Multi-head vertical digital control twisting and winding machine

A winding and vertical technology, applied in the field of multi-head vertical CNC winding machines, can solve the problems of inability to accurately control the cable tension in real time, inability to accurately detect the cable tension, irregular shape of the wire harness, etc. Easy to install and lay out, improve the effect of real-time and accurate control and convenient wire feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

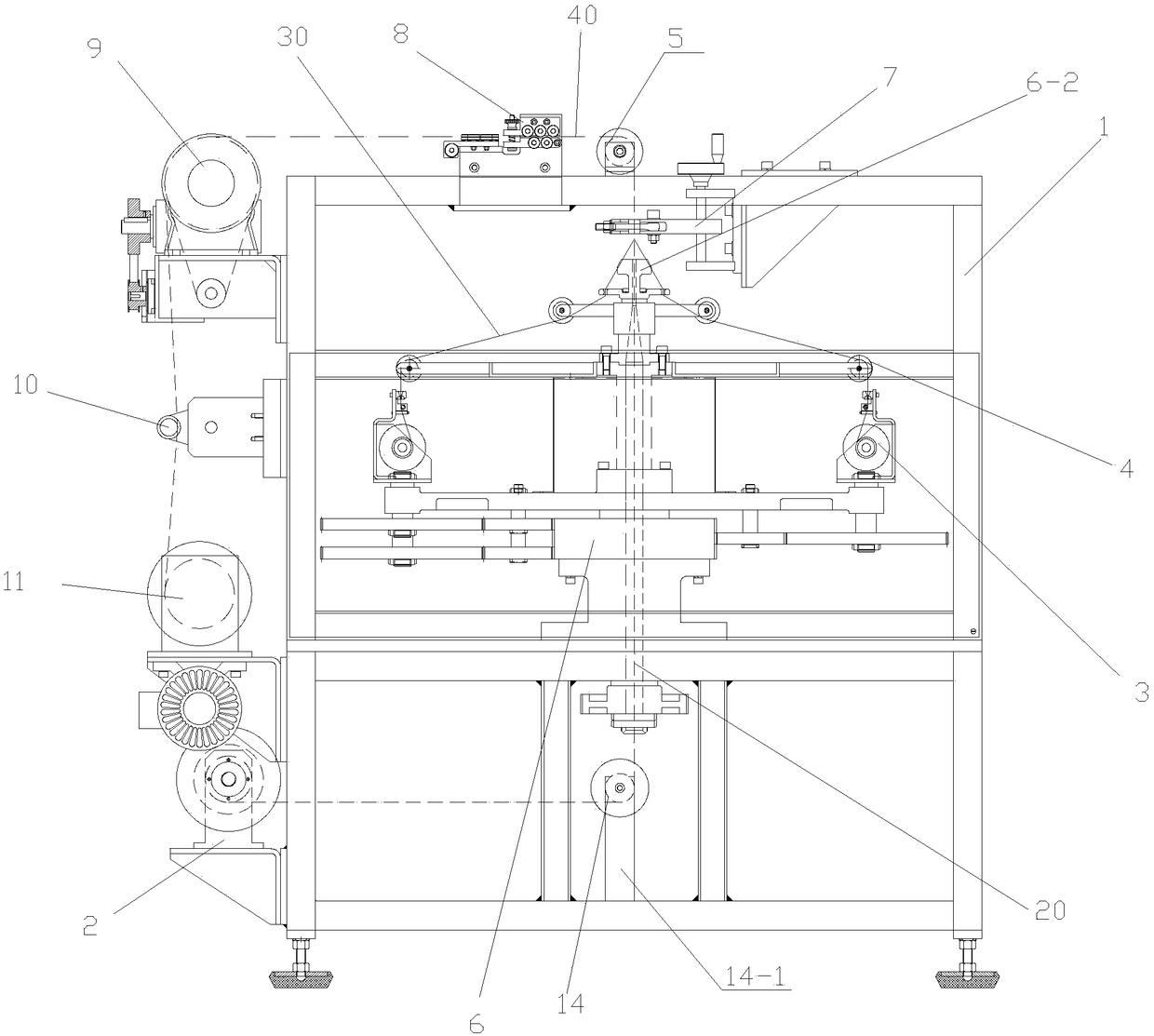

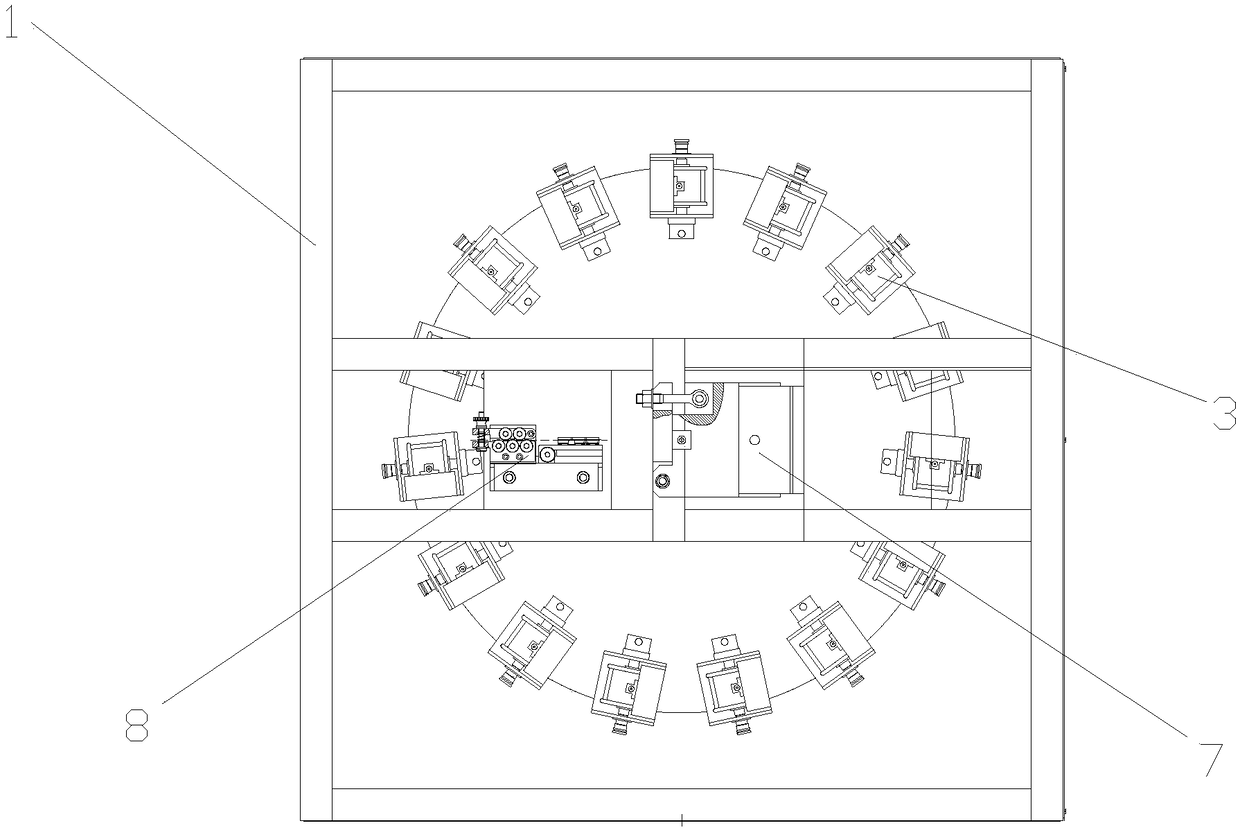

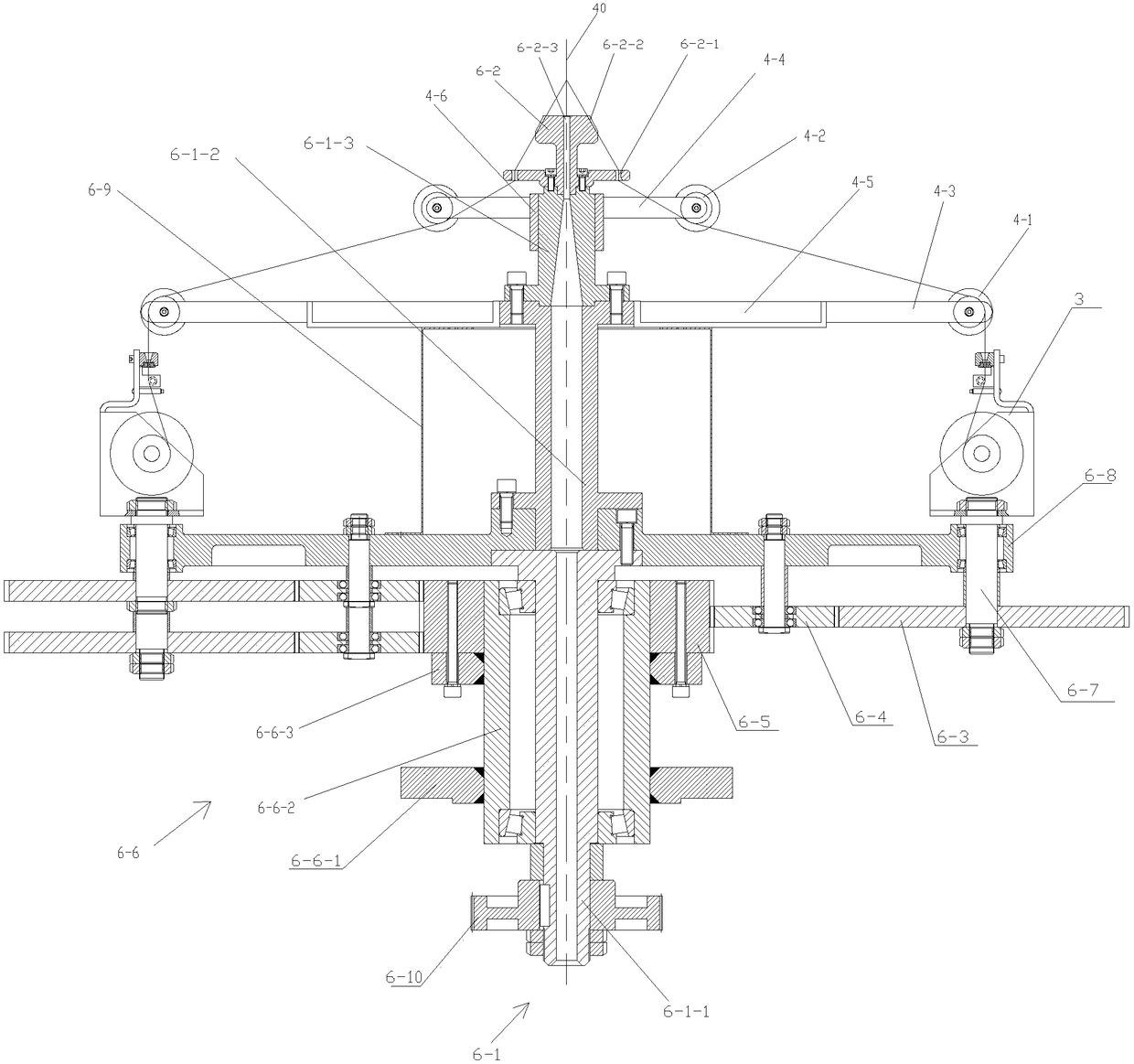

[0112] Such as figure 1 , figure 2 , image 3 and Figure 18 As shown, the present invention includes a frame 1, a twisting processing device installed on the frame 1 and a monitoring device for monitoring the twisting processing device;

[0113] The twisting processing device includes a pay-off device installed on the frame 1, a twisting device 6 for continuous twisting, and a correcting traction for correcting and pulling the twisted wire 40 twisted by the twisting device 6. device and a wire take-up device for taking up the twisted wire 40 after the rectification and traction device, the wire release device includes a wire release mechanism 2 for continuously feeding the core wire 20 to the wire twisting device 6, and a wire release mechanism for feeding The stranding device 6 continuously sends the shuttle rack mechanism 3 of the outer winding 30 and the guide mechanism 4 for guiding the outer winding 30 sent by the shuttle rack mechanism 3 , the number of the shuttle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com