Passenger conveyors and steps for passenger conveyors

A technology of passenger conveying equipment and steps, applied in escalators, transportation and packaging, etc., can solve problems such as step differences, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be described below with reference to the drawings. In each drawing and each embodiment, the same or similar constituent elements are denoted by the same symbols, and repeated description thereof will be omitted.

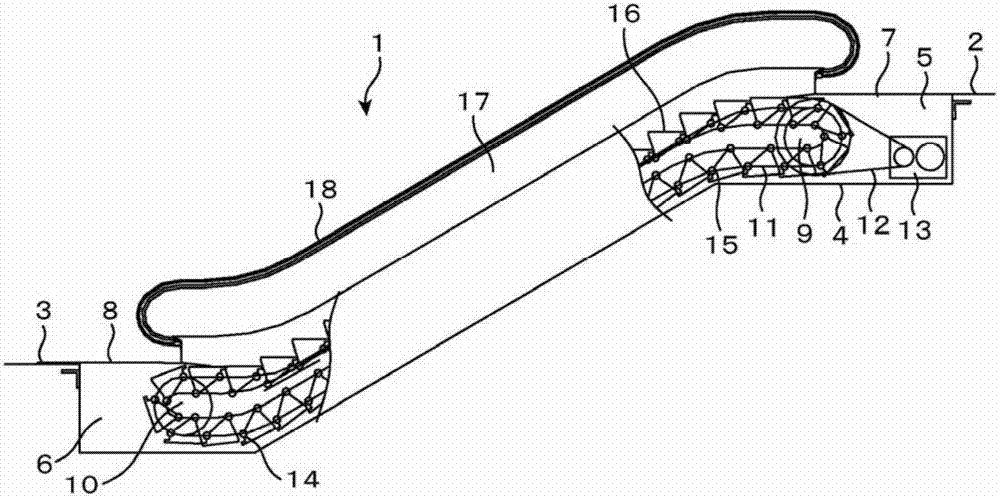

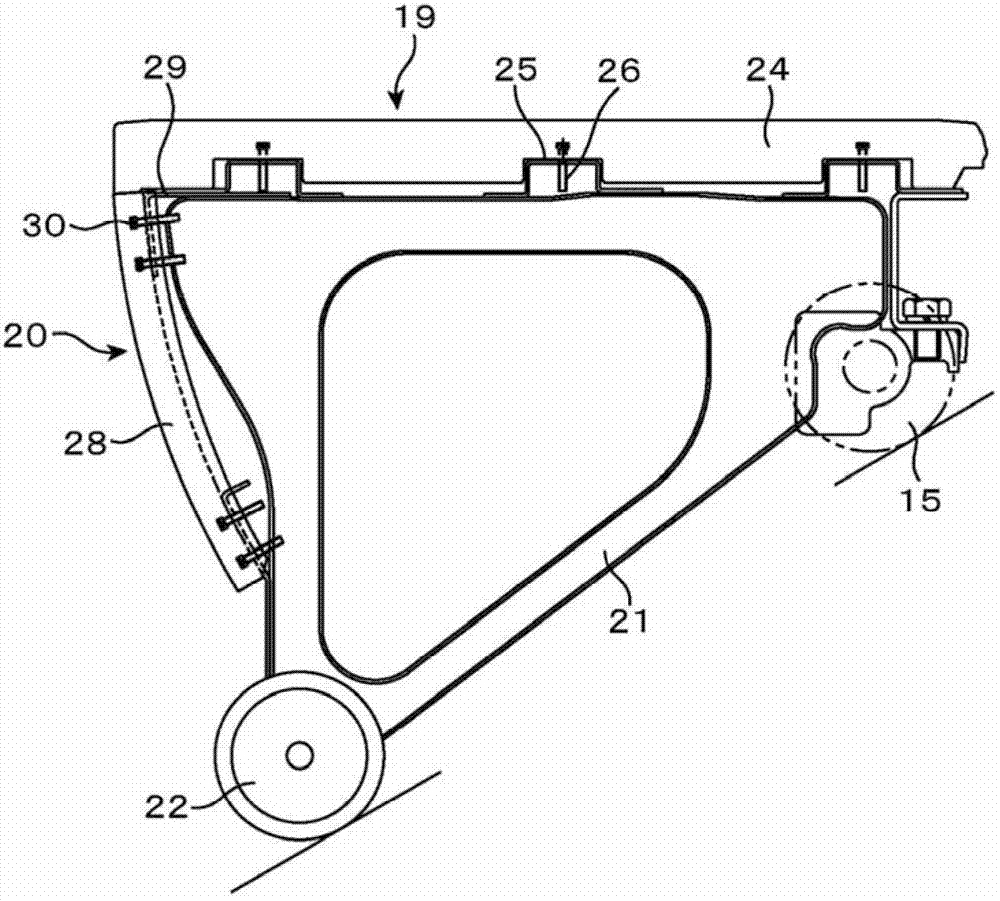

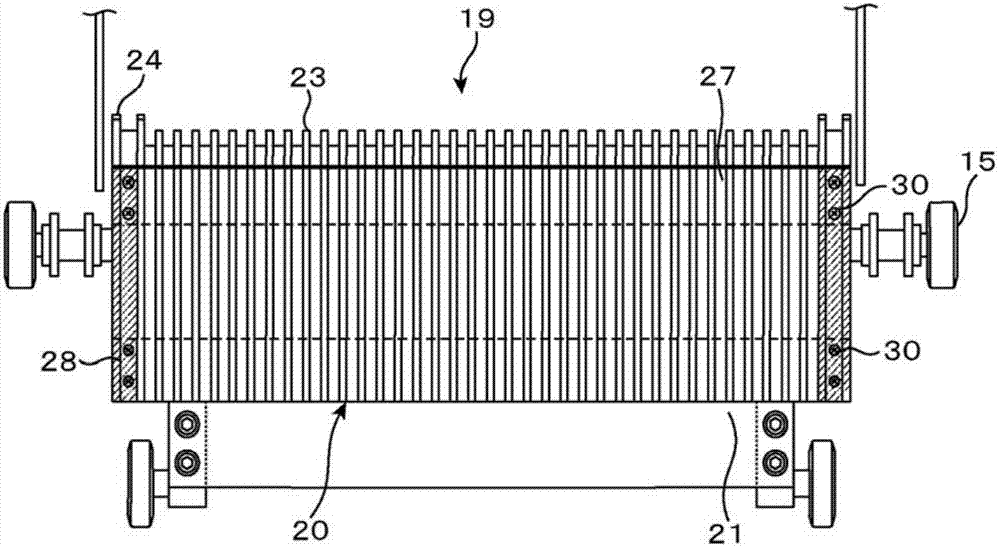

[0058] figure 1 It is a schematic diagram of the overall structure of the passenger conveying equipment. like figure 1 As shown, a passenger conveying device such as an escalator 1 has a frame body 4 arranged across an upper floor 2 and a lower floor 3 of a building structure, an upper machine room 5 and an upper machine room 5 arranged at both ends of the length direction of the frame body 4 The lower machine room 6, the upper doorway floor 7 covering the upper machine room 5 from above, the lower doorway floor 8 covering the lower machine room 6 from above, the upper terminal sprocket 9 installed in the upper machine room 5, and the lower The lower terminal sprocket 10 in the machine room 6, the left and right p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com