Angle iron punching machine added with chamfering function

A punching machine and chamfering technology, applied in the direction of perforating tools, forming tools, manufacturing tools, etc., can solve the problems of easy hand injury, low efficiency, high risk, etc., to facilitate chamfering processing, ensure stability, and overall good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

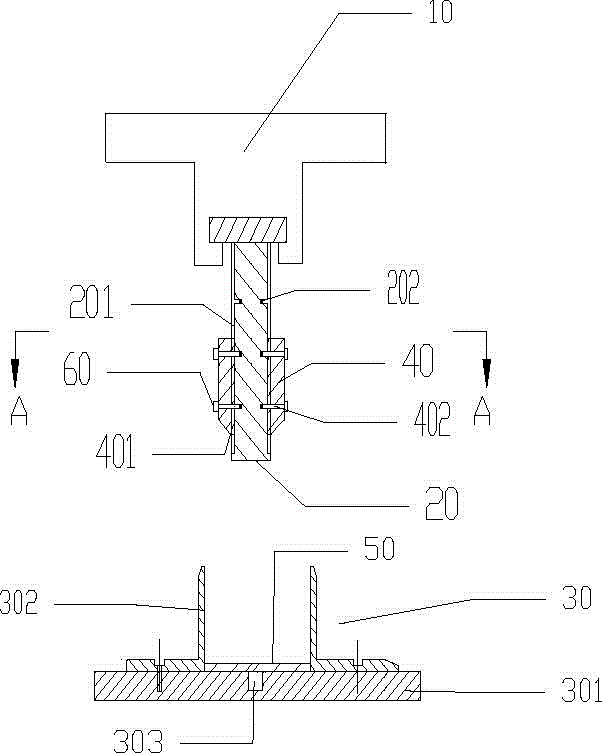

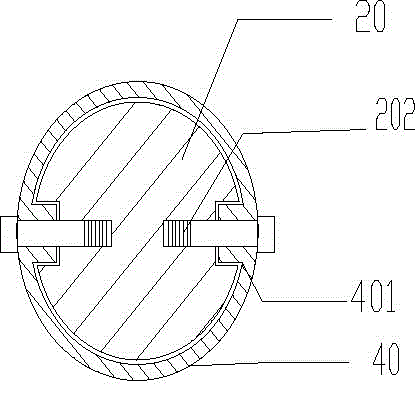

[0012] Such as figure 1 with figure 2 As shown, the angle iron punching machine attached to the angle of this embodiment includes a punching power device 10, a punching head 20, and a base 30. The base 30 is located below the punching head 20, and the punching power device 10 is located at the punching Above the head 20, the punching power unit 10 drives the punching head 20 to move in a direction perpendicular to the base 30. The outer wall of the punching head 20 is provided with a chamfering head 40, and the inner wall of the chamfering head 40 and the outer wall of the punching head 20 The center axes of the chamfering head 40 and the punching head 20 coincide; the base 30 includes a base plate 301 and a positioning slider 302, the base plate 301 is provided with a die 303, the processed object 50 is placed on the base plate 301, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com