Alignment method and apparatus for array type optical probe scanning IC photoetching system

A technology for scanning integrated circuits and photolithography systems, applied in the field of micro-engineering manufacturing, can solve the problems of inability to write error compensation and low efficiency, and achieve the effects of ensuring quality, improving alignment accuracy, and improving alignment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

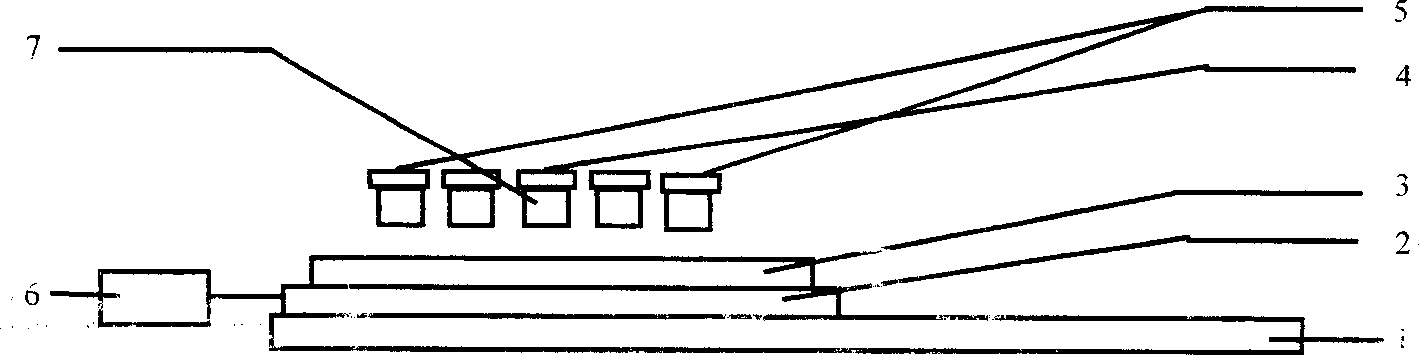

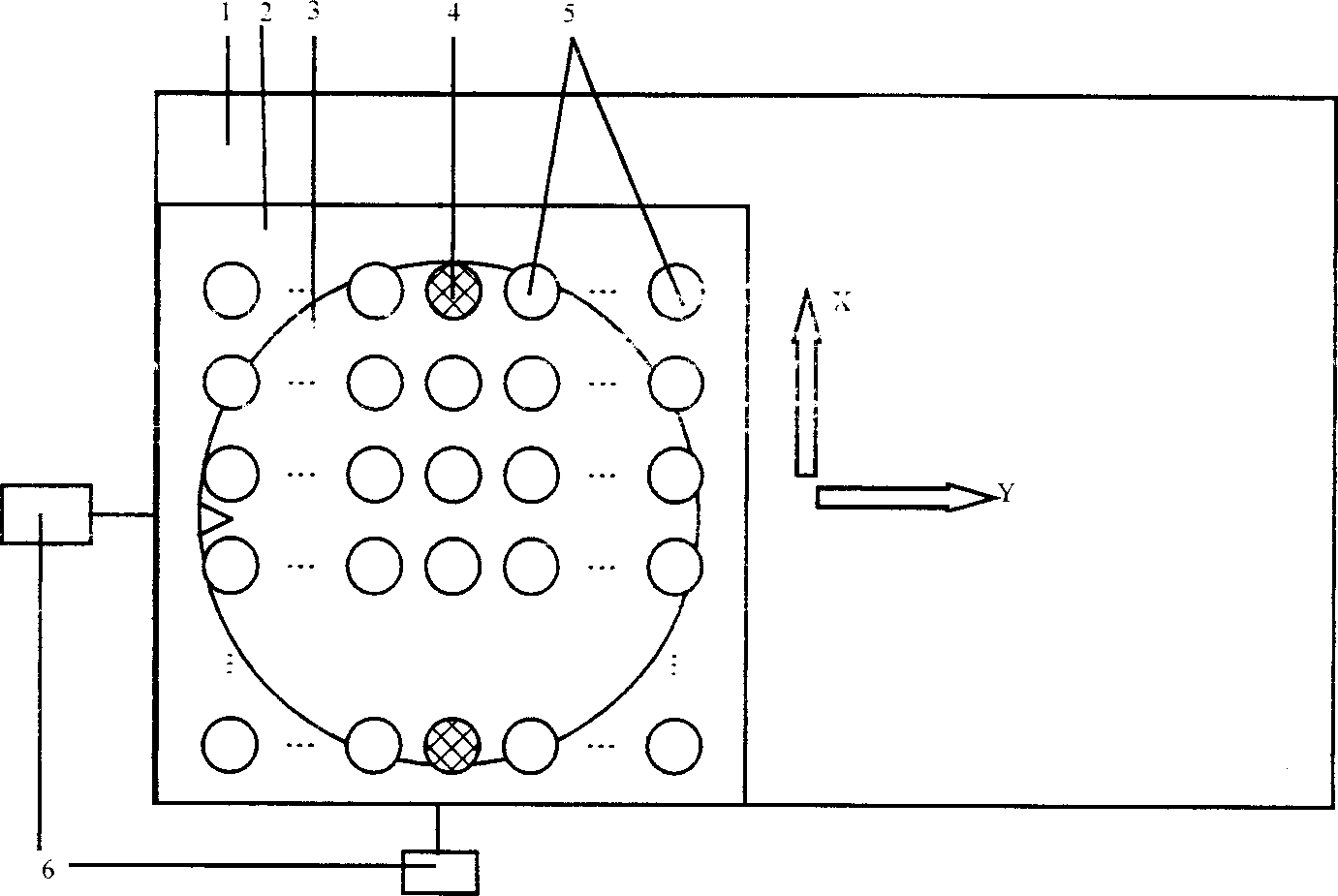

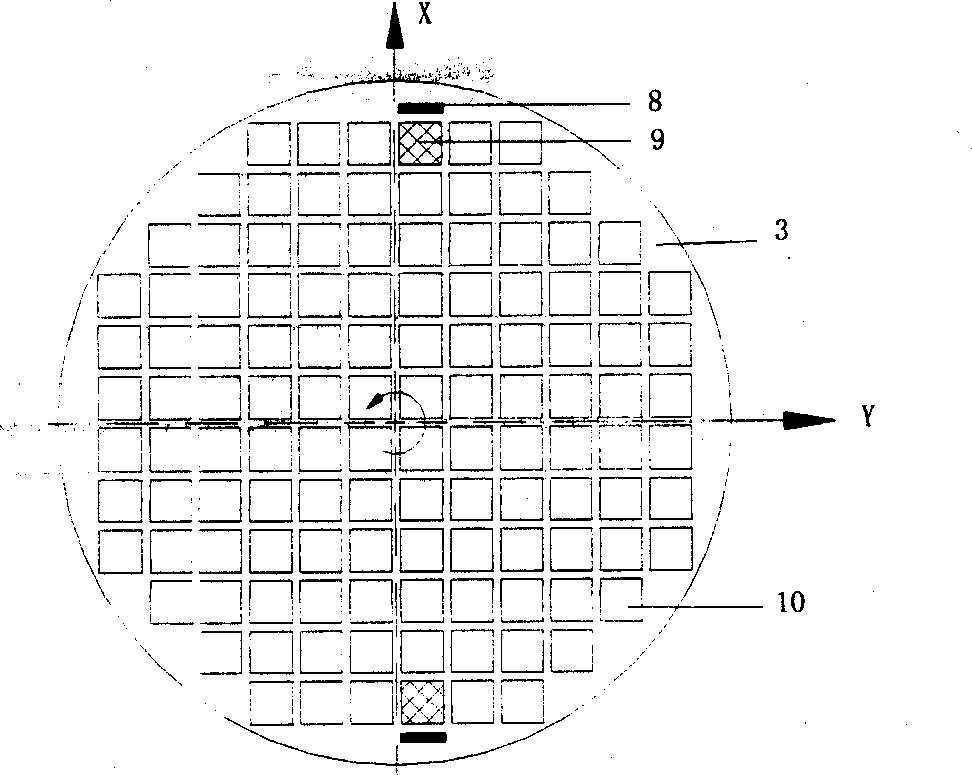

[0022] Such as figure 1 As shown, the alignment device designed in the present invention for array optical probe scanning integrated circuit lithography system includes base 1, work 2, optical probe array 5, calibration optical head 4 and its reading device 7. The workbench 2 is placed on the base 1, driven by the precision servo motor 6, and moves along the X and Y directions. The silicon wafer 3 to be processed is fixed on the workbench 2 through the suction cup, and the calibration optical head 4 and the optical probe array 5 are located on the silicon wafer. Above, a pair of calibration optical heads 4 are located in the middle of the optical probe array 5, which is symmetrical along the Y axis, and the optical probe array 5 is arranged in a rectangular shape. The calibration optical head 4 has a reading device 7 , which includes a light source 51 , a diffusion lens 52 , a polarizing beam splitter 53 , a quarter wave plate 54 , a focusing lens 56 and a photodetector 57 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com