Preparation method of tightly twisted fiber capable of preventing hook damage

A fiber and hook prevention technology, applied in the field of spinning, can solve the problems of easy hooking or breakage, defects on the surface of the fabric, decrease in strength, etc., to achieve a good anti-hook and scratch effect of monofilament, increase fiber twist, and good shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of tightly twisted anti-snag fiber, comprising the following steps:

[0031] 1) Preparation of POY filaments: POY filaments were prepared at a spinning speed of 3800-4000 m / min.

[0032] The material of the POY yarn is polyester or nylon 6. The specification of the polyester POY fiber is 30-475dtex / 3-288f; the specification of the nylon 6 POY yarn is 15-150dtex / 3-96f.

[0033] 2) The obtained POY yarn is wound on a rotatable winding disk, and the POY filament is transported to the false twist texturing machine while controlling the rotation of the winding disk; wherein the steering of the winding disk is related to the twisting of the POY silk in the false twist texturing machine. to the opposite. The rotating speed of the reel is 100-500 revolutions per 1 meter of POY yarn conveyed, so that the twist of the POY yarn when it reaches the false twist texturing machine is 100-500 twists / meter.

[0034] 3) False-twisting and deforming the POY yarn by...

Embodiment 1

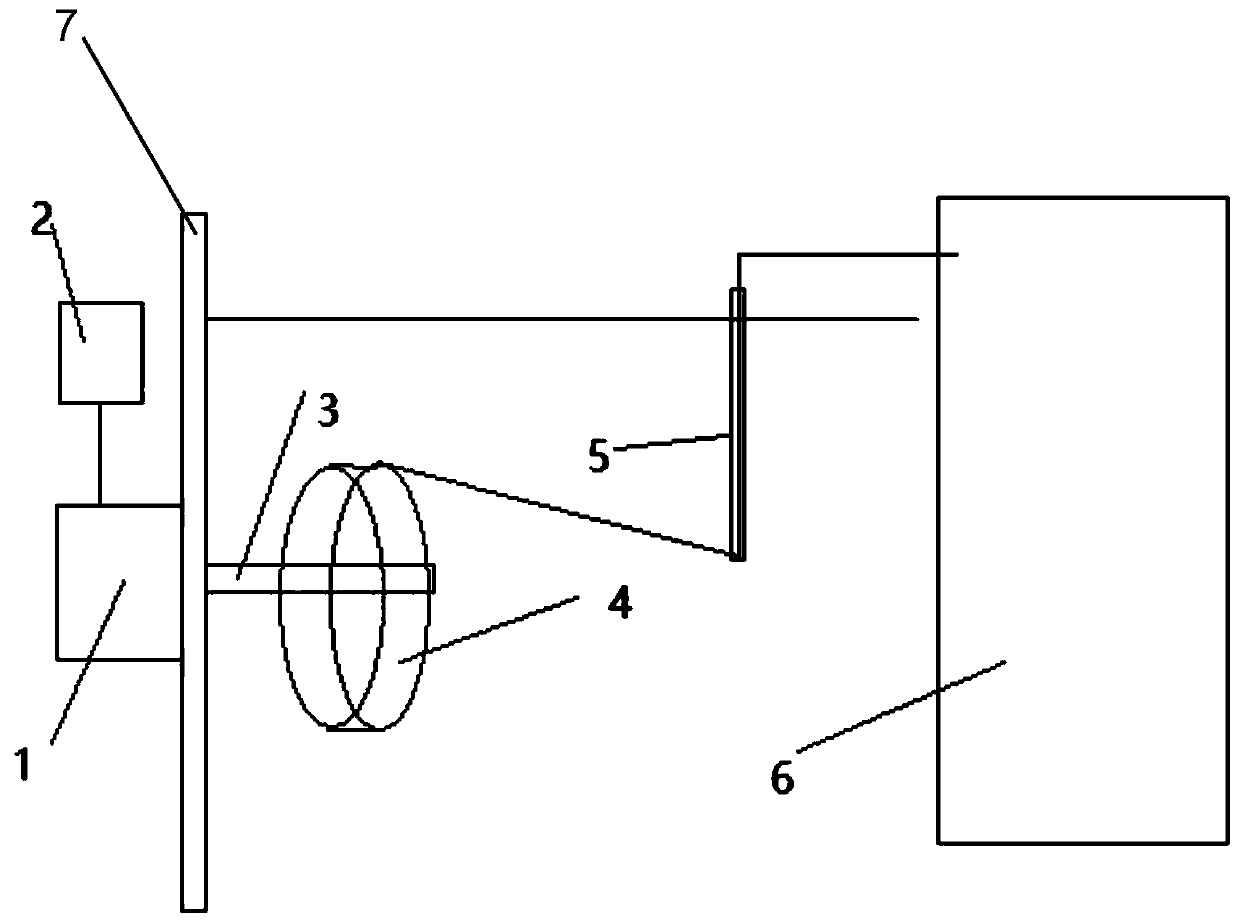

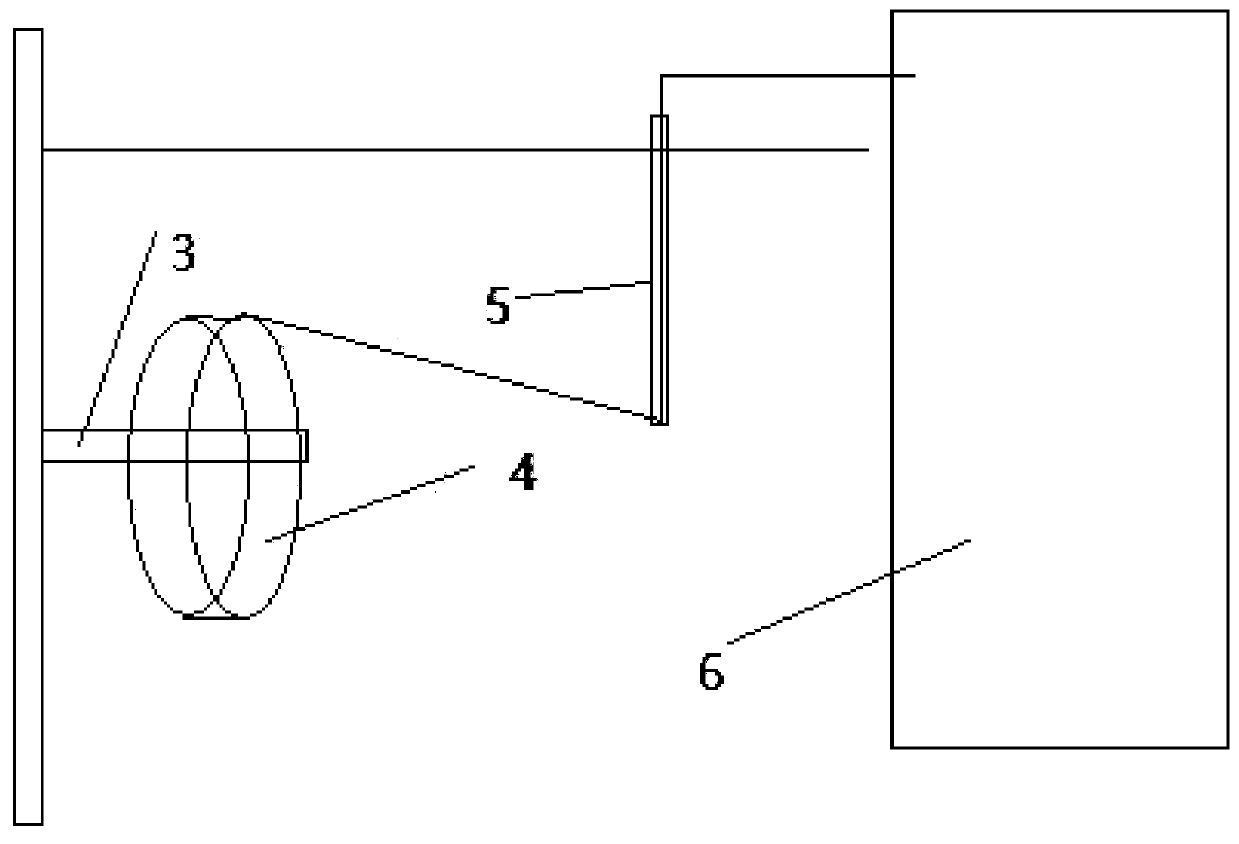

[0041] A preparation method of tightly twisted anti-snag fiber, the PA6POY yarn of 90dtex / 48f is produced at a spinning speed of 3900m / min, and the raw silk frame is transformed on a false twist texturing machine (for details, see figure 1), so that the wire roll can be driven by the motor to rotate, and the motor can be adjusted by the frequency converter, so that the POY monofilament has a twist of 100 twists / m before entering the false twist deformation processing area, and then undergoes false twist deformation, and the production speed 300m / min, draw ratio 1.30, a hot box 180°C, D / Y 1.8, 70dtex / 48f PA6 tight twist anti-snag fiber DTY was prepared.

Embodiment 2

[0043] A kind of preparation method of tight-twisting anti-snag damage fiber, the PET POY silk of 50dtex / 24f is made with the spinning speed of 3800m / min, transforms the raw silk frame on the false twist texturing machine (reformation details see figure 1 ), so that the wire roll can be driven by the motor to rotate, and the motor can be adjusted by the frequency converter, so that the POY monofilament has a twist of 300 twists / m before entering the false twist deformation processing area, and then undergoes false twist deformation, and the production speed 500m / min, draw ratio 1.72, first hot box 200°C, second hot box 180°C, D / Y 1.90, 30dtex / 72f PET tight twist anti-snag fiber DTY was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com