Metal-resin composite pipes

A metal resin and composite pipe technology, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problem of metal strip plate damage to flexibility (flexibility, insufficient strength and rigidity, reduced workability, etc.) problems, to achieve the effect of light weight and low cost, improved flexibility and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

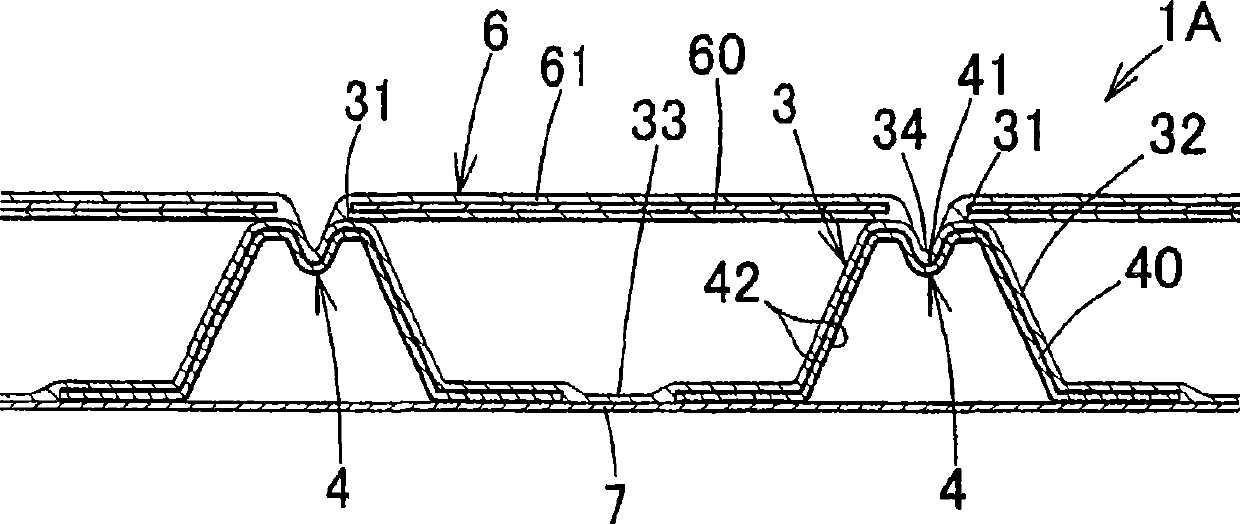

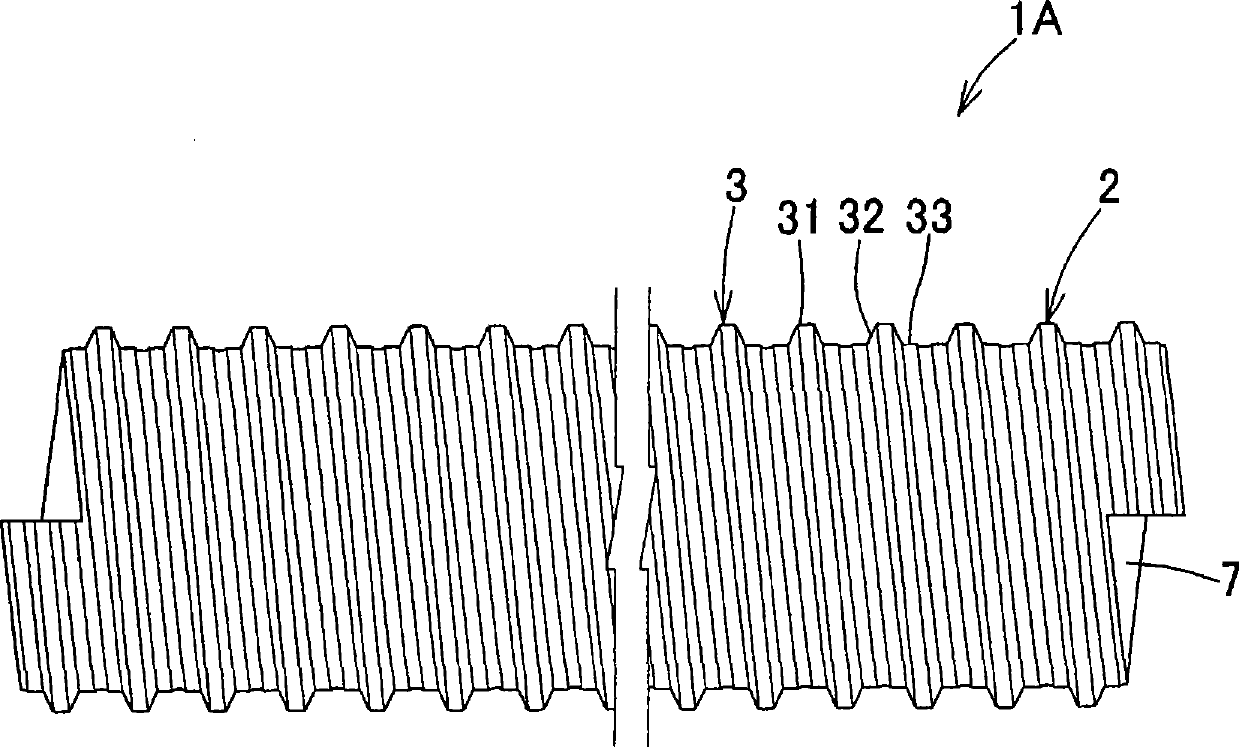

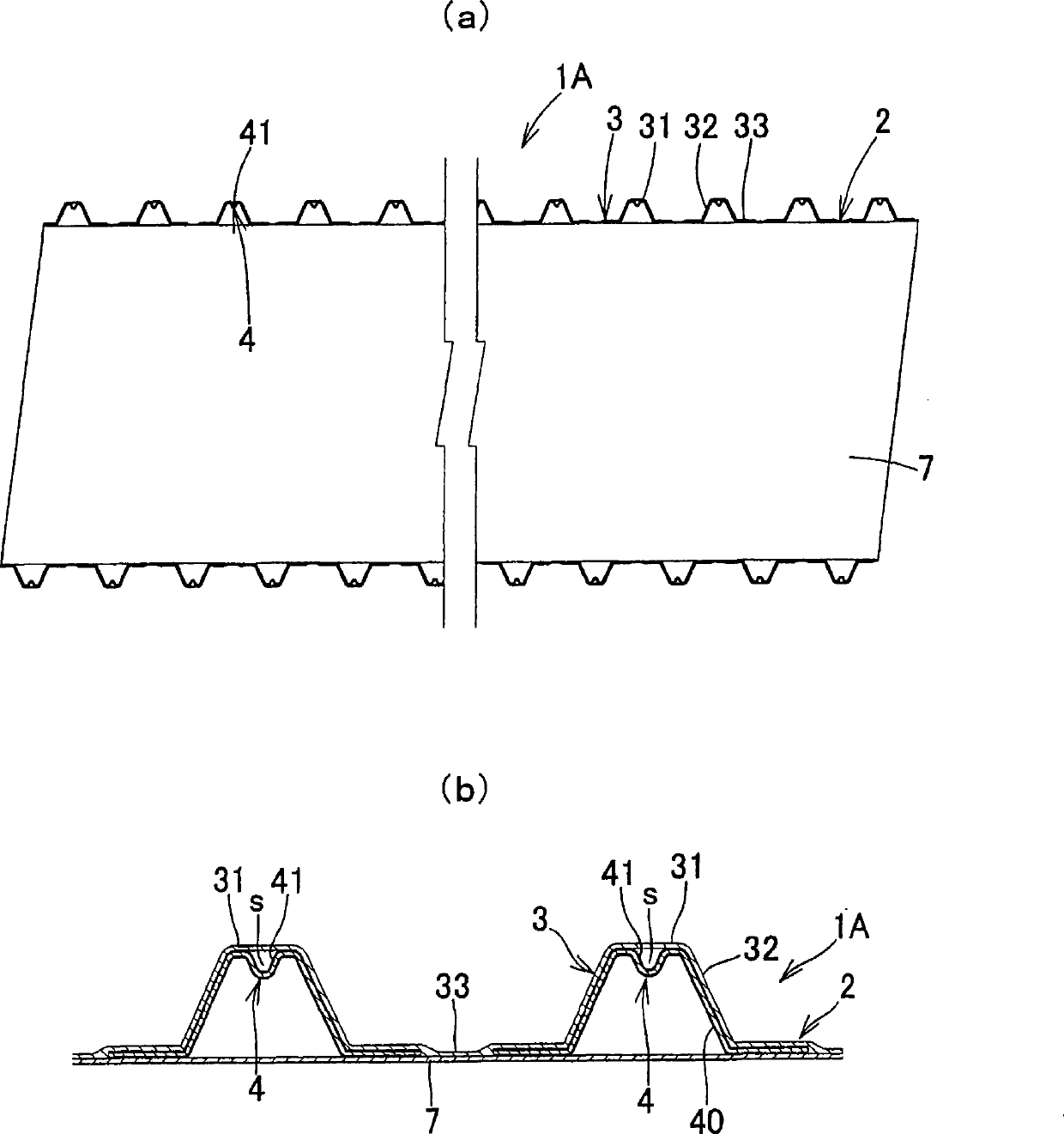

[0057] Next, according to Figure 1 to Figure 11 The structure of the metal-resin composite pipe according to the embodiment of the present invention will be described in detail. Figure 1 to Figure 5 Showing the first embodiment of the present invention, Figure 6 ~ Figure 11 shows the second embodiment, figure 1 Reference numeral 1 denotes a metal-resin composite pipe, 2 denotes a pipe wall, 3 denotes a synthetic resin wall portion, 4 denotes a reinforcing belt plate, and 5 denotes a synthetic resin belt body.

[0058] In addition, in the description of each of the following embodiments, the pipe wall 2 is described as an example of a structure in which substantially arc-shaped or trapezoidal peaks 31 and valleys 33 are continuously formed into waves via the side wall 32 . Type tube is the basic structure, on the mountain portion 31 is provided with a concave portion 34. However, the present invention is not limited to this structure. For example, the basic structure may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com