Processing method for terylene face fabric

A processing method, polyester technology, applied in the field of polyester fabric processing, can solve problems such as stifling exploration and thinking, and achieve the effect of meeting the requirements of diversified colors and full of three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

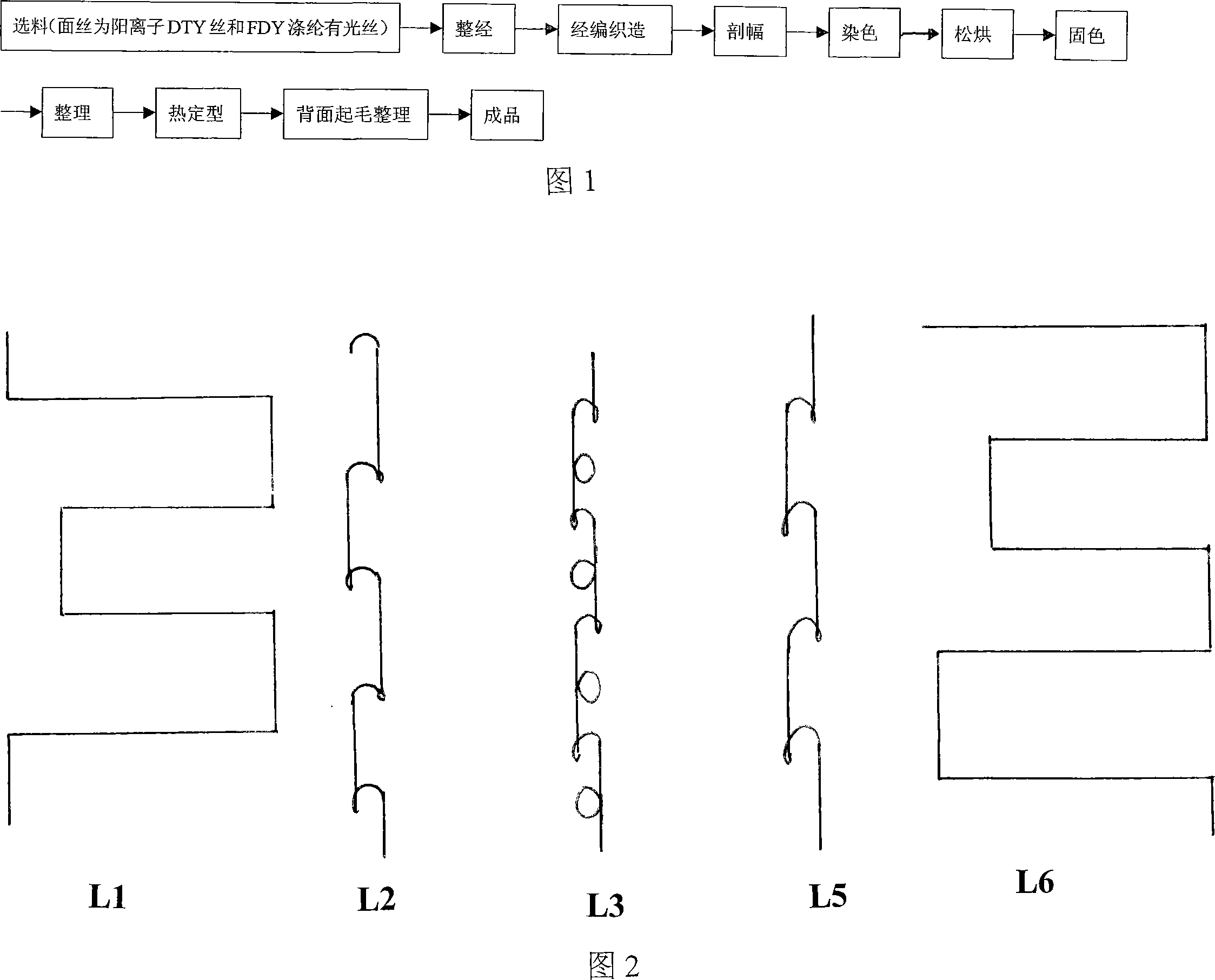

[0015] According to the process steps shown in Figure 1, the first is material selection. The applicant recommends using cationic DTY yarn with a specification of 300D / 144F and FDY polyester glossy yarn with a specification of 200D / 68F as the face yarn. The weft knitting chain pad yarn shows that the wool yarn ends are arranged in 22 parallel rows of 1 inch, and pass through the five bars of the GE-286 warp knitting machine: GB1, GB2, GB5, and GB6 to produce the bottom A and B fabrics, and GB3 passes through the five bars of the GE-286 warp knitting machine. The latch needles are advanced back and forth in the A and B face fabrics formed by the bottom layer. Among them, the combs of GB1, GB2, GB5, and GB6 use the front and rear needle beds to weave and chain the organization: L1 5-5-5-5 / 0-0-0-0 / 4-4-4-4 / 0 -0-0-1 / ×3; L20-1-1-1 / 1-0-0-1 / ×6; L3 0-1-0-1 / 1-0-0-1 / ×6; L5 0-0-0-1 / 1-1-1-0-1 / ×6; L60-0-5-5 / 5-5-0-0 / 0-0-4-4 / 4-4-0 -0 / ×3, wherein the knitting chain organization of GB3 bar (w...

Embodiment 2

[0017] Only the cationic DTY silk of 300D / 144F and the FDY polyester glossy silk of 150D / 48F are selected for use as the face thread, and the rest are the same as the description of embodiment 1.

Embodiment 3

[0019] Only the cationic DTY silk of 300D / 144F and the FDY polyester glossy silk of 108D / 48F are selected for use as the face yarn, and the wool yarn ends are arranged in parallel by 16 per inch, and all the others are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com