Oscillation positioning device of holder of bearing ball separating holder assembly machine

An alignment device and cage technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of cage stuck, cage deformation, rivet falling off, etc., to solve the problem of rivet falling off and improve alignment efficiency. and productivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

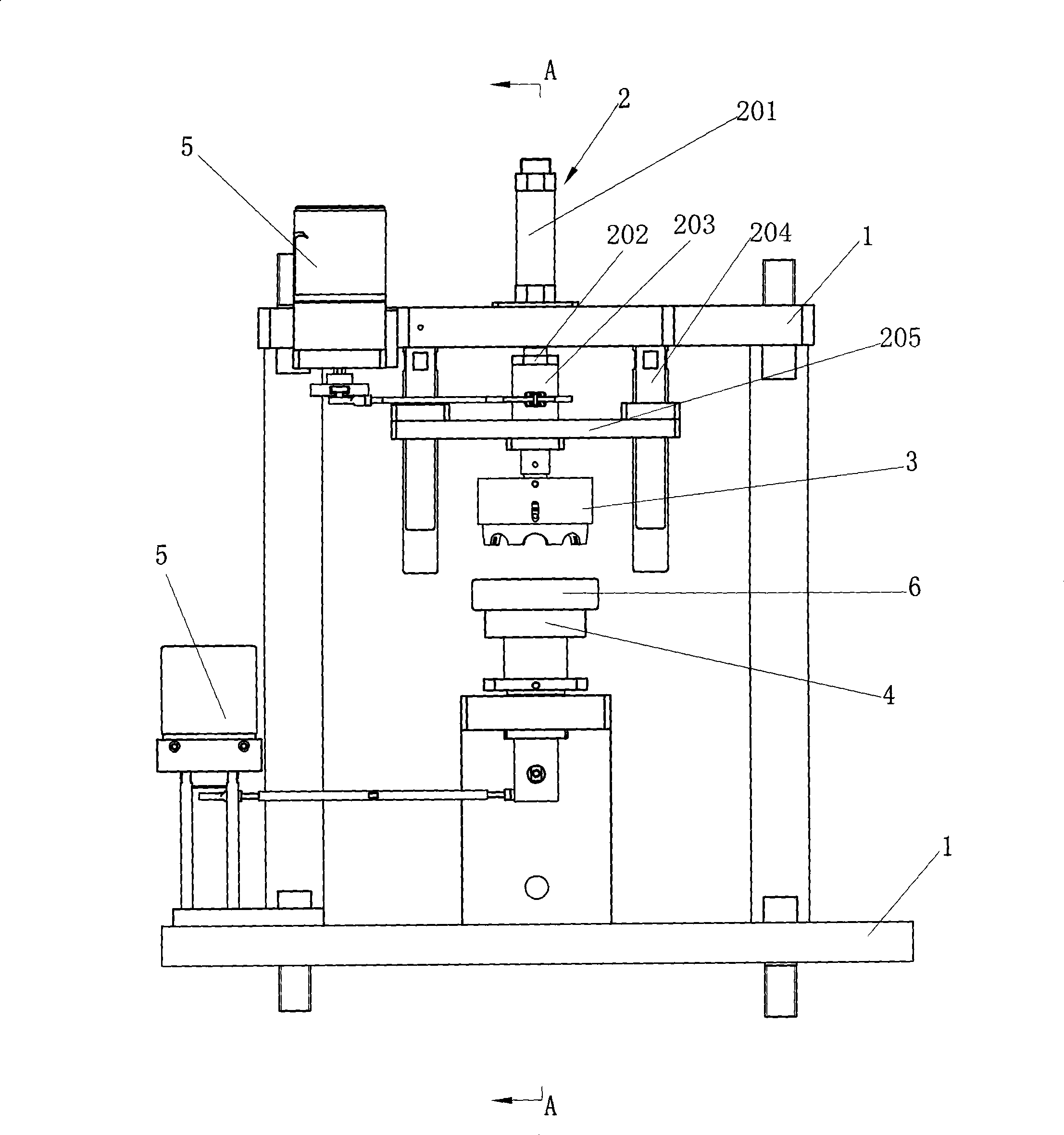

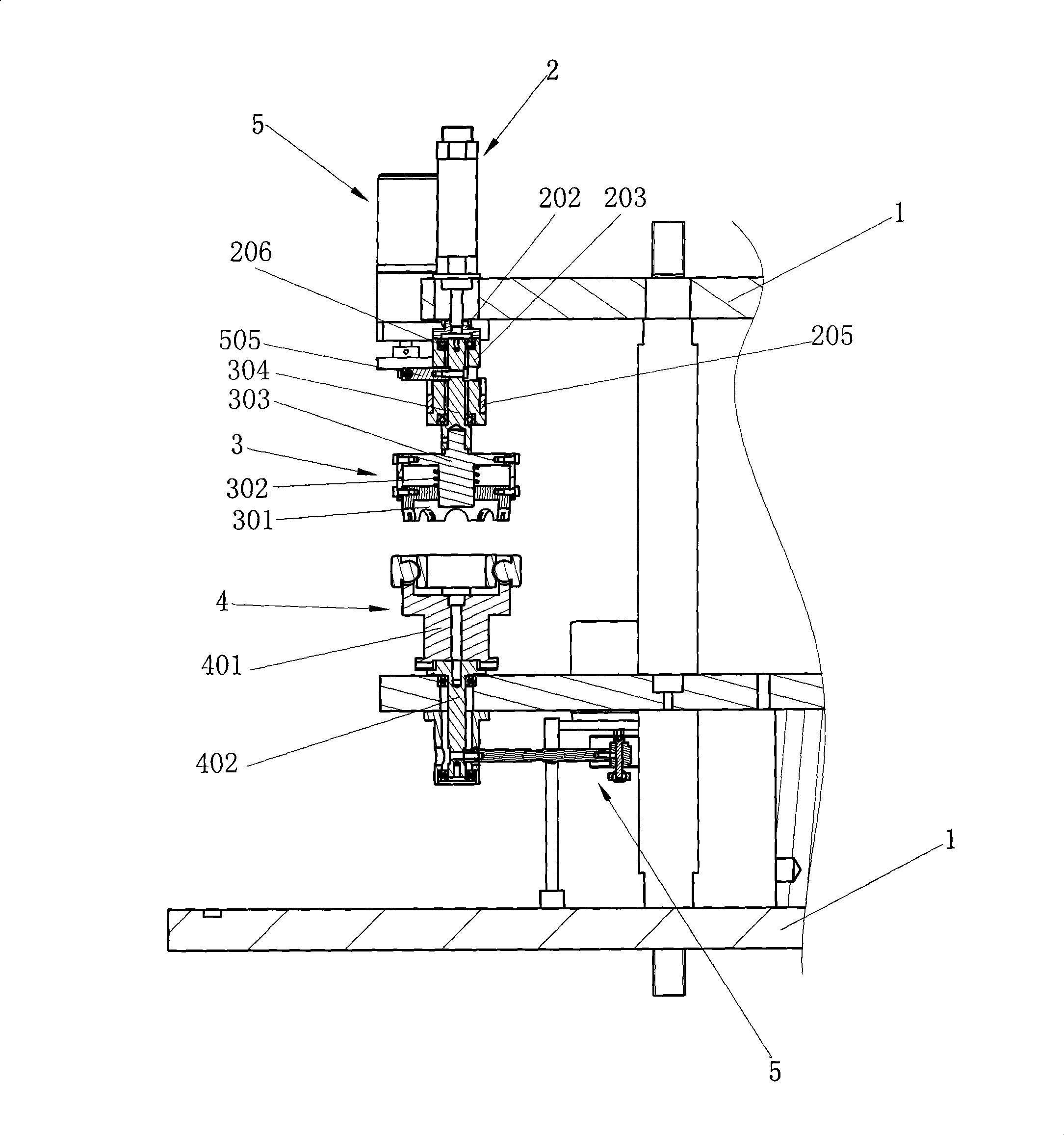

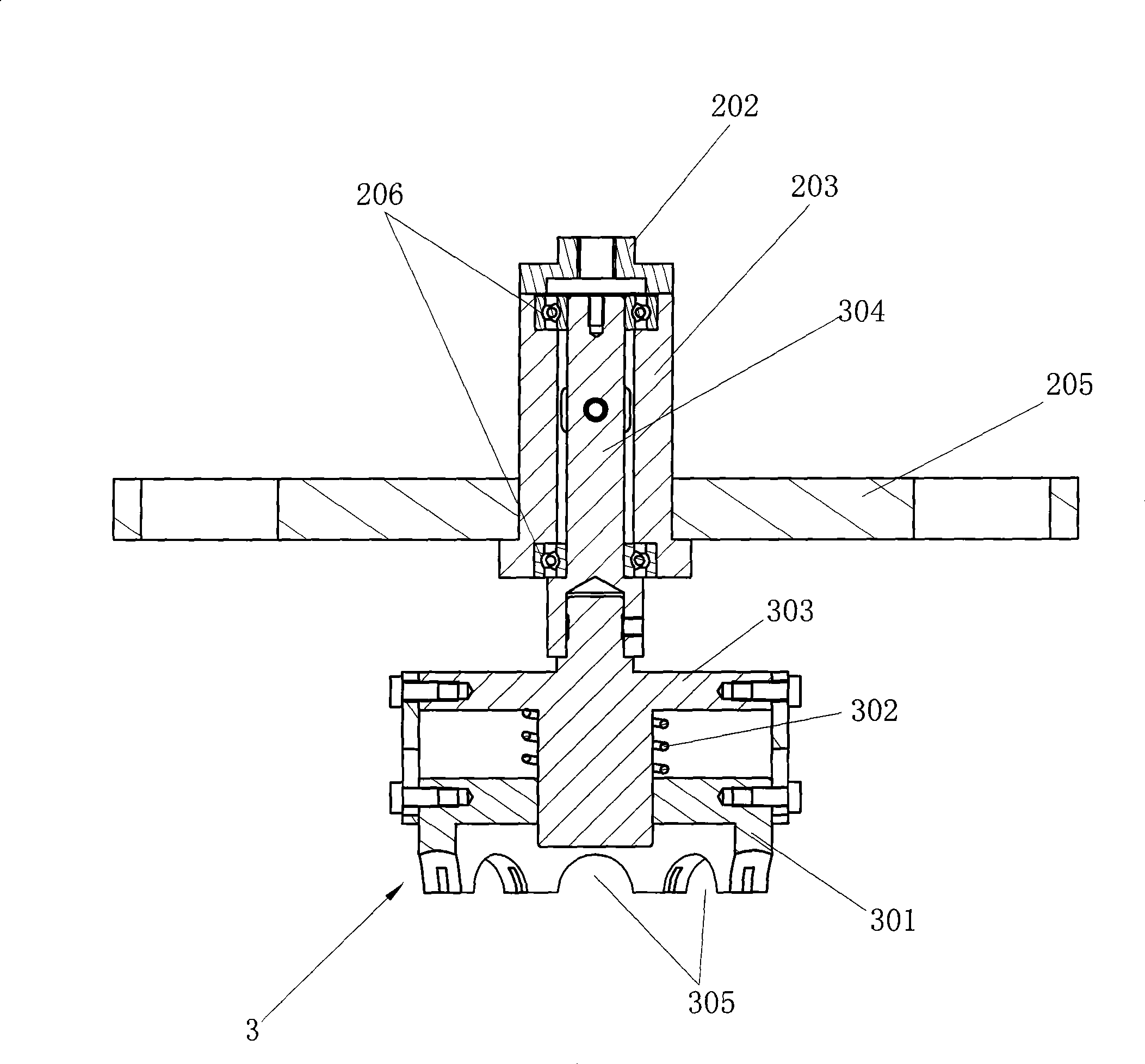

[0019] Such as figure 1 , 2 , shown in 3, the present invention comprises frame 1 and electric control system (not marked in the figure), and elevating mechanism 2 is arranged on frame 1 top, and elevating mechanism 2 comprises the cylinder 201 that cylinder body device is on frame 1, and cylinder The piston rod of 201 is connected with the upper bearing seat 203 through the connecting block 202, and the upper bearing seat 203 is installed on the guide slider 205, and the guide slider 205 is slidably connected with two guide rods 204 installed on the frame 1. The upper mandrel 304 of the upper die 3 is pivotally mounted in the upper bearing seat 203 on the lifting mechanism 2 through two bearings 206, the lower end of the upper mandrel 304 is connected to the upper die body 303, and the upper die head 301 is slipped on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com