Aligning system photolithography equipment

An alignment system and lithography equipment technology, applied in the field of lithography machines, can solve the problems of unreliable provision of the highest alignment accuracy, inability to use high-order signals, low power, etc., to reduce signal processing time overhead, simplify Difficulty in optical path design and debugging, effects of strong signal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

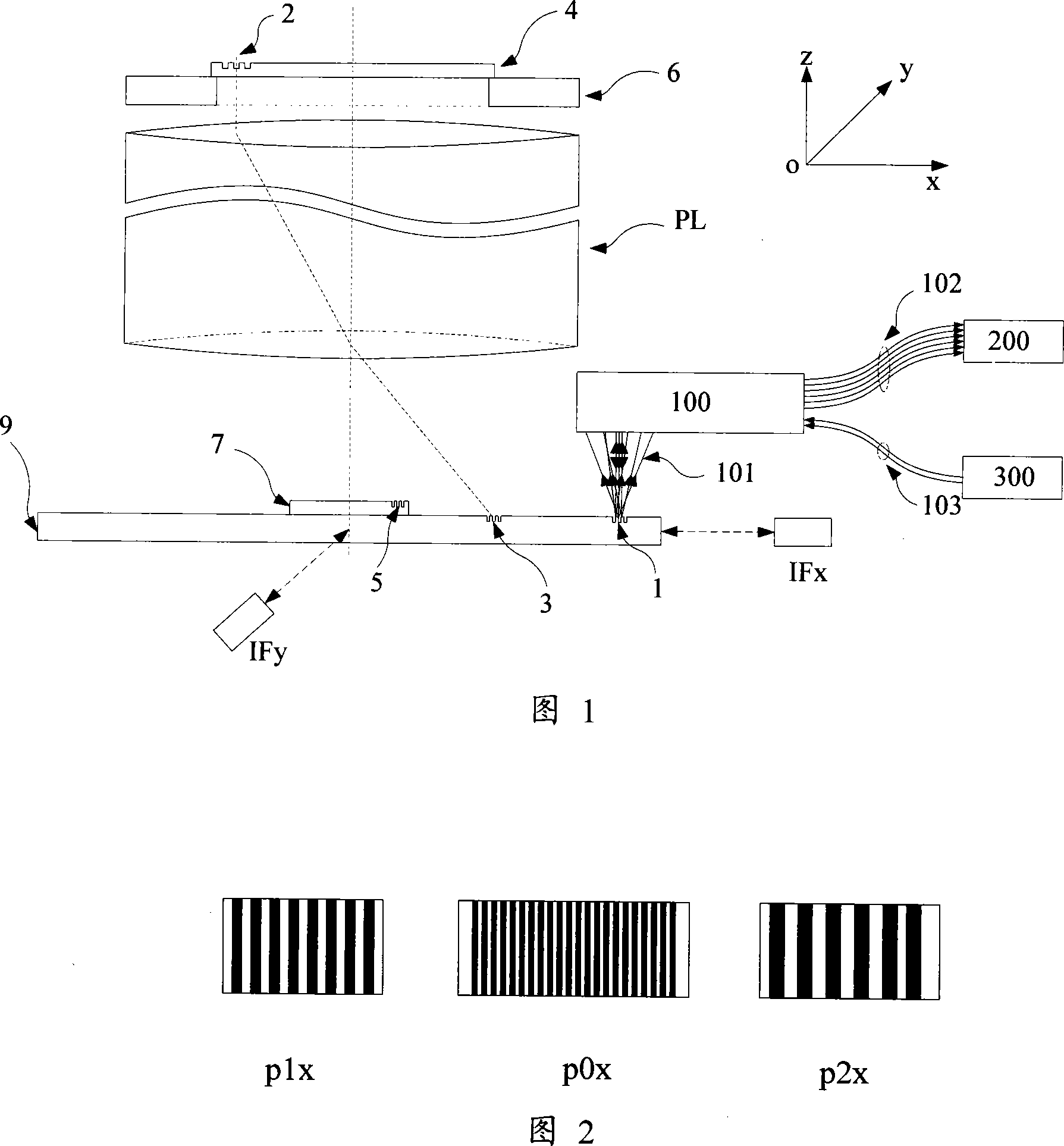

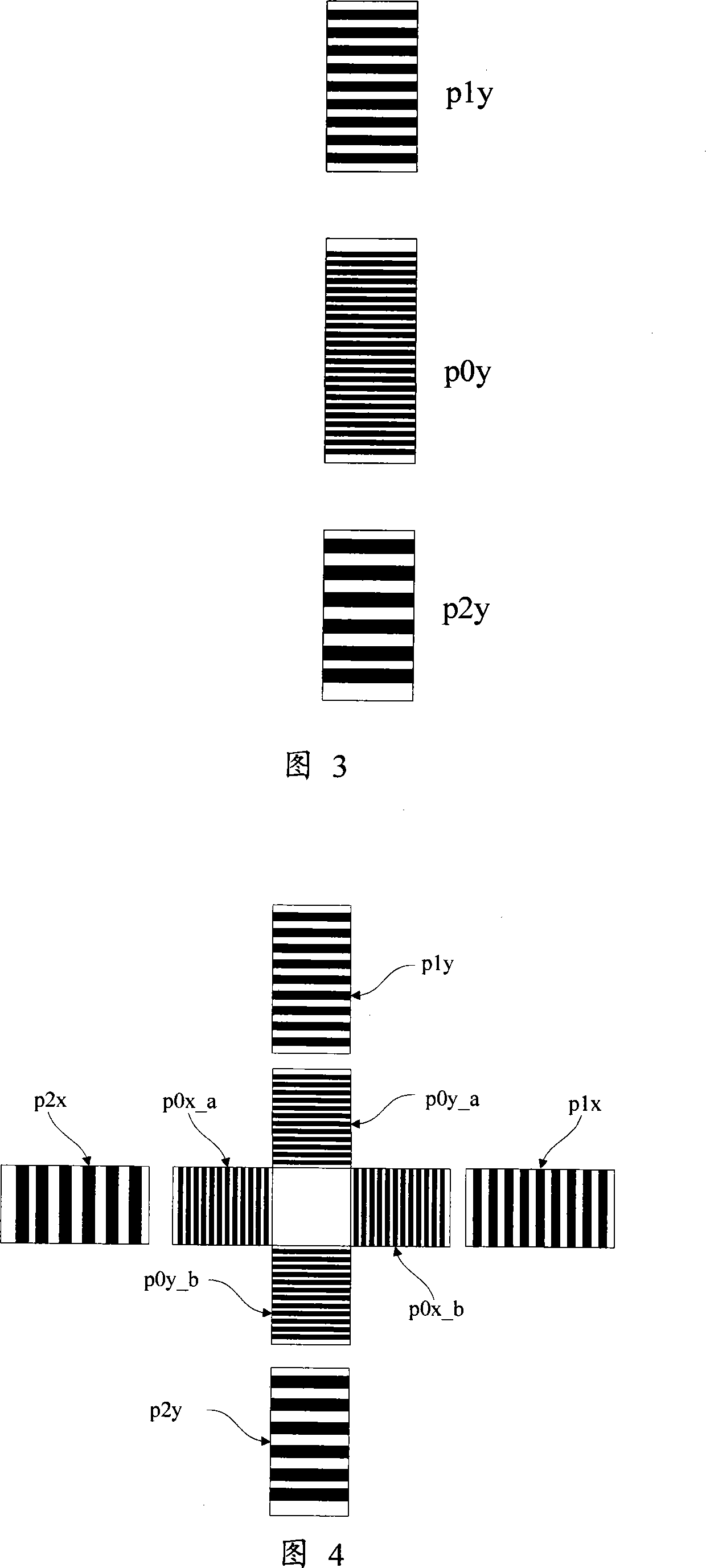

[0049] Accompanying drawing 1 (Fig. 1 is a schematic diagram of the alignment system of the lithography machine using the present invention) shows an alignment system used in the prior art and an embodiment that the alignment system of the present invention can adopt, the main components of the lithography machine The structure includes: a mask stage 6 , a mask plate 4 , a projection objective lens PL, and a substrate stage 9 . The substrate table marker 1 and the substrate marker 5 may be in the form of FIG. 2 , FIG. 3 or FIG. 4 . The distribution of the substrate marks 5 on the substrate 7 can be in the form of Fig. 15 or Fig. 16, wherein Fig. 15 is a combination of four groups of one-dimensional three-period marks.

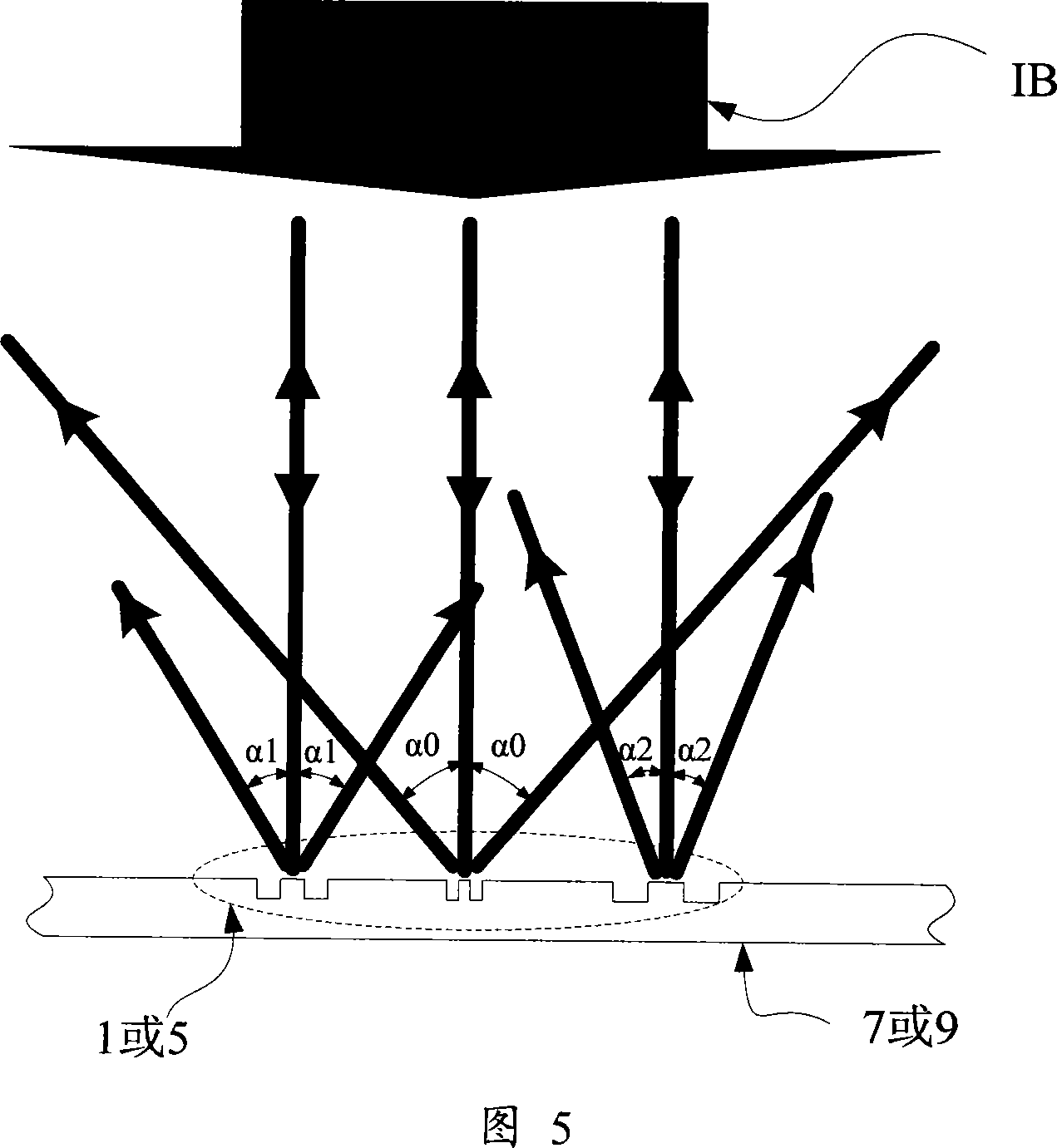

[0050] In the system used in the prior art, a lower-energy exposure radiation source or other non-exposure wavelength radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diffraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com