Special-shaped hole chamfering deburring device

A technology for deburring and special-shaped holes, applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve problems such as low work efficiency, loss, and affecting product processing quality, and reduce resource waste and economic losses , reduce customer complaints and repairs, deburring convenient and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

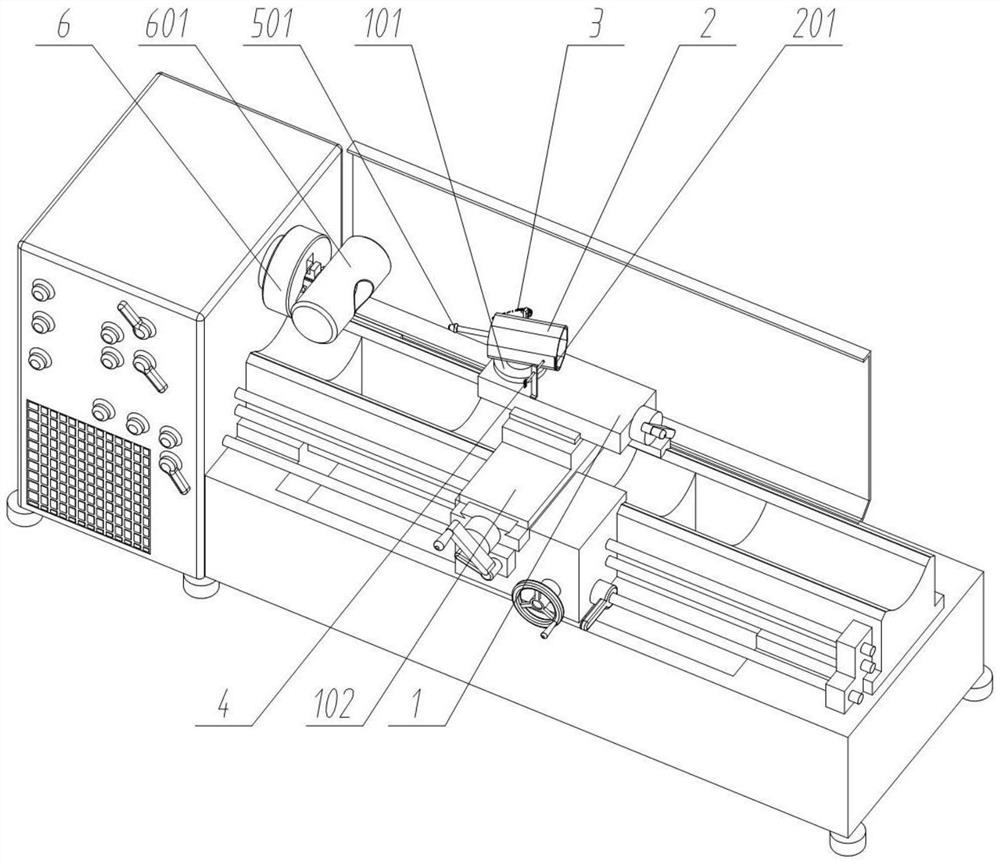

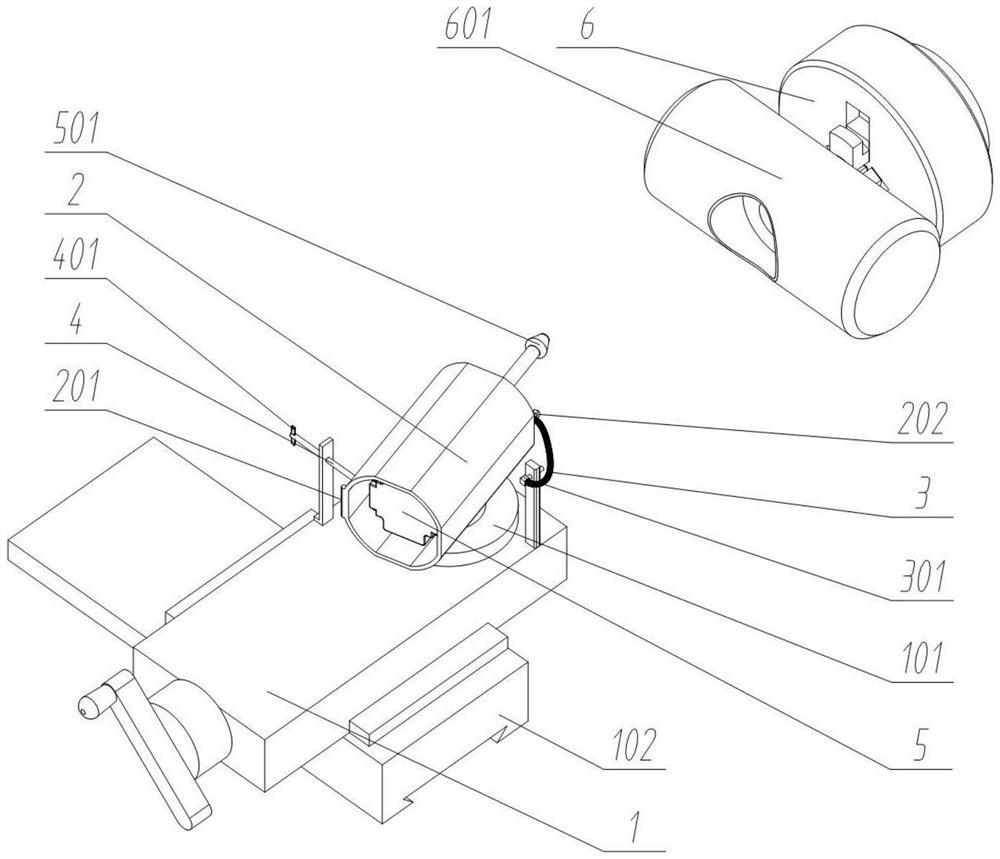

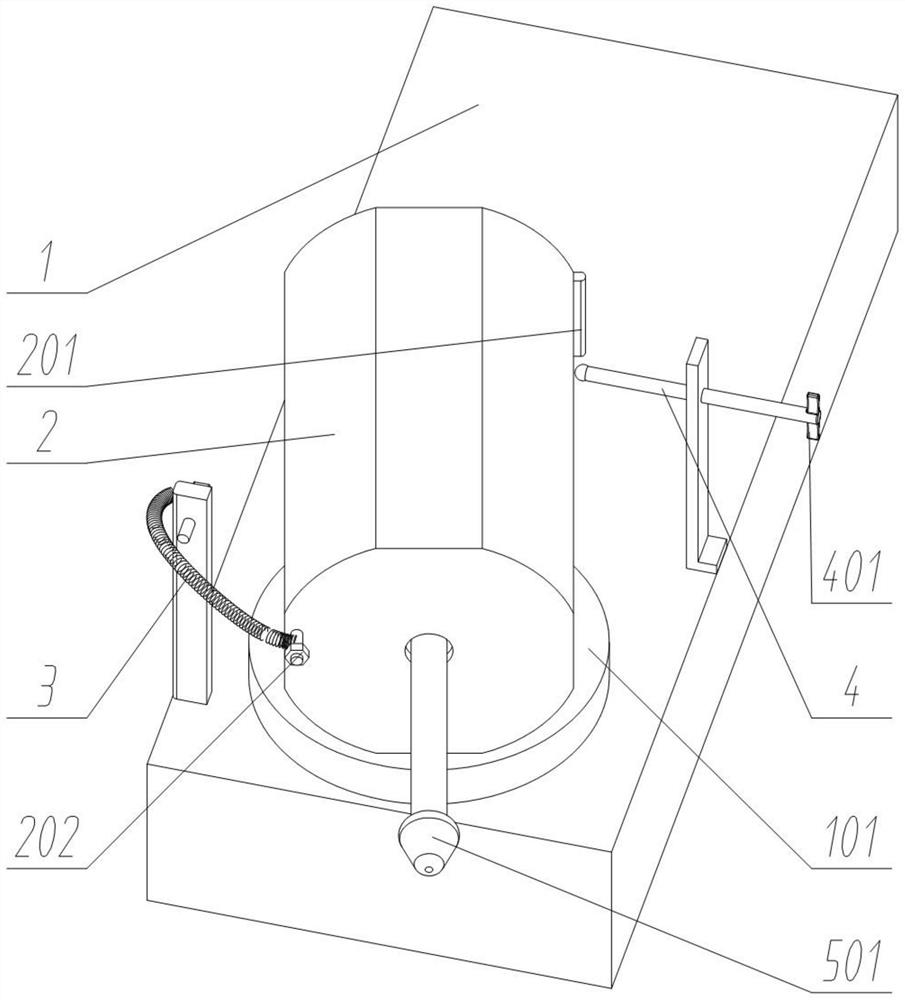

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028] The invention provides a chamfering and deburring device for special-shaped holes, which includes a tailstock 1 and an internal expansion chuck 6; the top of the tailstock 1 is fixedly connected with a group of annular floating tool holders 101 with chute; the top of the tailstock 1 is rotatably connected with a A group of electric grinder mounting bases 2; the front end of the tailstock 1 is rotatably connected to a set of electric grinder limit rods 4; the rear end of the tailstock 1 is fixedly connected to a set of tension springs 3; the tension spring 3 is elastically connected to a set of electric grinder mounting bases 2 A group of floating electric grinders 5 are fixedly connected inside the electric grinder mounting base 2; a group of floating electric grinders 501 are fixedly connected to the drive shaft on the left side of the floating electric grinder 5; A group of rocker shaft parts 601 are tightly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com