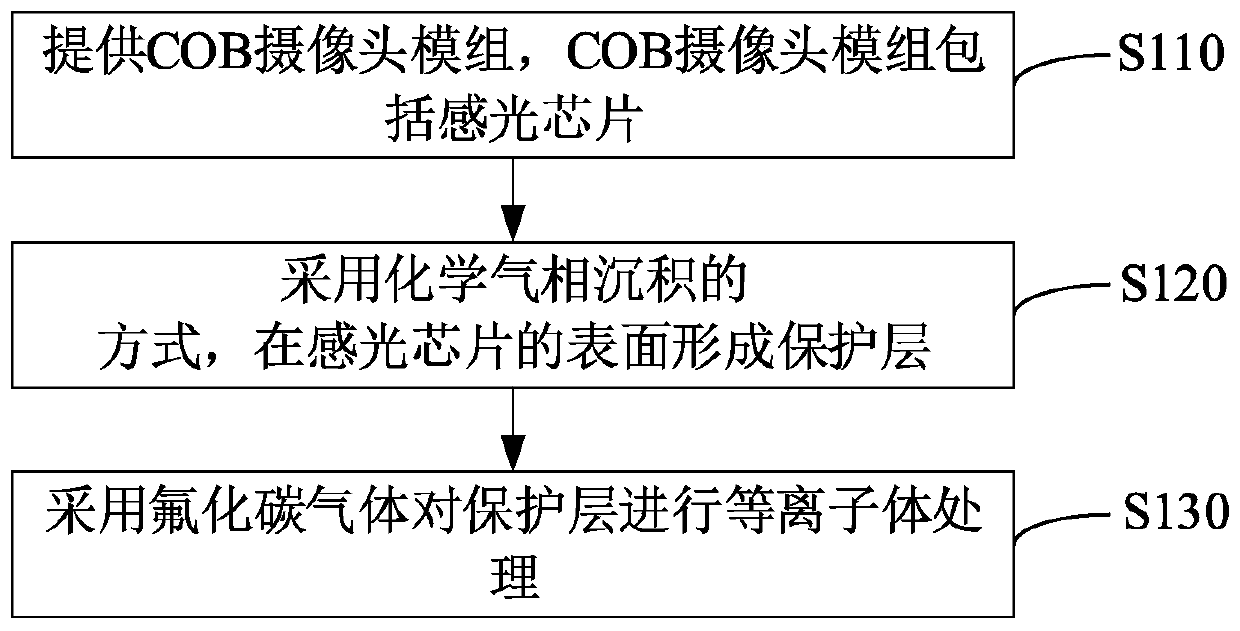

COB camera module and packaging method thereof

A camera module and packaging method technology, applied in radiation control devices and other directions, can solve the problems of photosensitive chip damage, affecting imaging quality, and difficult to remove impurity particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Place the COB camera module in a vacuum chamber, evacuate to 0.1Pa, and heat the COB camera module to 45°C. Then introduce parylene C-type monomer, after vaporization, pyrolysis, and chemical deposition for 15 minutes, a parylene protective layer with a thickness of 0.1 μm is obtained on the surface of the photosensitive chip.

[0059] (2) Assemble the bracket and the lens in the COB camera module on the PCB board respectively, adjust the focus and fix the lens, and complete the packaging of the COB camera module.

Embodiment 2

[0061] (1) Place the COB camera module in a vacuum chamber, evacuate to 5.0Pa, and heat the COB camera module to 100°C. Then, styrene monomer was introduced, and after vaporization, pyrolysis, and chemical deposition for 300 minutes, a polystyrene protective layer with a thickness of 5.0 μm was obtained on the surface of the photosensitive chip.

[0062] (2) Plasma treatment is performed on the protective layer. Wherein, the power in the plasma treatment is 200W, and the time of the plasma treatment is 10min. The working gas in the plasma treatment is argon and C with a flow ratio of 1:1. 3 f 8 of mixed gas. After the plasma treatment, the photosensitive chip whose surface is a hydrophobic protective layer is obtained.

[0063] (3) Assemble the bracket and the lens in the COB camera module on the PCB board respectively, adjust the focus and fix the lens, and complete the packaging of the COB camera module.

Embodiment 3

[0065] (1) Place the COB camera module in a vacuum chamber, evacuate to 2.5Pa, and heat the COB camera module to 55°C. Then introduce methyl methacrylate monomer, after vaporization, pyrolysis, and chemical deposition reaction for 60 minutes, a polymethyl methacrylate protective layer with a thickness of 1.0 μm is obtained on the surface of the photosensitive chip.

[0066] (2) Plasma treatment is performed on the protective layer. Wherein, the power in the plasma treatment is 400W, and the time of the plasma treatment is 3 minutes. The working gas in the plasma treatment is argon and C with a flow ratio of 1:2. 4 f 8 of mixed gas. After the plasma treatment, the photosensitive chip whose surface is a hydrophobic protective layer is obtained.

[0067] (3) Assemble the bracket and the lens in the COB camera module on the PCB board respectively, adjust the focus and fix the lens, and complete the packaging of the COB camera module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com