PCB and film alignment device

A film alignment and PCB board technology, which is applied to instruments, printed circuits, photoengraving processes of patterned surfaces, etc., can solve the problems of low alignment efficiency and low alignment accuracy, achieve stable positioning and improve alignment efficiency. , to ensure the effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

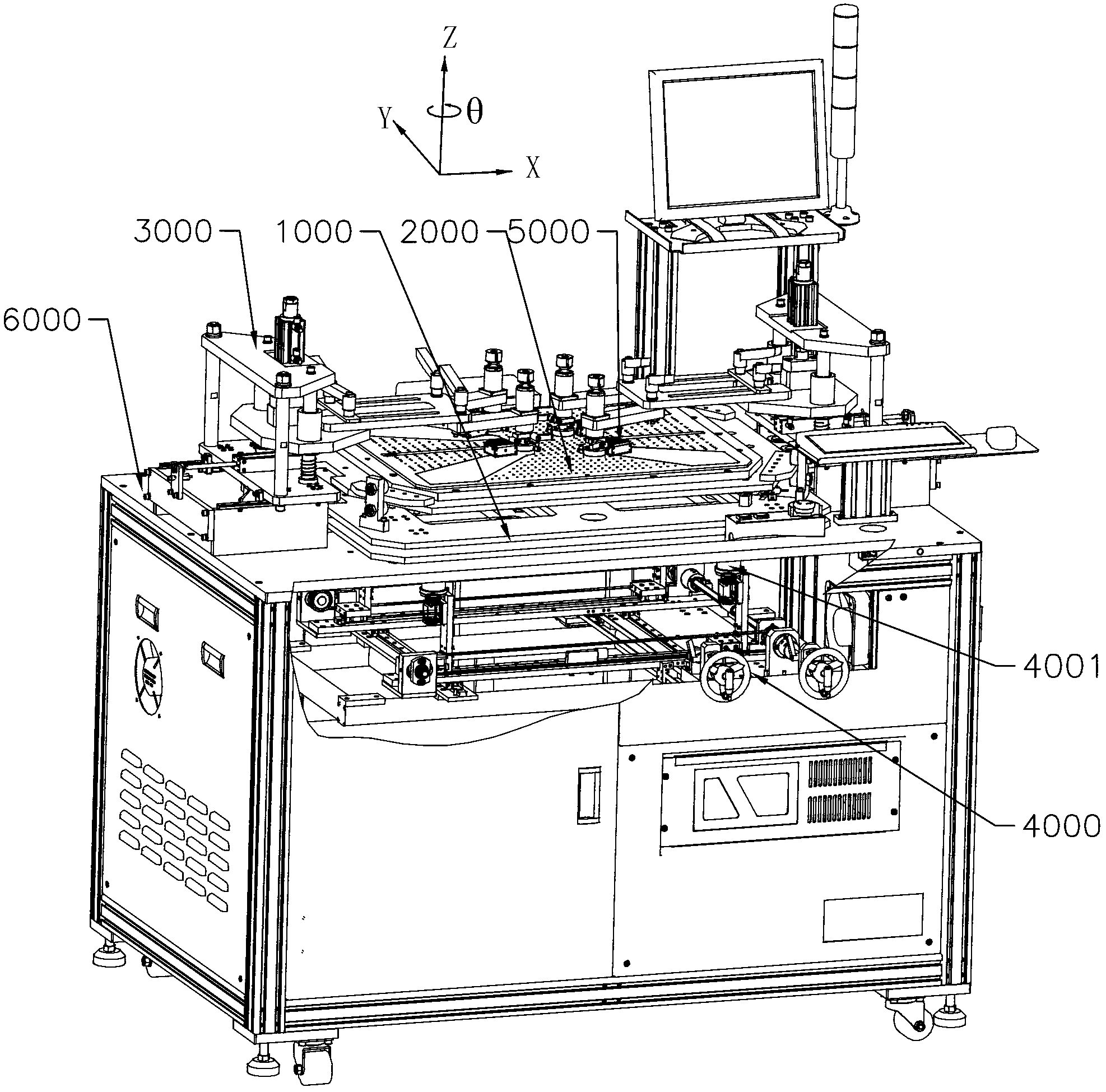

[0036] Such as figure 1 As shown, a PCB board and film alignment device. See X, Y, Z, θ directions in the three-dimensional coordinate system figure 1 , where the X direction and the Y direction are two directions perpendicular to each other in the horizontal plane, the Z direction is the direction perpendicular to the horizontal plane, and the θ angle rotation direction is the direction of rotation around the Z direction.

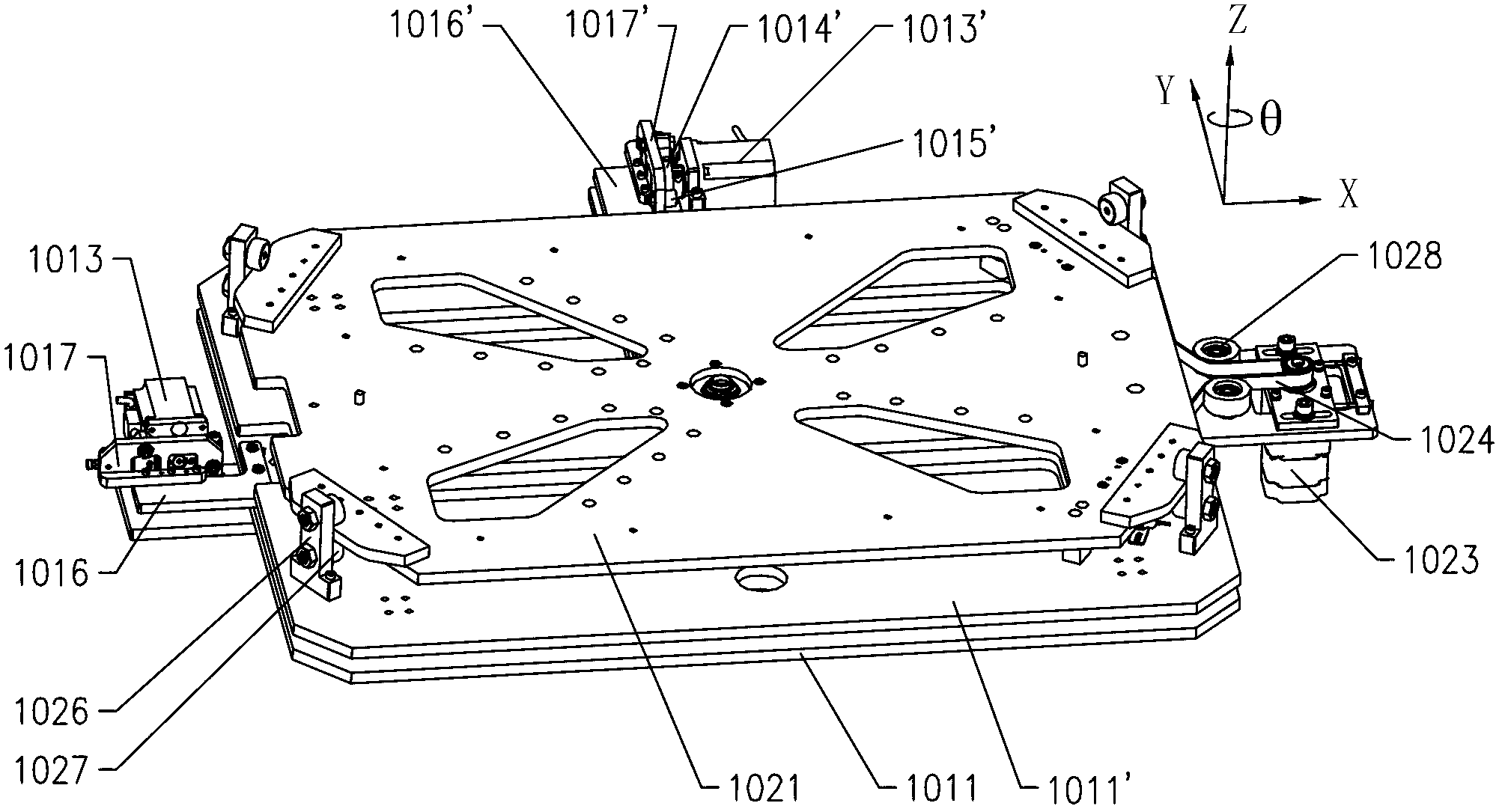

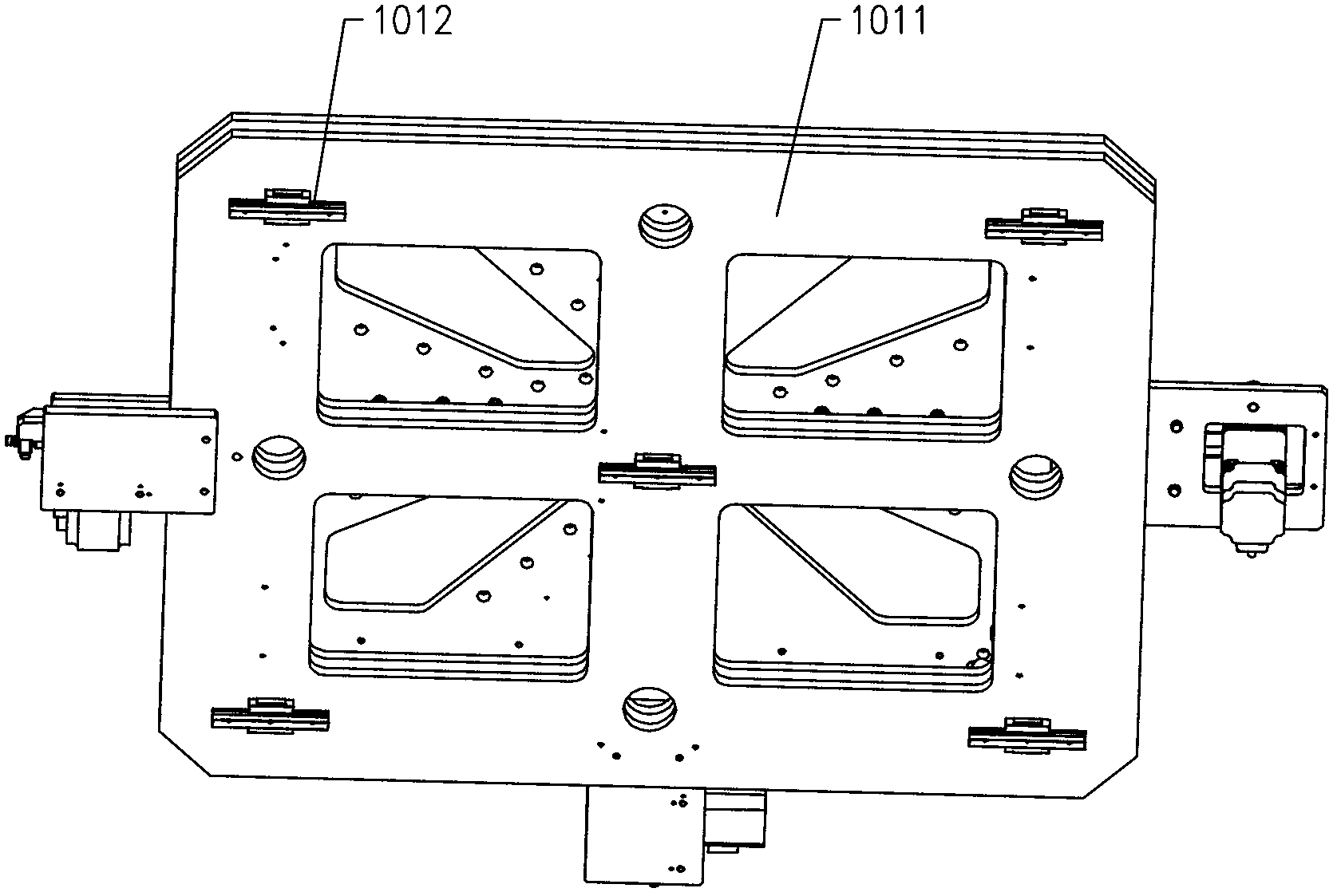

[0037] The PCB board and film alignment device includes a frame, and the following parts installed on the frame: X-Y-θ three-degree-of-freedom adjustment mechanism 1000; fixed on the X-Y-θ three-degree-of-freedom adjustment mechanism 1000 for adsorption PCB board The rectangular vacuum adsorption platform 2000, the X-Y-θ three-degree-of-freedom adjustment mechanism 1000 controls the translation and rotation of the vacuum adsorption platform 2000 along the X and Y directions, and the four corners of the vacuum adsorption platform 2000 extend diagonally. L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com