High-accuracy alignment mark structure based on machine vision alignment

An alignment mark and machine vision technology, which is applied in the field of high-precision alignment mark structures based on machine vision alignment, can solve the problems of decreased alignment efficiency, decreased alignment accuracy, and poor pattern matching accuracy, and achieves improved alignment. Bit Accuracy and Alignment Efficiency, Effects of Reducing Influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

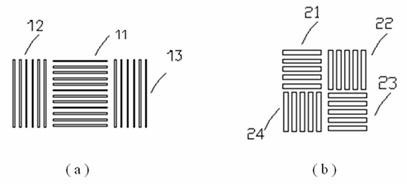

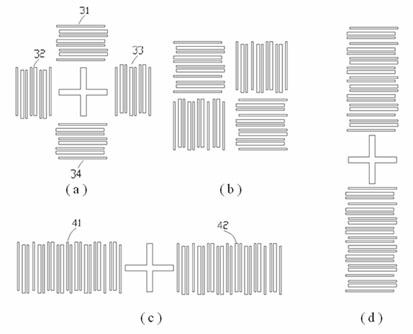

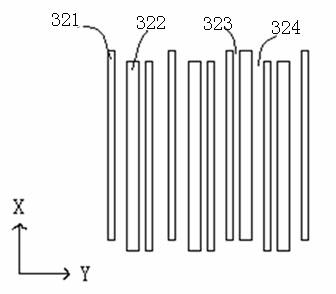

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0023] In the present invention, by changing the design structure of the alignment mark, each line element in the alignment structure is in a different optical environment during the actual exposure process, reducing the impact on the alignment mark due to process factors such as optical proximity effect and etching precision control. The influence of graphic imaging quality improves the alignment accuracy and alignment efficiency of the machine vision alignment system.

[0024] In order to fundamentally solve the dependence of the above-mentioned existing alignment marks on the process and improve the alignment accuracy. The present invention proposes a brand-new alignment mark, so that the optical environment of each line in the alignment mark is different in the actual self-exposure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com