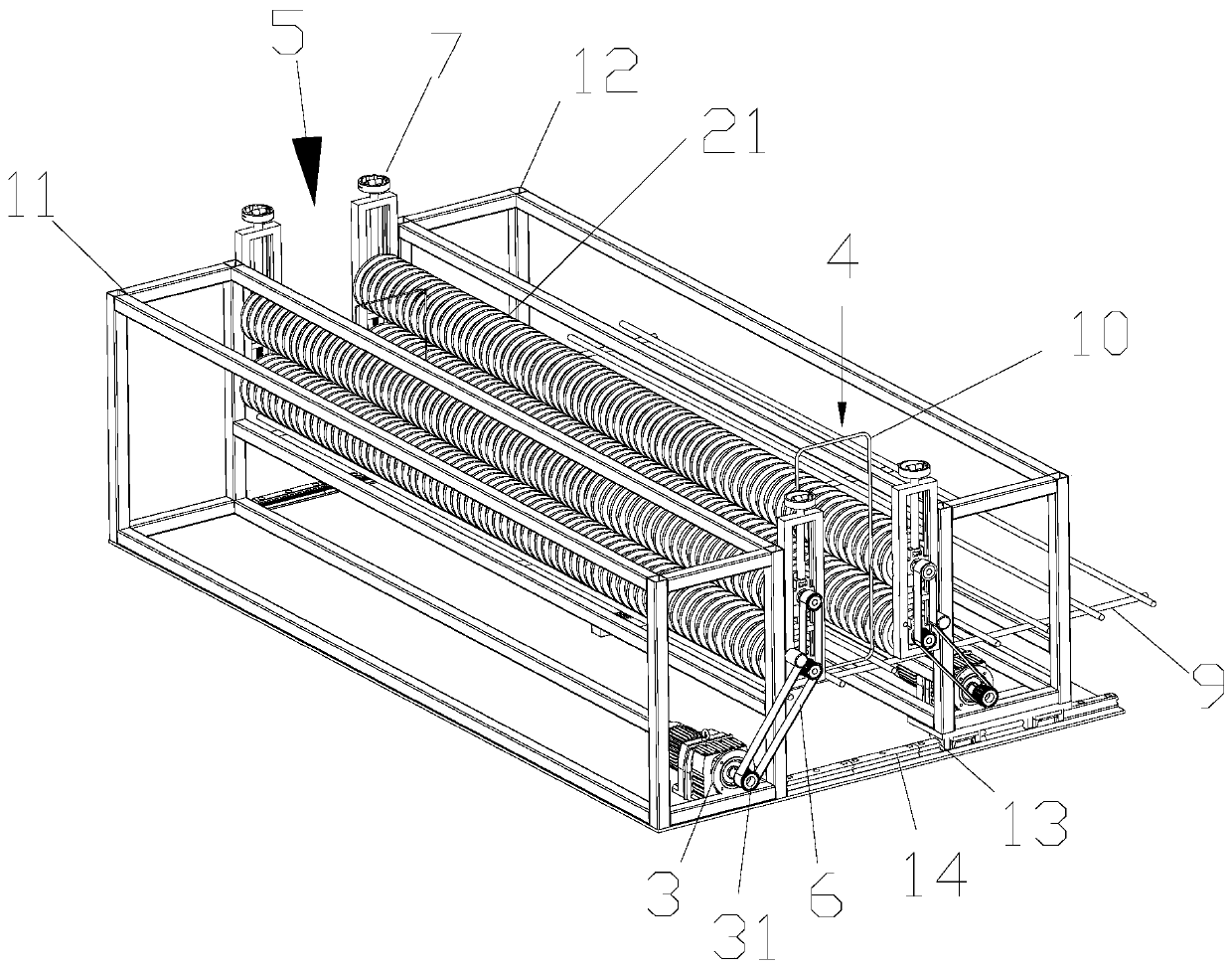

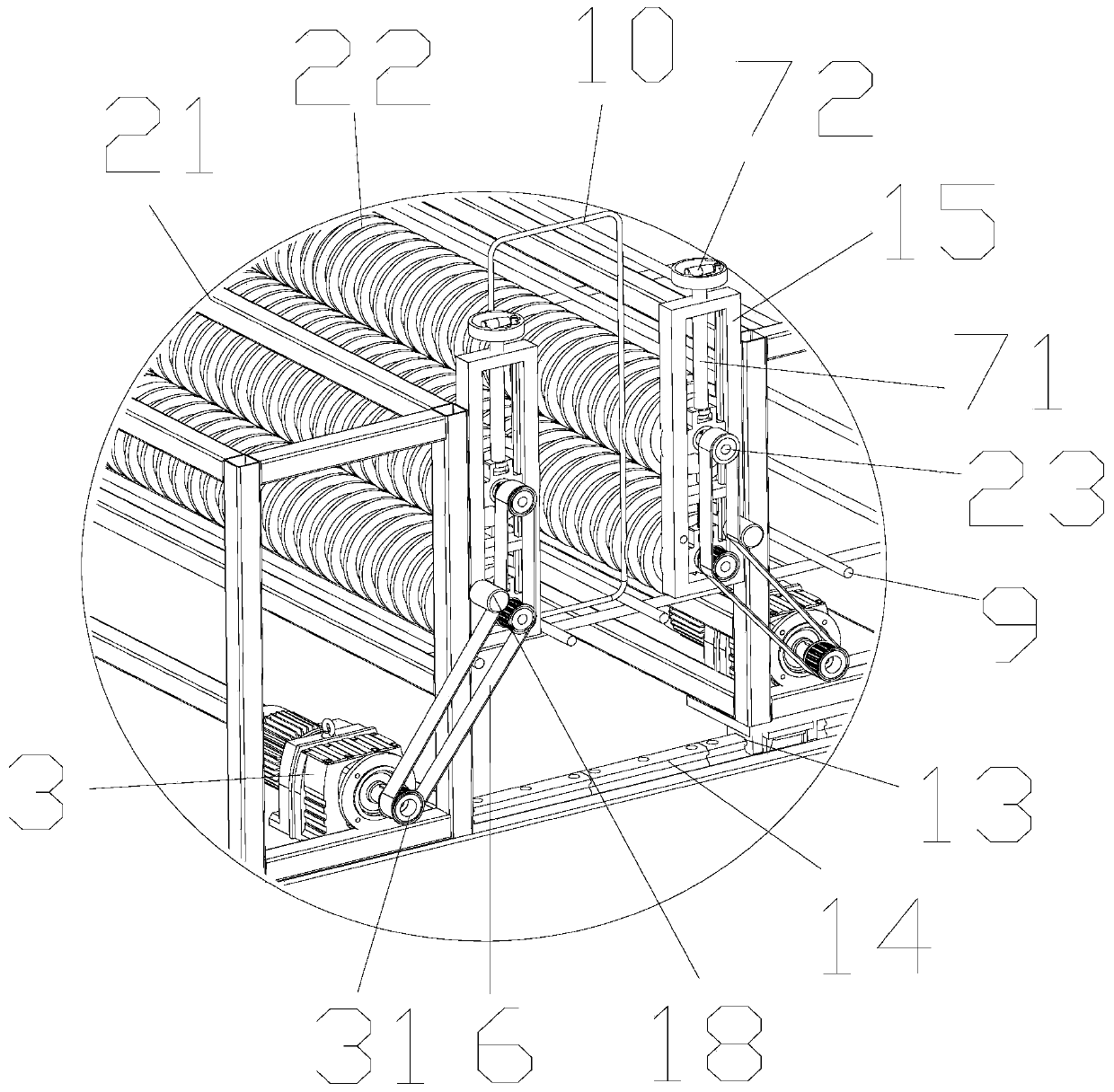

[0027] Reference figure 1 , The stirrup feeding device for steel cage welding in this embodiment includes a base 1, a screw conveying device 2 and a driving device 3. In this embodiment, the base 1 is a frame formed by welding a plurality of metal pipes, and gaps are respectively provided at both ends of the base 1 to form the inlet 4 and the outlet 5 of the stirrup. In order to enhance the overall stability, the bottom side of the base 1 in this embodiment is also provided with a bottom plate 17 fixedly connected with the metal pipe. The two ends of the screw conveying device 2 are respectively fixed on the two ends of the feed port 4 and the discharge port 5 on the base 1 . In this solution, the setting direction of the feed port and the discharge port is opposite, which does not affect the realization of the stirrup conveying function. The driving device 3 is fixed on the bottom plate 17 at one end of the base 1 . In this embodiment, the driving device 3 is a motor, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com